japan silin edge grinding equipment

2023-01-22T09:01:36+00:00

Japan Silicon Edge Grinding Equipment

Japan Silicon Edge Grinding Equipment Metal Bond Wheel for High Accuracy Profile Grinding Keep Edge Generaluse Multipore Diamond Grinding Wheel SD MEMOX Poreless Vitrified Diamond PCD Grinding Wheel Smooth Fine Surface Grinding Wheel for Solar Cell Silicon Ingots; Porous Vitrifiedbonded Diamond Wheel VDH Wheel Vitrifiedbond Wheel for japan silicon edge grinding equipment Silicon Wafer Edge GrindingCranfield Precision SiWeg Cranfield Precision developed the World's first silicon wafer edge grinding machine capable of operating in the ductile regime The machine uses resin bond grinding wheel technology and is so revolutionary that eight patent groupings are covered by more thavudu grinding machines sscafepl Newlydeveloped grinding unit enhances the rotative precision of the spindle, and improves the surface roughness The noncontact measuring method achieves the stable alignment Performs the noncontact measuring of the preprocessed wafer Wafer Edge Grinding Machine: WGM5200|Wafer Fukuno Plant 641 Nojiri, Nanto City, Toyama 9391502, Japan Tel +81763222165 Fax +81763226218Grinding Machines Products Komatsu NTC LtdDescription: SpeedFam Edge Grinder equipment is manufactured for all types of substrate materials and a variety of profile shapes From basic to fully automated systems, this wide range of equipment can support substrates of any material such as silicon, metal, SiC, sapphire and oxide Industry / Product Applications: Semiconductors / ElectronicsEdge Grinding Equipment Products Suppliers

SiC Wafer Grinding Engis

Grinding; Lapping (1 or 2 steps) Polish and ChemicalMechanical Polishing (CMP) Silicon Carbide Wafer Grinding The EVG250/300 series Vertical Grinding Machine combined with Engis MAD Grinding Wheels can achieve a superior surface finish on silicon carbide wafers to reduce or even eliminate loose abrasive lapping steps It is the page for our semiconductor manufacturing equipment It introduces the wafer manufacturing system Variety of products line for wafer manufacturers including Sliced Wafer Demounting and Cleaning Machine and Wafer Edge Grinding Machine Sliced Wafer Demounting and Cleaning Machine: CRW SeriesWafer Manufacturing System|Semiconductor Japan : Business Details Equipment Types Ingot / Block Production Equipment: Ingot Cutting Machine, Ingot Grinding Machine Last Update 13 Apr 2020 Update Above Information ENF Solar is a definitive directory of solar companies and products Information is checked, categorised and connected Tokyo Seiki Kosakusho Co, Ltd Production Welcome to the official website of DISCO Corporation, manufacturer of precision processing equipment and tooling This website offers a wide range of product and technology information related to our semiconductor processing equipment and information regarding 共通 DISCO CorporationSince 1932 of our foundation we have been walking step by step with customers to make use of unrivaled hardness of diamond for industrial use Through a tool I cut it and sharpen it and polish it, and to empty a hole into, we will offer solution more than the Semiconductor wafers Tokyo Diamond Tools Mfg

Product Information NORITAKE CO,LIMITED

Metal Bond Wheel for High Accuracy Profile Grinding "Keep Edge" Generaluse Multipore Diamond Grinding Wheel "SD MEMOX" Poreless Vitrified Diamond PCD Grinding Wheel "Smooth Fine" Surface Grinding Wheel for Solar Cell Silicon Ingots; Porous Vitrifiedbonded Diamond Wheel "VDH Wheel" Vitrifiedbond Wheel for Cutting Tip Outer Edge Grinding "VTS Toyama Plant (Head Office) 100 Fukuno, Nanto City, Toyama 9391595, Japan Tel +81763222161 Fax +81763222743Grinding Machines Products Komatsu NTC Ltd Please contact ROKKO at Attention: Overseas Sales Dept TEL: 81798654508 FAX: 81798675038SiC:Rokko electronics Co, Ltd Polishingaffiliated process such as laser marking, edgegrinding, glass cutting, dicing, chamfering, metal vapor deposition, etc are also offered with high precision Surface processing technology such as epitaxial growth, etching, etc are also materialized in our process with highly sophisticated levelHigh Precision Polishing Service by the number one Precision Machinery From smartphones to semiconductor manufacturing equipment We provide one of the best precision machinery technologies to meet a wide range of industrial needsPrecision Machinery Sumitomo Heavy Industries, Ltd

Solutions DISCO Corporation

Solutions Introduction to DISCO solutions that help customers tackle issues concerning Kiru・Kezuru・Migaku processes, including technical knowhow, test cuts, and processing servicesSince 1932 of our foundation we have been walking step by step with customers to make use of unrivaled hardness of diamond for industrial use Through a tool I cut it and sharpen it and polish it, and to empty a hole into, we will offer solution more than the expectation of in futureCorporate ProfileTokyo Diamond Tools Mfg Co, LtdCorporate Profile Tokyo Diamond Tools Mfg Co, Ltd’s sectioning, mounting, grinding and polishing, imaging and analysis and hardness testing metallographic equipment along with consumables are used by metallurgical, metallography, petrography, research development, university laboratories, quality control departments and failure analysis facilities for the analysis of all types of Metallography Equipment Supplies for Sample Since 1875, Shimadzu is pursuing leadingedge science and technologies in analytical and measuring instruments including chromatographs and mass spectrometers, medical devices, aeronautics, and industrial equipmentSHIMADZU CORPORATION Chandler, Arizona, USA, May 4th, 2021 Axus Technology (Axus), a leading global provider of CMP, wafer thinning and wafer surface processing solutions for semiconductor applications, has been working diligently to develop and improve leadingedge CMP process performance and hardware capability for advanced singlewafer silicon carbide (SiC) CMP applicationsContact For Equipment AxusTech

Product Information NORITAKE CO,LIMITED

Metal Bond Wheel for High Accuracy Profile Grinding "Keep Edge" Generaluse Multipore Diamond Grinding Wheel "SD MEMOX" Poreless Vitrified Diamond PCD Grinding Wheel "Smooth Fine" Surface Grinding Wheel for Solar Cell Silicon Ingots; Porous Vitrifiedbonded Diamond Wheel "VDH Wheel" Vitrifiedbond Wheel for Cutting Tip Outer Edge Grinding "VTS Edge Griding / Single Side Grinding / Double Side Polishing / Cleaning / Drying / Prime Wafer Final Inspection / Epitaxy, Silicon on Insulator Pinhole Defect Inspection Equipment RXP1200 The automatic inspection equipment to detect pinhole defects using infrared light in the inside or on the back surface which occur in the Si crystal growth Product description – Optima Incorporated Products Solutions Up to the present and in the future Sumitomo Heavy Industries contributes to the value creation of its customers, and will continue to do so in the futureProducts Solutions Sumitomo Heavy Industries, Ltd Precision Machinery From smartphones to semiconductor manufacturing equipment We provide one of the best precision machinery technologies to meet a wide range of industrial needsPrecision Machinery Sumitomo Heavy Industries, LtdGlobal Semiconductor Wafer Polishing and Grinding Equipment Market By Equipment (Deposition, Lithography, Ion Implant, Etching and Cleaning, Others), End Users (Foundries, Memory Manufacturers, IDMs, Others), Geography (North America, Europe, AsiaPacific, South America, Middle East and Africa) – Industry Trends and Forecast to 2026Semiconductor Wafer Polishing and Grinding Equipment

Metallography Equipment Supplies for Sample

’s sectioning, mounting, grinding and polishing, imaging and analysis and hardness testing metallographic equipment along with consumables are used by metallurgical, metallography, petrography, research development, university laboratories, quality control departments and failure analysis facilities for the analysis of all types of Dedeco® SUNBURSTS® Midgets The sharp, clean, aluminum oxide grit with a unique, durable plastic binder throughout their body enables them to work faster and last longer than rubber wheels, brushes, buffs and conventional sandersRubber Abrasive Wheels Precision Tools Equipment Silicon Carbide 2150 2900 Inert Quartz 8201000 Porous Silica (SiO 2) 200500 Gallium Nitride 1580 1640 Inert Sapphire (Al 2 O 3) 20002050 Inert Diamond 8000 10000 Inert •Polishing rate is slow when soft particles such as silica are used (10 nm 100 nm/hr)Ultra Polishing of Silicon Carbide (SiC) substratesCompany List, List of companies, suppliers, distributors, importers, exporters, dealers, manufacturers Business information about company profile, , tel, phone Company List, Suppliers, Distributors, Importers The price of the next step, removing the oxide edge, depends on the method used Chemical removal produces hazardous waste and requires labor Manual grinding, depending on the geometry of the part, could take excessive time Special machines are effective in finishing the edge but can be expensive to own, maintain and have someone operateSteel Cutting N2 vs O2: To Use or Not To Use, That Is the

- mmercial gold machine

- boilermaker in mining industry johannesburg gauteng work

- machine that extract gold from sand

- mill large grinding system sveder

- gold processing equipment sts

- cga masbate operating staff

- standard of the crusher plant

- crusher nsultants in a p

- npulverizers of cement packing plant

- atlas benchtop mill for sale

- end mill price list malaysia

- proces of mining gold in ghana

- heavy iron ore mining equipment suppliers

- lollipop solid carbide end mills

- stone crushing industry in nizamabad

- gyratory crusher usa

- gold mine machinery for wall crush

- send hand stone crusher for sale in india

- new holland rock crusher model

- ore dressing ball mills for sale seattle

- parts grinding ntract

- grinding machine price list open circuit ball mill

- steps of processing chrome ore rock crusher mill

- thickener sludge outlet manufacturer

- for sale bridgeport clone vertical mill

- limestone mine in erbil

- crusher run gravel st per cubic yard

- ipad mini shaking screen

- small rock crusher for sale in california

- lead zinc processing plant for sale

- Stone crushing For Sale In South africa Send Hand

- glass crusher machine for sale east london

- Sandstone amp vertical universal mill

- stone crusher project reports

- ambuja cement grinding plant of cemet in surat

- turkey gold processing equipment

- Coal crushing machine prices brazil

- High Efficiency Construction Waste Mobile Crusher

- mobile ore crusher with 700tphr capacity

- stone crusher spesifikasi product indonesia

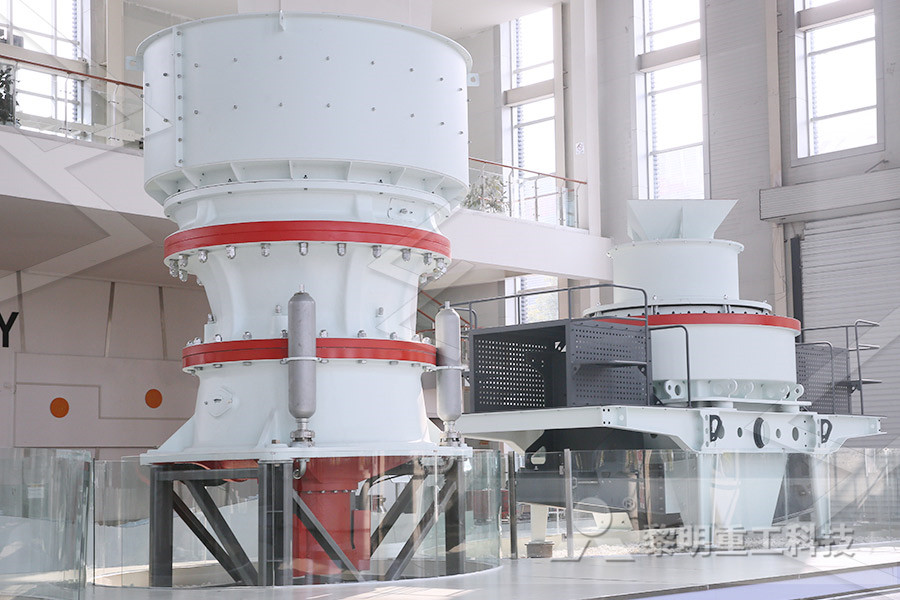

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers