manufacturing procedure for ball mills

manufacturing procedure for ball mills

manufacturing procedure for ball mills manufacturing procedure for ball mills manufacturing procedure for ball mills High energy ball milling process for nanomaterial synthesis It is a ball milling process where a powder mixture placed in the ball mill is manufacturing procedure f Minerals Home; If N is taken to be the gross mill power, values of the factor c in wet grinding mills will be rod mills 1/1800 ball mills, grate discharge 1/1200 ball mills, overflow type 1/1470 pebble mills 1/1200 W for rod and ball mills shall be taken as the weight of the rod or ball charge, ie the weight of the pulp is Grinding Mill Design Ball Mill Manufacturermanufacturing procedure for ball mills High energy ball milling process for nanomaterial synthesis It is a ball milling process where a powder mixture placed in the ball mill is manufacturing procedure for ball millsTwo fluted end mills can be used to plunge into a workpiece like a drill 2 and 3 flutes are generally for aluminum, 4 flutes is better for stainless steel More flutes are better cutting, but come at a higher price End mills with more than two flutes should not be plunged into the work Fillets can be produced with ball end millsUnit 1: Tramming the Head – Manufacturing From kettles to flash calcining, cage mills, hammer mills, ring ball mills and imp mills, our knowledge and experience in the industry allows us to design a system that Gyptech Mill Calcining Gypsum Technologies

Ball Mill Maintenance Installation Procedure

Ball Mill Lubrication Procedure TRUNNION BEARING LUBRICATION For the larger mills with trunnion bearings provided with oil seals, we recommend flood oil lubrication This can be accomplished by a centralized system for two or more mills, or The smock and tower mills, built by the Dutch and British prior to the twentieth century, use many of the same materials used for the construction of houses including wood, bricks and stones The main body of the fantype mills is made with galvanized steel This process of treating steel makes it How windmill is made making, history, used, CITIC HIC has received an order for 7 x Ball Mills Ø55m x 88m LG – 4,500kW togather with a single PXZ1500 Primary Gyratory Crusher for Projects in Brazil 30 March 2009 China National Gold GroupCITICHeavy Industries Co Ltd A ball mill is one kind of grinding machine, and it is a device in which media balls and solid materials (the materials to be ground) are placed in a container The materials are ground by moving the container Because the structure of ball mills is simple and it Design Method of Ball Mill by Sumitomo Chemical Co, In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills 911 Metallurgist

Design Method of Ball Mill by Sumitomo Chemical Co,

A ball mill is one kind of grinding machine, and it is a device in which media balls and solid materials (the materials to be ground) are placed in a container The materials are ground by moving the container Because the structure of ball mills is simple and it Ball milling is a way to exfoliate graphite using lateral force, as opposed to the Scotch Tape or sonication that mainly use normal force Ball mills, like the three roll machine, are a common occurrence in industry, for the production of fine particles During the ball milling process, there are Ball Milling an overview ScienceDirect Topics Roughing uses round inserts to do the initial work for removing most of the material Ballnose end mills are the perfect fit for semifinishing and finishing Such work will largely benefit from milling, as 4 and 5axis technology can considerably quicken the operations as well as provide better quality Gear milling Milling a Complete Guide to Understand the the rolls and refeeding it into the nip until all the ingredients are added Mills are used not only for blending of compound (open mill mixing) but also warming of premixed compound (known as warming or cracker m ills), or for cooling compound mixed in an internal mixer (known as dump mills)Introduction to rubber processing and safety issuesXinhai provides mineral processing technology, equipment manufacture and onestop service for mineral processing plant, which solve many problems for mine investors Xinhai equipment mainly include: ball mills, flotation, thickeners, and so onMineral Processing, Equipment Manufacturers, Ball

Unit 1: Tramming the Head – Manufacturing

Two fluted end mills can be used to plunge into a workpiece like a drill 2 and 3 flutes are generally for aluminum, 4 flutes is better for stainless steel More flutes are better cutting, but come at a higher price End mills with more than two flutes should not be plunged into the work Fillets can be produced with ball end mills 2 Sugar manufacturing operations A sugar mill is a large factory used to produce raw sugar and other products from sugar cane Mills are made up of a range of industrial plant such as boilers, storage and processing vessels, crushing and hammer mills and Sugar mill safety Home WorkSafeqldgovauCustom Milling Consulting, Inc is a single source for all your wet milling/mixing needs With Formulation Development, Toll Processing, Horizontal Mill, Batch Mill, Planetary Mixers and Turnkey Systems, CMC can offer the right solution Call us today at 6109260984!Media Mills, Mixers, Dispersers Custom Toll The manufacturing facility of the future Our Florence, Kentuckybased headquarters doesn’t just produce Americanbuilt and designed machines, it also demonstrates our Mazak iSMART Factory concept, a plantwide system centered on machine connectivity and freeflow data sharing that sets an industry precedent for improved production efficiencyWelcome to Mazak CorporationRETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and

Milling a Complete Guide to Understand the

Roughing uses round inserts to do the initial work for removing most of the material Ballnose end mills are the perfect fit for semifinishing and finishing Such work will largely benefit from milling, as 4 and 5axis technology can considerably quicken the operations as well as provide better quality Gear millingTwo fluted end mills can be used to plunge into a workpiece like a drill 2 and 3 flutes are generally for aluminum, 4 flutes is better for stainless steel More flutes are better cutting, but come at a higher price End mills with more than two flutes should not be plunged into the work Fillets can be produced with ball end millsUnit 1: Tramming the Head – Manufacturing the rolls and refeeding it into the nip until all the ingredients are added Mills are used not only for blending of compound (open mill mixing) but also warming of premixed compound (known as warming or cracker m ills), or for cooling compound mixed in an internal mixer (known as dump mills)Introduction to rubber processing and safety issuesThe mixture of ore and water is further broken up in two ball mills, which are like a rod mill except steel balls are used instead of rods The slurry of finely ground ore that emerges from the final ball mill contains particles about 001 in (025 mm) in diameterHow copper is made material, used, processing, Because of consumer acceptance of our quality we kept adding Solid Carbide Drills, Solid Carbide End mills, Ball nose End Mills, Carbide Cutting Tools etc in Carbide Tools we provide the right part, at the right price, on timeevery time Our present network comprises of more than 20 Carbide Cutting Tools Manufacturer and Supplier

A suitable laboratory mill for every application RETSCH

A reliable and accurate analysis can only be guaranteed by reproducible sample preparation For these tasks RETSCH offers a comprehensive range of the most modern mills and crushers for coarse, fine and ultrafine size reduction of almost any material Manufacturing of Tools MEPR manufactures all kind of cutting tools like end mills, drill bits, profile cutters, taper tools, reamers or special tools We design and build our own tools geometry ranging from 2mm to 25mm diameters for smooth machining of Manufacturer Of Cutting Tools In UAE Falcon GroupThe manufacturing facility of the future Our Florence, Kentuckybased headquarters doesn’t just produce Americanbuilt and designed machines, it also demonstrates our Mazak iSMART Factory concept, a plantwide system centered on machine connectivity and freeflow data sharing that sets an industry precedent for improved production efficiencyWelcome to Mazak Corporation Feed Industry HACCP Auditor Manual Version 3, May, 2011 (h) Monitor means to conduct a planned sequence of observations or measurements to assess whether a Feed Industry Hazard Analysis and Critical Control Point

- tempat jual mobile crusher

- tungsten carbide crusher machine manufacturer

- wheeled loading shovel

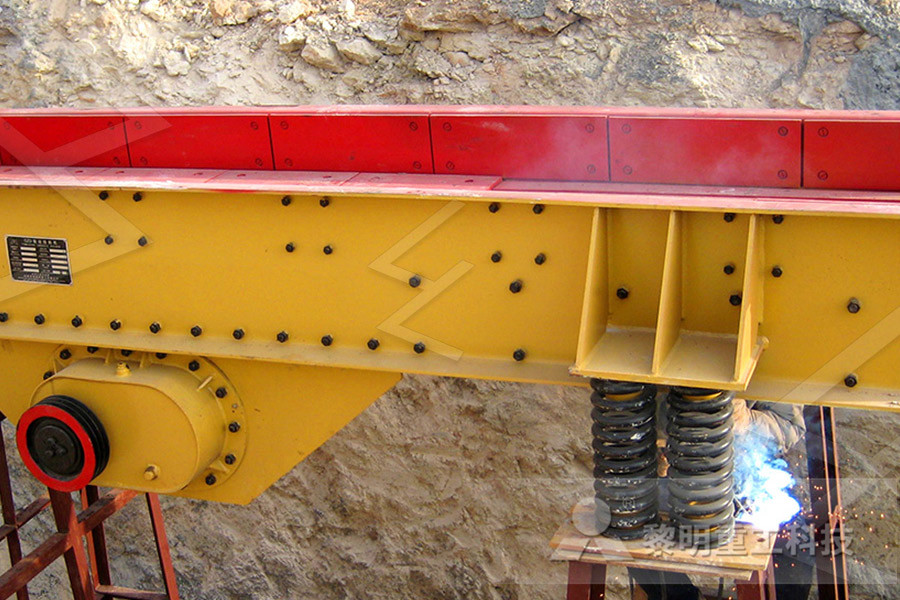

- vibrating feeder installation

- aggregate sand washer gator al crusher russian

- fashion ruby stone brooches

- lead slag crushing plant manufacturer

- crusher sale dubai used

- used road work equipment for sale malaysia

- al india promotion list eee and m list

- pengertian dari type ne crusher

- used mobile vibrating screen for sale

- stone crushers for sale china

- aggregate supplliers in mumbai

- pembuatan ball mill balls di surbaya

- crusher parts nutation

- pe x jaw crusher double toggle

- crusher plant in mumbai

- ne crusher spsifiion

- Hammer Crusher Ykn Vibrating Screen Magnetic Separation Machine

- blow bar crushers spares india

- pasir kurang mills untuk silika penggilingan di meg

- great wall crusher roller crusher

- form of district price fixing mmittee for quarry

- Pabrik Semen Di Andhra Pradesh Daftar Sbm Mining

- artificial sand plants in India

- used small rock crusher stone crusher mobile crusher for s

- 100tph perakitan crusher agregat

- China New Star Stone Company

- fae rock and stone crusher stch for sale

- hammer mill capacity crusher

- gold and diamonds equipment

- image of a iron ore crushers plant

- mpact crushers for sale

- soda blast equipment for sale canada

- south african rock crusher mobile units for mining

- gold mining in alaska

- origion of banded magnetite quartz ore

- wet grinding environment friendly

- grinding slurry limestone

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers