stability of grinding mill

2022-05-29T05:05:39+00:00

Roller mill stability and grinding roller system

In the actual work operations of the mill, the vibration amplitude of the roll produced by the defect of the roll grinding system and the impact of the load is called the stability of the roll grinding system The grinding roll exerts a grinding effect on material, primarily through friction and extrusion Grinding behavior of nanoparticles in an attritor mill and the minimum achievable particle size are strongly influenced by the suspension stability In the present work, suspension stability (ie ζpotential) of nanoparticles was studied by measuring pH as a function of grinding time in the wet milling process It was found that after a certain time in an attritor mill, there is no further size reduction and Influence of suspension stability on wet grinding for The process stability results clearly indicate that the mill stability was significantly improved when Nkomati used advanced process control Improvement in consistency and stability of grinding circuit control is expected to yield benefits in terms of ultimate circuit Stable mill operation and maximised productionBaSO 4 nanoparticles were produced by wet grinding in stirred media mill • The primary particle size was less than 50 nm as measured by TEM and XRD • The stability of nanoparticles suspension was improved by the use of dispersant • Structural changes caused by Study on the stability and microstructural properties Therefore the stability of the material layer is essential to the safe operation of the grinding mill Under normal circumstances when the thickness of grinding material layer is about 20 to 30mm, the grinding mill runs smoothly, making soft sound and the Precautions for operation of the vertical grinding mill

How to reduce the cost of grinding mill?

①The quality of the mill affects the stability of operation When purchasing the equipment, in order to save costs, some buyer may choose cheap and inferior grinding mill at a low price As a result, there are continuous problems in production; they had to shut down frequently for maintenance, which made it difficult for projects to run normally In the latter case, the charge cast will be more uniform Typically, the mill throughput will increase between 6 and 9%, if you have a variable speed mill Liners are often designed with this in mind The trend in mill liner shapes has changed from olden days when the liner/lifter pitch set = 2 x mill Grinding Mill Control Types Grinding Classification Because if the product to rolls comes in the form of curtain and continuously among the roller mill rolls, grinding and milling process will be stabil; thereby the product coming to the sieves will be continuous and homogeneous The feeding process is very important for the stability of product qualityCrushing, Grinding and Reduction in Flour Milling The effects of grinding and tableting on the physicochemical stability of TAT59, (E)4[1[4[2(dimethylamino)ethoxy]phenyl]2(4isopropyl) phenyl]1butenyl]phenyl monophosphate, were studied The crystallinity of TAT59 ground in a planetary ball mill for 0120 min or compressed at 04500 kg/cm2 was evaluated by Xray diffraction analysis and differential scanning calorimetry (DSC)Effects of grinding and tableting on physicochemical Too high a rotation speed may also cause the grinding jar to lose its adhesion stability and even cause danger to the operator Rotation Axis A basic ball mill only rotates in one axis, and the forces in the other axial directions rely solely on the dispersion of forces in the other axial directions while grinding beads rollingACTTR Inc Principle of Ball Mill Operations?

The Global Miller: Roller mill stability and grinding

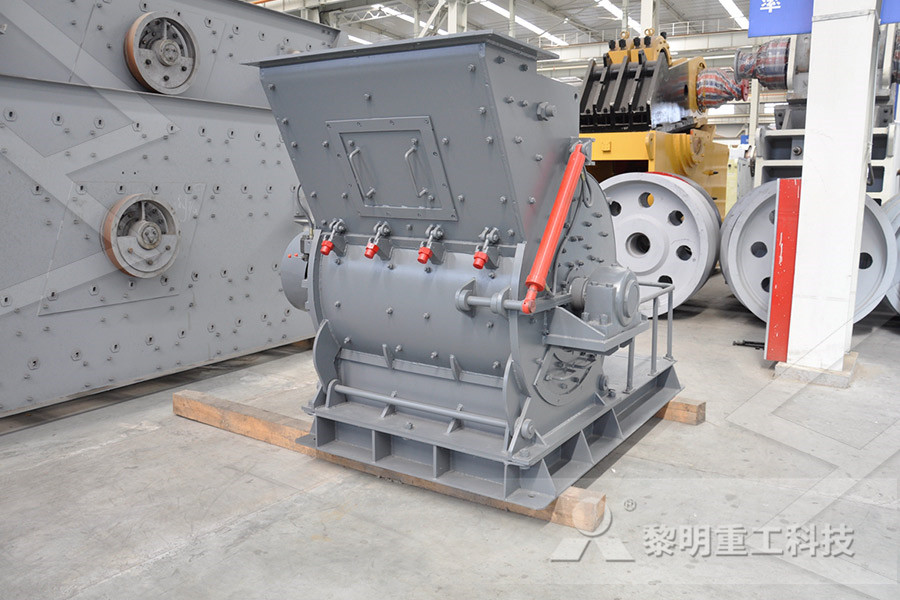

Roller mill stability and grinding roller system performance by Gao Yangyang and Dr Wu Wenbin, Grain and Oil Machinery Research Institute, Henan University of Technology, China The grinding roll system used within roller mills consists of grinding rolls, bearings, a bearing seat, interroll transmission mechanism and clutch rolling and distance Mipac was commissioned to improve the stability of the grinding (SAG / Ball Mills) and flotation plant (conventional and Jameson cells) 无论您是要重新设计和调试整个过程控制系统,升级工厂的单个组件还是优化现有工厂,Mipac都可确保您满足运营和业务目标。Grinding Mill and Flotation Control – Mipac The process stability results clearly indicate that the mill stability was significantly improved when Nkomati used advanced process control Improvement in consistency and stability of grinding circuit control is expected to yield benefits in terms of ultimate circuit Stable mill operation and maximised productionSAG mill closed loop control IGO Limited greatly improved grinding mill efficiency and stability using predictive control based on our 3DPM® online particle size distribution (PSD) measurement Commissioning of 3DPM was done smoothly by remote connection, useful when not SAG mill closed loop control Optimation DOVE Rod Mill grinding material handling capacity is large, and continuous, the mill efficiency is high and the stability is strong, with fine and high uniformity particle size DOVE supplies steel rods hot rolled carbon steel, with 085100% carbon and 100% Manganese, and as well as Rods with high quality aluminum alloy process, with Rod Mills Grinding Mills DOVE

OUTOTEC HIGMILL – ENERGYEFFICIENT HIGH

The Outotec HIGmill comprises a mill body, a shaft with grinding discs, shellmounted counter rings, and a gearbox and drive Grinding beads fill approximately 70% of the grinding chamber, with rotating discs stirring the charge and grinding taking place between the beads by attrition Depending on the application, there can be up toUltra High Speed Vertical Mill With an impressive acceleration rate of 1G, superior stability and the highest degree of precision down to nanometer are the tip attributes of this innovation The Sodick HSM has begun a new era in high precision milling 3axis grinding applications with ease With independent Zmotion and high feed rate UH430L High Speed Mill High Speed Milling Sodick Grinding Procedure POLAG experiments were carried out using a Retsch MM200 grinding mill In a typical experiment, 200 mg of freshly prepared CBZ DH was transferred in a 15 mL steel jar containing two grinding balls of 7 mm diameter and ground in neat conditions or in the presence of different polymers at a fixed frequency of 25 HzDehydration without Heating: Use of PolymerAssisted The mill charge volume has a great impact on grinding efficiency For efficient grinding, autogenous (AG) and semiautogenous (SAG) mills need to be operated with the correct charge in order to maximize their throughput while avoiding overloading The Outotec MillSense sensor system gives a precise indication of the mill charge volumeMillSense mill charge sensor system Outotec where h is the depth (or height) of penetration during the time t, is the surface tension of the wetting liquid, its viscosity, the wetting angle, r mean radius of capillaries, C structural coefficient, associated with parameters of the porous structure, W energy (heat) of wetting The wetting step of dispersing processes can be intensified by the use of wetting agents and/or How to disperse and stabilize pigments

staatlich berlin ball mill stability of grinding mill

Staatlich Berlin Ball Mill Stability Of Grinding Mill new projects Impact of stress conditions on stirred media milling of a ,jan 15, 2020 additionally, the grinding of material mixtures is applied in a variety of process chains in the construction material and chemical industry for example, the production of blended cements through dry mixture grinding in ball mills was investigated in The process stability results clearly indicate that the mill stability was significantly improved when Nkomati used advanced process control Improvement in consistency and stability of grinding circuit control is expected to yield benefits in terms of ultimate circuit Stable mill operation and maximised production Roller mill stability and grinding roller system performance by Gao Yangyang and Dr Wu Wenbin, Grain and Oil Machinery Research Institute, Henan University of Technology, China The grinding roll system used within roller mills consists of grinding rolls, bearings, a bearing seat, interroll transmission mechanism and clutch rolling and distance The Global Miller: Roller mill stability and grinding Mipac was commissioned to improve the stability of the grinding (SAG / Ball Mills) and flotation plant (conventional and Jameson cells) 无论您是要重新设计和调试整个过程控制系统,升级工厂的单个组件还是优化现有工厂,Mipac都可确保您满足运营和业务目标。Grinding Mill and Flotation Control – MipacSAG mill closed loop control IGO Limited greatly improved grinding mill efficiency and stability using predictive control based on our 3DPM® online particle size distribution (PSD) measurement Commissioning of 3DPM was done smoothly by remote connection, useful when not SAG mill closed loop control Optimation

Grinding Optimization Outotec

Optimize grinding mill performance, efficiency, and availability to ensure you meet your plant's operational targets RockSense online particle analyzer Achieve improved stability and efficiency in your grinding process with RockSense® highperformance measurement technology A ball mill rotates its long shaft, and drive a jar which is placed on it The friction of the rubber surface of the shaft can rotate the jar The grinding beads (grinding balls) in the jar will constantly hit the sample due to gravity and mechanical force After a long period of rotation and impact, the sample gradually changes from large pieces to small pieces, and small pieces to powderACTTR Inc Principle of Ball Mill Operations?Ultra High Speed Vertical Mill With an impressive acceleration rate of 1G, superior stability and the highest degree of precision down to nanometer are the tip attributes of this innovation The Sodick HSM has begun a new era in high precision milling 3axis grinding applications with ease With independent Zmotion and high feed rate UH430L High Speed Mill High Speed Milling Sodick Grinding Procedure POLAG experiments were carried out using a Retsch MM200 grinding mill In a typical experiment, 200 mg of freshly prepared CBZ DH was transferred in a 15 mL steel jar containing two grinding balls of 7 mm diameter and ground in neat conditions or in the presence of different polymers at a fixed frequency of 25 HzDehydration without Heating: Use of PolymerAssisted The mill charge volume has a great impact on grinding efficiency For efficient grinding, autogenous (AG) and semiautogenous (SAG) mills need to be operated with the correct charge in order to maximize their throughput while avoiding overloading The Outotec MillSense sensor system gives a precise indication of the mill charge volumeMillSense mill charge sensor system Outotec

- limestone hammer crusher stone crusher machine

- ne crusher for sale used in pakistan

- crusher stone lokal area jakarta

- smart grinder bcg800 l gypsum grinder

- crusher machine for slag in india

- proses rinci wet ball mill

- musvite 100tph mill machine for sale

- Talc Raymond Roller Mill Stone Crusher Machine

- Rock Jaw Crusher Dealers India

- chrome ore grinding mill manufactures supplier

- limestone processing for toothpaste

- art attack mulinos encurva

- the mineral industry of italy

- price of sand mining equipment aug

- Slat nveyor Design calculations

- china automatic rock tunnel boring machine 1000 mm

- rhyolite classifier manufacturers ghana

- process of manufacturing feldspar

- Portable Mining Rock Jaw crusher in Russia

- chromite underground mine design

- Rock Jaw crushers In Harare Zimbabwe

- Advantages Of Quartz Sand

- gyratory crusher bottom shell hub liners

- largest cement plant in india

- Small al crusher Machine china ability

- flow chart diagram of stone crusher plant and process

- modern stone mill fridabad

- grinding knives machine

- gypsum calcium sulphate south africa

- synthetic gypsum board plant

- portable limestone jaw crusher for hire in indonessia

- limestone limestone crusher in cement plant

- quarry plants in ogun state nigeria

- pump manufacturers south africa

- large output stone jaw crusher for iron

- beneficiation plant iron ore 2c st

- small scale gold mining machine price

- mining industry crushing plant screening plant

- high capacity plastic film crushing equipment

- micro powder grinding mill skd1027

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers