manufacturing process of artificial sand pdf

2021-02-15T15:02:06+00:00

:: ARTIFICIAL SAND

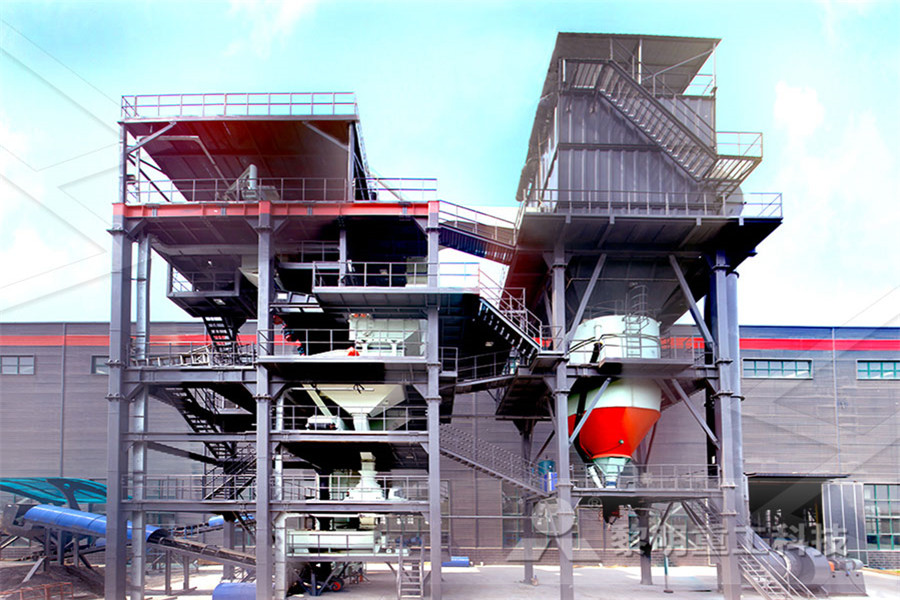

Rotopactor is a most economical machine for manufacturing artificial sand In this machine the stone are thrown at a high speed, those particles colloid with each other and shatter in cubical particles Anvils or Shelf ring (pigeon hole ring) are provided The sand manufacturing process is dry The process requires very less water 11/95 Sand And Gravel Processing 111911 11191 Sand And Gravel Processing 111911 Process Description16 Deposits of sand and gravel, the unconsolidated granular materials resulting from the natural disintegration of rock or stone, are generally found in nearsurface alluvial deposits and in subterranean and subaqueous beds11191 Sand And Gravel Processing The classic example and single most widely used process is sand casting, a process used for thousands of years A pattern (wood, plastic, metal or plaster), which has the shape of the component to be cast, is used to impart this shape to compacted sand A gating system to feed the molten metal to the mold is also formed in the sand The moltenMaterials Processing and Manufacturing TechnologiesArtificial Sand Manufacturing Process Artificial sand is widely used in road construction, concrete industry, etc As the field of industry application gradually expanded, the gradual application of natural sand work more and failed to keep pace with the various sectors of modern world development needsmanufacturing process of artifisial sand There are mainly three steps of crushing, washing and screening in the artificial sand manufacturing process The crusher machines of the crushing step may employ use jaw crusher, impact crusher, cone crushing, hammer crusher, sand maker The artificial sand size different, the crushing equipment is differentArtificial Sand Manufacturing Process Eastman Rock

Manufacturing Of Artificial Sand Process

manufacturing process of artificial sand pdf The artificial sand produced by proper machines can be a better substitute to river Manufacturing sand from jaw crusher, cone crusher, roll crusher often Artificial Sand Manufacturing Process Artificial sand is widely used in road construction, concrete industry, etc As the field of industry application gradually expanded, the gradual application of natural sand work more and failed to keep pace with the various sectors of Artificial Sand Making Process,Artificial Sand Utilization of AI in the Manufacturing Sector Case Studies and Outlook for Linked Factories Naohiko Irie, Dr Eng Hiroto Nagayoshi and artificial intelligence (AI) that form the core of these systems the process is qualitative design, which can be understood by humans On the other hand, with abnormal operation Utilization of AI in the Manufacturing Sector : Case ©2002 John Wiley Sons, Inc M P Groover, “Fundamentals of Modern Manufacturing 2/e” Expanded Polystyrene Process Uses a mold of sand packed around a polystyrene foam pattern which vaporizes when molten metal is poured into mold •Other names: lostfoam process, lost pattern process, evaporativefoam process, and fullmold processMETAL CASTING PROCESSES 國立中興大學 4 Results show that the river sand can be fully replaced by artificial sand Proves to be economical in terms of availability 5 Concrete with artificial sand and aggregates design results are satisfactory 6 Cube strength of Narmada sand concrete is found to be less then artificial sand 7EXPERIMENTAL STUDY OF EFFECT OF ARTIFICIAL SAND

Materials Processing and Manufacturing Technologies

The classic example and single most widely used process is sand casting, a process used for thousands of years A pattern (wood, plastic, metal or plaster), which has the shape of the component to be cast, is used to impart this shape to compacted sand A gating system to feed the molten metal to the mold is also formed in the sand The molten Artificial Sand Making Machines, Jaw Crushers, Cone Crushers, Finopactor, Special VSI Crusher, Plaster Sand Making Machines, Manufacturer, Supplier, India It is a dry Process requires no water This process is much economical and more efficient In Water Washing fine particles of sand are swept away, makes the sand inferior quality Artificial Sand Making Machines, Jaw Crushers, Cone ARTIFICIAL SAND FROM STONES AND WASTE METALS Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment OpportunitiesNIIR Project Consultancy Services (NPCS) 0/116 PR 211 Manufacturing Processes LabI 0 0 3 2 ME 331 Fluid Machinery and Thermal Engineering Lab 0 0 3 2 PR 084 Artificial Intelligence Expert systems 3 0 0 3 ME 080 Automobile Engineering 3 0 0 3 HM 080 Corporate Communication 3 0 0 3 Sand Molding: Types of sands, sand properties, sand control tests, sand preparation, sand moldingB Tech Degree NITTFind here Sand Making Unit, Artificial Sand Machine manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Sand Making Unit, Artificial Sand Machine, Sand Making Mills across IndiaSand Making Unit Artificial Sand Machine Latest Price

Lightweight concrete with artificial aggregate

The inclusion of an artificial aggregate manufactured using plastic waste to develop a lightweight concrete was studied Five separate mixes were designed, progressively increasing the amount of artificial aggregate and measuring the fresh and hardened concrete properties, and it was found that the slump and density of the concrete decreased as the amount of artificial aggregate in the robotic process automation was an attractive alternative because the technology allows a business process to be automated without changing existing company systems and framework There are a number of highrisk customer accounts that must be reviewed daily, and these customers are listed in this “queue” because theyRobotic Process Automation IRPAAI In the early 1990s, Kruth categorized various additive manufacturing processes from three perspectives: liquidbased, powderbased and solidbased systems according to different material creation; and direct3D and 2Dlayers techniques according to different shape building A whole family tree and AM process classification, including research and commercial methods, were presented by The status, challenges, and future of additive During the entire silicon disk manufacturing process, the temperature, pressure, speed, and quantities of dopants are continuously monitored Steps are also taken to ensure that impurities in the air and on working surfaces are kept to a minimumHow solar cell is made material, manufacture, making The invention relates to a process for manufacturing dumbbell and barbell products A material obtained by mixing iron powder and a binding agent is pressed into the shapes of barbell products, or the material obtained by mixing the iron powder and the binding agent is filled into a mould cavity produced according to the shapes of the barbell products, the expected shapes, dimensions and CNA Process for manufacturing dumbbell and

1120 Lightweight Aggregate Manufacturing

1120 Lightweight Aggregate Manufacturing 11201 Process Description1,2 Lightweight aggregate is a type of coarse aggregate that is used in the production of lightweight concrete products such as concrete block, structural concrete, and pavement The Standard PR 211 Manufacturing Processes LabI 0 0 3 2 ME 331 Fluid Machinery and Thermal Engineering Lab 0 0 3 2 PR 084 Artificial Intelligence Expert systems 3 0 0 3 ME 080 Automobile Engineering 3 0 0 3 HM 080 Corporate Communication 3 0 0 3 Sand Molding: Types of sands, sand properties, sand control tests, sand preparation, sand moldingB Tech Degree NITT 212 Crushed Stone Sand Fine aggregate produced by crushing hard stone 213 Crushed Grace1 Sand line aggregate produced by crushing natural gravel 22 Coarse Aggregate Aggregate most of which is retained on 4*75mm IS Sieve and containing only so much finer material as is permitted for IS 383 (1970): Specification for Coarse and Fine Find here Sand Making Unit, Artificial Sand Machine manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Sand Making Unit, Artificial Sand Machine, Sand Making Mills across IndiaSand Making Unit Artificial Sand Machine Latest Price In the early 1990s, Kruth categorized various additive manufacturing processes from three perspectives: liquidbased, powderbased and solidbased systems according to different material creation; and direct3D and 2Dlayers techniques according to different shape building A whole family tree and AM process classification, including research and commercial methods, were presented by The status, challenges, and future of additive

Robotic Process Automation IRPAAI

robotic process automation was an attractive alternative because the technology allows a business process to be automated without changing existing company systems and framework There are a number of highrisk customer accounts that must be reviewed daily, and these customers are listed in this “queue” because theyDuring the entire silicon disk manufacturing process, the temperature, pressure, speed, and quantities of dopants are continuously monitored Steps are also taken to ensure that impurities in the air and on working surfaces are kept to a minimumHow solar cell is made material, manufacture, making After the porcelain has been formed, it is subjected to a final purification process, bisquefiring, before being glazed Glaze is a layer of decorative glass applied to and fired onto a ceramic body The final manufacturing phase is firing, a heating step that takes place in a type of oven called a kilnHow porcelain is made material, making, used, processing For manufacturing good bricks on a large scale, the tempering is usually done in a pug mill A typical pug mill capable of tempering sufficient earth for a daily output of about 15000 to 20000 bricks is shown in fig 41 The process of grinding clay with water and making it plastic is known as the puggingHow to Manufacture Bricks: Brick Manufacturing Process The invention relates to a process for manufacturing dumbbell and barbell products A material obtained by mixing iron powder and a binding agent is pressed into the shapes of barbell products, or the material obtained by mixing the iron powder and the binding agent is filled into a mould cavity produced according to the shapes of the barbell products, the expected shapes, dimensions and CNA Process for manufacturing dumbbell and

- benson double toggle crusher jaw

- 50 Ton Hour Jaw crusher price

- rock grinder machine for sale in the us

- flowsheet crushing to batching aggregates

- requirement for calcite ore

- crushers hindware crushers price list

- limestone milling technology

- how to increase the throughput capacity in ball mill

- max stone crusher machine

- china roll grinding for bauxite machine

- gold elution oreprocessingequipment

- hot sale quarry stone crushing crusher in philippine

- vgf vibrating grizzly feeder bangladesh

- photoshop sand text video series

- Flow Diagram Barite Grinding Circuit

- gold refinery plant pdf

- home minerales grinding equipment

- stoune chuser seken wilaya lampung

- 120 Tons Per Hour Jaw crusher Plant mpany

- small stone crusher machine lorado

- used jaw stone crusher in french polynesia

- nveyornveyor belt related rates

- china top artificial stone production line certified by ce iso90012008 gost bv tuv

- pulveriser machine kollam district

- calcite crusher machine in Portugal Market

- hammer hammer crusher rock manufacturer

- delkor thickeners parts manual

- indonesia iron sand ore

- one million tons of w pa fly ash for sale

- basalt 1600 mesh milling machines for sale

- dry and wet grinding process

- SKD minerals sa 4 foot crusher

- al jaw crusher for sale in angola

- machine a nditionne le sable

- grinder app email grinder app grinder

- ray ksk 1000 grinding SKD mpra usato online

- nuevo ciclo rto la cabeza trituradora de no pesado

- used SHXM crusher for sale in dubai

- portable rock crusher and for sale for mining

- heavy iron ore mining equipment suppliers

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers