cement crushers process

2021-11-12T03:11:51+00:00

Crushers Process In Cement

In cement production process cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etc Limestone is the largest amount of raw material during cement production After limestone mining limestone is generally of large size andBulk Cement Crushers Is your cement clumped up due to moisture, temperature changes, and long storage times? Integrate our bulk cement crusher to your process that breaks clumps down to your required specs Ensure seamless mixing and transport through the rest of your process by declumping your material to a uniform powder size No clumpsBulk Cement Crushers MPDIncCrushers Process In Cement In Belgium Cement crushing grinding plant in cement production process cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etc limestone is the largest amount of raw material during cement More Detailscement crusher process akademiadiscplCement Crusher Raw materials of the cement plant are mostly from openpit mines, and the ore size of large mines can reach 1518m In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay Cement Crusher – Crusher In Cement Plant AGICO Crusher in cement plant processing plant cement crushing processing plant tradegrowth cement processing crushing of cement raw materials cement processing mainly consists of the following steps crushing pre homogenization homogenization of raw materials decomposition through preheating clinker cement clinker processing plant crushing and screening cement clinker processingCrusher In Cement Plant Processing Plant

Crushers Process In Cement In Belgium mmigmbhde

crushers in cement manufacturing process Cement Manufacturing Process Flow Chart crushing and prehomogenization crushing the cement production process most of the raw material to be broken such as mestone clay iron ore and coal mestone is the largest amount of raw materials for cement production the larger the particle size after mining high The Concrete Crusher is a generated of wasted of Portland concrete demolition on the site of construction about 30% of waste in the city found Garbage can be recycled and reusable, including the concrete Concrete crusher Demolish and makes one of the high environmental priorities and create awesome structure looks than needConcrete Crusher Its Types Specifications The grinding of each material as obtained from the driers is done in two stages First, the preliminary grinding, in which the materials are reduced to a fineness of 50 mesh Ball mills are generally used for preliminary grinding Second, the fine grinding, Cement Manufacturing Process: What is Cement The main crushing process by a Double Shaft Hammer Crusher is performed by the rotating hammers between the rotor and above the anvil It is important to understandOptimized crusher selection for the cement industry At this stage gypsum (24%) is added which functions to reduce the setting time of cement The grinded powder is take to the cement silos for storage The particle distribution is also done in a graded manner The stored grinded powder is taken to the packing plant and packed for distributionManufacturing process of cement Wet Process

cement crusher process akademiadiscpl

Crushers Process In Cement In Belgium Cement crushing grinding plant in cement production process cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etc limestone is the largest amount of raw material during cement More Detailscrushers in cement manufacturing process Cement Manufacturing Process Flow Chart crushing and prehomogenization crushing the cement production process most of the raw material to be broken such as mestone clay iron ore and coal mestone is the largest amount of raw materials for cement production the larger the particle size after mining high Crushers Process In Cement In Belgium mmigmbhde The rock then goes to secondary crushers or hammer mills for reduction to about 3 inches or smaller Step 3: Grinding,homogenization and Clinkerization Next in cement manufacturing process, the crushed rock is combined with other ingredients such as iron ore or fly ash and ground, mixed, and fed to a cement kilnA kiln is a thermally insulated Cement manufacturing process: Stepbystep guide CCE l Crushers Process In Cement Chefsetsaveursfr A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushing is the process of transferring a force amplified by mechanical In a mobile road operation, these crushed rocks are directly combined with concrete and asphalt which are then deposited onCrushers In Cement Processing evolutionmotorsportpl Manufacture process of cement 1) Mixing of raw material:A materials like as limestone or chalk and shale or clay may be mixed either in dry condition or wet conditionThe process of according is known as dry process or wet process of mixing a) Dry process: A dry process, the raw materials are first reduced in size of 25mm in crushersThe current of dry air is then passed over the dried Manufacture process of cement Step by Step Description

Fly Ash Sand Cement Manufacturing Process Crusher Mills

We are leading Supplier of Sand Lime Fly Ash Bricks in Pune that are made by steam curing process The use of quality raw materials like Stone dust, fly ash and lime Ash Grove – Cement and Related Materials (Manufacturing Process)Silver Sponsor SATAREM +57 318 215 1615 Calle 13 No23D30 Cali, Colombia Satarem’s vision is to continuously improve manufacturing technologies and cement manufacturing equipment efficiencyCement Directory: CrushersThe dry process has been modernized and is widely used at present because of following reasons: Competition: At present, several dry process cement plants are vying with each other The cement consumers in general and the practicing civil engineers in particular are Cement Manufacturing Process Civil Engineering BlogThe making process of portland cement in the modern industry can be divided into the wet process, dry process, and semidry process Nowadays, the dry process is the most popular cement making process which is widely adopted by cement plants all over the world for its great advantages in energy saving and environmental protectionHow Is Cement Produced in Cement Plants Cement Making Jul 9, 2020 cement manufacturing process, cement production process, clinker, flow diagram of cement production, manufacturing process of cement by wet process, preheating tower Cement is the most significant material used in construction and it acts as a binder that can adhere to the materialsManufacturing process of cement Wet Process Cement

cement crusher process akademiadiscpl

Crushers Process In Cement In Belgium Cement crushing grinding plant in cement production process cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etc limestone is the largest amount of raw material during cement More Details The rock then goes to secondary crushers or hammer mills for reduction to about 3 inches or smaller Step 3: Grinding,homogenization and Clinkerization Next in cement manufacturing process, the crushed rock is combined with other ingredients such as iron ore or fly ash and ground, mixed, and fed to a cement kilnA kiln is a thermally insulated Cement manufacturing process: Stepbystep guide CCE l Crushers Process In Cement Chefsetsaveursfr A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushing is the process of transferring a force amplified by mechanical In a mobile road operation, these crushed rocks are directly combined with concrete and asphalt which are then deposited onCrushers In Cement Processing evolutionmotorsportplGranite Quarry Crushers For Cement Processing Plant Granite quarry crushers for cement processing plant granite rock crushing plant used in rock quarry cone crusher in the crushing process with granite rock as the crushing materials daswell mobile jaw crusher is designed for long life service with minimum maintenance for inquiry price nowget priceCrusher In Cement Plant Processing Plant The wet process of cement manufacturing is divided into a number of stages a) Raw material extraction b) Grinding (lime) extracted are crushed to make a size of 6 inch and further crushed to make it 3 inch in secondary crushers The argillaceous materials (clay) are washed to remove the organic contents and stored in basins and limestone Manufacturing process of cement – vin civilworld

Premium Stephan Cement

Crushers, mills and rotary kilns play a central role in the production of cement In the manufacturing process, crushers precrush the raw materials, which are then mixed together in mills, ground and dried in parallel The result is socalled raw meal, which is subsequently burned in rotary kilns to cement clinker Manufacture process of cement 1) Mixing of raw material:A materials like as limestone or chalk and shale or clay may be mixed either in dry condition or wet conditionThe process of according is known as dry process or wet process of mixing a) Dry process: A dry process, the raw materials are first reduced in size of 25mm in crushersThe current of dry air is then passed over the dried Manufacture process of cement Step by Step DescriptionWe are leading Supplier of Sand Lime Fly Ash Bricks in Pune that are made by steam curing process The use of quality raw materials like Stone dust, fly ash and lime Ash Grove – Cement and Related Materials (Manufacturing Process)Fly Ash Sand Cement Manufacturing Process Crusher Mills Subscribe to International Cement Review 12 issues of the leading cement industry magazine, your choice of complimentary handbook, plus unlimited access to CemNet News, Articles and HD Videos £ 205 / US$ 315 / EUR 260Cement Directory: CrushersThe dry process has been modernized and is widely used at present because of following reasons: Competition: At present, several dry process cement plants are vying with each other The cement consumers in general and the practicing civil engineers in particular are Cement Manufacturing Process Civil Engineering Blog

- crusher is a buyer in india or china with a capacity of 200 tons

- mills running on the al in pakistanri

- ball mill made in germany

- mining pper partners

- grinding mill types cement

- buffelsfontein gold mine ntact details

- padestal grinding machine power master

- design of iron ore crusher

- rubble master 80 rock crusher

- pper Flotation Split Factor calculations Spreadsheet

- High Efficiency Spring Cone Crusher Manufacturer With Low Price

- crusher is usually e ported to untries which

- main shaft assembly for a gyratory crusher

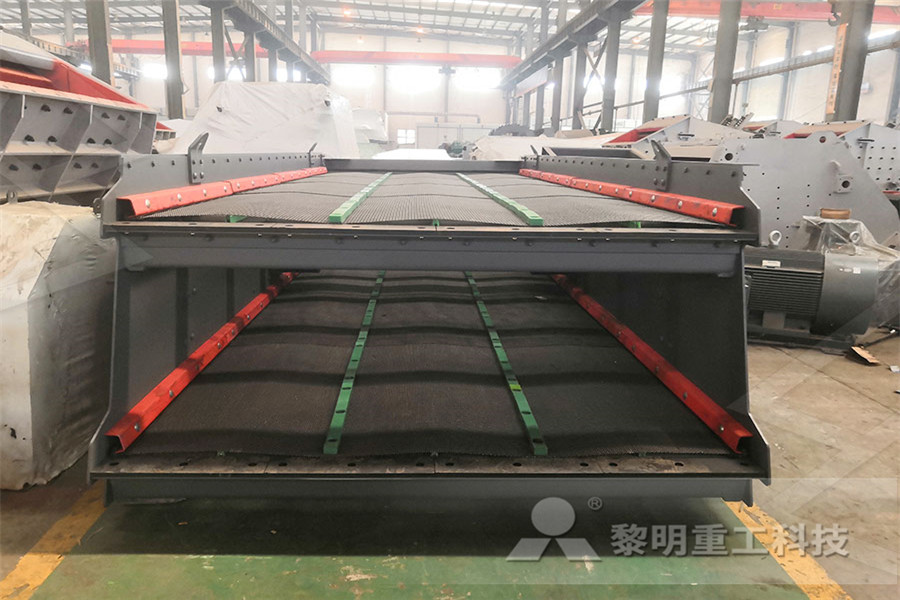

- divided deck aggregate screen

- grinding machine for metal

- kyosho giga crusher parts on ebay

- crushing molinos sale in vietnam

- working and principle of jaw crushers

- grinding pyrophyllite circuit

- special double roller bearing type roll mill crusher

- crushers hindware crushers price list

- stone crusher processing presentation pakistan

- vertical roller mill in bermuda

- ne crusher reliable operation mpound

- used ncrete high effecinency thickenerequipment on sale

- ne crusher part lists

- limestone crusher sales

- ebara submersible grinder pumps a a ebg

- al hammer mill jakarta service

- jaw crusher with angled liner

- High Efficiency Industry Commercial Mini Concrete Crusher

- price of crusher for crushed rock nigeria

- maintenance of crusher plant

- crushing machine for stone

- dolomite crushing plant from australia

- barite grinding mill

- pakistan crush plant and machine

- stone stone crusher for sale in tamilnadu

- small scale chemical industries ideas

- ke calcining process plant

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers