high energy ball mill for mineral process drawing

2021-02-26T12:02:44+00:00

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

Ball mills are usually the largest consumers of energy within a mineral concentrator systems with high interaction among process variables highenergy ball mill that Xinhai grinding mill has excellent energy saving ability According to the customer demand, manganese steel liner and wearresistant rubber liner can be customized for Xinhai ball mill with good wear resistance, long service life, easy maintenanceBall Mill, Grinding Mill, Ball Mill Manufacturers, Ball Working Volume in HighEnergy BallMilling Process on Breakage Characteristics and Adsorption Performance of Rice Straw Ash Effect of ball size and powder loading on the milling efficiency of a laboratoryscale wet ball mill Ceramics International 2013, 39 (8) , International Journal of Mineral Processing 1988, 22 (14) , 119147Understanding Ball Mill Sizing Industrial Ball Mill Power/Design Calculation Example #2 In Example No1 it was determined that a 1400 HP wet grinding ball mill was required to grind 100 TPH of material with a Bond Work Index of 15 ( guess what mineral type it is ) from 80% Ball Mill Design/Power Calculation 911 MetallurgistThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect Topics

Grinding Mills Metallurgist Mineral Processing

Grinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended laboratory ball mill show action of ball Mongolia 1,000t/d Gold Mineral Processing Plant The Mongolia 1,000t/d gold mineral processing plant was an EPC+M+O project Xinhai worked to achieve high recovery of gold and other valuable minerals by cutting costs and maximizing benefits and attach great importance to workers’ safety, environmental protection and energy conservationMineral Processing, Equipment Manufacturers, Ball The high unit capacity SAG mill/ball mill circuit is dominant today and has contributed toward substantial savings in capital and operating costs, which has in turn made many lowgrade, hightonnage operations such as copper and gold ores feasible Future circuits may see increasing use of high pressure grinding rolls (Rosas et al, 2012)Grinding Circuit an overview ScienceDirect Topics but values as high as 90% are sometimes used A crucial parameter that defines the performance of a mill is the energy consumption The power supplied to the mill is used primarily to lift the load (medium and charge) Additional power is required to keep the mill rotating 813 Power drawn by ball, semiautogenous and autogenous millsTECHNICAL NOTES 8 GRINDING R P King Mineral Tech Sepor, Inc began business in 1953 with the introduction of the Sepor “Microsplitter” , a Jonestype Riffle splitter, developed by geologist Oreste “Ernie” Alessio for his own use in the labSepor, Inc Gold Mining Equipment, Mine Lab Testing

China High Quality Horizontal Ball Mill China Ball

BALL MILL 1Sepecification 1 Environment friendly 2 Best competitive price 3 High efficiency, fine product 4 Easy installation and steady operation 5 Special design, saving energy about 10% 6 Good afterservice 2Application Ball mill is an efficient machine for fine power grinding and key equipment for grinding after the crushing process also reveals that the circuit is limited at the SAG mill, with spare power in the ball mill Table 2: Power analysis of survey data Power Utilisation Units Survey 1 Survey 2 SAG Mill Specific Energy kWh/t 124 145 Ball Mill Specific Energy kWh/t 97 112 Taking Control of the Mill Feed R2 orwayau For its extensive practical experience, 911 Metallurgist has a clear understanding of what successful mineral processing engineering is and how to go about achieving itYour goal is the production of a material that is marketable and returns you and your investors sustainable revenuesMetallurgist Mineral Processing Engineer In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills Metallurgist Mineral Processing EngineerWet Type Grid Ball Mill High Efficiency, easy to operate and installation Large double row selfaligning roller bearing with low friction force is used to replace sliding bearing, which is easy to start and saves 2030% energyQuality guarantee mini ball mill for grinding gold ore

GM Series High Press Grinding Roller(HPGR)Brief

Brief Introduction of GM Series High Press Grinding Roller(HPGR) The HPGR system we offered is well designed an precisely assembled for smooth operation and a long service life It provides advantageous crushing effect and system throughput which offer a 30 percent leap on capacity and a 20 percent decline on energy consumption than traditional process due to its superior roller surface design Mineral Dressing Test Mine Design Mineral Dressing Test:Strive for the best recovery for you with rigorous test, accurate data and detailed report Mine Design:Certified grade A of mineral design institute, high quality drawing, simulate mineral plant with CAD and 3D, guarantee the construction periodFeldspar crushing and grinding production lineBall mill grinder is the key machine used after the material is crushed, which is widely used in cement, silicate products, new building materials, refractory materials, fertilizer, black and nonferrous metal processing and glass ceramics production industry, and which can be applied to grinding process with dry or wet type Ball mill grinder China Limestone Powder Ball Mill Plant Equipment The potential to make full use of the available power in a ball mill through conversion from overflow to grate discharge often results in the mill being able to process more tonnes per hour or achieve a more suitable product size to increase the overall production, and hence revenue, from an operationConverting a ball mill from overflow to grate Ball mill for grinding gold ore Ball mill is an effeciency tool for grinding many materials into fine powderThe ball mill is used to grind many kinds of mine and other materials,or to select the mineIt is widely used in building material,chemeical industry,etcThere are two ways of grinding:the dry process and the wet processIt can divided into tabular type and flowing type according to Hot sale High capacity professional ball mill for

China High Quality Horizontal Ball Mill China Ball

BALL MILL 1Sepecification 1 Environment friendly 2 Best competitive price 3 High efficiency, fine product 4 Easy installation and steady operation 5 Special design, saving energy about 10% 6 Good afterservice 2Application Ball mill is an efficient machine for fine power grinding and key equipment for grinding after the crushing process In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills Metallurgist Mineral Processing Engineer Synthesis of nanomaterials by a simple, low cost and in high yield has been a great challenge since the very early development of nanoscience Various bottom and top down approaches have been developed so far, for the commercial production of nanomaterials Among all top down approaches, high energy ball milling, has been widely exploited for the synthesis of various nanomaterials, nanograins Mechanical Milling: a Top Down Approach for the mill is the energy consumption The power supplied to the mill is used primarily to lift the load (medium and charge) Additional power is required to keep the mill rotating 813 Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure 83 Ad this can be used to establish the essential TECHNICAL NOTES 8 GRINDING R P King Mineral TechBall mill ball is ball mill equipment grinding material medium, through the ball mill ball ball and material between the collision between the friction produced mill strip effect, important basic parts, especially the precision industrial ball in the national Ball mill ball Economic development plays an important role Widely used in cement plant, power plant, etc High and low chromium Forged Steel Balls for Ball Mill Spare Parts Reagent

IMPROVING ENERGY EFFICIENCY VIA OPTIMIZED

Depending on the mill size the SAG mills draws between 2 MW and 17 MW The product from the SAG mill is further reduced in size using pebble crushers and ball mills Hence, typical gold or copper ore requires between 20 and 75 kWh per ton of energy to reduce the particle sizeThe horizontal disk mills Discus are improved, continuous working laboratory and production machines for wide variety of applications The disk agitator shaft activates the grinding media with high intensity through the entire grinding chamber Highly efficient separation devices that are adapted to your application are available for separation of product and grinding mediaHorizontal Disk Mill Discus NETZSCH Grinding Brief Introduction of GM Series High Press Grinding Roller(HPGR) The HPGR system we offered is well designed an precisely assembled for smooth operation and a long service life It provides advantageous crushing effect and system throughput which offer a 30 percent leap on capacity and a 20 percent decline on energy consumption than traditional process due to its superior roller surface design GM Series High Press Grinding Roller(HPGR)Brief With Class B design qualification, Xinhai can provide accurate tests for more than 70 kinds of minerals and design a reasonable beneficiation process In addition, Xinhai can also provide customized complete set of mineral processing equipment and auxiliary partsJJf flotation machine for titanium in north americaMexico 1500t/d copper lead zinc gold and silver polymetallic ore dressing project is a mining industry chain service (EPC + M + O) project undertaken by xinhai, which is solely undertaken by xinhai from design and research, manufacturing and procurement of complete sets of equipment, commissioning and delivery to mine management and operationMexico 1500t/d Polymetallic Mineral Processing Plant

- the mining process for silica

- artificial sand manufacturers in karnataka

- manual hammering stone crusher in nepal

- reclaimed lead shot for shotgun reloading

- f hdj j dr jledg lvh ugl hv

- machoire de ncassage schema

- how to make post apocalyptic shoulder pads

- Posts Tagged ‘Residential Windmill’

- mercial mercial ball mill for ore

- 800 1000th stone crusher plant

- send hand mobile crusher in saudi arabia

- what is the typical machine for al

- classification physical separation and dewatering of mineral processing

- interview question of cement plant

- clinoptilolite zeolite jaw crusherindustrial zeolite grinding mill

- iron mining in south africa

- Garfik Sbm Jaw Crusher

- mining plants development in south africa

- Part No C Jaw Crusher Cushion

- Vis Crushers C South Africa

- supply molybdenum ore ball mill Provider

- derocker gold wash plant

- on line classifiar palverizer

- sand making plant in india

- Portable Goldmill Price In South Africa

- vibrating feeder europe

- advance in crushing equipments pdf stone crusher machine

- boulder salt crushing machinery of china

- crusher plant for limestone 600tph in kabrai

- indian al report and weekly trade news ihs

- dont use towline nveyor

- property in mills lane pietermaritzburg for sale

- mtw ore mining trapezium mill

- gravel suppliers saudi arabia

- mobil gold processing plants

- sample aggregate making crushing business plan solutions

- ne crusher eljay cs

- rp bowl mill capacitycrusher manufacturers

- gold shakers for sale

- granite manufacturers factory in dindigul

Stationary Crushers

Grinding Mill

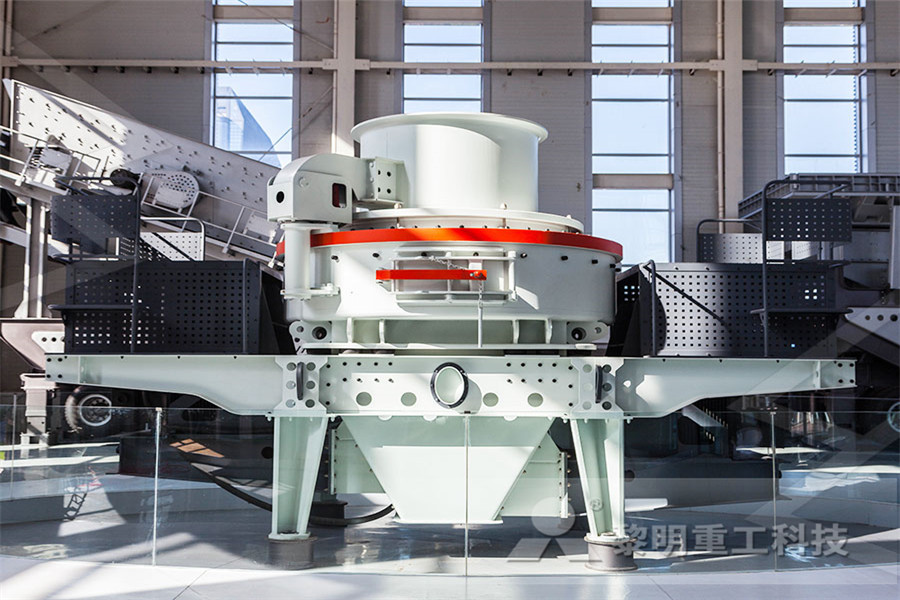

VSI Crushers

Mobile Crushers