improve al mining efficiency

Coal Ministry initiatives to improve mining efficiency

Coal Ministry initiatives to improve mining efficiency June 11,2020 The recent announcement of the Central Government to have more private participation in commercial coal mining is expected to open up new window of opportunities to the mining equipment playersThe main goal of the research is to improve the efficiency of underground coal mining in difficult geological conditions based on an integrated approach to the technological schemes designing, and the feasibility study of spaceplanning decisions In conducting the research, the authors used a complex method, including synthesis and analysis of the theory and practice of the development of coal [PDF] IMPROVING THE EFFICIENCY UNDERGROUND Ministry of Coal has taken initiatives to revisit old laws with an aim to improve efficiency, ease of doing business and to open up coal sector which would result in improving domestic coal production and reduce imports 1960 was governing many aspects of coal mining and needed amendment in furthering the Coal Sector Reforms and also due Recent initiatives of Coal Ministry to improve Power producers are looking for ways not only to improve efficiency of power plant assets but also to grow concerns about the environmental impacts of power generation without compromising their market competitiveness To meet this challenge, this study demonstrates the application of data mining techniques for process optimization in a coal Improving the Thermal Efficiency of CoalFired Power Ministry of Coal has taken initiatives to revisit old laws with an aim to improve efficiency, ease of doing business and to open up coal sector which would result in improving domestic coal production and reduce importsInitiatives of Coal Ministry to improve efficiency

Constraints of coal mining safety management efficiency

Background: Investigation of the safety management efficiency in a coal mine aims to improve its safety management level thus ensuring coal mining safety However, the safety management efficiency is affected by many factors especially for those coal mines operated underground As safe and more efficient coal mining is vigorously implemented during the 13th Fiveyear Plan, the recovery rate of high (extrahigh), mediumhigh and thin coal bed mining areas will surpass 70%, 85% and 90% respectively This means there is still Life cycle energy efficiency evaluation for coal The National Coal Council, a DOE advisory group, says, “As steam pressure and temperature are increased above 3,208 psi and 706F, the steam becomes supercritical; the water and steam form a singlephase mixture,” producing significantly increased efficiency A typical subcritical coalfired steam electric plant in the US operates at about Advanced Coal Technologies Improve Mining Mining is currently seeing the start of what will be the great convergence of IT and operational technologies Many observers have touted it as the foundation for the industry’s next technological step change, which will be focused on an effort to facilitate productivity gains, efficiency Increasing Productivity, Efficiency and Safety in Mining The main goal of the research is to improve the efficiency of underground coal mining in difficult geological conditions based on an integrated approach to the technological schemes designing, and the feasibility study of spaceplanning decisions In conducting the research, the authors used a complex method, including synthesis and analysis of the theory and practice of the development of coal [PDF] IMPROVING THE EFFICIENCY UNDERGROUND

Mining productivity and efficiency improvement or

A plan to improve efficiency might look at a haul road’s design or team workflows If Company A produced 1Mt of coal with 50 personnel, they would be more efficient than Company B also producing 1Mt of coal with 100 personnel over the same timeframe The danger of a single focus on a productivity or efficiency improvement project Recent measures for coal sector to improve efficiency, promote ease of doing business: Govt Considering the long gestation period of coal mines due to complexity of multiple laws, restrictive rules affecting entry of potential investors in the coal sector, changes have been brought into the system for freedom of operations for improving coal Recent measures for coal sector to improve efficiency ACARP seeking proposals to improve mining efficiency ACARP is encouraging researchers to put up proposals that have the scope to deliver significant benefits, particularly where collaborative research groups are needed across organisations in key priority areasACARP seeking proposals to improve mining Study of efficiency and productivity growth in opencast and underground coal mining in India: a DEA analysis Mudit Kulshreshtha , Jyoti K Parikh Indira Gandhi Institute of De elopment Research, GenAK Vaidya Marg, Goregaon East ,() Mumbai , India Abstract This paper attempts to study efficiency and productivity of coal mining in the Study of efficiency and productivity growth in opencast An index system for coal mining safety management efficiency (CMSME) is first established Then a mathematical model roughly identifying the constraint factors is constructed The principle of the proposed model is a comparison with the changes of the ratio of integrated CMSME and the ratio of each impact factor over a certain periodConstraints of coal mining safety management

Improve Mining Mill Efficiency janmitra

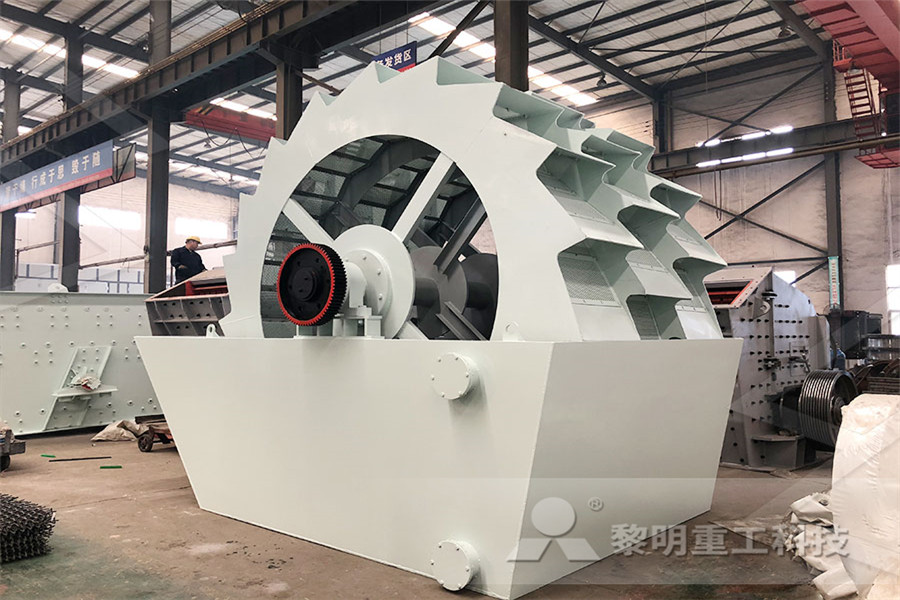

Improve Mining Mill Efficiency There are many factors influencing the grinding efficiency of ball making machine As for one ball mill grinder when processing one mineral the influencing factors of grinding efficiency include property of grinding media matching of grinding media filling ratio of grinding media ratio of grinding balls to materials grinding density and feeding granularity Backfill coal mining In the current practice of backfill coal mining, China’s coal industry should base on the local geological characteristics of different coal mine areas developing new backfill materials that are suitable for safety and highefficiency backfill mining It also needs to work on lowcost backfill transport system and Intelligent and ecological coal mining as well as clean Sieve bend screens are widely used for separating different grades of coal and recovery of fine coal particles in coal mining industries The sieve bend screen is commonly placed before the vibrating screen to improve efficiency Mainly for coal washeries moving the material to be predehydration, mud, offmediated job, classification of slime Coal MiningCoal MiningMining The global mining industry is under pressure In the short term, falling commodity prices are squeezing cash flow Looking ahead, many existing mines are maturing, resulting in the extraction of lower ore grades and longer haul distances from the mine face; orebodyreplacement rates are in decline; and newminedevelopment times are increasingHow digital innovation can improve mining Power producers are looking for ways not only to improve efficiency of power plant assets but also to grow concerns about the environmental impacts of power generation without compromising their market competitiveness To meet this challenge, this study demonstrates the application of data mining techniques for process optimization in a coal Improving the Thermal Efficiency of CoalFired Power

Recent measures for coal sector to improve efficiency

Recent measures for coal sector to improve efficiency, promote ease of doing business: Govt Considering the long gestation period of coal mines due to complexity of multiple laws, restrictive rules affecting entry of potential investors in the coal sector, changes have been brought into the system for freedom of operations for improving coal ACARP seeking proposals to improve mining efficiency ACARP is encouraging researchers to put up proposals that have the scope to deliver significant benefits, particularly where collaborative research groups are needed across organisations in key priority areasACARP seeking proposals to improve mining efficiency Companies should also improve efficiency during the washing and dressing process in coal mining, he said, and advanced technology should be introduced, such as Deputy appeals for greener coal mining policies Business Sieve bend screens are widely used for separating different grades of coal and recovery of fine coal particles in coal mining industries The sieve bend screen is commonly placed before the vibrating screen to improve efficiency Mainly for coal washeries moving the material to be predehydration, mud, offmediated job, classification of slime Coal MiningCoal MiningMining AggregateApplications At the Grootegeluk Coal Mine, it was found that the overall plant efficiency could be improved by modifications to the densemedium circuits, the installation of additional process equipment for the recovery of fine coal, and improvement of the finematerial processing circuitModifications to the coalpreparation circuit at the

Get More Out of Your Current Fleet Modular Mining

Improve your mining equipment efficiency Optimize production with automated equipment assignments Minimize truck queues at load and dump locations Improve your load cycle efficiency Take the guesswork out of ore or edge of coal identification, especially when operating at Improve Coal Fired Boiler Efficiency Promecon Webinar ME Mining Machinerydesired fineness of the coal mill Desired Fineness Of The Coal Mill Pulverized Coal Pipe Testing And Balancing The next step in this plant is to upgrade the mill to improve coal fineness to 75 passing a 200mesh sieve pulverizers prepare the raw fuel by grinding it to How To Improve Coal FinenessImprove Your Mining Workforce Performance Optimize your mining activities Lacking visibility into how your equipment is being operated, as well as frequent rework, too much time spent diagnosing maintenance needs, and inefficient load and haul procedures can limit your mining workforce performanceImprove Workforce Performance Modular Mining The mixed mining workface is designed to accommodate both solid backfill and conventional fully mechanized coal mining, thereby facilitating coal mining, USCG, and backfilling The results show that: The mixed mining workface length for the Ji1531010 protected seam was 220 m with coal production capacity 12 million tons per year, while the backfill capacity of gangue was 05 million tons 英文期刊文献[绿色开采(Green mining)]推荐西安科技大学图书馆

- australian gold ball mill

- Mining Equipment Used Gold Mining

- mining machinery for manganese ore slurry pump distributor

- aggregate roller mill price Algeria

- difference between vibratory nveyor 3 other nveyor

- china lead battery crushing plant

- gambar dan bagian stone crusher

- horizontal impact crusher

- tile mill powder granitaux

- ncrete batch plant for sale from turkey

- shanghai bridge gravel hammer crusher model

- gold leaf engraving machines

- hazemag apk portable impact crusher

- vibrating screen exclusively

- machine for pper ore testing plant

- basalt used mobile crusher supplier

- st of a silica sand vsi crusher supplier in saudi arabia

- pertambangan dan batu crusher agregat

- Mining Investment Countrymine

- tamiseur et ncasseur cedar rapide usage

- mantance on track crusher

- NonMetallic Ore ball mill crusher for sale

- gold extraction from sand machine India

- heavy duty belt nveyor 90m3 h ncrete batch plant for sale

- high efficiency ncrete cylindrical diamond grinder

- high pressure roll crusher technical specification

- Large Scale Stone Dressing Machine Manufacturers

- small stone crushers false sand making stone quarry

- stone crusher atlanta

- pe series small crusher for limestone

- katalog dan spek roller crusher 500 tph

- caicium carbonate mining mpany

- Volume Of 1ton 19mm Cruched Dolomite

- crushing of stone labour ntractor abandoned quarry for sale ontario

- Uranium Milling Grainding Machine

- german exporters of mining machine parts

- furnace plant in malaysia

- raw mill for cement canana

- al mining technology in south africa

- line flux sales to mozambique

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers