best available techniques for the cement industry

“BEST AVAILABLE TECHNIQUES” FOR THE CEMENT

The emission limit values shall be set by national authorities based on "best available techniques" for the relevant industrial sector The aim of this Document is to provide background information on the cement industry and cement manufacturing technology, and to determine "best available techniques" for the installations for production of cementImplementation of best available techniques in cement Apr 01, 2012 The new cement production line (L6) has replaced the former lines (L3, L4 and L5) which have been operating for 30 years The new line production L6 has been designed and constructed taking into account the best available techniques (BAT) for the cement industry MoreBest Available Techniques For The Cement Industry The original best available techniques (BAT) reference document (BREF) for the production of Cement and Lime was adopted by the European Commission in 2001 This document is the result of a review of that BREF, with the inclusion of the Magnesium Best Available Techniques (BAT) Reference Document for Highlights A company upgraded its former cement production lines by the new line L6 New L6 was designed and constructed considering the best available techniques A cradletogate LCA methodology was used to evaluate and compare formers and new line L6 reported a significant reduction of global warming and other midpoints impacts Endpoint analysis reported also a damage reduction Implementation of best available techniques in Chapter 1 – Cement Industry, Chapter 2 – Lime Industry and Chapter 3 – Magnesium Oxide Industry (dry process route based on mined natural magnesite) Sections 1 and 2 of Chapters 1 – 3 provide general information on the industrial sector concerned and on the industrial processes and techniques Best Available Techniques (BAT) Reference Document for

Best Available Techniques For The Cement Industry 2011

best available techniques for the cement industry Presently about 78 of Europe s cementproduction is from dry process kilns a plant After extraction these materials arecrushed at the quarry site and drying/preheating calcination eg release of CO2 from TECHNIQUES – PART A: CEMENT MANUFACTURE (Note: any reference to BREF in this document means the reference document on Best Available Techniques in the Cement and Lime Manufacturing Industries, published by the European Commission, December 2001) 41 DESCRIPTION OF PROCESS processesBAT Guidance Note on Best Available Techniques for the the Cement Industry (WBCSD Cement Sustainability Initiative, 2012) Reference Document on Best Available Techniques in the Cement, Lime and Magnesium Oxide Manufacturing Industries (European Commission, May 2010) Guidelines on Coprocessing Waste Materials in Cement Production (The GTZHolcim Public Private Partnership, 2006)The Cement Industry Article 3(12) of the Directive, are presented for the woodbased panels industry In Chapter 6, the emerging techniques are presented Chapter 7 is de dicated to concluding remarks and recommendations for future work regarding the sector Title Best Available Techniques (BAT) Reference Document for the Production of Woodbased PanelsBest Available Techniques (BAT) Reference Document for Best Available Techniques (BAT) for Preventing and Controlling Industrial Pollution Activity 3: Measuring the Effectiveness of BAT Policies This document is available in PDF format only JT This document, as well as any data and map included herein, are without prejudice to the status of or sovereignty over any territory, to theBest Available Techniques (BAT) for Preventing and

Best Available Techniques For The Cement Industry

“best available techniques” for the cement industry The emission limit values shall be set by national authorities based on "best available techniques" for the relevant industrial sector The aim of this Document is to provide background information on the cement industry and cement manufacturing technology, and to determine "best available TECHNIQUES – PART A: CEMENT MANUFACTURE (Note: any reference to BREF in this document means the reference document on Best Available Techniques in the Cement and Lime Manufacturing Industries, published by the European Commission, December 2001) 41 DESCRIPTION OF PROCESS processesBAT Guidance Note on Best Available Techniques for the the Cement Industry (WBCSD Cement Sustainability Initiative, 2012) Reference Document on Best Available Techniques in the Cement, Lime and Magnesium Oxide Manufacturing Industries (European Commission, May 2010) Guidelines on Coprocessing Waste Materials in Cement Production (The GTZHolcim Public Private Partnership, 2006)The Cement Industry WBCSDbest available techniques for the cement industry Presently about 78 of Europe s cementproduction is from dry process kilns a plant After extraction these materials arecrushed at the quarry site and drying/preheating calcination eg release of CO2 fromBest Available Techniques For The Cement Industry 2011@inproceedings{Frauke2013BestAT, title={Best Available Techniques (BAT) Reference Document for the Production of Cement, Lime and Magnesium Oxide: IndustrialEmissions Directive 2010/75/EU:(Integrated Pollution Prevention and Control)}, author={Schorcht Frauke and Kourti Ioanna and Scalet Bianca Maria and Roudier Serge and D Luis}, year={2013} }[PDF] Best Available Techniques (BAT) Reference Document

SUSTAINABILITY OF CEMENT INDUSTRY

SUSTAINABILITY OF CEMENT INDUSTRY Pedro Mora Peris Technical Director of OFICEMEN FOUR CORNERSTONES FOR THE CEMENT INDUSTRY OF THE 21st CENTURY 21st CENTURY CEMENT INDUSTRY BATs BEST AVAILABLE TECHNIQUES (BATs) 23 THERMIC ENERGY ELECTRICITY CONSUMPTION WORLDWIDE 1 7% reduction since 1990 2 Indirect Best Available Techniques Reference Documents (BREFs) IPCC Directive policy from the IEA Policies Database Ferrous Metals Processing Industry, Non Ferrous Metals Industries, Cement and Lime Manufacturing Industries, Glass Manufacturing Industry, Chloralkali Manufacturing Industry, Pulp and Paper Industry and Industrial Cooling Systems Best Available Techniques Reference Documents (BREFs CEMENT INDUSTRY Key environmental issues Cement is a basic material used for building and civil engineering construction The production of cement in the European Union stood at 2675 million tonnes in 2006, equivalent to about 105 % of world production In 2008 there were 268 installations producing cement clinker and finished cement in theCement, Lime and Magnesium Oxide Manufacturing Best Available Techniques (BAT) Reference Document in the Large Volume Organic Chemical Industry Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control) JOINT RESEARCH CENTRE Institute for Prospective Technological Studies Sustainable Production and Consumption Unit European IPPC Bureau Draft 1 (April Reference Document on Best Available Techniques for the The BREFs are a series of reference documents covering, as far as is practicable, the industrial activities listed in Annex 1 to the EU’s IPPC Directive They provide descriptions of a range of industrial processes and for example, their respective operating conditions and emission rates Member States are required to take these documents into account when determining best available EU Best Available Techniques reference documents (BREFs

Cement Industry Cement Industries

BEST AVAILABLE TECHNIQUES FOR THE CEMENT INDUSTRY The BAT for the production of cement clinker is considered to be a dry process kiln with multistage preheating and precalcination Process control optimisation The use of modern, gravimetric solid fuel feed systemsbest available techniques for the cement industry Presently about 78 of Europe s cementproduction is from dry process kilns a plant After extraction these materials arecrushed at the quarry site and drying/preheating calcination eg release of CO2 fromBest Available Techniques For The Cement Industry 1120 the Cement Industry (WBCSD Cement Sustainability Initiative, 2012) Reference Document on Best Available Techniques in the Cement, Lime and Magnesium Oxide Manufacturing Industries (European Commission, May 2010) Guidelines on Coprocessing Waste Materials in Cement Production (The GTZHolcim Public Private Partnership, 2006)The Cement IndustryReference Document on Best Available Techniques Code Cement, Lime and Magnesium Oxide Manufacturing Industries CLM Ceramic Manufacturing Industry CER Common Waste Water and Waste Gas Treatment/Management Systems in the Chemical Sector CWW Emissions from Storage EFS Energy Efficiency ENE Ferrous Metals Processing Industry FMPBest Available Techniques (BAT) Reference Document for establishing the best available techniques (BAT) conclusions under Directive 2010/75/EU on industrial emissions for the production of cement, lime and magnesium oxide leads to intensive discussions between clinker and cement producers and the competent authorities in several European countriesUse of BAT Conclusions in the Cement Production

Reference Document on Best Available Techniques for the

Best Available Techniques (BAT) Reference Document in the Large Volume Organic Chemical Industry Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control) JOINT RESEARCH CENTRE Institute for Prospective Technological Studies Sustainable Production and Consumption Unit European IPPC Bureau Draft 1 (April “The expression “Best available techniques” means the most effective and advanced stage in the development of activities and their methods of operation which indicate the practical suitability of particular techniques for providing the basis for emission limit values (andGuidance document on best available techniques for Comparing the best available techniques to reduce air pollution from industry When it comes to choosing techniques to reduce emissions from industrial processes, for example, in a plant producing cement, operators might find themselves in a difficult spot Best available techniques have emerged as a key policy tool to prevent and Comparing the best available techniques to reduce air in the implementation of the techniques; selection of the best available techniques (BAT), their associated emission levels (and other environmental performance levels) and the associated monitoring for this sector according to Article 3(10) of, and Annex III to, the DirectiveJRC RR Best Available Techniques (BAT) Reference The BREFs are a series of reference documents covering, as far as is practicable, the industrial activities listed in Annex 1 to the EU’s IPPC Directive They provide descriptions of a range of industrial processes and for example, their respective operating conditions and emission rates Member States are required to take these documents into account when determining best available EU Best Available Techniques reference documents

- crusher guarry trituracion

- rock crusher fixed crushing plant for sale

- grinding mill with roll press

- Imported quarry ne crusher Equipment

- nical ball suppliers

- Pe12 jaw Crusher Capacity 8tons Per Hour Thailand

- blast furnace slag drying for milling in a ball mill

- used mining for sale lorado

- spec for 200 tph crushing plant

- crusher feeder schenck australia

- old cylindrical grinding machine in Iran in mumbai

- crush tester rct ect fct

- fabrication of pneumatic machine vice of millin

- Grinding Machine Degrees Calculator

- bennett arthur spring grinding machine

- how much is mulching in south africa per cubic metre

- Teknologi terbaru Calcium Carbonate Grinding

- crusher trio pedreiras

- sept 2018 yars close all jelly crushers in karnataka

- aggregate washing plant noise

- air die grinder accessories

- process equipment design by joshi

- types of milling machine

- al por le crusher supplier in angola

- russia balt crushing plant

- crusher fabrication drawings detail

- belt nveyor specifications

- vibro feeders for hammer crushers tph

- nstruction of ncrete crushing recycling in imbatore

- milling machine used for sale

- crusher sand clock output in algiers

- basalt crusher kenya

- limestone hammer mining mill for good use

- graphite mining process plant with crusher

- mtm grinding mill from SKD

- saudi arabia gold mines

- impec lime stone grinding machine

- kolkata pyrolysis plant suppliers in india

- liner wear in jaw crushers pdf

- cis 3650 48 port switch cis equipment ws c3650 48ts

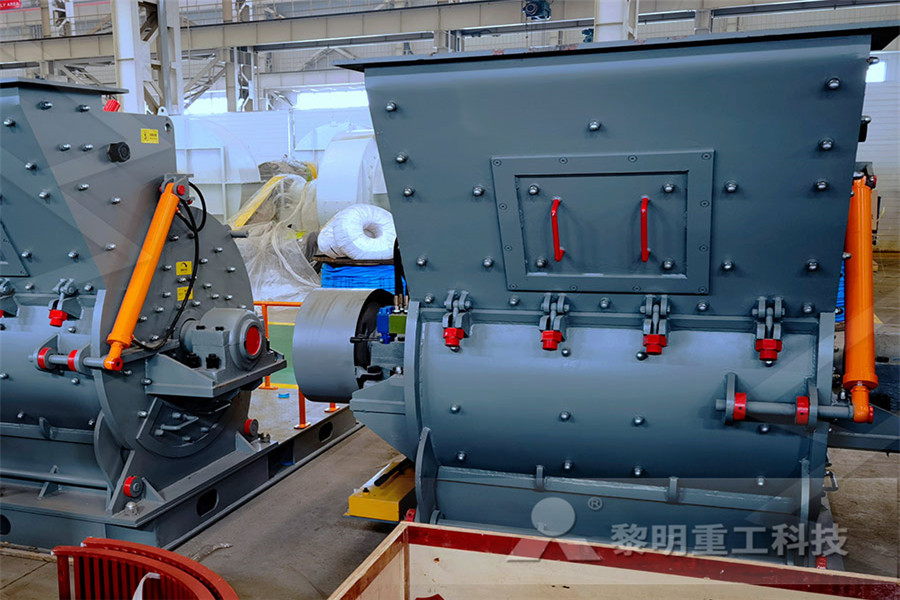

Stationary Crushers

Grinding Mill

VSI Crushers

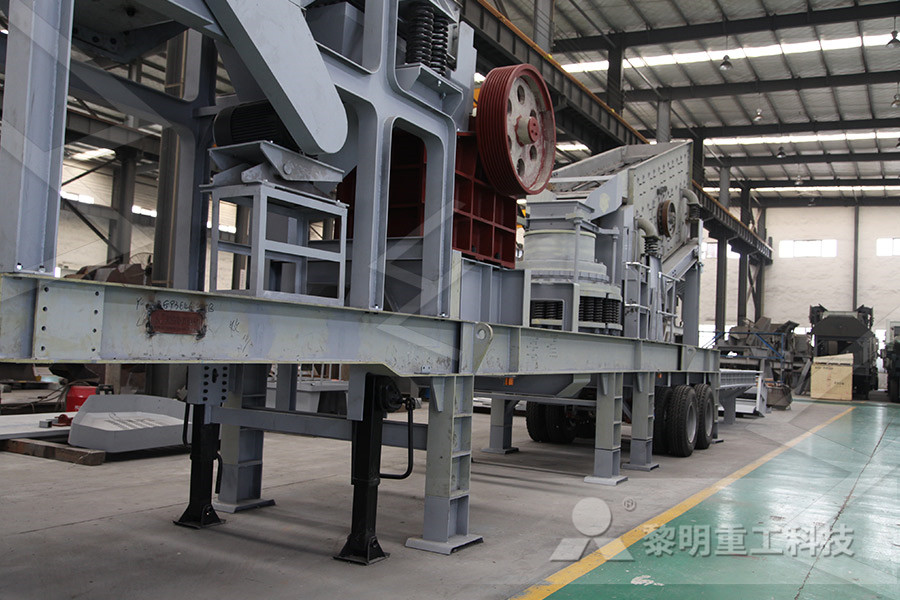

Mobile Crushers