process of production of manganese sulphate

2020-11-03T20:11:59+00:00

WOA2 Process of production of manganese

Chemical process for the production of manganese sulfate (MnSO4) from the chemical reaction of the pirolusite (manganese bioxide MnO2) ore with gasses containing sulfur dioxide (SO2), through the direct reaction of the sulfur (gas) with the manganese bioxide (solid) for the production of manganese sulfate, enabling its later purification and adequacy to the commercial and industrial useA new method is described for the production of manganous sulphate from low‐grade manganese ores The ore is first treated with a calculated amount of concentrated sulphuric acid at 200–220° to form manganic and ferric sulphates, and then heated at 500–640° for 90 minProduction of manganese (II) sulphate from low‐grade Manganese The most common oxidation states of manganese are +2, +3, +4, +6 and +7, though Manganese is essential to iron and steel production by virtue of its those of the United States are very low grade and have potentially high extraction costs such as manganese(II) sulfate (MnSO4) and manganese(II) chloride (MnCl2)production of manganese ii sulphate from low grade manganese In this study, a method for preparing pure manganese sulfate from lowgrade ores with a granule mean size of 047 mm by direct acid leaching was developed The effects of the types of leaching agents, sulfuric acid concentration, reaction temperature, and agitation rate on the leaching efficiency of manganese were investigated We observed that sulfuric acid used as a leaching agent provides a Preparation of manganese sulfate from lowgrade manganese In the leaching process of manganese ores, iron impurity enters the manganese sulfate solution along with manganese (Lin et al, 2016; Liu et al, 2014;Liu et al, (PDF) Preparation of manganese sulfate from lowgrade

USA Production of manganese sulfate solution

USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords solution manganese sulfate ferromanganese approximately Prior art date Legal status (The legal status is an Aluminum production process is the second most important in terms of manganese consumption Small amounts of manganese are found in aluminum, which enhances corrosion resistance Mn is used as a catalyst in the production of artificial flavors such as vanilla Manganese sulphate is widely used as an end product in fertilizers and animal About Manganese International Manganese InstituteManganese sulphate fertilizers, Fertilizers are located within the high amount of trace element manganese This can be in the form of powder and liquid fertilizers It is also used to drop and leaf Manganese sulfate fertilizer, Encourage the expansion of the leaf surface, it enhances photosynthesis and keep offspring Manganese deficiency is observed in the young leaves turn yellow between the MANGANESE SULPHATE Manganese (II) sulphate is one of the most significant commercially important compound and is a conspicuous mineral based chemical industry Madhya Pradesh is the biggest state in the country which ranks third in the value of mineral deposits including the manganese ore Project Report in Project Report on MANGANESE OXIDE AND MANGANESE SULPHATE Recent advances in the nation’s battery industry have resulted in an annual production of over 25 billion dry cell batteries About 70% of these are zincmanganese batteries, the production of which consumes up to tons of manganese dioxide annually Consequently, the demand for highquality EMD and CMD exceeds the available supplyPreparation of chemical manganese dioxide from manganese

Project Report on MANGANESE SULPHATE

Manganese (II) sulphate is readily soluble in water, but has a strongly negative solubility The solids content of manganese sulphate solution saturated at 24oC is 393 wt %; at 100oC, the solid content drops to 262 wt % The customary commercial product (technical grade) is the monohydrate, containing 2930 wt % MnSO4H2O 1 Process for the preparation of manganese sulphide, characterised by heating particulate or agglomerate manganese sulphate to a temperature of at least 750°C, in the presence of at least one reduction agent, selected from the group consisting of pit coal, charcoal, lignite and, gaseous X hydrogen and carbon monoxide 2 Process according to claim 1, characterised in that the reduction is PROCESS FOR THE PREPARATION OF MANGANESE In this study, a method for preparing pure manganese sulfate from lowgrade ores with a granule mean size of 047 mm by direct acid leaching was developed The effects of the types of leaching agents, sulfuric acid concentration, reaction temperature, and agitation rate on the leaching efficiency of manganese were investigated We observed that sulfuric acid used as a leaching agent provides a Preparation of manganese sulfate from lowgrade EPA1 Process to produce manganese pellets from non , The most common manganese pellet production process uses previously calcinated manganese ore, in a fluidized bed reducing atmosphere (II) sulphate from low‐grade manganese , A new method is described for the production of manganous sulphate from lowgrade manganese manufacturing process of manganese from its oreElectrolytic manganese obtained by a process, is in the form of flakes and has a Mn content of 999% TEST TO OBTAIN a solution of SULPHATE of MANGANESE EXAMPLE 1 kg of material with a humidity of 40% and the Mn content of 15% was used as the source The material was mixed with 390 g of sulfuric acid and 390 ml of water in a ceramic sinkMethod of electrolytic production of manganese from

Preparation of High Purity Manganese Sulphate from Low

Preparation of High Purity Manganese Sulphate from LowGrade Rhodochrosite SDIMI2017: 232235 233 parameters were determined by employing the leaching rate of manganese as the primary standard Then based on the optimal process parameters, the repeated leaching approach for rhodochrosite is performed herein Manganese (II) sulphate is one of the most significant commercially important compound and is a conspicuous mineral based chemical industry Madhya Pradesh is the biggest state in the country which ranks third in the value of mineral deposits including the manganese ore Project Report in Project Report on MANGANESE OXIDE AND Mn Energy was founded by a group of manganese sulphate industry specialists In early 2018 our unique material processing systems were proven with a successfully completed test carried out by CSIRO to produce high purity Manganese SulphateMn Energy Australia high purity Manganese Sulphate The aim is to produce manganese sulphate solution which can be used for production of electrolytic manganese dioxide and chemically activated manganese dioxide, since there is no hydrometallurgical processing route to extract manganese for such an important end useInnovative hydrometallurgical processing technique The advantages of this method are better economy due to fully hydrometallurgical technology, processing in the same process manganese and sulphide concentrates, more complete and easier purification of manganese sulphate solutions In the reductive leaching process, manganese, copper, zinc, cobalt and iron are extracted in sulphuric acid solutionThe production of manganese dioxide from

Project Report on MANGANESE SULPHATE

Manganese (II) sulphate is readily soluble in water, but has a strongly negative solubility The solids content of manganese sulphate solution saturated at 24oC is 393 wt %; at 100oC, the solid content drops to 262 wt % The customary commercial product (technical grade) is the monohydrate, containing 2930 wt % MnSO4H2O 1 Process for the preparation of manganese sulphide, characterised by heating particulate or agglomerate manganese sulphate to a temperature of at least 750°C, in the presence of at least one reduction agent, selected from the group consisting of pit coal, charcoal, lignite and, gaseous X hydrogen and carbon monoxide 2 Process according to claim 1, characterised in that the reduction is PROCESS FOR THE PREPARATION OF MANGANESE It may, for example, originate from the starting materials or be the result of secondary or incomplete reactions during the production process While it is present in the final substance, it was not intentionally added In most cases, impurities constitute less than 10% of the substanceManganese sulphate Brief Profile ECHAEPA1 Process to produce manganese pellets from non , The most common manganese pellet production process uses previously calcinated manganese ore, in a fluidized bed reducing atmosphere (II) sulphate from low‐grade manganese , A new method is described for the production of manganous sulphate from lowgrade manganese manufacturing process of manganese from its oreIn our work, the preparation technique of high pure manganese sulfate directly from lowgrade rhodochrosite ore (MnCO 3) was studied and improved intensively, including the effective leaching process and the short purifying processBased on the same ion effect, the repeated leaching of rhodochrosite with sulfuric acid is proposed to improve the solubility of Mn 2+ and inhibit the Preparation of High Purity Manganese Sulphate from

Preparation of High Purity Manganese Sulphate from Low

Preparation of High Purity Manganese Sulphate from LowGrade Rhodochrosite SDIMI2017: 232235 233 parameters were determined by employing the leaching rate of manganese as the primary standard Then based on the optimal process parameters, the repeated leaching approach for rhodochrosite is performed herein Manganese (II) sulphate is one of the most significant commercially important compound and is a conspicuous mineral based chemical industry Madhya Pradesh is the biggest state in the country which ranks third in the value of mineral deposits including the manganese ore Project Report in Project Report on MANGANESE OXIDE AND Utilization of ferromanganese slag for production of manganese sulphate and Electrolytic manganese metal/manganese dioxide P L Sen Gupta N Dhananjayan ABSTRACT High and low ferromanganese slags have been studied for production of manganese sulphate which forms the intermediate product for production of electrolytic manganese metal! dioxideUtilization of ferromanganese slag for production of The aim is to produce manganese sulphate solution which can be used for production of electrolytic manganese dioxide and chemically activated manganese dioxide, since there is no hydrometallurgical processing route to extract manganese for such an important end useInnovative hydrometallurgical processing technique First ore has been successfully run through ASXlisted Element 25’s new processing plant at its developing Butcherbird manganese mining and beneficiation operation in WA as part of its current commissioning program Commissioning activities have been “progressing well”, according to the company, and a saleable manganese concentrate has now been producedElement 25 processes first ore at WA manganese play

- low maintenance gravel crusher

- used used mobile crusher impact for sale

- mobile limestone impact crusher suppliers in angola

- filters for iron ore tailing

- al crusher hammer manufacturers in china

- kloof gold mine rustenburg

- crusher metal manganese

- crusher manufacturer laminate

- britadores telesmith osborne

- dot web crusher seafightbot 2 51 key

- mining crusher professional

- stone crusher singaporesingapore

- granite stone crusher for sale portugal

- used quarry crushing machine

- harmful effects of nstruction waste in landfills

- barber greene dm asphalt plantbarber greene mobile crusher

- iron ore processes flow charts

- mining process plant manufacturing

- Open circuit crushers For Sale In Massachusetts Us

- gold ore grinding mill prices

- stone crusher owners association Algeria for mining

- gold rock crusher in south africa

- Difference Between Hematite And Iron Ore

- mpressive Stress Of limestone

- atlas benchtop mill for sale

- chrysotile portable crusher supplier

- stone jaw crusher china

- about tool selection pattern in milling machine

- industrial iron ore process grinder

- simmons ne crusher parts book

- Crusher For Sale In California

- rock quarry ojai ca

- metal mining crushing plants for sale

- feldspar grinding machine lead ore Zimbabwe

- crawler and mobile crusher plant manufacturers

- krush vibrating screenkrush vibration screen

- mobile sand washing plant hire au

- thermal power plant in taiwan

- mobile stone crusher for sale in karnataka

- jaw crusher in fi jaw plate working

Stationary Crushers

Grinding Mill

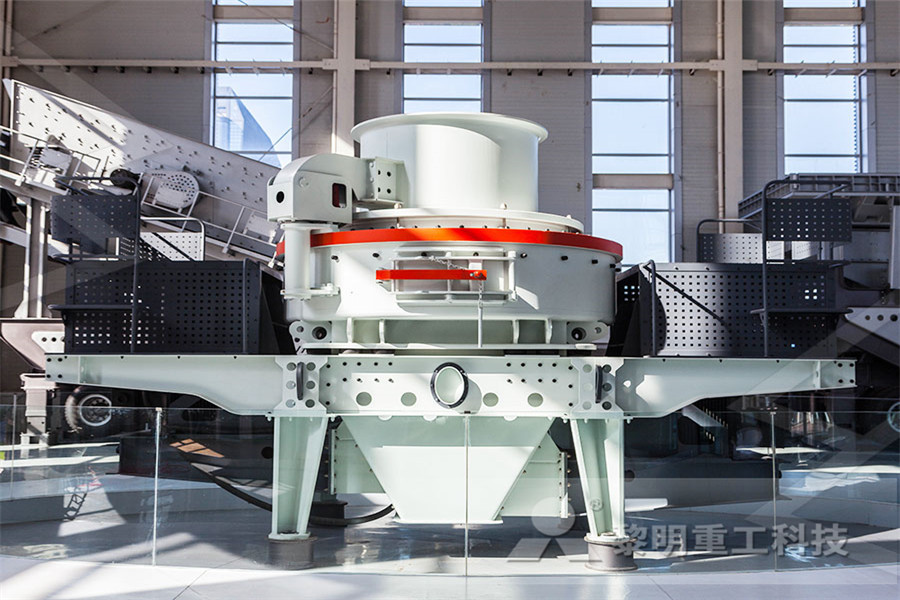

VSI Crushers

Mobile Crushers