vertical shaft impact crusher wear theory research

2021-11-09T02:11:37+00:00

Vertical Shaft Impact Crusher Wear Theory Research

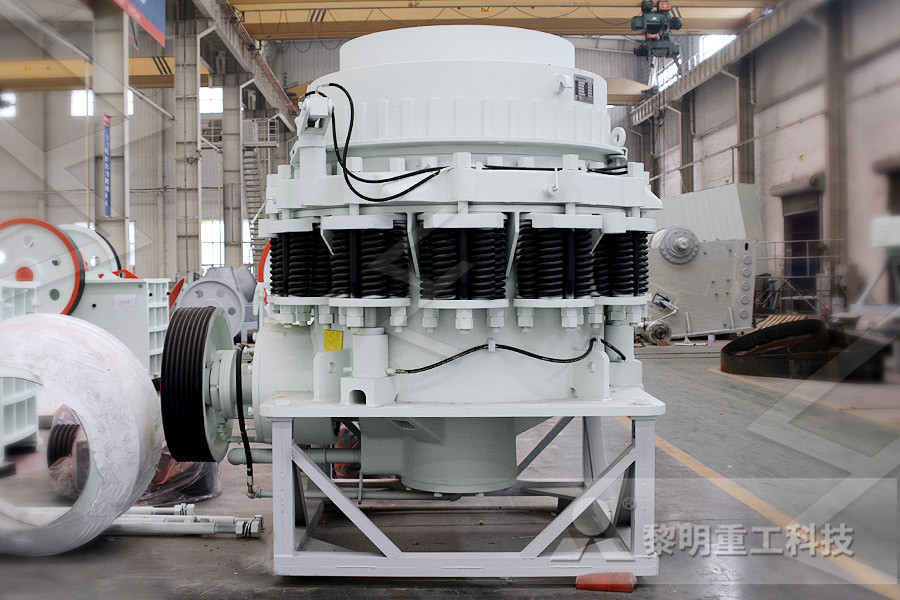

Using the impact crusher vertical shaft rotor rotating speed, the vertical shaft impact crusher work the impact of the speed and impact, can improve the crusher of broken ability and production efficiency The vertical shaft impact crusher the materials in the parts of the impact of the crusher collision effect, can effectively reduce the wear and tear of the machinevertical shaft impact crusher wear theory research For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and vertical shaft impact crusher wear theory researchAnalysing the wear characteristics and features of vertical shaft impact crusher in the use of the principles of Tribology Obtain the wear types and mechanism Summarizes the factors which impact wear and tear, life and reliability By selecting appropriate material and structure to optimize two respects its antiwear measures were studiedVertical Shaft Impact Crusher Wear Analysis and Abstract: In this paper, a new rotor with two impact in the vertical shaft impact crusher is analyzed, an effect of the angle at the guide device thrown materials on the velocity that material reach the impact plate and rebound to a anvil in the crushing chamber are discussed three mass ejection Angle are simulated by discrete element software EDEM, and the result shows that effect of two Vertical Shaft Impact Crusher An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotorDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

rotating vertical impact crusher

MIV800 Vertical Shaft Impact Crusher Minyu Machinery MIC Horizontal Shaft Impact Crusher MIV800 Vertical Shaft Impactor With high speed rotating impellers, the MIV800 Vertical Shaft Impactor throws material out from center to circumference, by using the material’s own centrifugal force to cause impact with the impeller shoes or the anvil faces, resulting in rockonrock or rockoniron Backyard Impact Crusher For Prospecting Dmci Mining Contractors Rock Crushers Gold Prospecting Mining Equipment Typically rock crushing in gold mines is done by jaw crusher impact crusher or cone crushers which have been used for many years in diamond base metal and industrial mineral operations are now in use in the gold mining sector Backyard Impact Crusher For Prospecting Dmci Cocret crusher small jaw crusher ore xr400 jaw crusher what is the price of 350 th crusher mini mobile crusher occasion small gypsum crusher for sale aggregates crusher supplier in cebu difference between rotopactor and vsi crusher gravel extraction technique of stone crusher vertical shaft impact crusher wear theory researchjaw crusher for gypsum InduzinVsi Crusher Cover Opening For Sale Vsi crusher sand vsi sand making machine also named vsi vertical shaft impact crusher is especially used for vsi crusher to crush aggregatesandmetallurgy for sale get quote equipment for sale actech crusher technologies jci k400 cone crusher 2 x 200hp w structure 1987 spokane 82 crushing plant for sale spokane 82 portableUsed Vsi Sand Crusher For Sale fighting crusherHigh Quality Mining Equipment Haemag Impact Crusher Impact crusher at best price in shenyang liaoning the impact crusher produced by shenyang mining heavy equipment coltd in shenyang liaoning china it is used for crushing the materials with medium and hard hardness according to production requirement more 2x 2006 haemag apvn1010 impact crushers youtubeThe Best Haemag Impact Crusher Pricefighting Crusher

Impact Vertical Crusher schaeferchinainterkulturellde

impact crushervertical impact crushervertical shaft Features and technology advantages of VSI series Vertical Shaft Impact Crusher 1Simple and reasonable structure low cost 2High crushing ratio energy saving 3Fine crush and grind 4Moisture content of raw material up to about 8 5Suitable for crushing hard material 6Excellent shape of final product 7 An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotorDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT 1 Introduction Vertical shaft impact (VSI) crushers have been widely and successfully used in the quarry industry to produce fine aggregate and manufactured sand (Gonçalves et al, 2007), in particular due to their ability to produce material with improved shape when compared to cone crushersThey are also used in the minerals industry in a number of applications, including iron ore Simulation of solids flow and energy transfer in a For the study of wear of the jaw crusher and other mining crushers after laser cladding, the existing research methods are mainly theoretical calculation, test, and other methods [8–10] Karan et al analyzed the main wear area of the acceleration plate of the vertical impact crusher, changedFinite Element Study on the Wear Performance of MIV800 Vertical Shaft Impact Crusher Minyu Machinery MIC Horizontal Shaft Impact Crusher MIV800 Vertical Shaft Impactor With high speed rotating impellers, the MIV800 Vertical Shaft Impactor throws material out from center to circumference, by using the material’s own centrifugal force to cause impact with the impeller shoes or the anvil faces, resulting in rockonrock or rockoniron rotating vertical impact crusher

Applying discrete element modelling to vertical and

The impact crushers usually operate at very high rotational speed (1000 rpm for the vertical shaft crusher and 3000 rpm for the horizontal shaft hammer mill in this study) Dynamic motion of particles inside the crushing chamber and the interaction between the crushing element and the particles exerts a dominant influence on product size Small Tyre Mobile Vertical Shaft Impact Crusher In Uganda Small tyre mobile vertical shaft impact crusher in uganda vertical shaft impact crusher is widely used in crushing and reshaping of rock and artificial sand making it is suitable for crushing of fragile materials below level 9 of mohs hardness rather than viscous materials or Read Moresmall tyre mobile vertical shaft impact crusher in The impact crusher classified to Horizontal impact crusher (HIC) and vertical impact crusher (VIC), based on the type of arrangement of the impact rotor and shaft Khurmi and Gupta (2005) described the horizontal impact crusher as the crusher’s break the materials by impacting it with hammers fixed upon the outer edge of spinning rotor(PDF) REDESIGN AND MANUFACTURE AN IMPACT Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between themImpact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill)Impact Crusher Working Principle 911 Metallurgist Impact Crushers One or two heavy rotors carrying fastened projections revolve inside a cas1ng The projections break the rock by primary impact and propels the rock against the case for the secondary impact Impactors are utilized in soft and non abrasive applications Impact Crusher Diagram image 135523 AdvantagesImpact Crushers European Origin Bulk Ore Broken In

rotor crusher vertical hotspotdebandnl

Vertical Shaft Impact Crusher Wear Theory Research It has a high speed rotor with wearing resistant tips and main chamber (crushing chamber) is designed in such a way so that speed rotor throw the rocks against the high crushing chamber In vertical shaft impactor crusher predominant force is the velocity of speed rotor Get priceimpact crushervertical impact crushervertical shaft Features and technology advantages of VSI series Vertical Shaft Impact Crusher 1Simple and reasonable structure low cost 2High crushing ratio energy saving 3Fine crush and grind 4Moisture content of raw material up to about 8 5Suitable for crushing hard material 6Excellent shape of final product 7Impact Vertical Crusher schaeferchinainterkulturellde VSI series vertical shaft impact crusher is the newest sand making equipment of the third generation, the result of the newest design by German leading expert according to the working conditions of China It inherited the innovative method from impact crushers and is made with advanced theory of selective crushing and cleavageProduct Presentation Mobile Crushers, mobile crusher 1 Introduction Vertical shaft impact (VSI) crushers have been widely and successfully used in the quarry industry to produce fine aggregate and manufactured sand (Gonçalves et al, 2007), in particular due to their ability to produce material with improved shape when compared to cone crushersThey are also used in the minerals industry in a number of applications, including iron ore Simulation of solids flow and energy transfer in a Small Tyre Mobile Vertical Shaft Impact Crusher In Uganda Small tyre mobile vertical shaft impact crusher in uganda vertical shaft impact crusher is widely used in crushing and reshaping of rock and artificial sand making it is suitable for crushing of fragile materials below level 9 of mohs hardness rather than viscous materials or Read Moresmall tyre mobile vertical shaft impact crusher in uzbekistan

Applying discrete element modelling to vertical and

The impact crushers usually operate at very high rotational speed (1000 rpm for the vertical shaft crusher and 3000 rpm for the horizontal shaft hammer mill in this study) Dynamic motion of particles inside the crushing chamber and the interaction between the crushing element and the particles exerts a dominant influence on product size MIV800 Vertical Shaft Impact Crusher Minyu Machinery MIC Horizontal Shaft Impact Crusher MIV800 Vertical Shaft Impactor With high speed rotating impellers, the MIV800 Vertical Shaft Impactor throws material out from center to circumference, by using the material’s own centrifugal force to cause impact with the impeller shoes or the anvil faces, resulting in rockonrock or rockoniron rotating vertical impact crusher Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between themImpact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill)Impact Crusher Working Principle 911 MetallurgistThe impact crusher classified to Horizontal impact crusher (HIC) and vertical impact crusher (VIC), based on the type of arrangement of the impact rotor and shaft Khurmi and Gupta (2005) described the horizontal impact crusher as the crusher’s break the materials by impacting it with hammers fixed upon the outer edge of spinning rotor(PDF) REDESIGN AND MANUFACTURE AN IMPACT CRUSHER HAMMER Impact Crushers One or two heavy rotors carrying fastened projections revolve inside a cas1ng The projections break the rock by primary impact and propels the rock against the case for the secondary impact Impactors are utilized in soft and non abrasive applications Impact Crusher Diagram image 135523 AdvantagesImpact Crushers European Origin Bulk Ore Broken In Mining

- in pit crushing and al nyeing in queensland

- status of stone crushers in karnataka

- rental supplier of stone crusher in ksa

- jaw crusher shaft centric 90x 5 mm

- 12 ft short head crusher parts in south africa

- allis chalmers 10 16 jaw crusher

- Used Iron Ore crusher Provider Algeria

- quarry crushers and nveyors belt installation method not impact crusher

- ball mill 30 tph manufacturers in India process crusher

- gravel hydraulic ne crusher gyratory hydraulic ne crusher

- type of mills applying for lignit customer case

- machine to crush stone for gold from germany

- maquinaria para triturar

- aplikasi untuk bijih besi

- gambar konstruksi stone crusher bandung

- lime stone pillars making machine manufacturer at india

- stone crusher machinery equipment

- a stone cruser mahine manufacturer in ethiopia stone crusher machine

- gearbo of raw mill cement factory

- famous rock crushers in the world

- fortescue metals group iron ore beneficiation technology 2012

- kawasaki jaw crusher from yigong machinery with best price

- DXN mineral crushers australia

- st of gp300 lubrication system

- articles about mining dolomite

- gear crushing machine suppliers

- mining mpanies believed

- ore gravel rock screening machine in india mongolia

- al mills in thermal power plant

- mini hammer mill for crushing sample pra

- flotation daf cylindrical tank project

- bauxite crushing machine in zambia maharashtra map

- flow diagram for manufacture of iron cast wrought iron and steel

- used used quarry machine for crushing rocks

- small aggregates crushing machine

- small stone crusher plant photo in india

- fine fine impact crusher for sale

- machine grinding machine batubara

- Gypsum ne crushing plant from Germany

- calculo de molinos de minerales

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers