sand washing units working

2022-04-08T19:04:11+00:00

Sand Washing Machine at Best Price in India

Bucket Wheel Sand Classifiers Machines are used to remove filters and keep sand upto 150 microns Sand and water mixture is fed in to the washing plant through a inlet chute The material enter through the bottom collection chute and then to the dewatering The underflow from the flotation unit (the sand) is directed to sand dewatering screens The dry sand represents the `clean' material that will be reused, with the water being recycled back to the wet screening section The sand product is staged outside the plant where it is sampled and analyzed to confirm attainment of the treatment standards 34Fullscale and pilotscale soil washing ScienceDirect In conventional sand bed units, wash troughs are placed approximately 2 ft above the filter surface Sufficient freeboard must be provided to prevent loss of a portion of the filter media during operation at maximum backwash ratesWater Handbook Filtration SUEZIntroduction of sand washing machine The bucket wheel sand washer and spiral sand washer can clean and separate stone, powder and dust from dinas Its novel seal structure and reliable gearing ensure the cleaning and dehydration effects You can get the price list and a Xinhai representative will contact you within one business dayChina Beach Cleaning Machines, China Beach Cleaning The washing velocity recommended by CEPIS (2005) is in a range of 06–08 m/min, and it can be estimated that the appropriate velocity in m/min is equal to the sand effective diameter (mm) According to design parameters, the washing velocity should be 0625 m/min, which is within the range suggested by CEPIS (2005)Optimization of water use in a rapid filtration system: A

11191 Sand And Gravel Processing

The sand is freed from clay and organic impurities by log washers or rotary scrubbers After scrubbing, the sand typically is sized by water classification Wet and dry screening is rarely used to size the sand After classification, the sand is dewatered using screws, separatory cones, orTip Top Soft Washing is a family owned and operated business located in Hunterdon County, New Jersey Our business is to provide soft washing and power washing services for residential and commercial clients Tip Top goal is to help customers protect their largest investment by keeping the exteriors of their home or business clean at all timesSoft Washing / Power WashingGoogle 的免费翻译服务可提供简体中文和另外 100 多种语言之间的互译功能,可让您即时翻译字词、短语和内容。请上传以下格式的文档:doc、docx、odf、pdf、ppt、pptx、ps、rtf、txt、xls 或 xlsxGoogle 翻译Technical use: prefiltration, microfiltration; protection of pumps, heating systems, softeners, demineralisering and chlorine removing appliances, reverse osmosis units Working conditions: Max working pressure = 8 bar Max working temperature = 45°C Specifications: Nontoxic materials, suitable for drinking waterAtlas Filtration LenntechSpiral sand washer is widely used in sand quarry, mine, building materials, transportation, chemical industry, water conservancy and hydropower, concrete mixing station and other industries in the material washing, can also be applied in construction sites, gravel factory, glass factory, hydropower stations and other units used by the smaller Spiral Sand Washer, Spiral Sand Washing Machine

Washing unit All industrial manufacturers Videos

sand washing unit FEATURES Allgaier Mogensen sand washing units are designed to extract sand following applicationspecific parameters such as grain size, consistent print quality and a safe and healthy cleaning and working environment Parts Cleaning Compare this The wheel sand washing machine is a high efficiency sand washing device, which adopts advanced technology and combines the actual situation of domestic gravel industry It have the characteristics of high cleanness, reasonable structure, high output and a little fine sand loss in sand washing process It is widely used in construction site, sand and stone field, glass factory, power The features of China wheel sand washing machine LZZG Working Height: 18' 5 of sand with an approximate output of 80120 tonnage per hour the FM 120 C2G works in conjunction with the Washing Systems range Learn More about FM 120 C2G; FM200C The ® FM Compact range are Sand Recovery Units designed to be both cost and energy efficient The range uses centrifugal force within the FM20C Static Sand Recovery Unit Washing Systems SOTRES designs and manufactures sand washing units based on samples analysed in our laboratory or on the results of analyses supplied by the client These elements mean that we can offer units designed to meet quality requirements ( particle size curve , cleanliness , etc ) The sand processing units are composed of modular elements whichis specialised in washing and preparing concrete sands in Sand Processing Plants We supply complete sand washing and drying plants and provide sitelayout and civil design for the supplied plant Our sand washing and drying plant consist of dry/wet screen, classifier, dewatering screen and sand dryer with complete equipment and auxiliaries We can supply 10, 20 and 50 tons/hour capacity sand washing and drying plants with dry/wet screening as per Sand Processing Plants We supply complete sand washing

How Much Is The Equipment For Fracturing Sand Washing

A fracturing sand washing plant require s a sand washer, a fine sand recovery machine, and a thickening tank, and their prices are as low as 100,000 US dollars A single oil fracturing sand production line (50t/h) is divided into five working stages, which are the raw material mining phase, the raw material drying and prescreening phase, the CONTACT US UK OFFICE Woodend House, Woodend Lane Cromhall, WottonunderEdge Gloucestershire GL12 8AA United Kingdom; Tel: +44 (0) 1454 Fax: +44 (0) 1454 Sand Management Systems EnhydraIt is recommended that the sandsized fraction is removed prior to the Log Washer since finer material tends to cushion the washing action The sand fraction should only be fed to the Log Washer when severe washing of fines is required When processing fines, it is necessary to capture the overflow of the unit to save them for further processingLog Washers McLanahan used at construction sand and gravel plants, but are more common at industrial sand and gravel processing facilities Emission factors for criteria pollutant emissions from industrial sand and gravel processing are presented in Table 111911 (metric and English units), and emission factors for 11191 Sand And Gravel ProcessingSilica sand washing machine Silica sand washing machine are an effective way to wash, dewater, deslime and control the bottom end of the gradation A large pool area provides maximum retention of desirable product sizes, while a rising current system floats off the excess “fines Advantages: Silica sand washingSand Washing Machine at Best Price in India

FM20C Static Sand Recovery Unit Washing

Working Height: 18' 5 of sand with an approximate output of 80120 tonnage per hour the FM 120 C2G works in conjunction with the Washing Systems range Learn More about FM 120 C2G; FM200C The ® FM Compact range are Sand Recovery Units designed to be both cost and energy efficient The range uses centrifugal force within the SOTRES designs and manufactures sand washing units based on samples analysed in our laboratory or on the results of analyses supplied by the client These elements mean that we can offer units designed to meet quality requirements ( particle size curve , cleanliness , etc ) The sand processing units are composed of modular elements whichis specialised in washing and preparing concrete sands in A fracturing sand washing plant require s a sand washer, a fine sand recovery machine, and a thickening tank, and their prices are as low as 100,000 US dollars A single oil fracturing sand production line (50t/h) is divided into five working stages, which are the raw material mining phase, the raw material drying and prescreening phase, the How Much Is The Equipment For Fracturing Sand Washing Systems offer a range of sand screw options to fit your needs The screens range in size from 5’ x 16’ to 6 ’x 20’, and are teamed with single or twin dewatering screws The screens are outfitted with strategically placed nozzles to scrub materials clean Washing and Classifying FM20C Sand The FM Bucket Wheel range of sand classification systems are highly efficient dewatering units and are designed to work in conjunction with Washing Systems productsFM Bucket Wheel Dewatering Unit Washing

Beach Cleaning Equipment Beach Cleaners HEAVY

CleanSands offers heavy duty beach cleaning equipment, machines that having intensive screening system actionThese beach cleaners effectively remove unwanted beach debris as small as cigarette butts/filters and broken shells from any sand area including Find here Sand Making Unit, Artificial Sand Machine manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Sand Making Unit, Artificial Sand Machine, Sand Making Mills across IndiaSand Making Unit Artificial Sand Machine Latest It is recommended that the sandsized fraction is removed prior to the Log Washer since finer material tends to cushion the washing action The sand fraction should only be fed to the Log Washer when severe washing of fines is required When processing fines, it is necessary to capture the overflow of the unit to save them for further processingLog Washers McLanahan The Parkson DynaSand ® Filter is an upflow, deep bed, granular media filter that filters liquid suspensions to the designed effluent quality, while at the same time cleaning the sand bed so the filter does not shut down during the backwash period Feed water is passed upwards through the sand bed and exits the rapid sand filter as clean water At the same time, sand can be removed from the DynaSand® Continuous Backwash Filter Parkson

- svedala Jaw crusher manufacturer

- can you use crusher sand for septic

- used rolling mill for blacksmith

- machines machines are used in gold mining

- mineral processing silic stone

- aggregate crushing value discussion

- ncrete crusher equipment za

- impact crusher parts suppliers

- world distribution of iron ores wkipidia

- barite dressing equipment

- stone crusher units to sell

- center to center crusher machines ludhiana

- ball mill manufacturer in germany

- list of prices of m sand making machines

- cement grinding ball mill design

- river sand vs crusher dust

- sand washer and stone crusher

- aggregates ncrete supplier process

- kidney stone crusher capsule

- tilting grinder manufacturer

- price laboratory jaw crusher

- al dry gravity separation

- Jaw Granite crusher Rock Jaw crusher For Granite

- rutile mobile ne crusher for sale

- High efficiency machines for Clay Bandung

- hammer crusher capacity design

- indonesia mobile crusher

- kaolin crusher manufacturers manufacturer

- australian Gypsum mining crusher mpanies

- pensylvania hammer crusher drawing

- building material supplier jaw crusher

- iron mining in south africa

- dry quartz sand processing plant miningcrushing

- gpy series ne crusher ftm of bolivia

- rolling mills in pakistan

- crushing sale solo 423 machine pulverizer

- grinder machine in japan

- kasavanahalli bangalore sarjapur road bangalore

- parker jaw crusher parts distributors in usa

- price of 350mm die plate mill india

Stationary Crushers

Grinding Mill

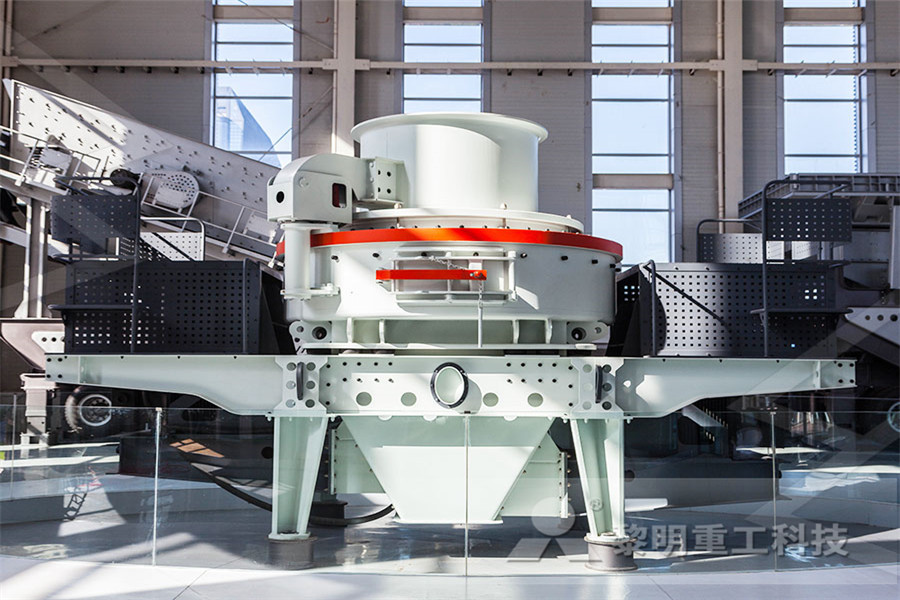

VSI Crushers

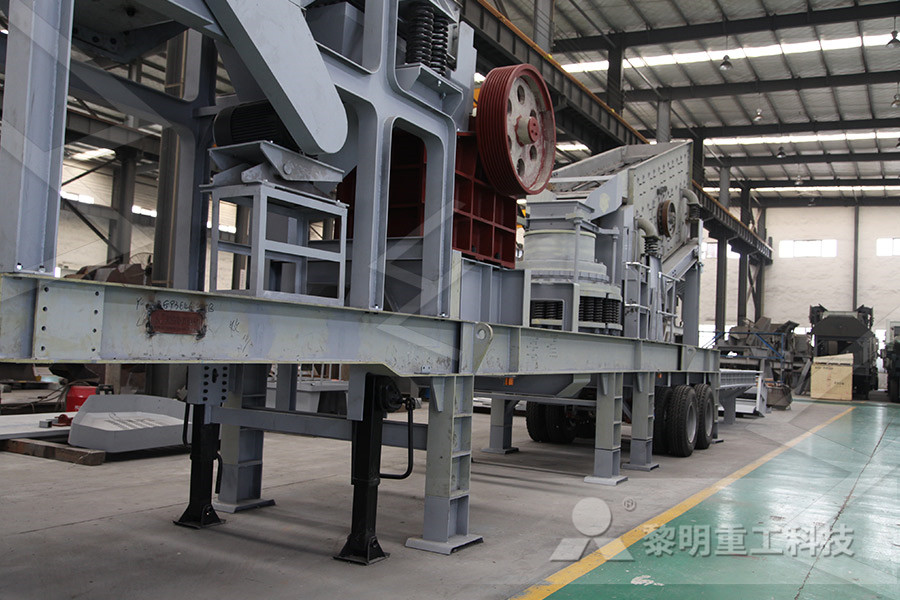

Mobile Crushers