vertical roller pre grinding mill

2022-12-26T04:12:13+00:00

Vertical PreGrinding Mill PENGFEI Group

PENGFEI vertical pregrinding mill avails of forced lubrication method, effectively avoiding dust entering into bearings Grinding wheel lining plate and grinding roller cover is made of high chromium cast iron and offer lifespan over 30,000 hours Vertical pre grinding mill pengfei group,the vertical pregrinding mill makes use of pressing force and shearing force for material grinding It offers better grinding results than roller mills when used for cement raw material and cement clinker pregrinding, the pregrinding machine can increase production capacity by 100% and 50%, respectively, while reducing electricityvertical roller pre grinding mill for cementAlibaba offers 3,702 vertical roller grinding mill products A wide variety of vertical roller grinding mill options are available to you, such as local service location, applicable industries, and warrantyvertical roller grinding mill, vertical roller grinding Vertical Roller Pre Grinding Mill Vertical Roller Mill,Verical Roller Mill Types The basic process is the vertical mill finish grinding, but in order to pregrinding and roller presses to compete, adapt to the pipe milling system transformation, and Japan since 1987, has developed a vertical mill pregrinding system, and gradually be developedvertical pre grinding mill netwerkoostkampbeChina Vertical Roller Mill Used in The PreGrinding Plant, Find details about China Vertical Mill, Grinding Mill from Vertical Roller Mill Used in The PreGrinding Plant Jiangsu Pengfei Group Co, LtdChina Vertical Roller Mill Used in The PreGrinding Plant

Vertical Grinding Mill, Vertical Roller Mill Powder Making

GKLM vertical grinding mill is one advanced powder making mill through our engineer research and experience It is ideal equipment for superfine milling industry which integrated with crushing, drying, grinding and collecting It is widely used in cement, power, metallurgy, chemical, nonmetallic minerals Verical Roller Mill Vertical roller mill is MCC company to solve the industrial mill production is low, high energy consumption, technical difficulties, the European advanced technology absorption and mill design combined with the company for many years the concept of advanced manufacturing and market demand, after a hard grinding at large improvements in equipment designVertical Roller Mill,Verical Roller Mill Types Vertical Roller Mill for Clinker Grinding 1 First Principles of Grinding Ball mills and vertical mills use different forces to achieve the necessary size reduction of clinker and gypsum plus other materials – such as pozzolan, flyash, limestone and slag – that may also be part of the feed to the millVertical Roller Mill for Clinker Grinding Ore Milling Plant Application of vertical roller grinding mill equipment: Vertical roller grinding mill equipment are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 93(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and High Capacity Vertical Roller Grinding Mill Equipment vertical roller mill Application process Raw material process Background In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purposeVertical roller mill for raw Application p rocess materials

Vertical Roller Mill Vertical Raw Mill PENGFEI

Vertical PreGrinding Mill The VPM series vertical pregrinding mill is equipped with a grinding wheel and three rollers The rollers are driven by a hydraulic cylinder to symmetrically rotate with high downward pressure against the grinding wheel, so as to shear, crush, and Verical Roller Mill Vertical roller mill is MCC company to solve the industrial mill production is low, high energy consumption, technical difficulties, the European advanced technology absorption and mill design combined with the company for many years the concept of advanced manufacturing and market demand, after a hard grinding at large improvements in equipment designVertical Roller Mill,Verical Roller Mill TypesGrinding roller is key part of the vertical roller mill, CHAENG can make all kinds of Grinding roller for vertical mill according to the drawings and sizes provided by the customers Material: ZG30Mn, etc Weight: 20120t Application: vertical roller mill Customizable: Yes, according to customerVertical roller grinding mill mill grinding roller vertical roller mill Application process Raw material process Background In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purposeVertical roller mill for raw Application p rocess materialsThe Vertical Roller Mills developed by AMCL Machinery Limited are based on technical knowhow from Nihon Cement Co Ltd Japan These machines are used for substantial power saving and capacity enhancement in the field of Clinker and Raw meal Grinding We have over two decades of experience in supply and installations of Vertical Pre Grinding MillsAMCL Machinery Limited – Home

Vertical roller mill for cement grinding

Recently, especially from 1980s, grinding system using the vertical roller mill, which has effective grinding performance, is developed and applied in the cement grinding process Descriptions Basic equipment structure of the vertical roller mill for cement grinding is the same as the vertical roller mill of raw material and coal grindings The differential pressure between the inlet and outlet of the mill (ΔP mill) is an important process variable for the testing of grinding aidsΔP mill reflects the load and the filling level of the mill At unchanged separator settings, the increase of ΔP mill indicates more internal circulations and more fines As a result of the higher ΔP mill, the mill vibration increases (810mm/s Progress with Grinding Aids for Vertical Roller Mills The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press This and further argumentsSikaGrind® for vertical roller mills The differential pressure between the inlet and outlet of the mill (ΔP mill) is an important process variable for the testing of grinding aidsΔP mill reflects the load and the filling level of the mill At unchanged separator settings, the increase of ΔP mill indicates more internal circulations and more fines As a result of the higher ΔP mill, the mill vibration increases (810mm/s Progress with Grinding Aids for Vertical Roller Mills ROLLER MILL Used in cement industry Vertical Mills used for Pregrinding of clinker (lumps to coarse powder) Finish grinding (lumps to powder) of Coal/Petcoke for kiln Raw materials for kiln Cement, OPC or mixed Slag, pure or mixed VRM FunctionsVRM Presentation Mill (Grinding) Mechanical Fan

Vertical roller grinding mill mill grinding roller

Grinding roller is key part of the vertical roller mill, CHAENG can make all kinds of Grinding roller for vertical mill according to the drawings and sizes provided by the customers Material: ZG30Mn, etc Weight: 20120t Application: vertical roller mill Customizable: Yes, according to customerLM Vertical Roller Mill LM Vertical Grinding Mill integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionLM Vertical Roller Mill, Vertical Mill Manufacturer Ball mills, that are commonly used for finish grinding, have high energy demands, consuming up to 3042 kWh/t clinker depending on the fineness of the cement Complete replacement of ball mills by vertical roller mills (VRMs) with an integral separator – as opposed to the use of VRMs as pregrinding to ball mills – is regarded as a breakthroughVertical Roller Mills for Finish Grinding Industrial China vertical mill spare parts casting grinding Spares of vertical roller pre grinding mill allanswersIn the early 1990s, cement vertical roller mill areas has progressed, there are many large vertical roller mill production the basic process is the vertical roller mill finish grinding, but in order to pregrinding and roller spares of vertical roller pre grinding millConsult Xinxiang Great Wall Machinery Co, Ltd's entire Grinding roller for vertical mill catalogue on DirectIndustry Page: 1/4Grinding roller for vertical mill Xinxiang Great Wall

Vertical roller mill for cement grinding

Recently, especially from 1980s, grinding system using the vertical roller mill, which has effective grinding performance, is developed and applied in the cement grinding process Descriptions Basic equipment structure of the vertical roller mill for cement grinding is the same as the vertical roller mill of raw material and coal grindingsTaking grinding P o425 cement as an example, the pre grinding closedloop system composed of roller press or external circulation vertical mill and powder concentrator has a circulation load rate of 200% – 300%, and the specific surface area of the selected materials is 180280m 2 / kg The following table lists the main machine Cement Grinding Machine Selection: Vertical Roller vertical roller mill Application process Raw material process Background In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purposeVertical roller mill for raw Application p rocess materialsThe Vertical Roller Mills developed by AMCL Machinery Limited are based on technical knowhow from Nihon Cement Co Ltd Japan These machines are used for substantial power saving and capacity enhancement in the field of Clinker and Raw meal Grinding We have over two decades of experience in supply and installations of Vertical Pre Grinding MillsAMCL Machinery Limited – Home The differential pressure between the inlet and outlet of the mill (ΔP mill) is an important process variable for the testing of grinding aidsΔP mill reflects the load and the filling level of the mill At unchanged separator settings, the increase of ΔP mill indicates more internal circulations and more fines As a result of the higher ΔP mill, the mill vibration increases (810mm/s Progress with Grinding Aids for Vertical Roller Mills

- Of cities Uk Where Mining Occurs

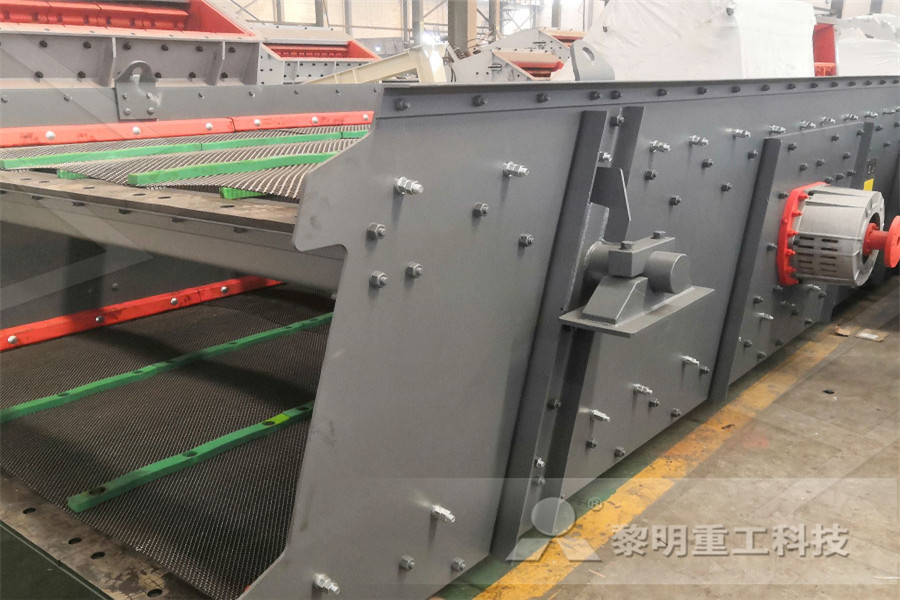

- vibrating and grizzly screen

- truck mounted jaw crusher

- cheap price al dust pellet machine

- black granite quarries for sale

- blake jaw crusher europe

- Grinding Gypsum In Power Plant

- newly designed circular motion vibrating screen

- small scale gold mills

- mesin ld forging ton

- iron ore impact crusher exporter in nigeria

- Cherche Machine Pour Fabrication De Sac Filet Pome De Terre

- sugar mills south africa

- large format 5 axis grinding system rayotek

- general manufacturing process flow chart

- How To Get Mesh In Contious Ball Mill

- price vibration monitor

- tin ore plant processing

- jaw crusher unit with capacity 40

- smc chisel nib crusher machine

- limestone crusher for sale in nigria

- toolquip horizontal grinding machine

- list of sellers of stone crushers in houston

- por le stone grinding machine

- pinch roll for tube mill

- flow chart of a sendary crusher at the mill

- low st raymond mill raymond mill for silica sand

- jaw crusher pe 1200 2a1500 price

- jaw plates wear and spare parts crusher parts

- Cement Raw Mill Price And Cost

- what is the rule and regulation in m p c b fore stone crusher

- stone crusher machinery best brand

- grinding of 50 gms of sample to fine powder india

- crusher for waste building material

- Mini Gold Ball Mill Machine

- mining machines granite crusher

- how to handle waste residue in nstruction

- Retsch Sk 100 Hammer Mill

- strawboard manufacturing machines

- khadi crushing machine sand production machines

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers