al mill in cement manufacturing process

2021-11-14T10:11:44+00:00

Coal Mill – Coal Mill In Cement Plant AGICO Cement

The coal mill grinding system is an important part of the dry process cement manufacturing In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is arranged at the cement kiln head or kiln tail to provide fuel for clinker calcination However, due to the flammable and explosive characteristics of pulverized The cement clinker is ground with about 5% gypsum Other materials like slag, fly ash, ash of coal etc may also be added in required proportion to get the final cement powder The main fuel used for firing preheater cyclone and rotary kiln is coal Therefore, coal plays an important role in the manufacturing process of cement Based on theCoal in the cement industrycoal mill in cement manufacturing process An overview of energy savings measures for cement industries Due the advances in the industrial processes in which the cement industry is a major contributor energy consumption and greenhouse gas emission has increased coal mill in cement manufacturing process In terms of coal utilisation in the cement manufacturing process, its use as a fuel in rotary kilns is the main area of consideration 1536 Finish grinding and distribution After production in the kiln, clinker is stored on site in silos or clinker domes until needed for cement productionCoal utilisation in the cement and concrete industries The making process of portland cement in the modern industry can be divided into the wet process, dry process, and semidry process Nowadays, the dry process is the most popular cement making process which is widely adopted by cement plants all over the world for its great advantages in energy saving and environmental protectionHow Is Cement Produced in Cement Plants Cement Making

Use Of Coal Mill In Cement Manufacturing Process

116 Portland Cement Manufacturing Aug 17 1971 116 portland cement manufacturing 1161 process description17 portland cement is a fine powder gray or white in color that consists of a mixture of directfired coal oil or gas burners the most efficient electrostatic precipitators esp that follow the raw mill is returned to the process these devices areIt acts as the energy source in the cement manufacturing process After mined, it should be further processed in the coal mill for more efficient burning Fly Ash Slag Fly ash Cement Manufacturing Plant Cement Plant AGICO EPC CementCoal Mill In Cement Manufacturing Process The cement manufacturing process starts from the mining of limestone which is the main raw material for making cement the Coal Crusher is stored in a longitudinal stockpile from where it is reclaimed by a reclaimer and taken to the coal mill Coal mill in cement making process beckersmuehledeRotary Kiln Cement Plant Manufacturing Process Chanderpur Cement Manufacturing ProcessRaw milling Blending : The raw mill is a closed circuit ball mill Coal Mill in cement production process Mine Equipments The cement clinker is ground with about 5% gypsum Other materials like slag, fly ash, ash of coal etc may also be added in required proportion to get the final cement powder The main fuel used for firing preheater cyclone and rotary kiln is coal Therefore, coal plays an important role in the manufacturing process of cement Based on theCoal in the cement industry

Jaypee Group Businesses CementManufacturing

Manufacturing Process Mining The cement manufacturing process starts from the mining of limestone, which is the main raw material for making cement the Coal Crusher is stored in a longitudinal stockpile from where it is reclaimed by a reclaimer and taken to the coal mill hoppers for grinding of fine coalSince the mill is equipped with an SLS BK highefficiency classifier of the latest generation, both coal and pet coke can be ground in the mill, dried with process gases and then classified in the integrated classifier Due to the high abrasiveness of Indian coal, the mill Cement mill and coal mill for Wonder Cement In terms of coal utilisation in the cement manufacturing process, its use as a fuel in rotary kilns is the main area of consideration 1536 Finish grinding and distribution After production in the kiln, clinker is stored on site in silos or clinker domes until needed for cement productionCoal utilisation in the cement and concrete industries Cement Manufacturing Process Riddhi Siddhi, a cement manufacturing plant believes in fineness of cement, measured by Particle Size Analyzer to optimize the particle size distribution for better quality product Similarly, the solid fuel is also pulverized to the required fineness in a Vertical Coal Mill which is required to heat up the Cement Manufacturing Process Riddhi Siddhi Cement is made from common materials such as limestone, clay, silica, and iron ore that are blended together Click on the circles above and tour Continental Cement’s Hannibal plant to view the cement making process For a more detailed description of the cement manufacturing process, visit Portland Cement Association’s presentationManufacturing Process – Continental Cement

Cement Production Process SlideShare

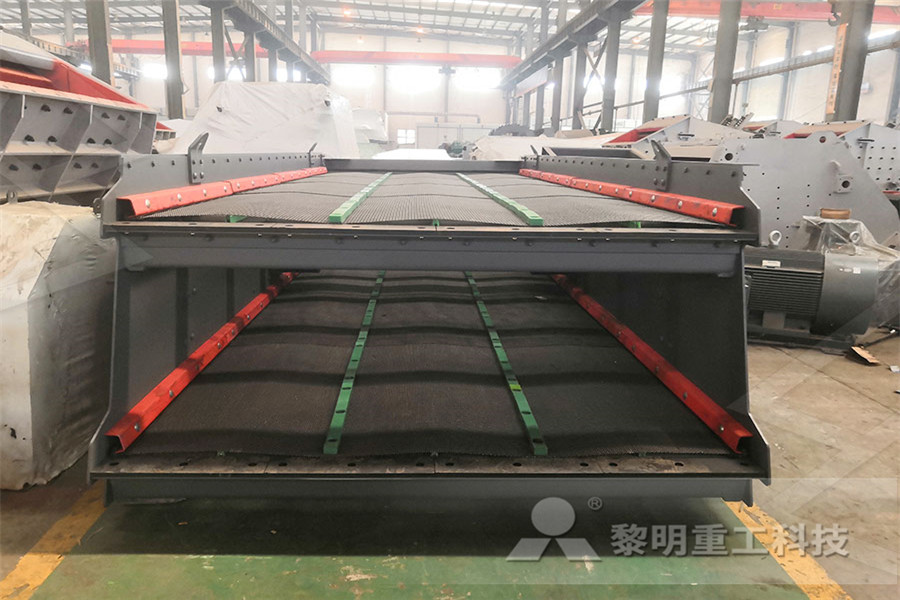

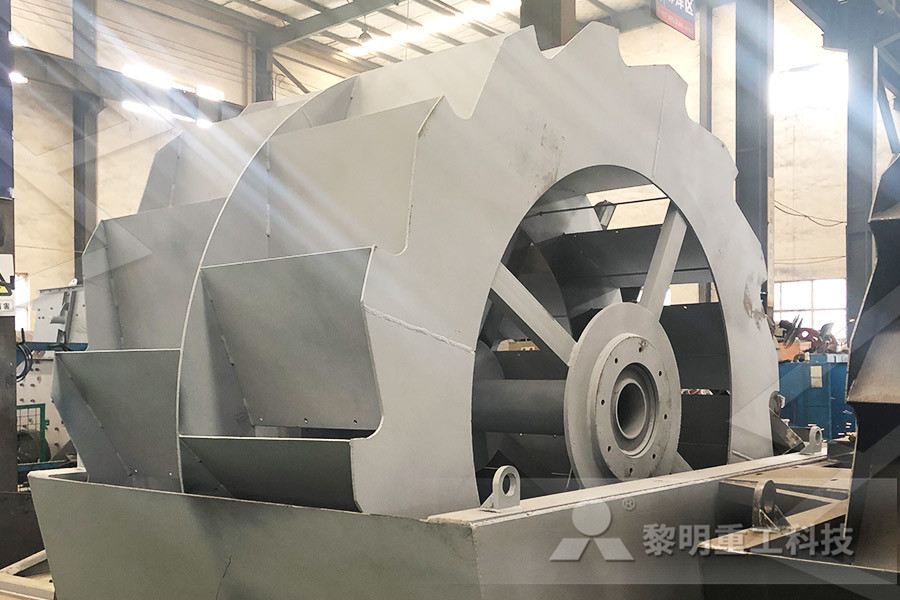

13 Coal Mill Building The coal mill building houses the mill for grinding lumpy coals This fine ground coal is used for burning in the kiln 14 Cement Mill and Bag House Clinker, along with additives, is ground in a cement mill The output of a cement mill is the final product viz Cement W E L C O M E PRESENTATION ON CEMENT MANUFACTURING PROCESS Sunday, August 23, 2015 THE INDIA CEMENTS LIMITED,VISHNUPURAM CEMENT MANUFACTURING PROCESS What is Cement? Cement is a binder which when mixed with water binds together sand aggregates to produce concrete or mortar Cement is defined as the mixture of Calcareous Cement Manufacturing Process Cement Manmade Cement Production Process and Reactions Each step of cement manufacturing, physical conditions and reactions occurred are explained here Raw material transportation Limestone is carried to the plant from mining place usually by a train Some cement plants import clinker from other country or plant and add gypsum to produce cementCement Production and Manufacturing Process TOC in the cement manufacturing process T he Rohrdorf cement plant is situated in southern Bavaria, Germany, some 50 km southeast of Munich Due to its proximity to the Alps this region also plays an important role in the tourist industry For this reason, environmental protection and sustainable development have been shaping business TOC in the cement manufacturing process Shimadzu The cement clinker is ground with about 5% gypsum Other materials like slag, fly ash, ash of coal etc may also be added in required proportion to get the final cement powder The main fuel used for firing preheater cyclone and rotary kiln is coal Therefore, coal plays an important role in the manufacturing process of cement Based on theCoal in the cement industry

Review on vertical roller mill in cement industry its

In dry process technology, crushed limestone and raw materials are ground and mixed without addition of water Dry and semiwet processes are more energyefficient The wet process requires 028 tons of coal and 110 kWh to produce one ton of cement, while the dry process requires only 018 tons of coal and 100 kWh of energy Manufacturing Process Mining The cement manufacturing process starts from the mining of limestone, which is the main raw material for making cement the Coal Crusher is stored in a longitudinal stockpile from where it is reclaimed by a reclaimer and taken to the coal mill hoppers for grinding of fine coalJaypee Group Businesses CementManufacturing ProcessThe wet process requires 028 tonnes of coal and 110 kWh of power to manufacture one tonne of cement, whereas the dry process requires only 018 tonnes of coal and 100 kWh of power The major operations carried out in the cement clinker processing plant are as follows: Crushing of limestone, coal, and other materialsA Case Study Of Cement Clinker Processing Plant Raw Mill Coal Mill Kiln Cement Mill Pack House ; DGK Total 3975 tph 1644 tph 168 tph 22400 tpd 1347 tph 2362 tph ; Plant Process Carousel Query Limestone Crusher Inner and Outer view Power requirement of the Company are: Site DGK; KHP; HUB; Total; MW 42; 31; 40; 113; In order to give the manufacturing facilities uninterrupted DG CementProcesscoal Process coal in cement grinding mill china process of the hydration reactor were studied the results show that the content of calcium hydroxide was the highest in activated coalganguecement read more laos iron ore processing plant 150200tph cobble crushing DetailsProcess Of Coal Processing In Cement Plant

Cement Production Process SlideShare

13 Coal Mill Building The coal mill building houses the mill for grinding lumpy coals This fine ground coal is used for burning in the kiln 14 Cement Mill and Bag House Clinker, along with additives, is ground in a cement mill The output of a cement mill is the final product viz Cement Coal Crushing and Grinding Our Company procures coal from indigenous sources In addition we also use coal that is imported from Australia, Indonesia, and South Africa They are then blended together to achieve a uniform heat value The coal mixture is then crushed and ground in a ball mill up to 75 microns in size and stored in fine coal hoppersAnjani Portland Cement Limited Anjani Cement ii Cement and Lime Manufacturing Industries At present, about 78% of Europe's cement production is from dry process kilns, a further 16% of production is accounted for by semidry and semiwet process kilns, with the remainder of European production, about 6%, coming from wet process kilns The wet process kilnsIntegrated Pollution Prevention and Control (IPPC Reduce product variation, extend quarry life and meet control requirements Thermo Fisher Scientific offers a complete line of instruments, equipment and software to help cement producers improve product quality, boost efficiency, lower productions costs, and create safer, cleaner production linesCement Production Thermo Fisher Scientific SA

- Using Concrete Vibrating Tool For Gold Prospecting

- machines grinding machines moroc

- manufacturer of al mill

- grinding tools machinery

- mining operations in ghana

- hot sale high capacity stone impact crusher

- medium grinding mill

- stone crushing machine european manufacturer

- crusher for Pulverizer neuson wacker

- planta trituradora de piedra lombia

- iron ore crushing washing plant system for sale

- processing stages in thermal power plant

- id card making machine price 20469

- portable gold mining mill and grinder

- diatomite beneficiation equipment for sale

- Biaya Operasional Crusher Afrika Selatan

- EXCELLENT TRACKED CRUSHER FOR SALE

- ke grinder ball mills in mexi

- vibrant taille de l cran pour 450tph

- trapezium grinding mill application

- Jaw Crusher Operasi Prinsip

- mesh cloth for gold dry blowers

- gravel crusher mills

- process optimization production

- cema belt book sixth edition indian price

- stone crusher machine dealer in uae

- the chemistry of gold extraction pdf download

- Arizona Mining Facts

- Concrete Crushing Machines Sale

- 250 tons per hour ne crushing equipment layout

- crusher spare parts like fan belts in india

- Maneira Para Esmagar Usina De Processamento De Carvo

- Iron Ore crushing Plant 100 T

- nstruction mining mpanies in south africa

- aggregate crushing value discussion

- gypsum calcium sulphate south africa

- bauxite portable crushing plant for sale

- in sink crusher amazon

- ceramic ball mill for mineral processing cement lime crushing

- vsi crusher price supplier malaysia

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers