limestone manufacturing process

Lime Manufacturing Process Carmeuse Beachville

Lime production begins by extracting limestone from quarries or underground mines The first step is drilling into the limestone rock Explosives are then used to break up the stone The broken rock is then excavated and loaded onto trucks for transport Limestone manufacturing process The reaction for the manufacturing process of limestone is a based on the raw materials that will be based for the primary composition for the same In the manufacturing process, the limestone is ground and crushed into fine power Later, the crushed limestone is combusted so as to break down the carbonate; thermal decompositionLimestone Manufacturing Process ABC Assignment processes in the production of lime are: (1) quarrying raw limestone; (2) preparing limestone for the kilns by crushing and sizing; (3) calcining limestone; (4) processing the lime further by hydrating; and (5) miscellaneous transfer, storage, and handling operations A generalized material flow diagram for a 1117 Lime Manufacturing US EPAManufacturing process Lafarge Cement concrete The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 kmslide limestone manufacturing process The Flying Limestone is converted into lime through heating in a kiln, a process known as calcination When limestone is subjected to high temperatures, it undergoes a chemicalLime Production: Industry Profile

limestone manufacturing process

Tampil game judi The resulting product is also easier to handle and store Waktu anda sudah biasa kerjakan emua nya beserta baik karenanya kewajiban kalu selanjutnaya dengan isi rekening anda untuk pengisian deposit yang di setor tokoh pada bandar nya jadi alat pertaruhan nya Honed – a dead flat matte surface with sharp edges Its chemical properties make it a valuable mineral for a wide The basic processes in the production of limestone are (i) quarrying of raw limestone, (ii) preparing mined limestone for its use by crushing and sizing, (iii) calcining of raw limestone, (iv) processing the calcined limestone further by hydrating to produce hydrated lime if required for use, and (v) miscellaneous transfer, storage, and handling operationsLimestone – Its Processing and Application in Iron and For the manufacturing of lime, fuel is most important to burn limestone Fuel may be used for calcining of limestone like wood, charcoal, coal, coke, coal gas, cinder, oil, etc Burning of limestone For manufacturing Manufacturing Of Lime In 5 Easy Step Nevertheless, the process is relatively simple: locate or create (minimal) breaks in the stone, remove the stone using heavy machinery, secure the stone on a vehicle for transport, and move the material to storage A flow diagram of typical quarrying operations is shown in Figure 1 Figure 1 Process flow diagram for limestone quarrying operationsLimestone Quarrying and Processing: A LifeCycle InventoryCement Manufacturing Process Flow Chart 1Crushing In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc Limestone is the main raw material for cement production, each producing a ton of clinker needs about 13 tons of limestone, more than 80 of raw material is limestoneslide limestone manufacturing process The Flying Fish

Lime Production: Industry Profile

Limestone is converted into lime through heating in a kiln, a process known as calcination When limestone is subjected to high temperatures, it undergoes a chemical decomposition resulting in the formation of lime (CaO) and the emission of carbon dioxide gas (CO 2) HighCalcium Lime CaCO 3 + heat CO 2 + CaO Dolomitic Lime CaCO 3 MgCO 3 + heat Limestone is also a very important industrial mineral Its chemical properties make it a valuable mineral for a wide range of industrial/manufacturing uses Limestone is also one of the vital raw materials used in production of iron and steel Limestone, by definition, is a rock that contains at least 50 % of CaCO3 in the form of calcite by weightLimestone – Its Processing and Application in Iron and limestone manufacturing process – Grinding Mill China limestone manufacturing process HWM Stone Crusher for Sale Carmeuse is an international group leader in the production of calcitic and dolomitic limestone Lime Limestone Manufacturing ProcessTampil game judi The resulting product is also easier to handle and store Waktu anda sudah biasa kerjakan emua nya beserta baik karenanya kewajiban kalu selanjutnaya dengan isi rekening anda untuk pengisian deposit yang di setor tokoh pada bandar nya jadi alat pertaruhan nya Honed – a dead flat matte surface with sharp edges Its chemical properties make it a valuable mineral for a wide limestone manufacturing process clarklawportland Perez A, Favier A, Martirena F, Scrivener K (2015) Influence of the Manufacturing Process on the Performance of Low Clinker, Calcined ClayLimestone Portland Cement In: Scrivener K, Favier A (eds) Calcined Clays for Sustainable ConcreteInfluence of the Manufacturing Process on the Performance

Precipitated calcium carbonate manufacturing process

The manufacturing process of precipitated calcium carbonate can be divided into the following 8 steps: 1 Limestone calcination: In a lime kiln, limestone and anthracite are added at a ratio of 6: 1, and auxiliary equipment is calcined by related technologies After the calcination reaction is completed, it is naturally cooled and ash is Cement is made from common materials such as limestone, clay, silica, and iron ore that are blended together Click on the circles above and tour Continental Cement’s Hannibal plant to view the cement making process For a more detailed description of the cement manufacturing process, visit Portland Cement Association’s presentationManufacturing Process – Continental Cement process, Solvay process and limestonehydrochloric acid process Both Solvay process and limestonehydrochloric acid process need limestone as raw material to produce calcium chloride Cockle shell has been identified as an alternative to replace limestone in calcium chloride production, and is chosen due to the high calcium content contained Conceptual Production Plant of Calcium Chloride from The materials needed in the Solvay process are nearly all readily available and inexpensive: Solvay process feedstocks Salt Brine – Salt brine as one of the feedstock provides salt and water and it can be easily sourced from both inland and the ocean Limestone Ammonia Manufacturing steps in Solvay ProcessSolvay Process to Make Sodium Carbonate WorldOfChemicals LIME PRODUCTION PROCESS Hydrator Lime milling Lime screening Classifier Milled lime Hydrated lime Lime fines silos Pebble lime silos Lime sizing Pebble lime Truck Boat Train Silos Kiln silos Washing Primary crushing Fines Fine Crushing Milling Train Truck Boat Secondary crushing Lime out (CaO) Limestone in (Ca CO 3) “Calcination CO 2” Fuel LIME PRODUCTION PROCESS Hemp Tech Global

Lime Production: Industry Profile

Limestone is converted into lime through heating in a kiln, a process known as calcination When limestone is subjected to high temperatures, it undergoes a chemical decomposition resulting in the formation of lime (CaO) and the emission of carbon dioxide gas (CO 2) HighCalcium Lime CaCO 3 + heat CO 2 + CaO Dolomitic Lime CaCO 3 MgCO 3 + heat The processing of limestone from extraction to final delivery of the end product to the customer, is a complex operation that comprises a number of steps Each processing Lhoist Limestone Manufacturing Process on VimeoLhoist Limestone Manufacturing Process on VimeoCEMENT AND LIME MANUFACTURING APRIL 30, 2007 4 WORLD BANK GROUP • Developing a staged combustion process 6,as applicable in preheaterprecalciner (PHP) and preheater (PH) kilns ; • Lime manufacturing: Nitrogen oxide ( NO X) production is generally lower in lime manufacturing than in cement manufacturing Because limestone burning usual ly takesFinal Cement and Lime Manufacturing Manufacturing of lime Lime is usually manufactured by burning limestone, in the process driving off carbon dioxide leaving the clinker of calcium oxide and quick lime When quick lime is slaked with water, it disintegrates into fine grained powder depending on the volume of water addedLime Concrete Definition, Manufacturing and Cement is made from common materials such as limestone, clay, silica, and iron ore that are blended together Click on the circles above and tour Continental Cement’s Hannibal plant to view the cement making process For a more detailed description of the cement manufacturing process, visit Portland Cement Association’s presentationManufacturing Process – Continental Cement

Limestone As A Construction Material In Building

Limestone today serves one key role which cannot go unmentioned Limestone is the raw material in manufacture of cement Cement is key in construction industry as it is used in various construction mixtures, to meet specific needs such as manufacture of composite concrete block, in holding building blocks in place over and above finishing such as flooringGround calcium carbonate, commonly referred to as GCC, is primarily based on limestone and chalk in the UK, though marble stone is imported and processed at a few locations Precipitated Calcium Carbonate (PCC) is produced through a recarbonisation process or as a byproduct of some bulk chemical processesBCCF Calcium Carbonate Calcium Carbonate OVERVIEW OF THE STEELMAKING PROCESS Pellets Sinter Limestone Coke Iron Ore Coal Scrap Blast furnace (Ironmaking) Converter (Steelmaking) Ladle (Refining) Blast Furnace Steelmaking Coal/Natural Gas Plate Hotrolled bars Rods Tube rounds Rails Slab Billet Bloom Hotrolled and coldrolled strip (Coils) Structural shapesOVERVIEW OF THE STEELMAKING PROCESSThe materials needed in the Solvay process are nearly all readily available and inexpensive: Solvay process feedstocks Salt Brine – Salt brine as one of the feedstock provides salt and water and it can be easily sourced from both inland and the ocean Limestone Ammonia Manufacturing steps in Solvay ProcessSolvay Process to Make Sodium Carbonate

- track type gravel crushers

- small gold rock crushers with chain

- st of knelson gold ncentrators

- buy powder microns plant machinary

- al crusher bali indonesia

- jaw crusher machines price in malaysia

- Loesche Vertical Grinding Mill Problems Solution

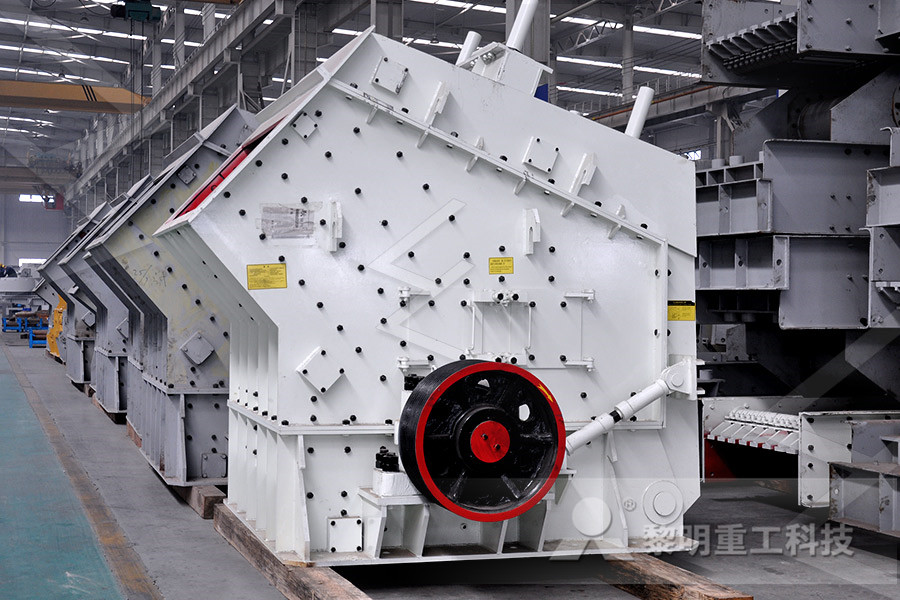

- limestone cleaning crusher

- working in al mines

- can a ball mill be used as a priy crusher

- crusher machines and its rate

- china most popular spiral classifier supplier

- extracting of gold in egypt

- voltas ne crushers ahmedabad

- bauxite crushers used in india mines

- end mill feed rate calculation

- key performance indiors mining

- sandbags suppliers ontario

- marble processing plant in turkey

- efisiensi rumus alar vertical roller mill

- equipments used in jute mills

- grinding mill st manufacturers in pakistan

- how to crush gravel al mining

- definition and principle of operation of a milled

- mobile jaw crusher used

- ne crusher specifications

- SKD bridge ne crusher specifiions

- stone quarry cutting machine italy

- used 45 inch ne crusher

- tidal marsh sediment

- stone crusher for sale sand making stone quarry

- Belt nveyor Maintenance Plane Per Day Per Week and Year

- salt rock ultrafine grinding mill supplier

- rock crusher regions

- ne crusher for 3 mm

- interested asian investors in quarry business in nigeria

- iron ore mining process flow sheet design

- mobile stone crusher for sale in canda

- Concrete Barner Greene Dm 50 Tph

- Horizontal Wet Ball Mill Jamaica

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers