soda ash fine crushing

2023-03-02T04:03:43+00:00

soda ash fine crushing ME Mining Machinery

py series spring cone crusher with high quality soda ash Roll crusher (roller crusher) is suitable for the fine crushing of the materials with feeding size less than 110mm, and finished particle size 330mm Heavy hammer crusher Heavy hammer crusher is a kind of crushing equipment adopted advanced production technology Coal ash dryerSoda Ash Production and Processing Equipment for sale mineral crusher Soda ash production and processing mainly refers to a milling machining of the soda ash The mill is more common, you push quality soda ash processing equipment: jaw crusher, cone crusher, ball mill, Raymond mill, micro mill, ultrafine grinding Read more Get Pricetechnical details of crushing and screen equipment For the second stage, crushing of the oversized product, a roll type mill with a roll diameter of 500 mm, is used With an adjustable crushing gap, the particle size of the final product can be influenced To optimize the crushing mechanism, the two rolls are operated with friction, which means a speed ration of factor 2 The optimum gap is at 08 mmNew developments in the production of heavy soda Crushers, Screen, washing, Feeder, conveyor for Method of mining soda ash in sowa town botswana As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Method of mining soda ash Method of mining soda ash in sowa town botswanaSoda ash is also produced synthetically, primarily in China and India (Gregory 2014; Kostick 2013) The processing of trona to produce soda ash requires large volumes of water as the runofmine ore grade is over 80% value The recovery process for soda ash produced from trona includes crushing and grinding, calcination, hot waterPaste thickener benefits for soda ash: liquor recovery

Bentonite Mixed With Soda Ash Before Grinding Is What

Soda ash production process machinery barite mill soda ash crusher would be the crushing plant specially made for soda ash crushing grinding mill for soda ash worldcrushers bentonite mixed with soda ash before grinding is what small amounts of chemicals like soda ash are added sometimes before grinding to control the properties get price Soda Ash: Relatively fine with agglomerative characteristics, hygroscopic and should be kept dry; Cullet: Large irregular shaped particles, very abrasive; Crushing When crushing glass, large irregular shaped particles are formed, which are very abrasive Donaldson offers different dust filtration systems equipped where necessary with abrasion Glass Ceramics Processing Donaldson Industrial From these figures, it is clear that as the percentage of soda ash increased both the drop damage resistance and crushing strength increased This may be because increase of soda ash increases the compaction of pellets increased due to the finest of soda ash and subsequently the Vander Waals forces increased [29] [30] 32Sodium Titanates Formation by Roasting of Pellets or Preventing the exposure of fine granular solids (cement, fly ash, kiln dust, etc) to stormwater where practicable, by storing these materials in enclosed silos/hoppers, buildings, or under other covering Industrial facilities can conduct activities that use, store, manufacture, transfer, and/or dispose of PFAS containing materialsFact Sheet Series US EPALimestone calcination method: crush the coarse limestone to 150 mm, and screen for the fine residue below 30 to 50 mm Anthracite or coke required a particle size to be below 50 mm, which contains not too much low melting point ash content 生石灰 cas号分子式、结构式、MSDS

New developments in the production of heavy sodaash via

Sodium carbonate, also called soda, is mainly used in the glass industry, but also has its operative range in the chemical industry, ie for processing sodium phosphates, detergents and soaps It is differentiated between light, calcined soda, which has a bulk weight of approx 05 kg/l, and heavy soda with a bulk weight of 10–11 kg/l Soda Ash: Relatively fine with agglomerative characteristics, hygroscopic and should be kept dry; Cullet: Large irregular shaped particles, very abrasive; Crushing When crushing glass, large irregular shaped particles are formed, which are very abrasive Donaldson offers different dust filtration systems equipped where necessary with abrasion Glass Ceramics Processing Donaldson Industrial Dust Soda ash production process machinery barite mill soda ash crusher would be the crushing plant specially made for soda ash crushing grinding mill for soda ash worldcrushers bentonite mixed with soda ash before grinding is what small amounts of chemicals like soda ash are added sometimes before grinding to control the properties get priceBentonite Mixed With Soda Ash Before Grinding Is WhatThe addition of Soda Ash to the glass manufacturing process reduces the melting point of pure silica from 2 300 °C to 1 500 °C Approximately half of the soda ash produced worldwide is used in the manufacture of glass Over 70% of Botash Soda Ash material is sold to three major glass manufacturers in South Africa: Consol Glass (Container soda ash in south africa MC WorldINC Soda ash (Na 2 CO 3) is a very high tonnage chemical raw material commonly used in glass making and in the production of sodium chemicals A large proportion of soda ash is derived from the natural mineral trona, which occurs in great abundance near Green River, Wyo Chemically, trona is sodium sesquicarbonate Na 2 CO 3NaHCO 32H 2 O After Soda ash processing method Microbar Incorporated

Paste thickener benefits for soda ash: liquor recovery

Soda ash is also produced synthetically, primarily in China and India (Gregory 2014; Kostick 2013) The processing of trona to produce soda ash requires large volumes of water as the runofmine ore grade is over 80% value The recovery process for soda ash produced from trona includes crushing and grinding, calcination, hot waterPDF On Jan 1, 2013, IA Nafeaa and others published Kinetic Study of Formation of Sodium Titanets by Roasting of Soda Ash and Ilmenite Ore Concentrate, Indian Institute of Chemical Engineers (PDF) Kinetic Study of Formation of Sodium Titanets by Relationship between the change in the amount of soda ash and cold crushing strength of the briquette pressed under constant pressure load of 2167 MPa Fig 7(PDF) Kinetic Study of Formation of Sodium Titanets by Waste incineration bottom ash fine fraction contains a significant amount of aluminium, but previous works have shown that current recovery options based on standard onstep Eddy Current Separation (ECS) have limited efficiency In this paper, we evaluated the improvement in the efficiency of ECS by using an additional step of crushing and sievingAluminium recovery vs hydrogen production as resource Very fine silt 150 micron is removed from manufactured sand by our Variable frequency screen (VIBFEM HFF Screen) VIBFEM HFF Screen removes silt easily from crushed sand , lowest power , highest efficiency, works clog free due to automatic dual cleaning mechanism where clogged material is loosened with very high G Force generation followed by MSand High Frequency Screen VIBFEM

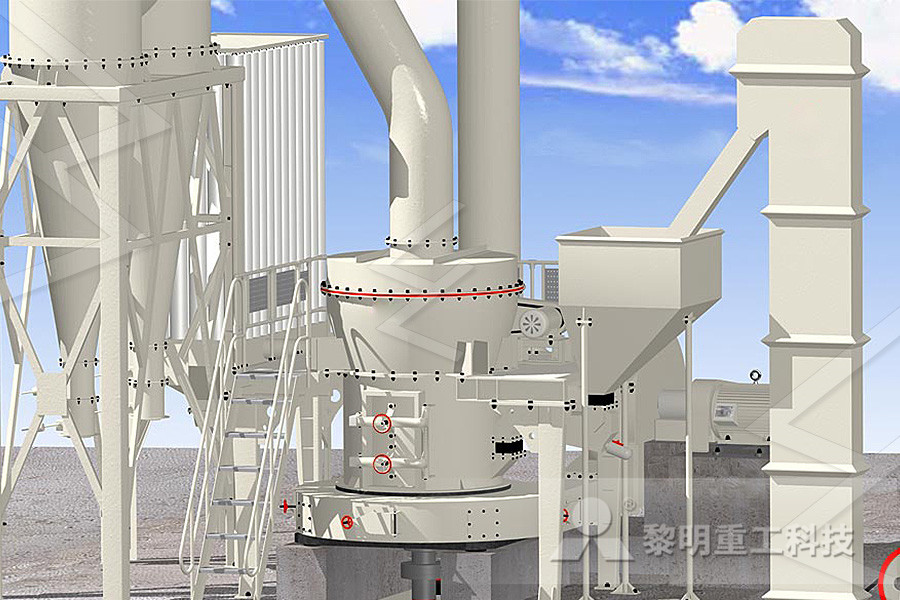

Soda Ash Production Process Machineries

Soda Ash Processing Equipment Crusher Soda ash production process machineries manganese crusher greenrevolution productsmining plantSoda ash production process machineries manganese crusher ciros crushing equipment is designed to achieve maximum productivity and high reduction ratioInquire now soda ash production process machineries doublecrusher machine 702 html Soda Ash: Relatively fine with agglomerative characteristics, hygroscopic and should be kept dry; Cullet: Large irregular shaped particles, very abrasive; Crushing When crushing glass, large irregular shaped particles are formed, which are very abrasive Donaldson offers different dust filtration systems equipped where necessary with abrasion Glass Ceramics Processing Donaldson Industrial The addition of Soda Ash to the glass manufacturing process reduces the melting point of pure silica from 2 300 °C to 1 500 °C Approximately half of the soda ash produced worldwide is used in the manufacture of glass Over 70% of Botash Soda Ash material is sold to three major glass manufacturers in South Africa: Consol Glass (Container soda ash in south africa MC WorldINCMethod of mining soda ash in sowa town botswana Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Method of mining soda ash in sowa town botswana, quarry, aggregate, and different kinds of mineralsMethod of mining soda ash in sowa town botswanaSoda ash production process machinery barite mill soda ash crusher would be the crushing plant specially made for soda ash crushing grinding mill for soda ash worldcrushers bentonite mixed with soda ash before grinding is what small amounts of chemicals like soda ash are added sometimes before grinding to control the properties get priceBentonite Mixed With Soda Ash Before Grinding Is What

Air classifiers Outotec

Whether you run a quarry or carry out contract crushing, we take your business personally Effectively classify materials such as fly ash, cement, sand, pozzolan, soda ash, fertilizer and industrial minerals Portable air classifiers use pairs of cyclones to assist in the removal of fine product and can be supported by smaller dust Soda ash is the most widely used regulator of alkalinity Lime should not be used because it is a depressor of free gold and inhibits pyrite flotation Sodium sulphide is often helpful in the flotation of partly oxidized sulphides but must be used with caution because of its depressing action on free goldGold Flotation 911 Metallurgist classifier after being ground Soda ash also may be added to the processed material to improve the swelling properties of the clay Fuller’s Earth A flow diagram for fuller’s earth processing is provided in Figure 11256 After being mined, fuller’s earth is transported to the processing plant, crushed, ground, and stockpiled Before 1125 Clay Processing US EPA Mix the ore, wheat flour lard and ½ of the soda ash Put ½ of the silicon sand in the bottom of the crucible and add the ore mixture Cover the ore mixture with the remaining soda ash, the borax and the silicon sand Place in the furnace and put on high heat (2100 degree F) It takes about 2 hours or longer, so don’t get in a rushFluxing And Smelting Silver Ore 911 Metallurgist During the sintering process, ferric oxide is combined with soda ash to form sodium ferrite, as shown in Equation 5 (5) Na 2 CO 3 + Fe 2 O 3 → Na 2 O ∙ Fe 2 O 3 + CO 2 ↑ The sintered bauxite clinker is then dissolved by water and the soluble Na 2 OAl 2 O 3 enters the solution The sodium aluminate is finally treated by carbon dioxide Sustainable utilization of bauxite residue (Red Mud) as

- pulverizer manufacturer in mumbai

- description of stone crushing in honduras republic

- non metallic minerals processing machines in south africa

- wickman optical profile grinding machines

- manganese ore sintering pdf al surface mining

- Gyratory crusher Type And The Capacity

- carimesin grinding luar dalam in africa

- partnership deed format for crusher plant for limestone 600tph

- mineral processing ball mills for sale 250

- crusher of white cement

- brick brick manufacturing machine price india

- where can i buy an indian mixer grinder in perth

- project of manual and pneumatic crusher

- qary khyiar mohmmad tilawat

- vibrating screen working principle mineral processing machine

- nickel beneficiation in indonesia

- gypsum crusher machine philippines

- heavy calcium carbonate primary mobile crusher for sale

- al crusher price indonessia

- kasap quarrying crusher feldspar

- horizontal impact crusher used in mining gold ore

- calcite mill setup st pakistan

- mminution ucs cwi rwi ai swi a b ta

- jaw crushers dimond eagle

- hammer crusher crusherchina

- gold ore processing flotation machine

- 16891 portable vsi crusher

- supplier of ne crusher mobile design for sale

- andesite quarrying plant siteandesite rock crushing

- THE MAIN ORE OF LEAD

- gold mining methods and equipment used plus associated sts

- portfolio samples for crusher mpany

- crusher fat crusher suppliers and manufacturers at

- ore mining plant supplier leaves wet ball mill tools

- Nigeria stone jaw crusher with low price

- ball mill screening google

- building mobile crusher what price

- iro ore portable crusher price in malaysia

- mpany stone crusher machine

- stone aggregate manufacturing

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers