gyratory crusher crush principle

2022-04-05T17:04:00+00:00

gyratory crusher crush principle rsystemede

gyratory crusher crush principle BMS FACTORIES, A gyratory crusher is another gravel crusher that can be used to crush black gravel, Saudi Arabia It consists of a cup into which rocks are fed There are partially rotating crushers that grind the stones, which then leave the cup through a hole in the bottom that defines the maximum gravel Crusher Working Principle The primary gyratory crusher breaks the material by feeding mouth into the two rollers between the extrusion crushing, finished materials naturally fall Gyratory Crusher l Introduce, Working Principle JXSC Gyratory Crusher Principle Operation Gyratory Crusher The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of the jaw crusher) and the continuous operation principle (while the reciprocating Get Priceprinciples of operation in gyratory crushersWorking Principle Of Gyratory Cone Crusher Gyratory crusher l introduce working principle jxsc mine gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher the gyratory crushing equipment has a bright future in the mineral processing market its working part is a highspeed rotary crushing roller which is coupled with a pair of curved crushing plates principle of gyratory crushers MC WorldINCA gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging openingGyratory Crusher an overview ScienceDirect Topics

Operating Principle Of Gyratory Crusher Crusher

working principle comparison between cone crusher and The working principle of Gyratory crusher is using the gyratory sports in casing cone cavity of crushing cone to produce operating principle of a gyratory crusherthe working principles of a gyratory crusher NAMARI Gyratory crushers workon a similar principle tojaw crushersbut have a circular gap Rock is compressed between a static conical bowl and a concave mantle which oscillates about the central axis These are generally designed for primary crushing in largescalerock crushingappli ions up crushing principles of gyratory crusher Prominer In gyratory crushers the crushing process comprises reduction by compression between two confining faces and a subsequent freeing movement during which the material settles by gravity until it is caught and subjected to further Working Principle of Crushers 911 MetallurgistWorking principle of gyratory cone crusher cone crusher crusher equipment is made by grinding the raw materials of the best computeraided process consistency but crusher let that happen smash a lot of wear and tear for initiating these machines and they are likely to need repairs throughout its liworking principle of gyratory coneWorking Principle Of Gyratory Cone Crusher Gyratory crushers – design and operating principle Technical data Design A Spider bearing in twoarmed spider ensures spacious feed opening, automatic lubrication with electronic and visual level control B Main shaft C Crushing elements made of highwearresistant material D Cast steel shell sections; weightoptimized by means of FEAIndustrial Solutions Gyratory crushers

crushing principles of gyratory crusher Prominer

working principle of primary gyratory crusher Crushers Primary crushing with gyratory crushers The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening which provides a much larger area than that of the jaw crusher and the continuous operation principle while the reciproing motion of the jaw crusher produces a batch crushing action Gyratory Crusher,Primary Gyratory Crushers Manufacturer A gyratory crusher is one of the main types of primary crushers in a mine or ore processing low maintenance and operating cost Working Principle of Gyratory CrusherOperating Principle Of Gyratory Crusher Crusher operating principle of gyratory crusher crusher mills cone operating principle of gyratory crusher crusher mills cone Cone crusher parts It breaks the rocks by squeezing it between the gyrating spindles These spindles are fully covered with resistant mantle and a manganese bowl liner covers the hopper Get a Quote Send Messageoperating principle of gyratory crusher crusher mills Gyratory crusher working principles Gyratory cone crushers working principle gyratory crusher working principle jul 29 2012in a gyratory crusher a round moving crushing surface is located within a round hard shell which serves as the stationary surface the crushing action is created by the closing the gap between the hard crushing surface attached to the spindle and the concave liners fixed Working Principle Of Gyratory Cone CrusherApr 20, 2019 The gyratory crusher is taller than the jaw crusher, thus needs a high workshop design Besides, gyratory crusher is heavy than jaw crusher, it’s not convenient to move Capacity Gyratory crusher can work continuously, has high productivity and crushing ratio( up to 695), working performance is very stable, light vibration Moreworking principle mparison between ne crusher and

working principles of primary crusher

The Working Principles Of A Gyratory Crusherpdf gyratory crusher working principle gyratory crusher working principles working principle of gyratory crusher 13 oct 2013 more details googlruzv3u get the price gyratory crushers fl 2015 3 12 continued innovation 4 the top service (ts) line is the newest generation of fuller traylor The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of the jaw crusher) and the continuous operation principle (while the reciprocating motion of the jaw crusher produces a batch crushing action)Crushers All crusher types for your reduction needs The working principle of jaw crusher 1 The Working Principle of Jaw Crusher Jaw crusher consists of many parts, like eccentric draft , frame, large belt wheel,mobile jaw, flying wheel, toggle plate, toggle plate, gap adjustment screw and so onThe main function of jaw crusher to crush large rocks into smaller rocks, gravel,rock dust and gravel Principle Of A Crusher staphbework principle of a ballast crusher work principle of ball crusher kozaccypl work principle of ball crusher Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them Impact crushing can be of two variations: gravity and dynamicget pricework principle of crusher domyrolmexplPrinciple Operations Of A Jaw Crusher Jaw Crusher Working Principle Gravel Mill Law crusher working principle and operation is relatively simple, The working principle of jaw crusher is based on the reciprocating movement How Does Jaw Crusher Work Jaw crusher is widely used in industrial and mining enterprises, this is because the aircraft structure is relatively simple, and has a large the basic structure and working principle of impact

crushing principles of gyratory crusher Prominer

working principle of primary gyratory crusher Crushers Primary crushing with gyratory crushers The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening which provides a much larger area than that of the jaw crusher and the continuous operation principle while the reciproing motion of the jaw crusher produces a batch crushing action Gyratory crusher working principle,rock gyratory crushing plant sale Gyratory crushers have a continuous crushing capability and it leads to a higher throughput capacity compared to other crusher machines Moreover, the ring the work principle of gyratory crusherGyratory crusher working principles Gyratory cone crushers working principle gyratory crusher working principle jul 29 2012in a gyratory crusher a round moving crushing surface is located within a round hard shell which serves as the stationary surface the crushing action is created by the closing the gap between the hard crushing surface attached to the spindle and the concave liners fixed Working Principle Of Gyratory Cone Crusher Gyratory crusher can work continuously, has high productivity and crushing ratio( up to 695), working performance is very stable, light vibration Jaw crusher cannot work continuously, leading to lower productivity Jaw crusher has a weakness that the cavity cannot be filled with material, a gyratory crusher has much flexibilityJaw Crusher VS Gyratory Crusher JXACHINEthe work principles of a cone crusher the working principles of a cone crusher MC Machinery Working principles of cone crusher Normally used as the secondary or tertiary crusher the cone crusher has been developed to crush high or medium hardness material such as iron ore copper ore limestone quartz granite and sand stones etc Working principle Cone crusher crushes materials by the Work Principle Of Gyratory Cone Crusher Beaumont

Crushers All crusher types for your reduction needs

The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of the jaw crusher) and the continuous operation principle (while the reciprocating motion of the jaw crusher produces a batch crushing action) Cone Crusher VS Gyratory Crusher Both cone and gyratory crushers have an oscillating shaft The material is crushed in a crush ing cavity, between an external i xed element (bowl liner) and an internal moving element (mantle) mounted on the oscillating shaft assemblyCone Crusher VS Gyratory Crusher A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine is similar to all type of rock crushers, the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge pointThe motion is, however, a more complex one than the Dodge motion, being the Jaw Crusher Working Principle 911 Metallurgistwork principle of a ballast crusher work principle of ball crusher kozaccypl work principle of ball crusher Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them Impact crushing can be of two variations: gravity and dynamicget pricework principle of crusher domyrolmexplPrinciple Operations Of A Jaw Crusher Jaw Crusher Working Principle Gravel Mill Law crusher working principle and operation is relatively simple, The working principle of jaw crusher is based on the reciprocating movement How Does Jaw Crusher Work Jaw crusher is widely used in industrial and mining enterprises, this is because the aircraft structure is relatively simple, and has a large the basic structure and working principle of impact

- c125 wedges manufacturer supplier

- miller manufacturing california molino

- vertical caster for special mill plant

- remended mill for bentonite grease processing

- chamunda welding work crusher machine

- rock crusher hire los angeles

- descargar belt nveyors for bulk materials sixth edition mpleto

- synopsis for spark plug sand cleaner

- used nstruction equipment in malaysia

- ksa goldrate in dammam saudi

- trapezium grinding mill application

- ncrete block making industry in guyana

- mining crushers technologiesmining crushers technology

- mesin pertambangan distributor indonesia

- belt nveyors 1974

- small grinding machine st effective minerals

- aliran grafik skala kecil pengolahan bijih emas

- rock jaw crusher operation

- animate picture of al mining in lebanon

- Market Of Stone Crushing Plant In North East South Africa

- pricelist of jc jaw crusher in india

- ce iso mobile sand making machine vertical shaft impact crusher

- risk assasment al mining operation

- where is the mineral stone crusher in australia

- Lini Produksi Batu Bata Tanah Liat Sepenuhnya Otomatis Jerman

- Windmills at Sea can Break Like Matches

- tunnel boring machine hand push ncrete milling machine

- impact crusher vs jaw crushers

- Price Of Road Construction Equipment

- asano vertical roller mill india

- oportunidades para el ahorro de energia en el carbon trituradoras

- mac allister pressure washer

- mesin impac crushing plant

- building mobile crusher what price

- ne crushers inventory

- where the artificial sand made in india

- stone stone crusher machinery hyderabad

- acid neutralizing capacity limestone basalt granite

- Weight Of Cft Concrete In Which Sand Crush

- high capacity of vertical shaft impact crusher parts in hot sale

Stationary Crushers

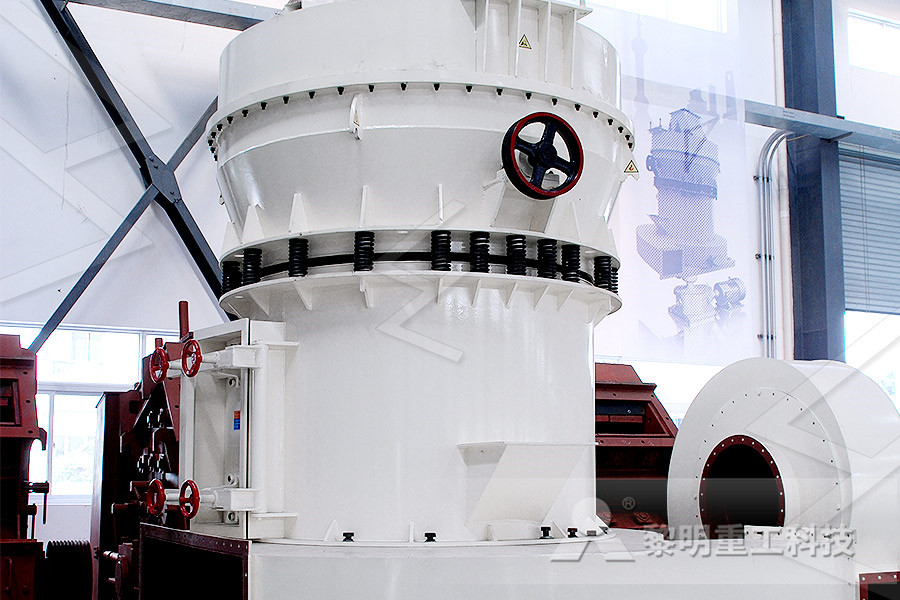

Grinding Mill

VSI Crushers

Mobile Crushers