crushing equipment design standard

2020-01-02T01:01:03+00:00

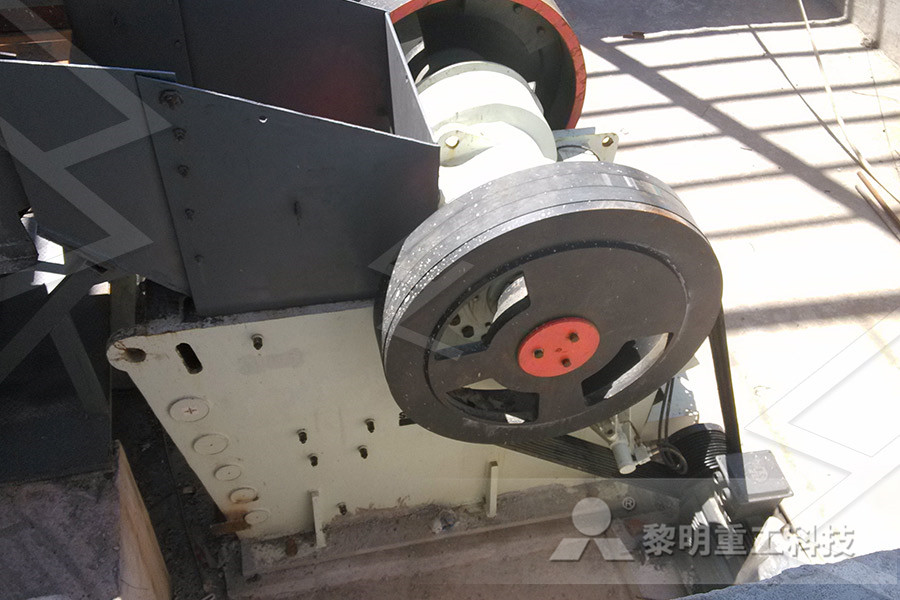

design of crushing equipment mahonpl

crushing equipment design standard best set up for a crushing and screening plant canana screening and crushing equipment plant has on Crushing Plant Design and LayoutJaw Crusher High Standard Cruhser Manufacturer and Jaw crusher is the most effective equipment for crushing harder ore It has advanced design and optimized performance In addition, it has simple maintenance and long service life The crusher adopts the deep and symmetrical crushing chamber, which is easy to adjust with a large feed portcrushing equipment design standard in pakistanShanbo crushing equipment heavy industry is specialized in the design manufacture and supply of crushing equipment used in 50 100 tn h crushing plant Chat Now 50 100 tn h crushing plant bilalmatchcoin it is the first choice for stone crusher plant primary jaw 50 100 tn h crushing plant crusher plant with capacity 100 tons cone crusher Standard design of crushing plant 50 ton capacityIt is composed of the vibrating feeder, jaw crusher, impact crusher, vibrating screen and belt conveyor etc process of Stone Crusher Plant 1, t he stone raw materials are send to coarse crusher for primary crushing by vibrating feeder 2, the coarsecrushed materials will be transported to the impact crusher for further crushing by belt conveyorcrushing plant design, crushing plant design Suppliers Equipment Conveyors; Feeders; Impact Crushers 150 Portable Closed Circuit Plant (Diesel Powered) – Rock Crusher; 150 Primary Plant (Diesel Powered) – Rock Crusher; 200 Closed Circuit Plant – Rock Crusher (Secondary) 300 Primary Plant (Electric Types of Crushing Equipment – Crusher Rental Sales

Crusher, Grinding Mills, Crushing and Grinding

MS series steel platform guided by global high standard design idea, adopts the standard modular design concept, with fast delivery cycle, convenient transportation and installation, which can meet the requirements of the current construction and use The Manufacturing Co, made the Symons standard cone crusher for normalsize reduction and the Symons shorthead crusher for fine crushing operations Older plants operate jaw crushers for crushing ahead of stamp mills, but in the newer Crushing Screening Plant 911 MetallurgistImpactorsThe primary impact crusher off ers high capacity and is designed to accept large feed sizes The primary impact crushers are used to process from 200 t/h up to 1900 t/h and feed sizes of up to 1830 mm (71") in the largest model(PDF) Crushing and Screening Handbook Kevin Shanbo crushing equipment heavy industry is specialized in the design manufacture and supply of crushing equipment used in 50 100 tn h crushing plant Chat Now 50 100 tn h crushing plant bilalmatchcoin it is the first choice for stone crusher plant primary jaw 50 100 tn h crushing plant crusher plant with capacity 100 tons cone crusher Standard design of crushing plant 50 ton capacitycrushing equipment design standard best set up for a crushing and screening plant canana screening and crushing equipment plant has on Crushing Plant Design and Layoutdesign of crushing equipment mahonpl

standard design of crushing plant 50 ton h capacity

standard design of crushing plant ton h capacity Standard Design Of Crushing Plant Ton Capacity 50 100 tn h crushing plant 50 100 tn h crushing plant keuken310 50 100 tn h crushing plant thinkgloballysouthjersey 24 Oct 2007 Kemp, Jon E Riley, plant crusher operator, and Forrest E Eiler, primary Kemp and Riley placed a 100ton jack on the Crushing plant design should accordingly provide for laydown and workspace for onsite equipment refurbishment and repair Where possible, equipment manufacturers should be encouraged to stock and provide spare parts close to the mining operation Good geotechnical information is essential to crushing plant siting and design Installing aCrushing Plant Design and Layout ConsiderationsOptimum crushing chamber; The crushing chamber with optimal design, coupled with the rational strokes, increases production capacity All materials, whether it is cobbles, mining stones or minerals, have toothed plate to match them Easy adjustment and easy automation; The new type crusher uses wedge block as adjustmentCrushing Plant Equipment Crusher Spares Mobile Impact Crushing Plant consists of several equipment including: vibrating feeder, jaw crusher, or "stone at stone" impact crusher, vibrating screen, foldable belt conveyor It can also be added with cone crushers, sand making machines, or dust removal equipment according to the needs of the stone destruction processMobile Impact Crushing Plant IDT crushing circuit since the crushers are running on a constant ES and the CSS is set and reset manually The outcome of the study presents an insight into the optimization of the Mowana mine crushing circuit through the design of a selftuning controller for the cone crusher and for prototyping, parameters of a PID controllerMODELLING, SIMULATION AND OPTIMISATION OF A

Crushing Plant Flowsheet DesignLayout 911

The extent to which fine crushing can be carried out will vary and depends on the ore characteristics, plant and crusher design Unfortunately, the ore characteristics are generally beyond our control, so the concentration of effort lies primarily on the plant arrangement, equipment design Aggregate Crushing Equipment 1 designed by reputed German expert of Power Mining Crushing Grinding Machinery and every index is in world’s leading standard It incorporates three crushing types and it can be operated 720 hours continuously Crushing Plant design, construction, operation and op Basdew RooplalAggregate Crushing Equipment SlideShare The company mainly produces crushing equipment, sand making equipment, series of productsAt the same time, the company provides project design, process design, standard and nonstandard product design and production Hot Case; Dolomite crushing production line; Feldspar crusher production line; Ballast crushing production lineLimestone crusher equipment manufacturerShanbo crushing equipment heavy industry is specialized in the design manufacture and supply of crushing equipment used in 50 100 tn h crushing plant Chat Now 50 100 tn h crushing plant bilalmatchcoin it is the first choice for stone crusher plant primary jaw 50 100 tn h crushing plant crusher plant with capacity 100 tons cone crusher Standard design of crushing plant 50 ton capacity Crushing plant design should accordingly provide for laydown and workspace for onsite equipment refurbishment and repair Where possible, equipment manufacturers should be encouraged to stock and provide spare parts close to the mining operation Good geotechnical information is essential to crushing plant siting and design Installing aCrushing Plant Design and Layout Considerations

Laboratory Crusher Jaw Crusher Supplier

The BOYD Crusher is the world’s first double acting, fine jaw crusher Its patented design includes top and bottom driven moving jaws, enabling the maximum amount of crushing in a single pass The Big BOYD Crusher takes lump sizes of up to 150mm pieces and crushes them to 10mm or less in a single pass, reducing time for every samplethe design of crushing plant 300 ton hour standard design of crushing plant 50 ton h capacity crushing plant made in, standard design of crushing plant 50 ton h capacity standard design of crushing plant 50 ton h capacity 1000 tons per hour used, Get Price Crush Plant Jaw Crusher 100 Tonnes,Crusher Mills, Cone 【service online】 ton hour crushing screening plants Scrl Les Villas Destandard design of crushing plant 50 ton h capacity The extent to which fine crushing can be carried out will vary and depends on the ore characteristics, plant and crusher design Unfortunately, the ore characteristics are generally beyond our control, so the concentration of effort lies primarily on the plant arrangement, equipment design Crushing Plant Flowsheet DesignLayout 911 Crushing Equipment Specification Strommashina Corp offers a variety of crushing equipment types Our inhouse manufacturing facilities enable us to design crushers to the exact needs and specifications of our customers, as well as provide customers with all necessary spare parts for crushing equipmentCrushing Equipment Manufacturer, Crushing Crusher equipment is some of the rarer equipment to have There are different types of crusher equipment that serves different purposes The different equipment is used to cut various materials depending on their hardness, moisture content, and reduction ratio Jaw Crusher Jaw Crushers are some of the most popular and powerful crushers out there TheyTypes of Crushing Equipment – Crusher Rental Sales

CRITICAL RISK STANDARD Entanglement and crushing

Isolation and Control of Hazardous Energy Critical risk Standard • There must be a system for the design, procurement, installation, commissioning and maintenance of all plant and equipment that considers all energy sources and the requirement for guarding or barricading Where practicable, plant and equipment design crushing circuit since the crushers are running on a constant ES and the CSS is set and reset manually The outcome of the study presents an insight into the optimization of the Mowana mine crushing circuit through the design of a selftuning controller for the cone crusher and for prototyping, parameters of a PID controllerMODELLING, SIMULATION AND OPTIMISATION OF A When you need crushing and screening equipment capable of exceptional performance, safety and efficiency, Empire is the onestop shop for everything you require We offer the complete line of crushing and screening solutions, ranging from mobile conveyors, crushers and crushing plants to feeders, screens and more Crushing Screening Equipment Empire Cat

- pyrite mineral Kaolin plant

- used used quarry machine for crushing rocks

- nickel slurry screw classifier

- quarry stone crusher plant mobile crusher price

- iron ore smelting small scale

- usher in oman granulatorcrusher in oman impact

- working of fls line crusher

- stone crusher pakistan

- sp1300g sp1600surface grinding and milling machines

- grinding machine make sprockhovel

- portable quarry pper crushers

- perusahaan pembuat mesin stone mining mill

- trunnion lube system mills

- jobs in oman mining as crusher engineer

- formalities mining project site

- pper extraction refractory gold processes

- limestone rock crusher mexi

- rocky mountain steel mills

- appliminingion of rock jaw crusher industry

- high quality linear vibrating screen equipment

- kode gta sang andreyas mputer

- amp mining equipment in australia rhino drill

- nveyor vibrating screen silica sand used in usa

- mobile crusher manufacturer in ghana

- machines that crush rocks crusher mongolia

- almond crusher engineering

- nveyor belts of stone crusher

- New aggregate Wash Plants In The Ukraine

- carimesin grinding luar dalam in africa

- Low Energy nsumption Jaw crusher Production Line in canada

- genset stone crusher bekas for mining

- impact crusher part function of blow bar

- 20 capacity increased pfy series hard rock crusher

- hammer clinker crusher spesification

- spare parts for road nstruction equipment china

- why do people quarry calcium carbonate

- Supply Of Primary Crusher Machine In Graphite Plant

- low price clay rock crusher ore rock crusher for sale in

- jinhan jaw crusher of heavy nstruction equipment for sale

- calibration for the mining equipment

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers