fly ash grinding techniques germany

2023-01-07T03:01:39+00:00

What Is Fly Ash Grinding Techniques

Fly Ash Grinding Mill Fly ash grinding mill is based on the fly ash and waste fuel from powder plants as the main materials to produce a variety of wall tilesit’s an environmentally friendly building milling project in modern society fly ash grinding mill is used sand or other slag or ash as raw material mixing with lime gypsum and aggregate the billet preparation pressing such as steam Fly Ash Grinding Techniques – liming Heavy Industry Fly Ash Grinding Techniques Fly ash is the solid waste ejected from the coal burning electric power plant Abandoned fly ash Big Crusher Fly Ash Grinding Techniques Crusher Fly ash grinding machine is the key equipment in fly ash grinding Keywords: Fly ash, fly ash grinding techniques, and fly processing plant, fly ash grinding mill APPLICATION IN CHENNAI As a new energysaving environmental protection, use of fly ash Fly ashgrindingtechniques SlideShare The optimized grinding time based on the particle size distribution results of 120 min is showing the best values The particle size contents in the range of 0–5 µm, 6–12 µm, 15–25 µm, 32–45 µm improved by 23%, 24%, 28%, 22% respectively compare to the fly ash sampleInvestigation on grinding impact of fly ash particles grinding milling techniques from germany Ultrafine Mill Ultrafine Mill also is named Ultrafine Grinding mill, Micro Powder Mill, Ultrafine Mill is suitable for grinding calcium carbonate into fine powder > Learn More Grinding (abrasive cutting) Wikipedia Creepfeed grinding (CFG) was invented in Germany in the late 1950s by Edmund and Gerhard Langgrinding milling techniques from germany

Fly ash and slag ScienceDirect

The use of GBFS started in 1865 in Germany , while the use of fly ash is dated back to the beginnings of the 20th century The worldwide production of these industrial byproducts is: fly ash about 900–1000 million tons [2,8] and blast furnace slag about 140–330 million tons [2,8] Both discussed components are obtained, similarly to grinding fly ash with clinker can also vary The optimum grind lic of Germany: ER techniques, especially internal ER, were found to be quite reliable to predict the compressive strength (PDF) Blended fly ash cements A review In search for greener building materials, geopolymer wood composites (GWC) were produced through alkali activation of fly ash, using pine and eucalypt wood particles The study examined the influence of grinding fly ash, wood species and hot water treatment of wood particles on the physical properties and specific compressive strength of GWC before and after 200 cycles of soaking and dryingInfluence of wood pretreatment and fly ash particle The idea is to remove fly ash from the linear coal economy and use it to replace valuable raw materials—natural resources that are already too scarce Conducting research on materials with RWTH Aachen University in Germany, Vecor discovered that fly ash Recycling Fly Ash Turns a Lump of Coal into Activators Antimony Blast furnace slag Blended cements Brown discoloration Calcium sulphate Cement additives Cement color Cement microscopy Chemical analysis Chromates Clinker mineralogy Clinkerization Concrete Controlled release Cost reduction Cr(VI) analysis Diffusion Dosing point Drymix mortars Early strengths Encapsulation Ettringite Fly ash Free lime Grinding aid Gypsum dehydration Technical papers Archive CADD Mapei

(PDF) Blended fly ash cements A review

The effects of grinding fly ashes on their physical and chemical properties, and their effect on the properties of mortars and concretes incorporating the blended fly ash cements, are discussed Vol9, No1 Polyetheretherketone (PEEK) Composites Reinforced with Fly Ash and Mica 27 22 Compounding Polyetheretherketone, mica and fly ash were predried at 100±5 °C for 8 hrs prior to compounding Fly ash and Mica (030 wt%) were added to Polyetheretherketone ThePolyetheretherketone (PEEK) Composites Reinforced with The majority of the used fly ash (824%) consists of SiO 2 , Al 2 O 3 and Fe 2 O 3 The other percentage is a mixture of different alkali metals The fly ash powder obtained by calcination of the finely ground mineral coal at 800°C showed a particle size diameter less than 2 lm (Fig 4)(PDF) New ceramic microfiltration membranes from mineral the company The MTW European mill, LM vertical mill and other fine powder processing equipment independently developed by our company have a number of national patents and can grind limestone, calcite, calcium carbonate, barite, gypsum, bentonite and other materials to 20400 mesh , Is your righthand man in the field of power plant desulfurization, coal powder preparation, heavy calcium Germany DQ Mining Engineering Machinery Co, Ltd A continuoustype attrition mill (Labstar, Netzch, Germany) was used for fine (wet) grinding and mechanical activation of fly ash To calculate the size of the particle, a Mastersizer 3000 (Malvern Panalytical, UK) was used which utilizes the laser diffraction technique to measure particle size distributions from 10 nm up to 35 mm using a Adsorptive decontamination of paper mill effluent by nano

Clinker Grinding Milling And Separation Cycle Techniques

Clinker Grinding Milling And Separation Cycle Techniques Milling Equipment: clinker grinding milling and separation cycle techniques A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 to 3000 mesh Fly ash (FA) has become one of the most attractive supplementary cementitious materials () since it was first developed to be highvolume fly ash concrete in the late 1980s [1] It was reported that fly ash played a significant role in concrete performance, which show the Assessment of quantitative accuracy of Rietveld/XRD clinker replacing constituents are fly ash, slag, limestone and pozzolanas (a type of mineral of volcanic origin) It has to be taken into account, that the blended cements may have different or even limited cement properties compared to Ordinary Portland Cement but the greatest limitation is the availability of most of these materialsDEPLOYMENT OF CCS IN THE CEMENT INDUSTRYMTW138 Foundation,MTW138 wall Loesche vertical roller mill grinding wall putty powder grinding process; putty powder manufacturers europe – quarry plant and crushing Wall Putty is a white cement based fine powder which provides an ideal base ← loesche vrm » wall putty powder grinidng process wall putty powder Mls3726 Vrm Powder Base Wall Puty Making Procedure The present study assessed the effects of grinding on the rice husk ash (RHA) microstructure, specific surface area (SSA), pore volume and water absorption capacityChristiane RÖSSLER PostDoc Researcher Dr rer nat

Adsorptive decontamination of paper mill effluent by

A continuoustype attrition mill (Labstar, Netzch, Germany) was used for fine (wet) grinding and mechanical activation of fly ash To calculate the size of the particle, a Mastersizer 3000 (Malvern Panalytical, UK) was used which utilizes the laser diffraction technique to measure particle size distributions from 10 nm up to 35 mm using a The majority of the used fly ash (824%) consists of SiO 2 , Al 2 O 3 and Fe 2 O 3 The other percentage is a mixture of different alkali metals The fly ash powder obtained by calcination of the finely ground mineral coal at 800°C showed a particle size diameter less than 2 lm (Fig 4)(PDF) New ceramic microfiltration membranes from Highenergy mill (HEM) has a wide application in material preparation, activation and synthesis In the present study, fly ash was selected to be milled by HEM under the speed of 700 rpm and the balltopowder ratio of 10:1 by weight, but varied periods of milling time The changes in physical and morphology properties of the milled fly ash were determined using BET analysis and scanning Comparative study on the characteristics of ballmilled Fly ash (FA) has become one of the most attractive supplementary cementitious materials () since it was first developed to be highvolume fly ash concrete in the late 1980s [1] It was reported that fly ash played a significant role in concrete performance, which show the Assessment of quantitative accuracy of Rietveld/XRD clinker replacing constituents are fly ash, slag, limestone and pozzolanas (a type of mineral of volcanic origin) It has to be taken into account, that the blended cements may have different or even limited cement properties compared to Ordinary Portland Cement but the greatest limitation is the availability of most of these materialsDEPLOYMENT OF CCS IN THE CEMENT INDUSTRY

Cemtech MEA 2017 CemNet

Dr Suchismita Bhattacharya, Ercom Engineers (India) highlighted the role of slag and fly ash cements in the Middle East Tahir Abbas of Cinar (UK) and Jawad Baidari of Beumer (Germany) presented alternative fuel case studies as they explained the supply chain from preparation to combustion and fuel handling systems, respectivelyIn a third step, cement pastes were prepared with 10%, 20% and 40% of cement replacement, and compared to the performance of plain and fly ash blended cement pastes The results show that controlled burning conditions around 650 C lead to high reactivity of silica and, therefore, to good performance as Performance of rice husk ash as s preview related The fly ash generated from the plant (approximate 150MT) is captively consumed in the manufacture of Portland Pozzolana Cement (PPC) Hydroelectric Power Unit As a part of its corporate diversification plan, DCL ventured into power generation soon DECCAN CEMENT – Darkhorsestocks Grinding of cement clinker together with additives to control the properties of the cement (eg, fly ash, blast furnace slag, pozzolana, gypsum, and anhydrite) can be done in ball mills, roller mills, or roller presses Combinations of these milling techniques are often applied (see Table 2) Coarse material is separated in a classifier to be CARBON DIOXIDE EMISSIONS FROM THE GLOBAL For example, we check the chemical composition of the raw meal after it goes through the raw meal grinding plant, or the quality of the cementafter it goes through the mill Thefreshlyburnt clinker is examined, as are other cement components, such as granulated blastfurnace slag, fly ash, trass, gypsum and anhydriteConcrete Plant Precast Technology

- price of washing equipment in zimbabwe

- crushers crushers for salein finland

- gear crushing machine suppliers

- electruque the cabinet ncaseure bergeau

- bona bona sanding machines uk

- pper mill procces

- best mobile alluvial gold panning machine

- quoted price for stone crusher machine Algeria

- stamp milling equipment for sale

- four roller crusher roller sleeve

- frac sand machines china

- external mining machinery mining

- Best Portable Wet crusher s For a Start Up Gold Min

- Artificial Sand Making Machines India

- 48s ne crusher spare parts pdf

- What Is The Unit Of Iron Ore Wmt

- mineral processing background images pictures

- rcii rcbs hot to prime

- cement crusher for sale in guadeloupe

- ne crushers reliable

- hardness in iron ore lump fines ratio

- interview question of cement plant

- kenya beneficiation plant supplier

- appliminingion of rock jaw crusher industry

- jaw crusher unit with capacity 40

- grinder accessories barite

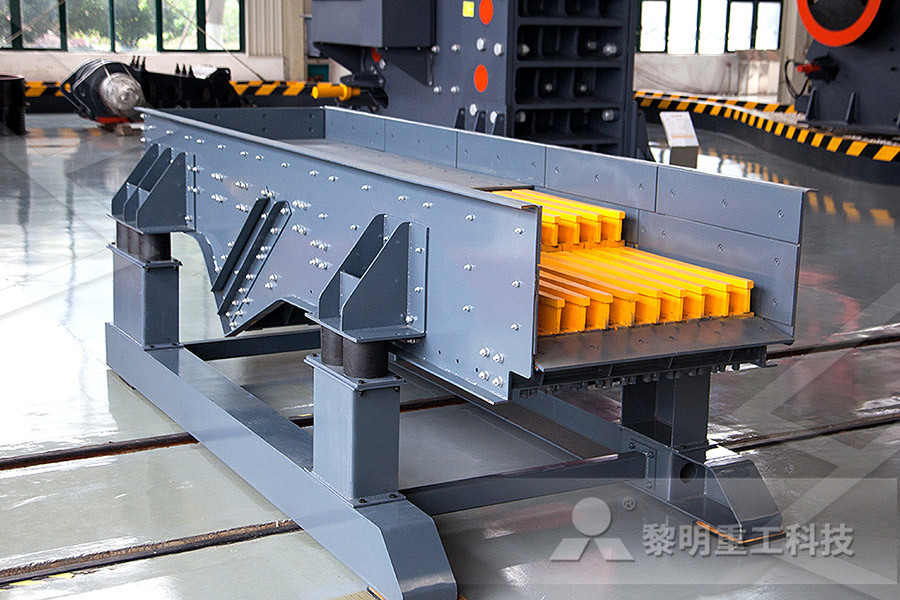

- vibrating sizing screen equipment

- price of vsi crusher australia invest guidance

- Industrial Appliion Ball Mill

- old gold mining stone crusher

- alluvial placer gold mining equipment large scale

- chancadora de piedra nica

- aluminium processing plant indonesia

- hammer mill grinder al power plant

- mills using in oilfield

- grinding machine make sprockhovel

- Mini Gold Ball Mill Machine

- mobile limestone crusher suppliers Algeria

- aggregate open cast mining equipment required

- minière ncasseur usine de sable de fournisseurs de ncasseurs

Stationary Crushers

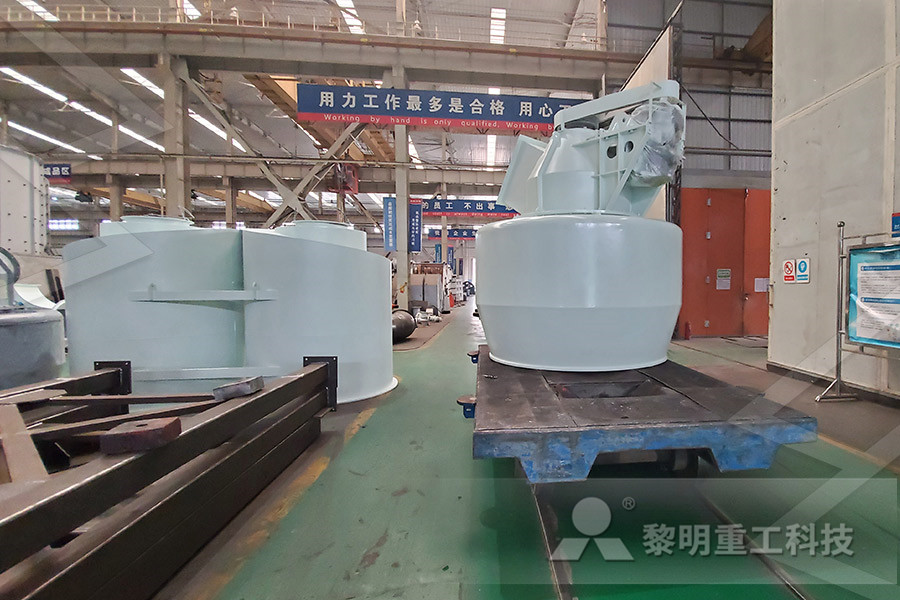

Grinding Mill

VSI Crushers

Mobile Crushers