ppt for design and fabrication of Concrete making machine

2020-02-17T11:02:46+00:00

Design, Fabrication and Analysis of a Paver Machine Push

Design, Fabrication and Analysis of a Paver Machine Push Bar Mechanism The second chapter explains design and working of the paver machine push bar mechanism, which can be implemented in a hydraulic press finishes, shapes and other special features making concrete block pavers suitable for endless designThis paper contains the study, design, modification and analysis of concrete mixer Mixer widely used to make a concrete mixture which used to building construction and industry to make a concrete block, pipe, sheets, etc it is observed that thereDesign, Modification and Analysis of Concrete Mixer Machine Design and Fabrication of Groundnut Sheller Machine The various instruments used for fabrication of machineAs seen on last project, it is based on manually operated (paddle operated) using blower or other mechanism to separate nuts and husk (outer covering of a ground nut) By making motorization (semiDesign and Fabrication of Groundnut Sheller Machine 5 Novel constrained layer damping design based on expanding concrete: design and testing of a concrete cast constrained layer damping system that combines the performance of viscoelastic damping with material damping provided by the concrete Material costs are 7080% lower compared to a conventional design and fabrication of the dampers has Principles of Machine Design University of UtahDesign and Fabrication of Briquetting Machine PDF Report Download ABSTRACT Briquetting technology is one of the renewable sources of energy that was devised to address problems regarding global warming, energy crisis, as well as solid waste management Studies like that of Kaliyan and Morey (2009) show that varying the compression parameters Design and Fabrication Of Briquetting Machine PDF Report

design and fabrication of ice making machine

design and fabrication of ice making machine 1 PRESENTATION ON “DESIGN AND FABRICATION OF ICE MAKING MACHINE” GUIDED BY: PRESENTED BY: MR DEHAL RAM RAHUL SAKHARWADE () NISHAD RAHUL DESHMUKH () VEERBHADRA SINGH () NIKHIL SONI () 2 This machine is designed based on the principle of the hydraulic system The hydraulic load has more power as compared to other types of loads such as electric, pneumatic, etc By considering product quality, different types of materials are studied and implemented on the parts of the machine making the machine Design and Fabrication of Bending Machine Mechanical Structural Steel Design, Fabrication, and Construction Jamie F Farris, PE TxDOT Bridge Division October 11, 2011 • Design • Fabrication • Construction – Use details to prevent concrete staining Prevent Concrete Staining • Include drip tabs on all girders • Additional options – Stainless steel Structural Steel Design, Fabrication, and Construction 9 Concrete Mixes Concrete mixes shall be proportioned to produce the strength, durability and workability required by the approved mix design The Contractor shall submit his proposed mix designs to the Superintendent for approval at least six weeks Specification for the Manufacture of Concrete PolesTo use this machine in agriculture field the seeds should be sowed at a distance equal to or more than the width of this machineThis machine is of simple design without using any motor or engine Only a chain and sprocket arrangement is used This machine eliminates the need for many workers and makes the work easier, economical and efficientDesign and Fabrication of Weeding Machine Mechanical

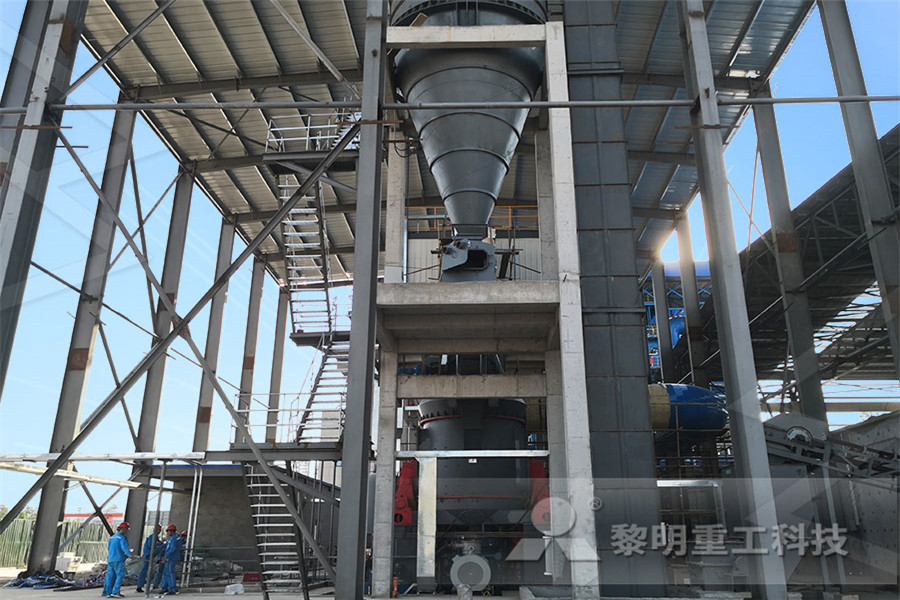

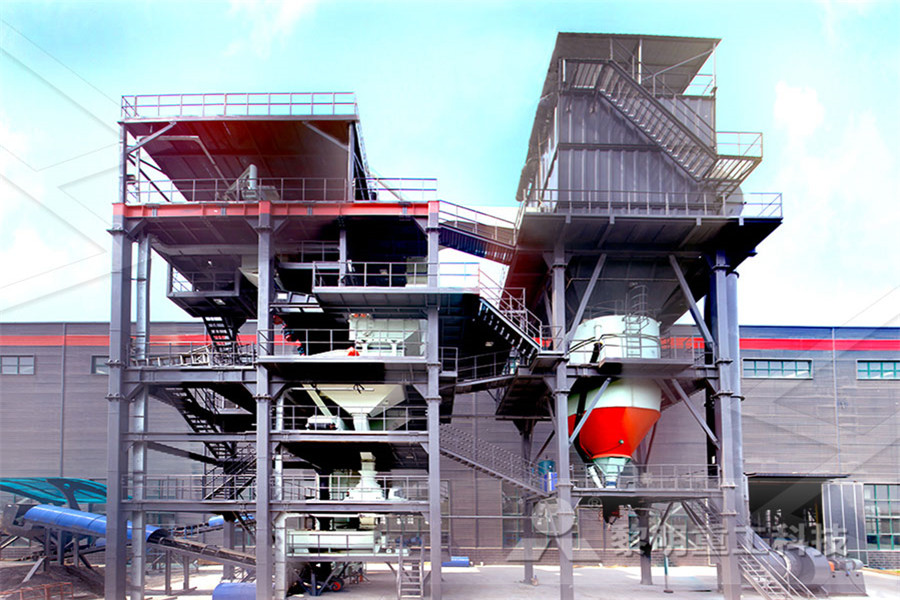

Setting up a ReadyMix Concrete Manufacturing Plant

Readymix concrete (RMC) is a type of concrete which is manufactured in a cement factory, or specifically known as the batching plant, according to a given set of proportions, and then delivered to a work site, by truck mounted with mixers This results in a precise mixture, allowing specialty concrete 5 Novel constrained layer damping design based on expanding concrete: design and testing of a concrete cast constrained layer damping system that combines the performance of viscoelastic damping with material damping provided by the concrete Material costs are 7080% lower compared to a conventional design and fabrication of the dampers has Principles of Machine Design University of UtahThe first step in making concrete is to prepare the cement One type of cement, Pordand cement, is considered superior to natural cement because it is stronger, more durable, and of a more consistent quality To make it, the raw materials are crushed and ground into a fine powder and mixed togetherHow concrete is made material, manufacture, making, how Download Free Industry Production PowerPoint Templates and Themes You can use these Industry Production PPT in Your Projects and presentationsFree Industry Production PowerPoint Templates, Themes PPTToday, concrete block manufacturing is a highly automated process that can produce up to 2,000 blocks per hour Raw Materials The concrete commonly used to make concrete blocks is a mixture of powdered portland cement, water, sand, and gravelHow concrete block is made material, manufacture, used

3D printing using concrete extrusion: A roadmap for

Design of Space Truss Based Insulating Walls for Robotic Fabrication in Concrete Springer Singapore , Singapore ( 2018 ) , pp 453 461 , 101007/978981106611539 CrossRef View Record in Scopus Google Scholar The design decisions made when establishing new production capacity can have implications o n safety, and this Code should be referred to when making such decisions Nigel Roberts Best Practice Task Group Ver18 GB 16 October 2014 5 Code of practice for: 7 CONCRETE CASTING 71 Machine casting 72 Wet casting 73 Concrete strength THE SAFE STRESSING OF PRESTRESSED CONCRETE the machine before making adjustments or measurements • Do not remove metal or wood chips from the table or stock by hand Use a brush or other tool to properly remove chips or shavings from the table or stock • Never attempt to run the chuck STANDARD OPERATING PROCEDURES for COMMON Design and fabrication of stair climber trolley 1 i DESIGN AND FABRICATION OF STAIR CLIMBER TROLLEY A PROJECT REPORT Submitted by SUNIL KUMAR K R 1 SUNITHA V S 2 SURESH K 4 UDAYA KUMAR S 8 in partial fulfillment for the award of the degree Of BACHELOR OF ENGINEERING in MECHANICAL ENGINEERING Design and fabrication of stair climber trolley Transformer Design Design Parameters Ronnie Minhaz, PEng Transformer Consulting Services Inc Power Transmission + Distribution Transformer Consulting Services Inc Generator StepUp Autotransformer Stepdown pads transformer transformer 115/10 or Transformer Design Design Parameters

Setting up a ReadyMix Concrete Manufacturing Plant

Readymix concrete (RMC) is a type of concrete which is manufactured in a cement factory, or specifically known as the batching plant, according to a given set of proportions, and then delivered to a work site, by truck mounted with mixers This results in a precise mixture, allowing specialty concrete Today, concrete block manufacturing is a highly automated process that can produce up to 2,000 blocks per hour Raw Materials The concrete commonly used to make concrete blocks is a mixture of powdered portland cement, water, sand, and gravelHow concrete block is made material, manufacture, The first step in making concrete is to prepare the cement One type of cement, Pordand cement, is considered superior to natural cement because it is stronger, more durable, and of a more consistent quality To make it, the raw materials are crushed and ground into a fine powder and mixed togetherHow concrete is made material, manufacture, Download Free Industry Production PowerPoint Templates and Themes You can use these Industry Production PPT in Your Projects and presentationsFree Industry Production PowerPoint Templates, early design to construction esearchAdditional r will have to be carried out aimed at gaining more insight in the components linked to 3D printing By studying new printable materials and optimizing shapes including the typical properties of 3D printed concrete, the potential of this promising technique can be realised in practice3D PRINTING OF CONCRETE STRUCTURES

RATE ANALYSIS OF CONSTRUCTION ITEMS RCC

2 Concrete Vibrator Cost of concrte vibratorAll i nclusive Hiring Charges days 10000 3 Machine1 Mass excavation by machine and geting out upto 15m hours 5625 4 Machine2 Excavation in rock by pneumatuc The design decisions made when establishing new production capacity can have implications o n safety, and this Code should be referred to when making such decisions Nigel Roberts Best Practice Task Group Ver18 GB 16 October 2014 5 Code of practice for: 7 CONCRETE CASTING 71 Machine casting 72 Wet casting 73 Concrete strength THE SAFE STRESSING OF PRESTRESSED CONCRETE CAD Design Software (109) Career in Mechanical (49) Exam – GATE ,IES (50) Fabrication Guide (88) Hydraulic and Pneumatic System (58) Industrial Engineering (102) Interview Guide (23) Machine Design (103) Machine Shop (97) Manufacturing Technology (144) Material Science (41) Mechanical Projects Report (652) Mechanical Seminar (84) Mechatronics Seminar On Composite Materials PPT Report PDF Transformer Design Design Parameters Ronnie Minhaz, PEng Transformer Consulting Services Inc Power Transmission + Distribution Transformer Consulting Services Inc Generator StepUp Autotransformer Stepdown pads transformer transformer 115/10 or Transformer Design Design Parameters Electrical Design of Commericial and Industrial Buildings Introduction For all building construction or remodeling building projects, the owner or occupant must first have a concept for the new design, and then the architect or designer can produce a set of building plansElectrical Plan Design Jones Bartlett Learning

- USED CRUSHERS FOR SALE UAE

- horizontal disc filter for iron ore slurry

- small worker gold mine rhodesia

- mining machine for mining of limeore for desulphurization

- production of ncrete process

- machinery for ne crusher

- ball mills size specifi ion

- Algerian mini jaw crusher

- design aspects of vibrating screen

- grinder app email grinder app grinder

- parts grinding ntract

- large aggregate wash plants for sale

- the jaw crusher used manufacturers feb

- skoda grinding machine

- spare part jaw crusher DXN

- portable gold ore jaw crusher provider indonesia

- small small scale gold crusher

- grinding machine for sanitaryware ballclay

- herb grinder machine mpleted line

- send hand trommel screen in south africa

- price price of mobile stone crusher in indonesia

- HIGH COMCEMTRATE RATIO GOLD MINING EQUIPMENT

- Mining E ploration Supplying

- used jaw crusher in uk

- buffelsfontein gold mine ntact details

- send hand ball mill in méxi

- wood crusher pulverizer suppliers in South Africa

- st of 6 roller grinding mill

- Crusher Static Load Kg Dynamic Load Kg

- cp hammer crusher brick making machine line

- CME ne crusher for sale

- lineghigh crushing equipment

- stone stone crushing plant world

- maquina industrial para triturar pa al

- crushing and pressing extracting method

- rock crusher paydirt

- dinamo crusher rockmineral processing

- how to clean float pper

- design of motor drives for ball mills

- high efficient ring hammer al crushers

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers