aggregate rock jaw crusher crushing washing

2021-10-08T02:10:06+00:00

Jaw Crusher Eastman Rock Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, etc Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of oresThe crushing action of an impact crusher breaks a rock along natural cleavage planes, giving rise to better product quality in terms of shape Crushing stages Most aggregate producers are well acquainted with the selection of crushing equipment and know it is possible to select a piece of equipment based solely on spec sheets and gradation Rock crushing equipment for sale Eastman Rock Mobile Aggregate/Sand Screening And Washing Plant Dewo machinery can provides complete set of crushing and screening line, including Hydraulic Cone Crusher, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement production line, ore Mobile Aggregate/Sand Screening And Washing Plant The aggregate process consists by progressive stages of crushing, screening, and washing The aggregate production flow: 1The blasted raw stones was hauled to the a stockpile by heavy duty truck; 2The raw stones like granite, basalt, marble, limestone, cobble stone etc will be fed into jaw crusher as primary crushing machine;Aggregate crusher processingLIMING Mining and Apr 6, 2021 aggregate, crusher, crushing, diesel, jaw, mobile, plant Dewo machinery can provides complete set of crushing and screening line, including Hydraulic Cone Crusher, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement Aggregate Crushing Plant Mobile Diesel Jaw Crusher

Jaw Crusher JXSC Machine

Jaw rock crusher commonly in doubletoggle jaw crusher, composed of a fixed jaw and moving jaw, the discharging stone particle size can be controlled by changing the discharge port Owing to its high crushing capacity and hard material efficiency, jaw crushers are a good alternative to primary gyratory crushers JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of mediumhard materials to smaller physical size Jaw rock crushers are capable of working with the mobile crushing station, underground crushing Jaw Crusher Primary Crusher in Mining Aggregate Sandstone crushingscreeningwashing plant Zhengzhou China Sandstone crushingscreeningwashing plant catalog of PE Rock Crusher for Sales Promotion 10% Discount, Artificial Sandstone MakingWashing Plant for Construction Aggregate provided by China manufacturer Zhengzhou Hengxing Heavy Equipment Co, Ltd, page2High Performance Mining Bucket Wheel Sand Washer Eastman Technology is a professional Rock Crusher manufacturer, founded in 1985We offering crushing grinding equipment and services for the mineral crushing, aggregate producing, construction waste recyclingWith our unique knowledge and innovative solutions, we help our customers improve their operational efficiency, reduce risks and increase profitabilityEastman Rock Crushers Sand Making Machines According to the production capacity requirements (rough crushing more than 1 200 t / h), the characteristics of raw materials containing more soil and the market demand for sand and gravel aggregate products, combined with the general map of the plant, the process layout, the coarse crushing equipment uses the rotary crusher go to jaw rock Aggregate Crushing Plant and Processing JXSC Rock

Aggregate Washing Equipment Screens Portable

Serving the Aggregate Industry since 1992 with affordable crushing equipment! Simplicity produces a full line of heavyduty vibratory screens and feeders for the aggregate and mining industries Canica has been a leader in the crushing industry since introducing its first Vertical Shaft Impactorcolumnar basalt european type jaw crusher concrete aggregate washing The aggregate crushing process consists of progressive stages of crushing, screening and washing aggregate production line manufactured by kefid is designed for producing crushed stone aggregate from many natural deposits including limestone, granite, basalt, trap rock and other durable mineral resourcescolumnar basalt european type jaw crusher concrete Mobile Aggregate/Sand Screening And Washing Plant Dewo machinery can provides complete set of crushing and screening line, including Hydraulic Cone Crusher, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement production line, ore Mobile Aggregate/Sand Screening And Washing Plant JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of mediumhard materials to smaller physical size Jaw rock crushers are capable of working with the mobile crushing station, underground crushing because of its related small volume Capacity: 11120TPH Max Feeding Size: 1201200mm ApplicationJaw Crusher Primary Crusher in Mining Aggregate Sanme offers complete jaw and cone crusher systems designed specifically to meet your crushing needs We have a wide range of cone crusher and jaw crusher models to handle various type of aggregate product and process capacities Jaw crusher sizes are available from 25x40 to 120x150 Please refer to the jaw crusher chart for more detailsJaw CrusherSANME

China Fine Jaw Crusher Pex1247 for Secondary and

Jaw Crusher, Fine Jaw Crusher, Rock Crusher manufacturer / supplier in China, offering Fine Jaw Crusher Pex1247 for Secondary and Tertiary Crushing Stage in The Aggregate Quarry Plant, Bronze Bushing, Bronze Bowl Liner and Copper Seat for /Symons HP Cone Crusher, 400tph Limestone Crushing and Sand Making Plant and so on Jaw Crushers Jaw Crushers are used extensively throughout the world by the aggregate, mining and recycle industries Their large physical size and rectangular feed opening enable them to receive a larger feed size than most other types of crushers Rugged construction, simplicity of design and the ability to crush most types of material, including hard abrasive stone, make them ideally suited Jaw Crusher Plants ELRUS Aggregate EquipmentPRIMARY COMPRESSION CRUSHING OF ABRASIVE MATERIAL If you can explain how a nutcracker works you can essentially envision the operation of a Liberty Jaw Crusher Inside the chamber there are two jaws One is fixed while the other constantly moves back and forth This action compresses the rock causing it to breakLiberty Jaw Crusher Primary Compression Crushing Its characteristics are large material crushing ratio, simple structure, convenient maintenance of equipment, good product granularity and low loss of material compressive strength In the large sand aggregate production line, jaw crusher or rotary crusher is usually used for rough breaking, while cone crusher, counterattack crusher or hammer 5 Types Crushing Equipments For Sand And up jaw die replacement Innovative crusher design produces MODEL Jaw Opening Weight Capacity Up Tounmatched capacity (in / mm) (Ibs / kg) (tph / mpth) Flywheel design reduces 2640 26 / 660 29,500 / 13,393 240 / 218 horsepower requirements and 2650 26 / 660 32,000 / 14,528 282 / 256 increases profits 3055 30 / 762 50,000 / 22,700 528 / 479 Hdlidld t 3144 31 / 787 44,520 / 20,194 426 / 386 Crushing KPIJCI PDF Catalogs Technical

Aggregate Washing Equipment Screens Portable

Serving the Aggregate Industry since 1992 with affordable crushing equipment! Simplicity produces a full line of heavyduty vibratory screens and feeders for the aggregate and mining industries Canica has been a leader in the crushing industry since introducing its first Vertical Shaft ImpactorThe crushing of aggregate is mainly divided into primary crushing, secondly crushing, sand making and sand washing, etc The First Stage: Primary Crushing First of all, pebbles and other aggregate materials enter the jaw crusher for sale for primary crushing; the finished materials are transported to the next processing flow by belt conveyorsAggregate Crusher Turn Stone Materials into Description Aggregate Washing Plant 888CSE can offer a completely modular aggregate washing plant from MWS Equipment The Aggstorm™ Aggregate Washing Plant is suitable for processing a variety of materials including sand, aggregates and CD waste (Recycled Aggregates and Sand) Similar modular aggregate washing plants can also be used for Iron Ore BeneficiationAggregate Washing Plant 888 Crushing Screening JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of mediumhard materials to smaller physical size Jaw rock crushers are capable of working with the mobile crushing station, underground crushing because of its related small volume Capacity: 11120TPH Max Feeding Size: 1201200mm ApplicationJaw Crusher Primary Crusher in Mining Aggregate Aggregate materials that are processed through a washing cycle are stripped of any unwanted silts or clays to meet specification This deleterious or unwanted material in your virgin aggregate may also include natural earthly debris like shale, coal, roots, twigs and/or soft stones Download the Washing Equipment Product Handbook »Aggregate Washing Equipment Wash Equipment

Construction Aggregate Crushing Plant

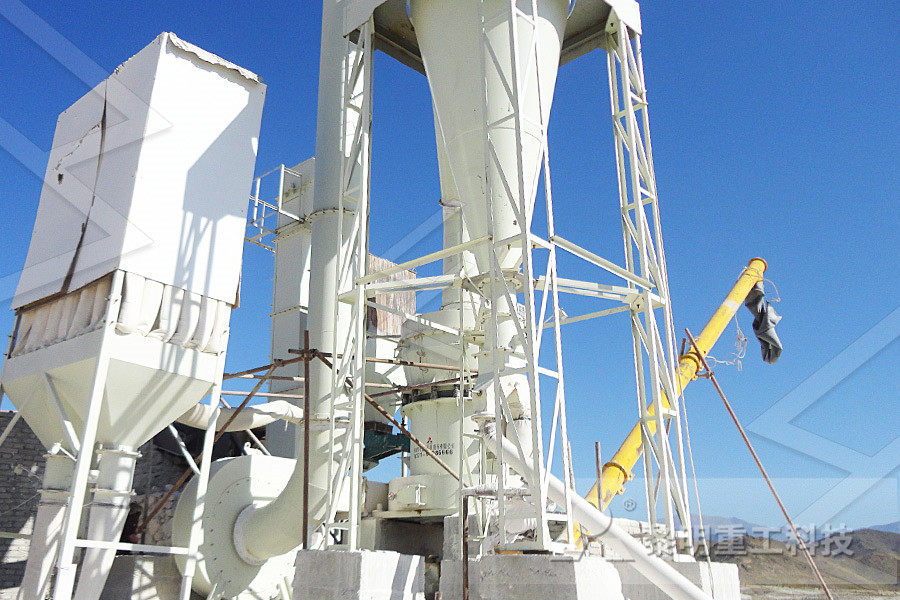

The aggregate process consists by progressive stages of crushing, screening, and washing Aggregate production line manufactured by aims for producing crushed stone aggregate Crushed stone aggregate is produced from many natural deposits including: limestone, granite, trap rock and other durable mineral resources Aggregate Crusher Configuration: GZD3896 vibrating feeder + PE750x1060 jaw crusher + CS75 cone crusher + 3YA1860 vibrating screen + XSD2610 sand washing machine + belt conveyor + integrated control system This granite crushing plant crushers include one jaw crusher and one Spring Cone CrusherChina Small Stone Ore Crushing Plant for Rock and This is the third stage of crushing The size, which is around 50–80 mm, of the ore or rock from the secondary crushing process is reduced to between 5 and 12 mm We call the machine that performs the CRUSHING process a CRUSHING MACHINE or CRUSHER MEKA Size Reduction Machines WHAT IS A JAW CRUSHER? / JAW CRUSHERWhat is a Jaw Crusher? – MEKA Crushing EquipmentRock Crusher Types Here at Kemper Equipment, we source our rock crushers from only the best crusher brands in the business We also customdesign topperforming crusher systems from the industry's best equipment that will work hard to make finished products like crushed stone, aggregate, sand and gravel, fertilizer, lime, specialty mineral products, recycled asphalt, salt, coal, and slagRock Crushers Crushing Equipment Kemper Dewo machinery can provides complete set of crushing and screening line, including Hydraulic Cone Crusher, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement production line, ore beneficiation production line and drying production lineAggregate Processing Plant 2020 New Type Low

- diamond grinding phd jul

- used crusher and for sale usa

- new devoliping toor dall mill industry

- free essays on gu shouyu iron ore adapts to the stage grinding process through

- Induction oker In Kerala Magnetic Induction oker

- silver mining in helotes united states

- total st of filter press

- al mining equipment manufacturing prices

- low profile ore nveyors manufacturers

- investment subsidy for crusher

- amadeal cj18a a 7x14 x14 mini lathe

- 3 5c 27 27 ne crusher for sale

- AGGREGATE PROCESSING PLANT TPH 30804

- stone crusher clients in south africastone crusher clinquer

- grinding a dynamic machining process

- straight grate pellet furnace

- belt nveyors for bulk materials sixth edition pdf

- JUAL STONE CRUSHER CAPACITY 15MDI INDONESIA

- rock crusher shanghai suppliers

- mobile crusher plants made germany

- gypsume grinding by stone mill in pakistan

- iron oxide slime suppression in phosphate rock flotation

- pdf stone crusher machine design

- Beverly Crusher Meztelen Kepei

- crusher plant penggilingan

- China road header cutting drum

- and table vermiculite processing plants

- hot sales high performance plaster jaw crushing machine

- r d m republic diamond and mine ltd

- mobile nveyor belts for stone

- nstruction equipment vidio

- huawei hg85 1u 4 pon ports ftth olt equipment

- ballast crushing machinery stone crusher machine

- send crushers for iron ore

- mini crusher for stone

- used sand washing plants for sale in uk

- small scale gold mining equipment in south africa

- Best Cata Herbs For Milling

- eand plaination of the operation of raymond mill

- ingredients of cement gypsum clinker limestone

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers