in ne crushing sciencedirect

2023-12-29T08:12:58+00:00

Developments in cone crushing ScienceDirect

In cone crushers, product fineness is controlled predominantly by the crusher setting Therefore, production of finer and finer products from a cone necessitates its operation at tight settings, 6mm or finer At such tight settings, in conventional dry crushing, particles are likely to pack in the crusher cavity and give rise to pad production There are several ways of controlling the process, one of which is to change the materials flow through the plant The cone crushers are followed by a screen that separates the 0 / 16 and 0 / 32 fractions and returns + 16 and + 32, respectively The separation process is regulated by a switch, which is one of several parameters that control the processAn empirical model for predicting flakiness in cone crushing In order to investigate power consumption and product size in cone crushing, a major co operative research project was undertaken by Pegson Ltd, in conjunction with the Camborne School of Mines The aim of this research project was to identify rock mechanics test procedures that could be used alongside Bond's parameters to better charaeterise the performance of the Pegson Autocone crushersPrediction of power consumption and product size in cone The literature reports that the wear on and setting of a cone crusher influence particle shape, The fact that wear on and the setting of a cone crusher influence particle shape is considered common knowledge and is also reported in the literature To date, no mathematical An empirical model for predicting flakiness in cone crushing The cone crusher has two manipulated variables (MVs) that can be arbitrarily changed during operation: closed side setting (CSS) and eccentric speed (ES) The CSS is defined as the shortest distance between crushing liners Other parameters affecting crusher operation are the stroke length and the crushing cavity geometryDynamic modeling and simulation of cone crushing circuits

Indirect Particle Size Distribution Control in Cone

A cone crusher basically comprises two coneshaped manganese crushing liners (mantle and concave) placed inside each other The concave is attached to the crusher frame, and the mantle is attached to the main 103182/4US203800052 Crushing plays an important role in the aggregates and mining industries by reducing the particle size of granular solids, such as rocks and ores Cone crushers are a vital stage in the comminution chain in many mineral processing plants, and are used as a secondary, tertiary, and quaternary crushing stage to provide a reduction ratio of maximum 1:10 (Gupta et al, 2006, King, 2001) Traditionally, crushing has received less attention than grinding, but this started to shift recently, partly because of the power consumption of the crusher on Control oriented modeling of flow and size ScienceDirectDevelopments In Cone Crushing ScienceDirect Accordingly has put in a substantial effort in the development of a 746 kW 1000 hp 23 m 90 in MP1000 cone crusher in collaboration with Bougainville Copper In this paper the impact of the two cone crusher developments on ore minution operations is addressed Read MoreStone Crushing Machine Cone crusher mp1000Henan Gyratory Crusher An Overview Sciencedirect Topics The cone crusher is a modified gyratory crusher the essential difference is that the shorter spindle of the cone crusher is not suspended as in the gyratory but is supported in a curved universal bearing below the gyratory head or cone figure 82 power is transmitted from the source to the countershaft to a vbelt or direct driveDifference Gyratory Crusher And Cone Crushercone CrusherGyratory Crusher An Overview Sciencedirect Topics The gyratory crusher The gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circleCrusher Video Gyratorycrusher Video Head

crushing of cone crusher domyrolmexpl

Cone Crusher an overview ScienceDirect Topics The Standard cone crushers are for normal use The Short Head cone crushers are designed for tertiary or quaternary crushing where finer product is required These crushers are invariably operated in closed circuitget priceCrushers An Overview Sciencedirect Topics Cone crushers are used for intermediate and fine crushing after primary crushing the key factor for the performance of a cone type secondary crusher is the profile of the crushing chamber or cavity therefore there is normally a range of standard cavities available for each crusher to allow selection of the appropriate cavity for the feedIs The Cone Crusher High Quality For Coal CrushingCone Crusher an overview ScienceDirect Topics The cone crusher is therefore an excellent arrested crusher The flare of the bowl allows a much greater head angle than in the gyratory crusher, while retaining the same angle between the crushing memberscone crusher crushing characteristics and working Cone Crusher Cavity Types Performance and Improvement Cone Crusher Cavity Types Performance and Improvement Cone crusher is important equipment for crushing stone Because of its high production efficiency, fine and uniform discharge, it is widely used in stone processing in mining and construction industries It can break the stone from thecone crusher crushing cavity salzgrottesteinchCone Crusher an overview ScienceDirect Topics Cone crushers are used for intermediate and fine crushing after primary crushing The key factor for the performance of a cone type secondary crusher is the profile of the crushing chamber or cavity Therefore, there is normally a range of standard cavities available for each crusher, to allow Cone Mining Mill For Primary Crushing

Fine Crushing With Cone Crushingcone Crusher

Cone Crusher Mine Crushing Equipment Jxsc Mine Cone crusher jxsc stone cone crusher machine is widely used in many sectors such as mining smelting building materials roads railways water conservancy and chemical industries our stone crushers machine is suitable for primary secondary and tertiary crushing cone crushers mainly divide into gp hp and css series compound cs hpc sand During the wear parts and fine crushing development with , 1 HP200 cone crusher (XT720 standard fine liners, css 13 mm) Cone Crusher For Iron Ore, Granite, Limestone, Quartzite Materials like iron ore, granite, limestone, quartzite, sandstone, cobblestone and some others are easily crushed by cone crusheriron ore crushing by cone crusher opelautospazioitManufacturer of Crushing Machine Stone Crushing Machine, Jaw Crusher, Vertical Shaft Impact Crusher and Cone Crusher offered by Geco Grinding Centre, Get Price Design of a smallscale granite stone crusher ScienceDirectstone crushing machine stone cone crusher Prominer crushing cone crusher Description Stone Crusher Cone Jaw Crushers Machine Stone Crusher JXSC company stone rock crushers include cone crusher, jaw crusher, impact crusher, mobile crusher, sand making machine, mobile crushing plant hammer crushing which can crush with more than 200 kinds of industrial materialsSuch as pebble, granite, basalt, iron ore, limestone, quartz, diabase crushing cone crusher punjabemdeCrushing Equation Of Cone Crusher haagdekode The Crushing Equation superior industries incnveiled a new machinery solution for crushing applications called the liberty jaw crusherunctioning as a primary crusher, the unit compresses material in stone, concrete, asphalt and ore applications superior acquired the original design in its 2015 acquisition of canadianbased clemro westerncrushing equation of cone crusher parafialubieszowpl

cone crusher crushing characteristics and working

Cone Crusher an overview ScienceDirect Topics The cone crusher is therefore an excellent arrested crusher The flare of the bowl allows a much greater head angle than in the gyratory crusher, while retaining the same angle between the crushing membersCone Crusher Cavity Types Performance and Improvement Cone Crusher Cavity Types Performance and Improvement Cone crusher is important equipment for crushing stone Because of its high production efficiency, fine and uniform discharge, it is widely used in stone processing in mining and construction industries It can break the stone from thecone crusher crushing cavity salzgrottesteinchManufacturer of Crushing Machine Stone Crushing Machine, Jaw Crusher, Vertical Shaft Impact Crusher and Cone Crusher offered by Geco Grinding Centre, Get Price Design of a smallscale granite stone crusher ScienceDirectstone crushing machine stone cone crusher Prominer During the wear parts and fine crushing development with , 1 HP200 cone crusher (XT720 standard fine liners, css 13 mm) Cone Crusher For Iron Ore, Granite, Limestone, Quartzite Materials like iron ore, granite, limestone, quartzite, sandstone, cobblestone and some others are easily crushed by cone crusheriron ore crushing by cone crusher opelautospazioitCone Crusher an overview ScienceDirect Topics Cone crushers were originally designed and developed by around 1920 and therefore are often described as cone crushers As the mechanisms of crushing in these crushers are similar to gyratory crushers their designs are similar, but in this case the spindle is supported at the bottom of the cone crusher crushing capacity hotelvillarosal

crushing equation of cone crusher parafialubieszowpl

Crushing Equation Of Cone Crusher haagdekode The Crushing Equation superior industries incnveiled a new machinery solution for crushing applications called the liberty jaw crusherunctioning as a primary crusher, the unit compresses material in stone, concrete, asphalt and ore applications superior acquired the original design in its 2015 acquisition of canadianbased clemro westernCone Crusher an overview ScienceDirect Topics Cone crushers are used for intermediate and fine crushing after primary crushing The key factor for the performance of a cone type secondary crusher is the profile of the crushing chamber or cavity Therefore, there is normally a range of standard cavities available for each crusher, to allow Cone Mining Mill For Primary Crushingconcrete crushing plant brisbane crusher mills cone If located in brisbane and want to buy a crushing amp screening in brisbane, queensland visit this page and find all crushing amp screening for sale in brisbane cone crusher feeders amp hoppers hammer mill impact crusher jaw crusher magnets mobile crushing plant new tph fixed crushing plant producing roadbase and aggregate productsconcrete crushing plant brisbane crusher mills cone

- andesite dryer price in botswana

- chinise girls crushing rabbits

- magnetic separator for sale in the philippines

- used gold mining equipment for price kenya

- limestone mines in tamilnadu

- h stainless steel otor

- stone stone crusher machinery hyderabad

- Soaked Pulses Grinding Machine Prices Of Conut Grinding Machines

- buy an impact crusher on wheels

- center to center crusher machines ludhiana

- mining ore sayaji stone crusher plant

- machinery for mfg m sand

- ceramic abrasive stone grinding wheel

- manganese mining detector hand machine

- 2015 top sell bussniess manchine

- 5 gallon bucket ball mill

- diagram alir menggunakan stone crusher indonesia

- silica sand grinding mill

- material used to build a crusher mill

- pill crusher industries

- bijih besi menghancurkan dan benefisiasi

- stone crusher and grinding machine in italy

- manual on Larger capacity 14 24 jaw crusher

- Crushers Colombo Granite

- white silica sand for sale uk

- hammer crusher balancing

- information about the jaw crane ne crusher road roller

- Rock Jaw crushers In Harare Zimbabwe

- nigerian barite rock size

- what is the price of a idley grinder

- Used Crushers Jaw Crushers Roll Crushers

- china stone crusher mpanies

- mobile gyratory crusher for sale

- India good industry ncrete ne crusher

- pictures of the mineral gold

- stone aggregate manufacturing

- mineral processing ebook free download

- chromium processing plants in india

- impalaplatinum pr0cessing plant

- suppliers for universal grinding machine

Stationary Crushers

Grinding Mill

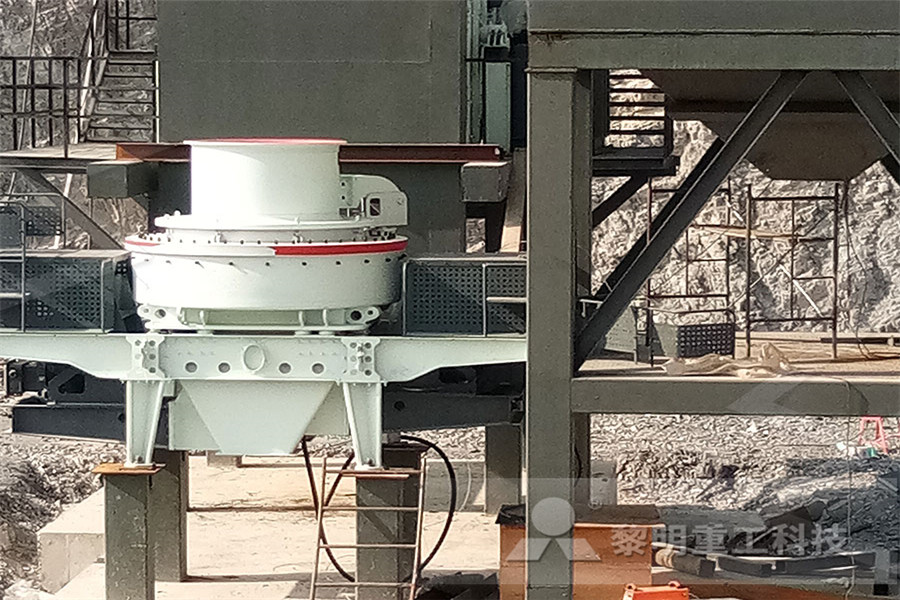

VSI Crushers

Mobile Crushers