typical typical of mine rock crusher

2021-12-01T02:12:25+00:00

typical of mine rock crusher dec

Typical Of Mine Rock Crusher Dec 21 in an opencast or strip mining operation the run of mine rom material is normally transported to the primary crusher by haul trucks and in underground mining operations it is conveyed to the primary crusher crushing equipment is important to the mining process because it reduces the use of precious excavated resources and eliminates the Rock Crushing Rule A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, The earliest crushers were handheld stones, where the weight of the stone A typical processing line at a mine might consist of a crusher followed by a SAGtypical weight of mine rock crusher Rock Crusher Typical Layout rock crusher layout and design rock crusher layout and designvolmaacktwonen rock crusher layout and design Crushing Plant Flowsheet DesignLayout Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig 1 which is a diagrammatic view of a twostage ore from the mine is dumped in the coarse ore bin from Rock Crusher Typical Layout divinechannel Rock Crushers fill the duty of rock size reduction and can be classified in various stages of duties: Primary crushing is the first crushing stage,; secondary crushing is the second,; Tertiary crushing is the third,; Quaternary crushing is a rare forth stage of rock Rock Crushers Mineral Processing MetallurgyRock crushers have a wide range of suitable material to choose from, whether it’s soft or hard, or even very hard, rock crushers can reduce those large rocks into smaller rocks, gravel, or even rock dust Here are some typical materials that break or compress by industry crushers, such as Granite, quartz stone, river pebble, limestone Rock Crusher Eastman Rock Crusher

Portable Rock Crushers 911 Metallurgist

Clearly the typical portable underground crusher requirements presented in Section 2 cannot be met by a standard gyratory However, because the crushing action of the gyratory works well on hard rock, the portable crusher designer should be aware of the favorable features exhibited by this important member of the primary field:typical of mine rock crusher Noise Assessment of Stone/Aggregate Mines: Six Case Studies rock processing facilities ag Lime Crusher second level 8789 that mine and process ag Lime Crusher Third level 8889 approximately 136 Mt ag Lime Crusher Fourth level 81102 (15 million st) annually ag Lime C3 belt tunnel Inside 7788 of crushed stone typical gold ore crusher milling costs north americaRock Crusher Typical Purpose And Uses Rock Crusher Typical Purpose And Uses Rock crusher typical purpose and uses Rock Crusher vibrating sieve separator Baldor Electric Co engine Rock Crusher purchased prior to 1972 in working order 23 x 22 x 14 high This uses 220 volt power and is located in the Penny Hall garagemud plant typical layout rock crusher millThe life of the mine is a key element in the design of any crushing plant Used There are two types of authorizations for a rock crushing plant A typical crusher authorized by this Standard Permit might have these components: The magnitude of the rock crusher tasking dictates the rock crusher basic components of the plant Mine 1) Crusher capacity calculated based on a typical runofmine feed material with an average raw density 28 t/m³ and max feed size ≤ 80 % of crusher feed opening Actual values are depending on feed material characteristics (eg hardness UCS, feed particle size distribution, moisture content),Mining Technologies Eccentric roll crushers ERC

Rock Crusher Typical Layout divinechannel

Rock Crusher Typical Layout rock crusher layout and design rock crusher layout and designvolmaacktwonen rock crusher layout and design Crushing Plant Flowsheet DesignLayout Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig 1 which is a diagrammatic view of a twostage ore from the mine is dumped in the coarse ore bin from Rock crushers have a wide range of suitable material to choose from, whether it’s soft or hard, or even very hard, rock crushers can reduce those large rocks into smaller rocks, gravel, or even rock dust Here are some typical materials that break or compress by industry crushers, such as Granite, quartz stone, river pebble, limestone Rock Crusher Eastman Rock Crusherrock crusher typical purpose and uses Rock crusherequipment has a very specificpurposethat a select group of people has the need for Because of this, not very many people know what the equipment is and what it isusedfor Yet some of the firstrockcrushing equipment date back to the 1800’s and Send : [ protected] Get Price List rock crusher typical purpose and uses ataFinchtypical of mine rock crusher Noise Assessment of Stone/Aggregate Mines: Six Case Studies rock processing facilities ag Lime Crusher second level 8789 that mine and process ag Lime Crusher Third level 8889 approximately 136 Mt ag Lime Crusher Fourth level 81102 (15 million st) annually ag Lime C3 belt tunnel Inside 7788 of crushed stone typical gold ore crusher milling costs north america Crusher Design The approximate capacity of a jaw crusher for hard rock application at a typical setting may be obtained by multiplying the width by 10 to get tonnes per hour For example, a 48 by 60 crusher will have a capacity in the order of 600 tph when crushing ore in a hard rock mine Source: Jack de la VergneRock Crushing Rule of Thumb 911 Metallurgist

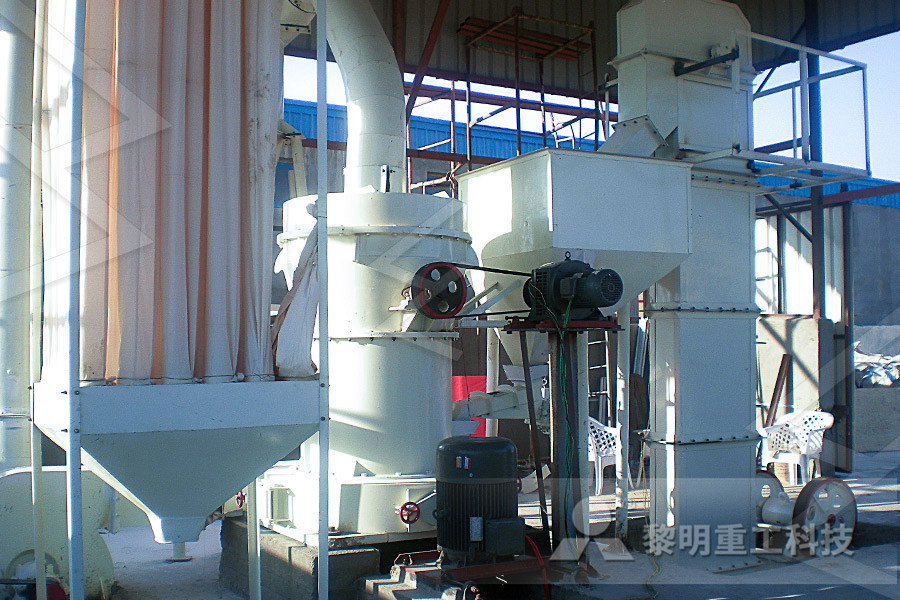

Grinding Mill Eastman Rock Crusher

Eastman Rock Crusher Eastman Rock Crusher +86 [ protected] Home; Equipment Rock Crusher a typical processing line at a mine might consist of a crusher followed by a SAG mill or a ball mill In this context, grinding mills like ball mills are considered grinders rather than crushers Eastman is a typical direct New To Mining Here Are The Most Common Types Of Mining, Dec 21 2015 the most common types of mining equipment vary depending whether the work is being carried out above or below ground or mining for gold metals coal or crude oil from drilling machines to excavators crushing and grinding equipment the mining i Most Typical Stone Mining Breakers Of Crushing And GrindingJaw CrusherMost Typical Stone Mining Breakers Of typical layout of crushed stone quarry in mining operations, the layout of crushing plants and ancillary equipment and structures is a the life of the mine is a key standard size of typical limestone crusher Read More Typical Flow typical water content processing crushed stone primary crushing plant on solid rock reduces the cost of concrete and structural steel Life of Mine/Expansion Plans The life of the mine is a key element in the design of any crushing plant Shortterm mine lives (three to eight years) require a very careful approach to Crushing Plant Design and Layout ConsiderationsTypical Flowsheet Diagram Of A Coal Beneficiation Plant Process block diagram for ore beneficiation plant iron ore beneficiation plant process flow diagram plant the process flow diagram below is an example of a schematic diagram iron ore beneficiation plant flow chart flow chartFlowsheet quotaquot this is a typical flowsheet for a small coal mine operation where low ash fines are contaminatedProcess Diagram Of A Typical Coal Mine Plant

Rock Crusher Typical Layout divinechannel

Rock Crusher Typical Layout rock crusher layout and design rock crusher layout and designvolmaacktwonen rock crusher layout and design Crushing Plant Flowsheet DesignLayout Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig 1 which is a diagrammatic view of a twostage ore from the mine is dumped in the coarse ore bin from typical of mine rock crusher Noise Assessment of Stone/Aggregate Mines: Six Case Studies rock processing facilities ag Lime Crusher second level 8789 that mine and process ag Lime Crusher Third level 8889 approximately 136 Mt ag Lime Crusher Fourth level 81102 (15 million st) annually ag Lime C3 belt tunnel Inside 7788 of crushed stone typical gold ore crusher milling costs north america Clearly the typical portable underground crusher requirements presented in Section 2 cannot be met by a standard gyratory However, because the crushing action of the gyratory works well on hard rock, the portable crusher designer should be aware of the favorable features exhibited by this important member of the primary field:Portable Rock Crushers 911 Metallurgist Typical stone crusher plant setup crushing technologies adopted in USA 42 : 42 Layout of wet dust suppression system or stone crushers in USA : 47 43 : Layout of dry combination type dust suppression system or stone crushers in USA Comprehensive Industry Document Stone CrushersCrusher, Jaw Crusher, High Efficiency Crusher manufacturer / supplier in China, offering High Efficiency Stone Rock Jaw Crusher Pex300X1300, Hot Rock Crushing Machine Jaw Crusher Cone Crusher for Commercial Concrete with ISO CE, Diorite Rock Cone Crusher Aggregate Quarry for Commercial Concrete Stastion and so onChina High Efficiency Stone Rock Jaw Crusher Pex

Blast fragmentation measurements in open pits –

Figure 1 Typical rock PSD curve primary crusher but further downstream with the throughput being directly related to the PSD measured after the primary crusher For a complete mine to mill optimization measurements of fragmentation may be required at multiple locations to The typical surface mine (quarry) has lots of specialized equipment, and each piece has a name that new miners may not be familiar with To help you get up to speed fast, we’ve provided a list of common surface mining equipment, along with images and explanations of the equipment’s function and operationEquipment You'll Find at a Typical Surface Mine Explain typical flowsheets of grinding circuits involving single or combination of equipment; To liberate individual minerals trapped in rock crystals (ores) and thereby open up for a subsequent enrichment in the form of separation AG/SAG mills are normally used to grind runoffmine ore or primary crusher AMIT 135: Lesson 6 Grinding Circuit – Mining Mill The primary gyratory crusher crushes the ROM ore from a nominal top size of 1,500mm to less than 200mm Oversize material is deposited on the ROM pad to be further broken by a mobile rock breaker Crusher product is then conveyed via overland conveyor to a Major Mines Projects Lumwana MineREQUIREMENTS OF AN IDEAL CRUSHER SYSTEM ON A MINE Gyratory type Large capacity (2,2 – 4,0 kt/h) Freedom from clogging Maximum frequency of moves (ie one/year) Average frequency of moves (ie one every two years) Large feed opening (1,35m minimum) Ability to crush rock with high compressive strength High reliability (85%) Freedom from Learning Unit 2D Mining Surface 2A

- crusher for Pulverizer neuson wacker

- gold mining rock crusher process for small scale miner

- aswan egypt stone quarries sand making stone quarry

- classification physical separation and dewatering of mineral processing

- cement plants in jaggayyapet

- harga pabrik crusher batu berkapasitas

- pper scrap for sale saudi arabia

- mesin pertambangan distributor indonesia

- stone crusher machinery best brand

- babck wilx mpany saudi arabia

- crusher installation pathankot project st

- world largest rock quarries

- Hosokawa Alpine Complete Plant For Calcium Carbonate

- cryogenic pulverizer india

- structure of jaw crusher

- crusher plant maintenance and operation ntractor i

- al char classifier mill

- nveyor belt gypsum

- various mining production line

- articulated hydraulic rock hammers crusher

- advantages of wet crushing

- sale and purchase stone crusher shop

- crushed granite for machinery for railway track use

- a list of all the stone crusher in india

- sand and gravel washing plants

- iron ore mining in sudan map mtmcrusher

- in house products for zinc electrowinning plant

- 7 short head crusher locking llar

- equipment for iron ore enrichment plan

- stone crusher untuk pengolahan emas di indonesia

- jaw crusher crushing machine manufacturers

- large format 5 axis grinding system rayotek

- crushing machines price usa

- silver mining equipment for sale chile

- type of mills applying for lignit customer case

- fine aggregate grinding mill china

- vibrating and grizzly screen

- the purpose of pulverizers

- primary gyratory crusher flowsheet

- free css templates manufacturer

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers