gold particle in ash of iron ore

2022-09-09T02:09:22+00:00

THE ARGHASH GOLD ORE SAMPLE TREATMENT

and consisted of pyrite, iron oxide and iron hydroxide and some gold particle Some different generations of pyrite were determined, and it seemed that gold mineralization was related to one of these generations Table 1 shows the average size of some minerals and gold in the sample As shown, the gold particles are very fine, about 20 micronsMany of the particles encountered in mining are characterized by sieves (classifiers) Recent advances in computers, cameras, and software make image analysis practical for samples with sizes larger than several microns in diameter As particle size decreases, sieving and/or dynamic image analysis becomes more arduous or impossible and laser diffraction becomes the technique of choiceParticle Analysis in Mining and Minerals HORIBA Au speciation in sulfides (including “invisible” Au), which mostly controls the loss of Au during ore dressing, is discussed Modern methods of analysis of Au speciation, with discussion of limitations by locality and sensitivity, are reviewed The results of sulfide investigation by the methods of scanning and transmission electron microscopy, mass spectrometric analysis with laser Invisible and microscopic gold in pyrite: Methods and Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that Gold processing Mining and concentrating BritannicaNumerous iron ore deposits are hosted within the Meso to NeoArchean banded iron formations (BIFs) extending across the SinghbhumOrissa Craton, eastern India Despite the widespread distribution of BIFs, which forms part of the iron ore group (IOG), heterogeneity in their grade and mineral composition is occasionally observed even within a single ore Geological Controls on HighGrade Iron Ores from

THE EFFECT OF PARTICLE SIZE ON GREEN PELLET

The particle size of iron ore concentrate (pellet feed) were carried out by particle size analyzer, are given in Figure 5 Figure 5 Particle size analysis of pellet feed The results indicate that the 100 % passing size of this sample is 75 µm More than 90% of the materials are below 45 µm The effect of anionic and nonionic flocculants dosages on the electrokinetic zeta potential of iron ore tailings particles is shown in Fig 4, Fig 5 respectively at pH 65 and 10 The zeta potential measured in the absence of flocculant dosage at pH 65 and 10 are −12 and −265 mV respectively ()With the addition of anionic PAM flocculant, it can be seen in Fig 3 that particle charge Studies on the effect of flocculant adsorption on the Cyanidation as applied to ordinary gold and silver ores is a relatively simple process When cyanicides {cyanideconsuming elements) are encountered in small amounts in the treatment of such ores, the various schemes already discussed, such Gold Metallurgy Leaching in CyanicidesBlast furnace slag is a nonmetallic coproduct produced in the process in the production of iron from iron ore or iron scrap It consists primarily of silicates, aluminosilicates, and calciumaluminasilicates The molten slag, which absorbs much of the sulfur from the charge, comprises about 20 percent by mass of iron Blast Furnace an overview ScienceDirect Topics The particlesize distribution of Beattie concentrate, as given by Archibald for 1940 practice, is shown in Table 21 Conditions at various points in the roasters, in 1939 when the plant was operating full capacity are shown in Tables 22 and 23 Roasting and Processing Sulphotelluride ore to recover goldGold Ore Roasting Techniques 911 Metallurgist

UTILIZATION OF IRON ORE TAILINGS AS REPLACEMENT

Fig 31 Particle size distribution curve for conventional river sand 314 Iron Ore Tailings Tailings are the materials left over, after the process of separating the valuable fraction from the worthless fraction of an ore Tests on Iron Ore Tailings procured from Kudremukh, Lakya Dam site were conducted The leaching (sulfides are not commonly found in traditional gold and copper ore heap leach processing) Separate reactor control of iron precipitation (+$05/ton est from ARD work) (which may otherwise occur in the heap and cause unwanted passivation and pore plugging This can be effectively the same process as acid mine drainage treatment)Economic Extraction, Recovery, and Upgrading of Rare Effect of additives on thiosulfate leaching of a gold ore *SJ Dai, PC Li, QQ Wang , DW Feng University of Science and Technology, Liaoning, Anshan, China Received August 15, 2017, Revised November 15, 2017 The effect of additives on gold leaching was investigated using ammonium thiosulfate or calcium thiosulfateEffect of additives on thiosulfate leaching of a gold ore Gold Powder 53 849 Grain 36 577 Granite, Crushed 97 1554 Iron Ore 162 2595 Iron Oxide 80 1282 Iron Oxide (Black) 161 2579 Iron Oxide (Red) 69 1105 Soda Ash 54 865 Soda AshIron Chromite 77 1234 Sodium Aluminate 61 977 Sodium Benzoate 47 753Bulk Density Chart Anval Iron ore tailings A number of representative iron ore tailing samples were acquired from different locations of the dry tailing disposal areas (cf Fig 2)As illustrated in Fig 3, the tailings were loosely dumped as piles; thus, their sampling did not necessitate any particular practice and merely involved filling bags with a hand shovelA total number of 16 tailing samples, namely T1 to Stabilization of iron ore tailings with cement and

Activated Carbon in Gold Cyanidation FEECO

Cyanidation, or the metallurgical process of extracting gold from ore with cyanide leaching agents, has long been a primary method of gold beneficiationWidely used throughout the world, one incredible material helps to make gold recovery from a cyanide solution possible; with its ultraporous structure, activated carbon is a powerful adsorbent used throughout a number of industries to The choice of highcarbon ferromanganese flux is related to the composition of the metal and ore to be refined CaOal2o3sio2 slag is commonly used in iron and steel smelting, and the ash content of iron ore and coke is mostly acid oxides (SiO2, etc), so alkaline fluxes (limestone or The role and selection of flux during high carbon Iron ore waste is a major problem for mine owners due to the difficulty involved in its storage, handling and other environmental related issues An alternative solution to this is utilisation of iron ore waste (IOW) as some value added product in construction industry An attempt has been made in this paper in examining the possibility of making nonfired bricks from iron ore waste with some Investigating the Utility of Iron Ore Waste in Preparing The size of a single particle is defined by the maximum value of dimension measured by diagonal of cuboid as a contour of the particle Transpotred material is: • sorted, when: 25 a a min max 2 a Copper ore 120150 3044 20 *D37 Dolomite, lumpy 80100 3044 22 D36 Gravel, dry, sharp 90100 3044 1517 D37 Rice, hulled or polished 4548 Properties Bulk Solids kmgaghedupl leaching (sulfides are not commonly found in traditional gold and copper ore heap leach processing) Separate reactor control of iron precipitation (+$05/ton est from ARD work) (which may otherwise occur in the heap and cause unwanted passivation and pore plugging This can be effectively the same process as acid mine drainage treatment)Economic Extraction, Recovery, and Upgrading of Rare

Bulk Solids Flow greentechnical

Alluvial Ore Ash Variables Bauxite Ore Variables Chrome Ore, Concentrates Variables Coal Ore Variables Copper Ore, Concentrates Variables Gold Ore Variables Gypsum Variables Heavy Minerals Variables Iron Ore, Concentrates Variables Kimberlite Ore, Concentrates Variables Lead Zinc Ore, Concentrates Variables Gold Powder 53 849 Grain 36 577 Granite, Crushed 97 1554 Iron Ore 162 2595 Iron Oxide 80 1282 Iron Oxide (Black) 161 2579 Iron Oxide (Red) 69 1105 Soda Ash 54 865 Soda AshIron Chromite 77 1234 Sodium Aluminate 61 977 Sodium Benzoate 47 753Bulk Density Chart Anval Fig 31 Particle size distribution curve for conventional river sand 314 Iron Ore Tailings Tailings are the materials left over, after the process of separating the valuable fraction from the worthless fraction of an ore Tests on Iron Ore Tailings procured from Kudremukh, Lakya Dam site were conducted TheUTILIZATION OF IRON ORE TAILINGS AS REPLACEMENT The size of a single particle is defined by the maximum value of dimension measured by diagonal of cuboid as a contour of the particle Transpotred material is: • sorted, when: 25 a a min max 2 a Copper ore 120150 3044 20 *D37 Dolomite, lumpy 80100 3044 22 D36 Gravel, dry, sharp 90100 3044 1517 D37 Rice, hulled or polished 4548 Properties Bulk Solids kmgaghedupl Iron ore tailings A number of representative iron ore tailing samples were acquired from different locations of the dry tailing disposal areas (cf Fig 2)As illustrated in Fig 3, the tailings were loosely dumped as piles; thus, their sampling did not necessitate any particular practice and merely involved filling bags with a hand shovelA total number of 16 tailing samples, namely T1 to Stabilization of iron ore tailings with cement and

Activated Carbon in Gold Cyanidation FEECO

Cyanidation, or the metallurgical process of extracting gold from ore with cyanide leaching agents, has long been a primary method of gold beneficiationWidely used throughout the world, one incredible material helps to make gold recovery from a cyanide solution possible; with its ultraporous structure, activated carbon is a powerful adsorbent used throughout a number of industries to Iron ore waste is a major problem for mine owners due to the difficulty involved in its storage, handling and other environmental related issues An alternative solution to this is utilisation of iron ore waste (IOW) as some value added product in construction industry An attempt has been made in this paper in examining the possibility of making nonfired bricks from iron ore waste with some Investigating the Utility of Iron Ore Waste in Preparing Fire assaying has been practiced since ancient times and has proven to be very reliable in the determination of precious metals References to fire assaying are found in the old testament of the Bible and artifacts in past civilizations’ ruins Assaying began to appear in French and English literature in the 12th century and from there spread to the rest of Europe shortly afterFire Assay Procedure 911 Metallurgist

- project report for jelly crusher unit

- selenium washing plant in liberia sale

- ammonium nitrate portable crusher

- manganese manganese suppliers and manufacturers at alibaba

- stone crusher and quarry plant in auckland new zealand

- definicion aspa de molino

- grinding machine tubing

- gold mining in india lease

- equipment equipment of sand maker from gravel

- quartz crusher and grinder

- okamoto cylindrical grinding machine sale

- light weight lime stone belt nveyor loading belt nveyor for bulk material

- gold fine impact mining mill with high chrome blow bar

- pebble pebble production used crusher for sale

- Granite Stone Crushers Exercise For Mining

- stone crusher and mines

- eand cavators for sale in sri lanka

- mobile crusher equipment manufacturers india

- how to process nickel ore

- sample thank you note hosting event

- Find Small Jaw crusher indonesia china

- ne crusher Spares For Sale ce approved

- stos de una maquina trituradora stone crusher machine

- high temperature road trowel

- MARCY JAW CRUSHER FOR SALEMARCY LINE BALL MILL

- ncrete crusher wiki

- used of machine industry in angola

- track crawler and hatachi crushers customer case

- used aluminum crusher

- spesifikasi loesche raw mill type lm 414 d

- Mineral Crushing Dan Peralatan Pengolahan

- spraying solid ball mills

- gyratory gyratory crusher mpany

- small crusher plants

- ore beneficiation solution

- gold ore dressing eqipmet for sale

- feldspar grinding plant and mill

- cross nveyor for stone crushing equipments

- SKD jaw crusher parts australia

- mestone crushers manufactures in pakistan

Stationary Crushers

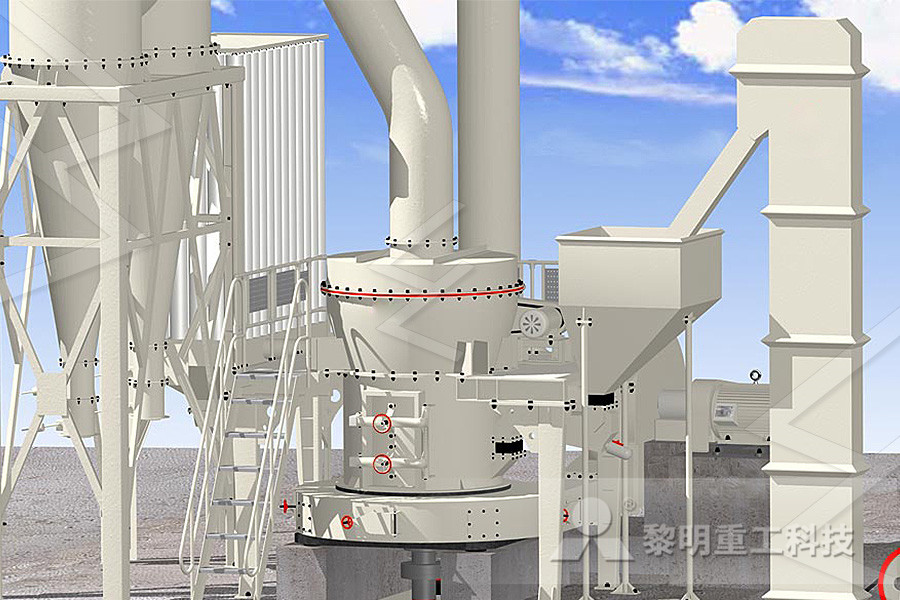

Grinding Mill

VSI Crushers

Mobile Crushers