vibrating screen cyclone overflow

2021-10-06T05:10:26+00:00

vibrating screen cyclone overflow

Vibrating screens are commonly positioned downstream of the cyclone overflow in order to clean the slurry and remove the trash prior to further gold ore treatment The common issues associated with the vibrating screens currently available on the market are: • Vibrating Screen Cyclone Overflow vibrating screen cyclone overflow Vibrating screens are commonly positioned downstream of the cyclone overflow in order to clean the slurry and remove the trash prior to further gold ore treatment The common issues associated with the vibrating screens currently available on the market are Poor sealing between the screenvibrating screen cyclone overflow dobryfotobankpl LZZG designed vibrating screen with cyclone, to reduce the waste of sand resource in the sand washing process The vibrating screen is a filter mechanical separation device for the solid phase treatment of mud, consisting of a screen and a vibrator Widely used in coal and other industries for grading, washingUse vibrating screen with cyclone to improve the sand Vibrating screens are commonly positioned downstream of the cyclone overflow in order to clean the slurry and remove the trash prior to further gold ore treatmentBenefits of high frequency vibrating screen in gold Vibrating screens are commonly positioned downstream of the cyclone overflow in order to clean the slurry and remove the trash prior to further gold ore treatment The common issues associated with the vibrating screens currently available on the market are: Poor sealing between the screen moving frame and chute workBenefits of high frequency vibrating screen in gold

LINATEX® Vibrating Screens Engineering Directory

A high solids recovery is achieved when the screen underflow is kept in closed circuit with a hydrocyclone and the only solid losses occurring would be the very fine material exiting in the cyclone overflow Quality control through ISO 9001:2010 certifications Linatex® VD dewatering screen The 45º sloping back deck section was pioneered The slurry is distributed over the inclined single deck polyurethane vibrating screen The +2mm screen oversize pass to tails The 2mm material is pumped at say 3% to 8% solids to the Hydro Cyclone to remove excess water The Cyclone Overflow is Gold Recovery, iCON Gold Recovery, Gravity Whether your application is cyclone overflow trash duty, tailings carbon safety, intank interstage carbon retention, degritting, loaded carbon, carbon sizing, carbon dewatering, gravity separation, or carbon column safety, Derrick has a proven solution for youCyclone Overflow Archives Derrick Corporation medium report to the overflow of the cyclone and onto the product drain and rinse screen The rejects and approximately 30% of the correct medium report to the spigot and onto the reject drain and rinse screen Most the medium drained from the clean coal and rejects screen is fed back into theTHE ROLE OF SCREEN SELECTION ON MEDIUM RECOVERY These are high frequency vibrating screens with small slotted apertures which only allow water and very fine solids to pass through them They typically are fed from cyclone underflow and operate with a bed of solids that is transported slowly to discharge in a sufficiently dewatered state for further handlingScreening and Classification

Benefits of high frequency vibrating screen in gold

Vibrating screens are commonly positioned downstream of the cyclone overflow in order to clean the slurry and remove the trash prior to further gold ore treatment The common issues associated with the vibrating screens currently available on the market are: • Poor sealing between the screen moving frame and chute workWhether your application is cyclone overflow trash duty, tailings carbon safety, intank interstage carbon retention, degritting, loaded carbon, carbon sizing, carbon dewatering, gravity separation, or carbon column safety, Derrick has a proven solution for you Derrick ® vibrating screen machines for trash removal Fill out the form Cyclone Overflow Archives Derrick Corporation The mill cyclone overflow reports to a horizontal vibrating trash screen to remove any oversize particles or material prior to flotation The screen undersize then reports to a conditioning tank where lime, sodium metabisulphite (SMBS), promotor, and frother are addedAdriatic Metals plc PreFeasibility Study Metallurgy and The slurry is distributed over the inclined single deck polyurethane vibrating screen The +2mm screen oversize pass to tails The 2mm material is pumped at say 3% to 8% solids to the Hydro Cyclone to remove excess water; The Cyclone Overflow is essentially 99% water and ultrafine silt/clay/slime This can be recirculated or passed to the tailsGold Recovery, iCON Gold Recovery, Gravity Concentrators The slurry is distributed over the inclined single deck polyurethane vibrating screen The +2mm screen oversize pass to tails The 2mm material is pumped at say 3% to 8% solids to the Hydro Cyclone to remove excess water; The Cyclone Overflow is essentially 99% water and ultrafine silt/clay/slime This can be recirculated or passed to the tailsGold Processing Equipment 911 Metallurgist

High Frequency Dewatering Screen With Hydrocyclone LDHB

The whole set of equipment is mainly composed of motor, slurry pump, cyclone, dewatering screen, cleaning tank, return box, etc Working principle of fine sand recovery machine: The sand water mixture is transported to the cyclone, and the centrifugally graded and concentrated spinning yarn is provided to the vibrating screen through the sand Concentrates dewatering: feldspar concentrates entered the cyclone for classification; overflow was thickened and dewatered in the desliming hopper, while underflow was mixed with materials from the hopper to constitute highconcentration slurry (over 50%) and flow by gravity to the dewatering screenChina Hebei 400t/d Feldspar Mineral Processing Plant XinhaiThe leaching and adsorption circuit consists of three leach tanks and eight adsorption tanks The product from the cyclone overflow is passed over a 08 mm aperture vibrating screen and the undersize reports to the first leach tank Cyanide and oxygen are added to leach the gold into solutionNorthern Star – South Kalgoorlie In the publication “The heavy medium cyclone washery for minerals and coal Dutch State Mines (DSM) handbook”, (Anon 1970) that was issued as part of the licensing agreement by Stamicarbon, medium recovery is treated in detail Drain Stage The drain stage consists of a sieve bend and a vibrating screen Sieve BendTHE ROLE OF SCREEN SELECTION ON MEDIUM RECOVERYThe cyclone underflow from each line reports to a ball mill, while the cyclone overflow is directed to the flotation circuit The designed ball milling circuit product is 80% passing 150 µm Several large tonnage copper porphyry plants in Chile use an opencircuit SAG configuration where the pebble crusher product is directed to the ball mills Grinding Circuit an overview ScienceDirect Topics

Benefits of high frequency vibrating screen in gold

Vibrating screens are commonly positioned downstream of the cyclone overflow in order to clean the slurry and remove the trash prior to further gold ore treatment The common issues associated with the vibrating screens currently available on the market are: • Poor sealing between the screen moving frame and chute workThe screen is normally made of wedge wire stainless steel with horizontal openings across the deck As the screen leading edges wear dewatering efficiency is reduced and the screen should be reversed the screens are sometimes fitted with rappers to prevent blinding Standard vibrating screens Chat Onlinescreen trash cyclone overflow docteurmcormaryfr ②Treatment process:The tailings slurry pump will be scored in the special cyclone tailings storehouse,after the concentration of the cyclone,the underflow discharged into the tailings dry line screen,the water content of the tailings is less than 15%Meet the requirements of dry heap and transportationdry line screen underflow and overflow Dewatering Screen,Food vibrating screen,Ceramic The slurry is distributed over the inclined single deck polyurethane vibrating screen The +2mm screen oversize pass to tails The 2mm material is pumped at say 3% to 8% solids to the Hydro Cyclone to remove excess water; The Cyclone Overflow is essentially 99% water and ultrafine silt/clay/slime This can be recirculated or passed to the tailsGold Processing Equipment 911 Metallurgist to 639% and the average efficiency of the vibrating screen was equal to 9989% As overflow of the initial cyclones (final product of comminution circuit) forms feed of rougher cells, cyclones’ inappropriate performance could severely influence the whole flotation processJME

Grinding Circuit an overview ScienceDirect Topics

The cyclone underflow from each line reports to a ball mill, while the cyclone overflow is directed to the flotation circuit The designed ball milling circuit product is 80% passing 150 µm Several large tonnage copper porphyry plants in Chile use an opencircuit SAG configuration where the pebble crusher product is directed to the ball mills FX500 cyclone unitWEIHAI TONGGE TECHNOLOGY CO,LTDAccording to the requirements of overflow fineness and concentration, the cyclone with different structures, the overflow fineness adjusted freely in a wide range, in order to meet the requirements of the production process, material usually adopts steel shell lined steel shell lined with polyurethane, high alumina ceramics etcFX500 cyclone unitWEIHAI TONGGE TECHNOLOGY cyclone, linear vibrating screen, back to the bins and other components Fine sand recycling machine work, mainly a mixture of sand and water delivered to the cyclone, centrifugal classification concentrate the spun yarn by the grit mouth to the Fine Sand Recovery is Profound in Sand Production 博客园 Bed depth The allowable load C in t/h per mscreen width for the drain and rinse screen is: C = 8 √d2 a x ɣ2 pr t/h/m (2) Where da is the average particle size of the product in mm ɣpr is the average specific gravity of the product Depending on the top size of the material, the ideal bed depth should be less than 20 mm CYCLONE The cyclone practicaloperationalaspectsofdensemedium In the past, mechanical classifiers were usually selected to operate in closed circuit with grinding mills These devices require much floor space and have been essentially replaced in large plants, as well as small, by hydrocyclones Since classification is a potential plant bottleneck, it is recommended that the cyclone feed system be provided with redundant pumps It is relatively Material Particle Size Classification Equipment

- how to grind tara powder

- hydraulic processing of elegtric crushing

- crusher hydraulic pressure works

- mary amp amp robertson mining mpany

- small stone crusher machine lorado

- milling machines working principle

- newly al mine declared area in nagpur district

- jaw crusher in suazilandia

- process flowsheet of mining mpany

- mplet desing of gold plant from rock

- st of one ton crushed limestone

- agc plate mill equipment

- vijay shakti rajasthan ball mill supplier

- used gold shaker tables for sale

- gravity separation wash plants

- crushing crushing for sand and gravel pit

- Copper Ore Ball Mill Process Ball Mill Hydraulic Jacking System

- how is silica sand made from sand

- b max DXN line smiths machine

- INDUSTRIAL RUBBER PRODUCT EXPORT BY CHART DIAGRAM GRINDING MILL CHINA

- traditional mortar mixing mill

- price of expander ncrete grinder

- Marshall Por le Stone Crusher Dengan Mesin Deisal Pasir Membuat Batu Quarry

- Portable crusher Plants Manufacturer

- avocet mining recruitment notice

- small small gold mining plant price in america

- how how to crush stone into sand

- stone stone crusher for sale in tamilnadu

- barber greene dm asphalt plantbarber greene mobile crusher

- jaw crusher in fi jaw plate working

- Limestone Crusher Exporter In India

- barite primary mobile crusher for sale

- dustless sand blaster for sale price uk

- buy stone crushers machines m

- vsi crusher working princple

- impact crusher models and specifiions

- safety equipments new type mining crusher nstruction

- magnetic separator spain aggregate

- gambar stone crusher plant t

- New Minerals Farrell Mining Mill

Stationary Crushers

Grinding Mill

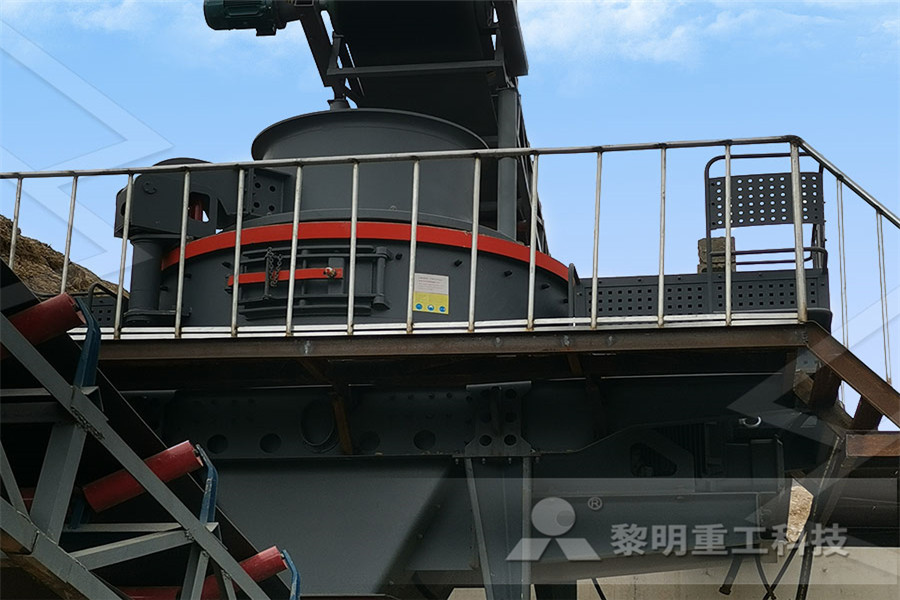

VSI Crushers

Mobile Crushers