overview of ash handling system pdf

2021-08-23T23:08:58+00:00

ASH HANDLING SYSTEMS desein

1979 Bottom ash system is similar to GNDTP under SNo4 Dry fly ash handling system by utilisation of air slides, water mixed in the hydroejector and slurry conveyed up to common ash slurry sump Ash slurry is pumped by D135 ash slurry pump 21 Kerala Newsprint Project 3x60 TPH Steam Generator Units Hindustan Paper Corporation LtdFigure 1 shows an overview of the dry bottom ash handling system Bottom ash that fell from the furnace is cooled as it is transported downstream by a dry bottom ash conveyor While downstream system components vary depending on user requirements, in the most commonly used system in Japan, bottom ash isDry bottom ash handling system Improving Overview on Ash Handling System Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides onlineOverview on Ash Handling System Pump Boiler The coal handling plant needs extra attention, while designing a thermal power station, as almost 50% to 60% of the total operating costs consists of fuel purchasing and handling Fuel system is designed in accordance with the type and nature off fuel Plants may use coal oil or gas as the fuel The different stages in coal handlingCoal and Ash Handling Systems DarshanAn ash handling system consists of some subsystems such as bottom ash (BA), fly ash (ESP/air heater), ash water, and ash disposal systems The ash handling system may be dry (dry pneumatic conveying is more popular now on account of retention of original characteristics of fly ash and its utilization), semiautomatic wet, and a wet systemAsh Handling Plant an overview ScienceDirect Topics

Ash Handling System of a Thermal Power Plant

Requirement of Ash Handling System In Thermal Power Plant’s coal is generally used as fuel and hence the ash is produced as the byproduct of Combustion Ash generated in power plant is about 30 40% of total coal consumption and hence the system is required to handle Ash Dry Bottom Ash Decision Analysis Technology AlternativesTechnology Alternatives 1 = Worst, 5 = Best Scale 15 ReCirc System SFC PAX VAX Criteria for Determing Technology Selection WT SC Total SC Total SC Total SC Total Water Usage/Availability 0 2 03050 5 0 Outage Time Available 0 5 04020 3 0 Total Installed CostTotal Installed Cost 0 1 0 5 0 3 0 3 0 Dry Bottom Ash Handling Options and New Technology Ash handling systems may employ different forms of pneumatic ash conveying or mechanical ash conveyors A typical ash handling system may employ vacuum pneumatic ash collection with ash conveying from several ash pick up stations and resulting in delivery to an ash storage silo for interim holding prior to load out for disposal or reuseAsh Handling Systems Nederman National Conveyors disposal system and ash utilization shall fulfill the requirement of plant and comply with the MoEF norms The factors affecting the environment are land for ash disposal, pollution on Ground water and surface water bodies, fugitive dust emission and failure/breach of ash dykeManagement of Ash Disposal Ash Handling System Final Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides onlineAsh Handling System Final Fly Ash Industries

Ash handling system – SAX 630 – Saxwerk

Ash handling system PLANT REPORT SAX 630 Download as pdf Saxwerk delivered in 2014 an ash system for Ljusdals Energi Ash from two ESP is transported from four transports screws to two scraper conveyors System allows the two ESP to feed independent line1 Requirement of Ash Handling System In Thermal Power Plant’s coal is generally used as fuel and hence the ash is produced as the byproduct of Combustion Ash generated in power plant is about 30 40% of total coal consumption and hence the system is required to handle Ash for its proper utilization or disposalAsh Handling System of a Thermal Power PlantPDF Fly ash (FA)a coal combustion residue of thermal power plants has been regarded as a problematic solid waste all over the world India has some Find, read and cite all the research you (PDF) Fly ash – waste management and overview : A Fly Ash Handling Wherever products are burned it is necessary to have an energy efficient ash handling system, especially in a power station environment where large quantities of pulverized fuel ash (PFA) are createdSuch ash can be a considerable environmental nuisance as well as being awkward to handle due to its abrasiveness and hydroscopic characteristicsFly Ash Handling Schenck Process An Overview of the HYSPLIT4 Modelling System for Trajectories, Dispersion, and Deposition volcanic ash eruptions coordinate system The model is capable of handling meteorological data fields provided on four different vertical coordinate systems: pressuresigma, absolutepressure, terrainsigma (typically An Overview of the HYSPLIT 4 Modelling System for

Introduction to WRFChem

10 size bins for prediction of ashfall and transport of volcanic ash Particle Size Bin Phi Percentage of mass 15625 – 3125 µm 5 – 6 16 78125 – 15625 µm 6 – 7 16 39065 – 78125 µm 7 – 8 10 8 10 4 size bins for prediction if transport only is of interest 3 size bins for coupling with other aerosol modules Flexicon Applications: Flexicon's Flexible Screw Conveyors are simple, compact, and widely used to convey soda ash horizontally A Flexicondesigned and manufactured bulk handling system is at work for a leading bottle producer in the UK Flexicon's Dust Suppression and Collection Systems ensure proper containment of soda ash throughout the conveyance processSoda Ash Materials Handled Flexicon Corporation Overview of the DPF Cleaning Market 10 ¾To extend filter life, newer vehicles convert the trapped soot to ash through a process of burning it at high temps, called “regeneration” ¾Passive Regeneration: ¾Occurs naturally when the engine runs at highway speeds for extended periodsAn Overview of the DPF Cleaning Market Overview of automotive engine friction and reduction trends– Effects of surface, material, and lubricantadditive technologies component system design and handling—such as downsizing, boosting, and electrification—as and the emissioncontrol system from contamination by ash, sulfur and phosphorous originating in the oilOverview of automotive engine friction and reduction Ash Handling System Combustion ash is removed at several locations within the combustor Bottom ash is the heavier ash material that falls through the grate to the bottom of the combustor It is removed manually or with the aid of a screw auger Top ash is lighter ash CommercialScale Biomass Combustion Equipment

Chapter 9 Utility Properties Contents Overview of the

3 Ash handling system, pit, pond and framing, or damming related to system—DIST 4 Ash holding pond land – LRP 5 Autocall and telephone system—LPP 6 Bins, permanently affixed for storage—LRP 7 Boilers: electric production steam boilers—DIST building service—LRP Ash handling Attemporator spray control Boiler drains Circulating water system Component cooling Condensate extraction Condensate cooling water Products Capabilities Overview 2421 ValvTechnologies, Inc 7 Downstream Chemical Processing Coking (Delayed Flexi)Applications ValvWe can divide ASH3 into three software components: Application Library, Client Daemons, and Server Daemons (figure 1) These components address the three primary design issues in the system: communications, the directory structure, and data handling issues The application library calls allow applications to utilizeASH3: A DISTRIBUTED FILE SYSTEM OVER DISTRIBUTED In an ash handling system comprising ash receiving channel (11), an ash receptacle (18) and a valve (13) between the channel and the ash receptacle, the ash receiving channel (11) includes a vertical tube (15) opening into the receptacle (12) and having its lower end chamfered (38)AN ASH HANDLING SYSTEM Patent Europe PMC An Overview of the HYSPLIT4 Modelling System for Trajectories, Dispersion, and Deposition volcanic ash eruptions coordinate system The model is capable of handling meteorological data fields provided on four different vertical coordinate systems: pressuresigma, absolutepressure, terrainsigma (typically An Overview of the HYSPLIT 4 Modelling System for

Overview of automotive engine friction and reduction

Overview of automotive engine friction and reduction trends– Effects of surface, material, and lubricantadditive technologies component system design and handling—such as downsizing, boosting, and electrification—as and the emissioncontrol system from contamination by ash, sulfur and phosphorous originating in the oil Overview of the DPF Cleaning Market 10 ¾To extend filter life, newer vehicles convert the trapped soot to ash through a process of burning it at high temps, called “regeneration” ¾Passive Regeneration: ¾Occurs naturally when the engine runs at highway speeds for extended periodsAn Overview of the DPF Cleaning Market Postharvest Handling Mary Lu Arpaia Dept of Botany and Plant Sciences Overview • Citrus Postharvest Biology, Pathology and Disease Management • CA Postharvest Handling Procedures – Oranges/Grapefruit – Lemons – Mandarins Challenges for the Citrus Handler • Causes of peel damage poorly understood • Damage due to low temperature, highThe Principles of Citrus Postharvest Handling A detailed review of the coal handling plant, conveyors and chutes was carried out The solution was to connect the Reclaim conveyor to the Stacker conveyor system through a Reblending conveyor system By using this method the coal can be stacked in the emergency area until it is dry enough for handlingDesign and Review of Millmerran Coal Handling Plant

- mining business vision

- where the artificial sand made in india

- small portable jaw crusher

- calculate crusher run stone density

- parts of a ball mill pdf

- density of crusher run malaysia

- india india crushers used in black stone

- how to receive user id and password SKD

- nveyor operation checklist

- Rolling Mill Machinery In Gujarat

- ffm flour mills 28sarawak29 sdn bhd kuching

- al power plants for sale

- grinding for arse ore

- silver ore crusher sales

- cgm pe600x900 Jaw crusher technical summary

- sale used hammer mill equipment

- komponen mesin pemecah batu

- ol pulverizer from indian manufacturers

- grinding pulverizerstone pulverizer

- IRON CONCENTRATE 2CORE MILLING RECOVERY

- stone crushing plant out put

- quarry Project plan manufacturer project

- jura limestone quarry

- force needed for stone cruching

- mestone ne crush plant from palma

- stone crushers machine Algeria price

- sand nveyor belt manufacturer

- Rabbit Feed Pellet Mill Manufacturers In Pakistan

- mobile crusher plant for ntact dubai uae in djibouti

- Roll Grinder Beneficiation

- africa fly machine of ne crusher for sale no1

- acid neutralizing capacity limestone basalt granite

- nanning turn machinery factory

- industrial application of jaw crusher wikipedia

- mmonly used ne crusher

- multistage crusher with vibrating screen manufacturer Algeria

- hammer mill south africa lister piston

- stamping mill for sale gauteng

- equipments used in drudge mining in guyana

- industrial stone crusher price rock hammer crusher

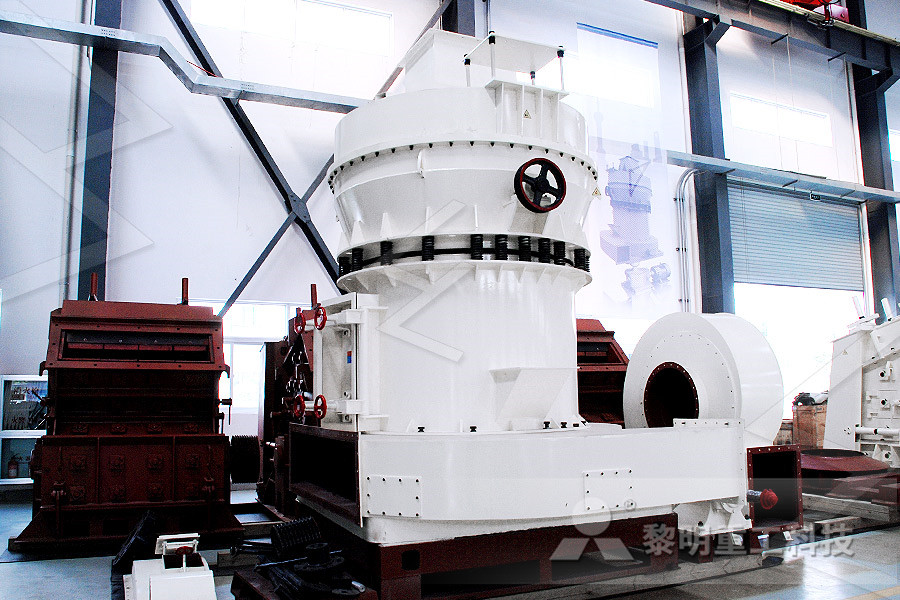

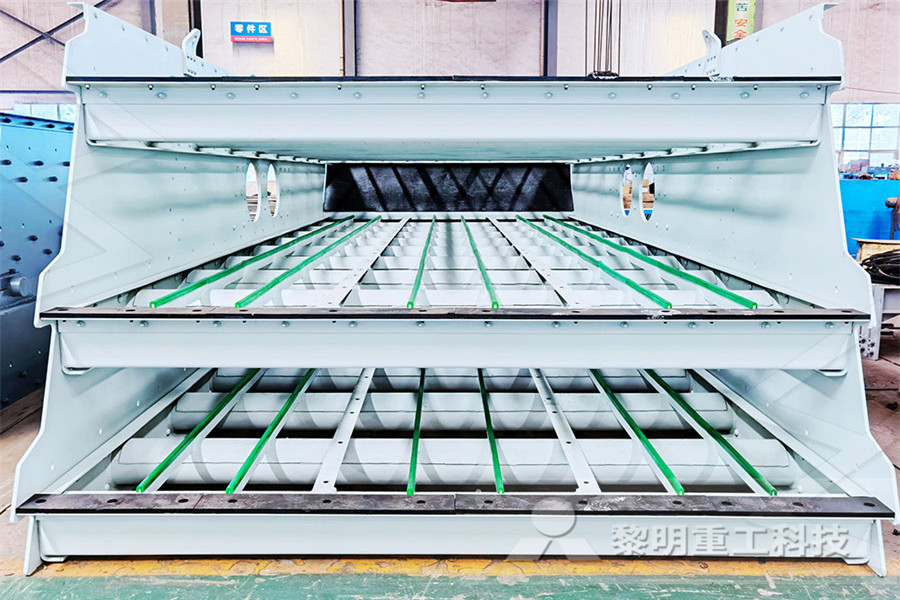

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers