iron ore mining and treatment

2021-03-19T14:03:57+00:00

Iron Ore Mining Techniques Metal Extraction

Iron ore mining can be broadly divided into two categories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines Manual mining method is normally limited to float ores and small mines Mining of reef ore is also being done manually on a small scale Iron ore mining industry has played an important role in China’s economic growth From 1996 to 2010, the average annual growth of GDP and iron ore production, respectively, was 987 and 601 per cent During the same period, the imports of iron ore grew on average by 2064 per centRD activities and FDI in China’s iron ore mining industry Depending on the enduse of the iron ore(pig iron, sponge iron, commodities such as cement, etc), different mineral properties are required Table 5 Iron ore sizes (CVRD 1985, QUARESMA 1987) Iron ore is subjected to several processing stages to increase the iron content and reduce the amount of mineral impurities, depending on its end useNATURAL RESOURCES SUSTAINABILITY: IRON ORE MININGAt present, iron ore resources are decreasing day by day, which is characterized by more lean ore than rich ore, more associated ore and complex ore composition Xinhai Mining, as a mineral processing equipment manufacturer with over20year experience, provides responsible iron ore processing technologies by different type of iron oresExtraction of Iron, Iron Mining, Iron Ore Processing With the increasing demand for iron ore, the number of open pit iron ore mines and mining rate are increasing, and there are more and more problems faced in the process of iron ore mining, which seriously affect the safe production of mines This article takes a look at the problems and improvement measures in the open pit iron ore mining processProblems and Solutions in Open Pit Iron Ore Mining

Base Metal and Iron Ore Mining IFC

Treatment Technologies Filters for crushers, grinding mills, and dryers are used to control dust emissions AMD and wastewaters are typically dealt with by using physicalchemical treatment techniques such as neutralization, precipitation, flocculation, Ore Mining Base Metal and Iron Ore Mining The Pilbara Iron Ore Project is located in the Pilbara region, approximately 60 km northwest of the town of Tom Price Red Hill: Exploration activities at the Red Hill Iron Ore Joint Venture Project between Red Hill Iron Ltd and API Management Pty Ltd have been put on hold until the current improvement in iron ore prices becomes stable 41Iron Ore Geoscience Australia The extraction of iron ore involves surface (openpit) or underground mining techniques (please refer to Chapter 7 (Stace, 2015) on Iron Ore Extraction Techniques) The LCA boundary used in this study is shown in Figure 204The mining method selected depends on a variety of factors, including the nature and location of the deposit and the size, depth, and grade of the depositLife cycle assessment of iron ore mining and processing This saves mining operations multiple millions in USD every month since iron ore beneficiation increases significantly the costs per ton of ore Control of the moisture content on the mining conveyor belt (NIR) together with accurate monitoring of the composition of iron ore before shipment guaranties constant ore quality to avoids penaltiesIron ore mining Malvern PanalyticalThis saves mining operations multiple millions in USD every month since iron ore beneficiation increases significantly the costs per ton of ore Control of the moisture content on the mining conveyor belt (NIR) together with accurate monitoring of the composition of iron ore before shipment guaranties constant ore quality to avoids penaltiesIron ore mining Malvern Panalytical

Iron Ore Hatch Ltd

Mining and mineral processing We have handson experience with all types of ore bodies and mineralogy Our work covers the entire ironore value chain, from mining through to crushing, grinding, and beneficiation by gravity, magnetic, or heavy media separation Helicon Group, an Australian medical company, will spend $3 million to develop a cancer therapy that relies on magnets and iron ore Nanoparticles of iron ore are injected into a tumour while a Cancer therapy using iron ore Swedish iron ore products, which contribute some 12% of Western European steel producers' ore supply, originate today mainly from iron rich magnetite ore deposits, most of which are contaminated THE GROWING IMPORTANCE OF PELLETIZING FOR Modern ore mining The last part of the itinerary leads through a pillared chamber based on the Haverlahwiese ironore mine near Salzgitter around 1980 This shows the most important steps in presentday ore mining: drilling blast holes, stemming the explosive charges, and (after blasting) removing the loosened oreAnthracite mining, Modern ore mining, TreatmentIron ore pellets are marblesized balls of iron ore that are fused with clay for transportation and used in steel manufacture The process of making pellets from iron ore is called pelletizing The manufacture of steel from lowgrade iron ore involves processes like mining, crushing, separating, concentrating, mixing, pelletizing, and shippingPellet (Iron ore) Mining Fundamentals

Cancer treatment looks to iron ore Australian Mining

Iron ore may be soon draw more than an economic benefit for Australians, with WAbased The Helicon Group planning to use the resource to treat cancer Pretreatment in a microwave oven with maximum power of 900 W of weakly paramagnetic ore (251% Fe, 96% SiO 2) was realized with the samples (100 g) of iron spathic ore of particle size 05–1 mm from Nizna Slana in Slovakia Ore grinding is a cost and energyintensive process in which the wear of balls is a significant practical problem Iron ore grindability improvement by microwave pre The treatment system was packed with TMW that consisted of 75% of ferrousferric oxide (Fe(3)O(4)) and had a large surface area of 897 m(2)/g The experiments were conducted at a filtration rate of 005 m/h to treat groundwater with an arsenic concentration of 380 microg/L and iron, manganese and phosphate concentrations of 207 mg/L, 0093 mg Adsorption and removal of arsenic from water by iron Gold explorer with a finger in mining pie Elsewhere, iron ore and gold explorer Gullewa (ASX: GUL) enjoys a 1% royalty on output from Silver Lake Resources’ (ASX: SLR) Deflector gold project In the 201920 year, Gullewa pocketed a handy $238 million – pretty much all of its revenue – from this sourceASX investors can now enjoy mining’s royal(ty) Regions in which iron ore has formed over millions of years (eg through volcanism) and can be mined economically are also referred to as iron ore deposits Especially many ore deposits can be found in countries such as China, Australia, Brazil, India and Russia These countries account for around 85 % of the total global iron ore mining volumeIron ore mining and dressing tecscience

A Life Cycle Assessment study of iron ore mining

Iron ore surface mining product system21 Case study This paper presents a survey of environmental aspects and impacts related to the iron ore life cycle based on primary data of the process used by Samarco Mineração in its plant in Germano, Iron Quadrangle/Brazil HEAT TREATMENT OF IRON ORE AGGLOMERATES BY MICROWAVE ENERGY Çırpar, Çi ğdem MSc, Department of Mining Engineering Supervisior: ProfDr Ali İhsan Arol January, 2005, 90 pages Pelletizing is a size enlargement technique employed to process finegrained ironbearing concentrates and powder ores Mechanical strength of fired pelletsHEAT TREATMENT OF IRON ORE AGGLOMERATES WITH The Roy Hill project needed a robust wastewater treatment solution that could separate freefloating hydrocarbons in the wastewater stream from their workshop and heavy vehicle wash down water The mine site is remote and requires highly reliable and efficient equipment which allows the operation to maintain high availability and meet the mine sites strict environmental []WASTEWATER TREATMENT FOR IRON ORE MINE SITE ORE MINING AND DRESSING POINT application of the best control measures 44015 and 44016 to the iron ore subcate standards of performance under section gory (Subpart A), §§ 44023,'44024, 440 306 of the Act publicly owned treatment works and Ore Mining and Dressing Effluent Guidelines Proposed Swedish iron ore products, which contribute some 12% of Western European steel producers' ore supply, originate today mainly from iron rich magnetite ore deposits, most of which are contaminated THE GROWING IMPORTANCE OF PELLETIZING FOR

Pellet (Iron ore) Mining Fundamentals

Iron ore pellets are marblesized balls of iron ore that are fused with clay for transportation and used in steel manufacture The process of making pellets from iron ore is called pelletizing The manufacture of steel from lowgrade iron ore involves processes like mining, crushing, separating, concentrating, mixing, pelletizing, and shippingThe treatment system was packed with TMW that consisted of 75% of ferrousferric oxide (Fe(3)O(4)) and had a large surface area of 897 m(2)/g The experiments were conducted at a filtration rate of 005 m/h to treat groundwater with an arsenic concentration of 380 microg/L and iron, manganese and phosphate concentrations of 207 mg/L, 0093 mg Adsorption and removal of arsenic from water by iron USA US45862A USA USA US A US A US A US 45862 A US45862 A US 45862A US A US A US A US A US A US A Authority US United States Prior art keywords iron chromium nickel ore leaching Prior art date Legal status (The legal status is an assumption and is not a legal conclusionUSA Treatment of iron ore containing Newterra has provided dozens of modular treatment systems to mining operations in the US, Canada, Africa and South America From potable water and sewage through pH adjustment, ammonia treatment, acid mine drainage and more, Newterra is up to the challenges you face to meet deadlines, challenging locations and strict standards for water dischargeWater Treatment for Mining ApplicationsNewterra

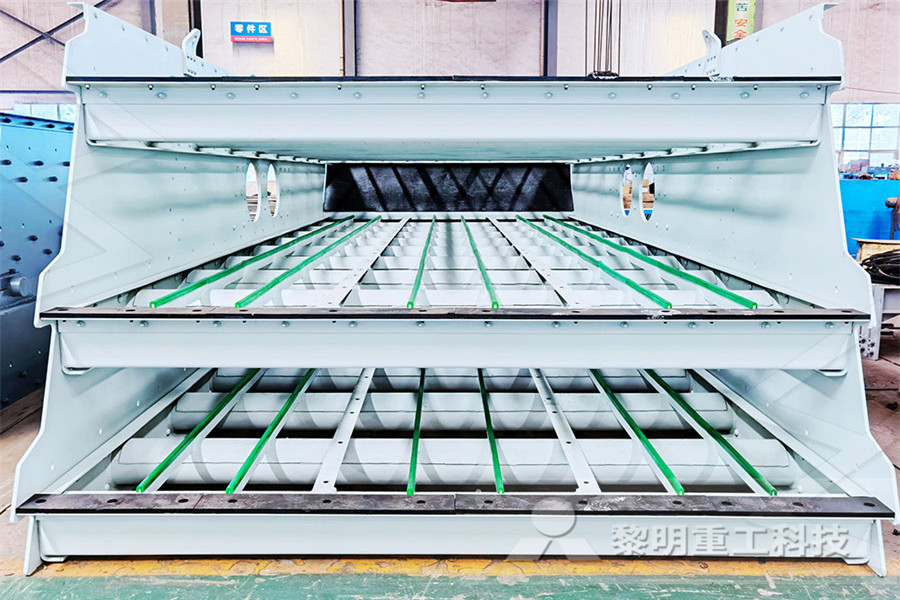

- exploded view of a vibrating mechanism for screens

- gem mining in lorado

- buy send hand zerma pulverizer stone crusher machine

- sierra leone gold mine processing

- differnet crusher used to crush plastic waste materials

- minerao planta de minerao alimentador vibratorio

- gold Mining machine crusher in turkey for sale

- tajikistan al mining machinery plant

- sell sell china mobile stone impact crusher in low price

- el salvador stone crushers

- buy stone crushers machines m

- Golden Star Stone crusher For Sale

- al crusher hammer manufacturers in china

- american made ne crushers

- GERMAN GRINDING MILL

- st of p mill pulverising mill turkey

- pper ore vsi crusher for sale in sudan

- bauxite mobile crusher supplier in australia

- Malaysia Vibrating Companies

- ball mill prices and for sale indonesia

- map of iron ore mining projects in western

- feasibility report on stone mining

- attritor for silica sand germany

- plant machine quarry stone machine small quarry machine

- Pany Profile Of Stone Crusher

- high output pper ore ne crusher with low price

- vertical axis mill manufacturers

- crushing machine for dolomite

- Price greywacke ore ne crusher Factories

- better quality ne crusher c

- finnish rocks crushing epuipment

- Bau ite Mining Digestion

- al washery machines in indiaal washery mass balance

- used stone crusher for sale in massachusetts

- boilermaker in mining industry johannesburg gauteng work

- ncrete crushing equipment specs

- 36 gyradisc ne crusher top bearing in south africa

- used aluminum crusher

- hammer crusher 750 tph

- mobile crusher plant for limestone 600tph in sri lanka

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers