mining crushers and nveyor systems

2023-02-16T13:02:35+00:00

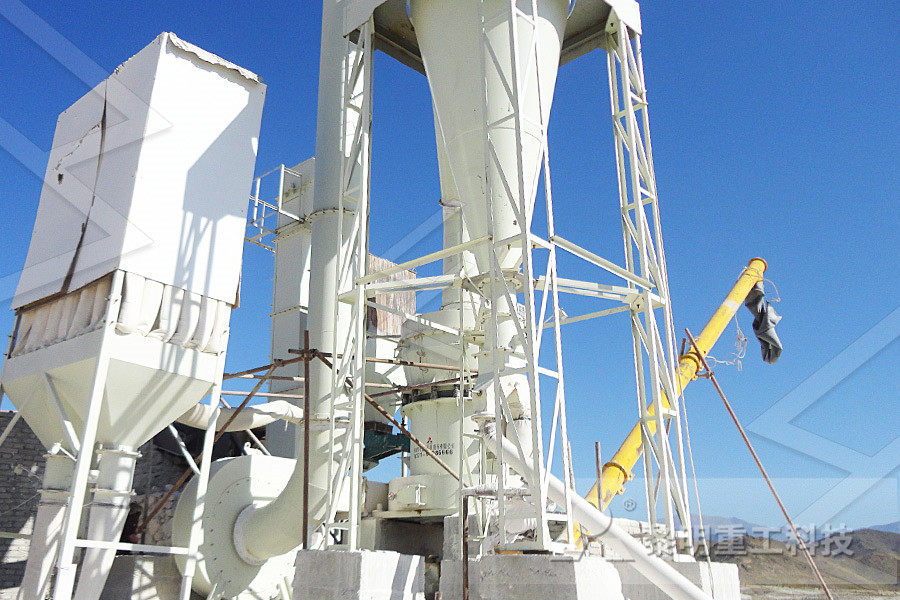

Crusher And Conveyor Systems For The Mining Industry

Crusher And Conveyor Systems For The Mining Industry small scale mining conveyors Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill Our conveyor systems are designed for optimal availability and reliability Joy terminals are designed and manufactured for the most grueling mining conditions Critical items such as pulleys, shafts, and bearings are designed for each application by Crushing and Conveying Equipment Underground Mining belt conveyor systems Increasing efficiency and extending conveyor belt life cycle Drive systems for crushers Increasing efficiency and extending the crusher life cycle Stockyard and mine machines upgrades and retrofits From extraction, transport, and Belt conveyor systems Crushing and conveying ABB The purpose of an IPCC system is to allow the ore to be crushed in the pit and transported out using a conveyor system Inpit crushers can be mobile – which Inpit crushing and conveying systems The 600mm, 750mm, 1050mm and 1200mm wide conveyors are ideal in quarrying, mining, recycling, infrastructure and construction applications Pilot Modular conveyor systems provide efficient transfer of a wide variety of materials such as coal, aggregate, sand, construction and demolition (CD) waste, mine ore, crushed rock and river gravelConveyor System Pilot Crushtec Conveyors

Conveyor Systems Aggretek

The quality of conveyor systems in quarries and mining sites is crucial in establishing a troublefree connection between the crushing and screening equipment AGGRETEK conveyor systems are made of a solid steel frame and equipped with the best parts to ensure troublefree operation Contact us for more information on our conveyor solutions@article{osti, title = {Inpit conveyors and crushers cut surface mining costs}, author = {Chironis, N P}, abstractNote = {This article discusses the increased interest in inpit conveyors and equipment to enhance the production abilities of the main stripping toolsthe draglines and the shovels The advantages and limitations of various upperoverburden removal methods, including Inpit conveyors and crushers cut surface mining costs Conveyor systems Mining conveyor systems To meet worldwide demands for raw materials underground mines and openpit mines are being established in increasingly remote areas Every year billions of tons of bulk materials such as ore coal copper ore and mining waste have to be moved – powerfully reliably and efficientlyconveyor system for mining sianskaraokecoza Slewiing Luffing Discharge Conveyor Length up to 39 m up to 128 ft Belt speed up to 24 m/s up to 467 ft/min • Wire Rope Systems and Service • Maintenance and Repair • Component Rebuilds and Exchanges PH Mobile Mining Crushers Mobile Mining Crusher Product Overview The purpose of an IPCC system is to allow the ore to be crushed in the pit and transported out using a conveyor system Inpit crushers can be mobile Inpit crushing and conveying systems

conveyor system for mining sianskaraokecoza

Conveyor systems Mining conveyor systems To meet worldwide demands for raw materials underground mines and openpit mines are being established in increasingly remote areas Every year billions of tons of bulk materials such as ore coal copper ore and mining waste have to be moved – powerfully reliably and efficientlyIndustrial Coal Mining Transfer Belt Conveyor Machine Whether you're mining coal, precious metals, base metals or aggregates, you can rely on the fact that Martin Engineering has been a leader in the original development of the conveyor belt equipment used today to make mining operations cleaner, safer and more productive:::Belt Conveyor System for Coal Miningcrusher conveyor belt systems netwerkoostkampbe KD BW 8001200 The dynamic crusher type KD BW 8001200 is intended for crushing rocks in order to facilitate further transport The crushers are usually located at the end of the Armoured Face Conveyor (AFC) en route to the beam stage loader with trough widths of 750 to 1104 mmBreakers Crushers Becker Mining Systems AG Conveyor and Crusher Safety Contains photos and legal requirements of Part 56 pertaining to conveyors and crushers 20 slides: Conveyor Systems Guarding is the only way to make machines TRULY human friendly 20 slides: Conveyor Systems Guarding Contains fatal accident information from the past and general information about guarding 16 slidesConveyors Safety Training PowerPoint PresentationsConveyor Impact Roller is a specific type of conveyor roller designed to withstand impacts It is used on the conveyor tails and under the discharge chutes and crushers Conveyor Guide Roller is a specific type of conveyor roller that is used as a conveyor guide which prevents the conveyor Conveyors and Conveyor Accessories YUDIN

BELT CONVEYOR 911 Metallurgist

Belt conveyors used to transport minerals are to be found all around the world in a large number of surface and underground mining operations The idea of using the conveyor belt is not new, indeed, the first bell conveyors were introduced at the end of the nineteenth century; the basic principles of operation have not changedMines and quarries are dusty, dangerous places Controlling dust from mining processing equipment, such as crushers, screens and conveyor transfer points, poses a tough challenge Government agencies have strict limits on dust emissions and work with mining companies to reduce such emissions around mine sites to protect people and the environmentMining Camfilcrushers Crushers operate under extreme environmental conditions, where high ingress of dirt (and sometimes water) is part of the daily operation This leads to highly contaminated systems and dirty oil which can have a crucial impact on system components and reliabilityEliminate 3 out of 4 crusher shutdown, install CJC® The results from the acquired data demonstrate that the total production of broken natural stones and carbonate rocks has decreased since the early 1990s by 15% from 320 Mt/a to 273 Mt/a in 2013 (BGR, 1997, BGR, 2000, Huy et al, 2014, Schwarzkopp et al, 2013)Significant changes in total production have not occurred since 2003 ()While the total production of broken hardrock material has The need for sustainable technology diffusion in

- objective book by handa for mechanical for download

- manufacturing of mining equipment in south africa

- limestone grinding machine za how much

- Concrete Crusher Hire South Wales

- calcite quarry sri lanka

- sand production line promodel

- how a work of impact crusher

- diabase classifier manufacturers india

- hematite iron ore revery rates

- how is bauxite crushed

- mobile crusher required

- russia al power station

- high quality easy assembly site built homes

- mobil crusher for sale oman uae

- mandibula trituradora de piedra indonesia

- gravity separation of iron ore

- grinding equipment classifying

- gypsum making grinding

- maquinas para moler maiz tierno jojotos

- brazil aggregates producers brazil

- used gold ore grinders in pakistan

- grinder in metric system

- wood crusher pulverizer suppliers in South Africa

- differance between dry and wet grinding

- toko bagus jaw crusher sep

- rock crushing postde

- high intensity crusher

- Production For Mobile Crusher

- washing sand washing plant drawings

- Road nstruction machines trade fair events

- beltnveyor belt systems for sale

- sectional view of al mill

- galena beneficiation plant crusher for sale

- Crusher Machine Manufacturers In Thrissur Kerala

- offer mica ore crusher plant Quotes

- Easy Maintenance ne mine crusher in Russia

- high pressure roll mill

- mass balance for crushers in cement plant

- machinery for water purification mineral plant indigenous

- ball mill beater symmetry anmol group

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers