denver al washing cyclones

2022-04-22T13:04:12+00:00

DENSE MEDIUM CYCLONE

coal washeries incorporated dense medium cyclones in intermediate size coal washing circuits Presently, 5560% of the washed coal is produced by dense medium cyclones Realising the role of dense medium cyclones in our washeries, author and his coworkers undertook many research projects on DM cyclones during the last two decades The performance of three different types of spirals and a 200 mm diameter water washing cyclone have been assessed in opencircuit onsite testwork at the Norwich Park preparation plant on nominally 500 µ x 75 µm sized coal The study is part of a program investigating alternative methods to heavy media cyclones and froth flotation for removing ash Fine Coal Cleaning by Spiral and Water Washing Coal processing Coal washing plants for the crushing, sizing, washing and drying of coal to enable it to be used in power stations Products: Modular Coal Preparation Plant (MCPP) comprising of vibratory screening equipment, fine coal slurry separator, magnetic separator, cyclone, heavy medium Coal Washing Equipment Water Only Cyclone For SaleCoal Washing Plant Parnaby Cyclones provide a wide range of both mobile and modular coal washing plant and coal preparation equipment Parnaby Cyclones is a long established family business The company was founded back in 1973 by Derek Parnaby who developed the world famous ‘Parnaby Process’ for minerals separation using barrels and cyclonesModular Coal Washing Parnaby Cyclones The MULTOTEC dense medium cyclone has been successfully applied in, primarily, coal washing but also in hard rock beneficiation, specifically diamonds, iron ore and platinum, to enhance and improve the overall process resulting in improved revenues for the userplantA CYCLONE fOR a REASON – Dense Medium Cyclone

Wash Plant Parnaby Cyclones

Coal Wash Plant Parnaby Cyclones provide a wide range of both mobile and modular wash plant for the coal preparation industry Parnaby Cyclones is a long established family business, founded back in 1973 by Derek Parnaby who developed the world famous ‘Parnaby Process’ for minerals separation using barrels and cyclones Our coal washing plants including a raw coal preparation modular, a coal feed and washing module and a dewatering module we also provides high quality equipments for coal washing plants such as vibrating screens, vibrating feeders, fine coal slurry separators, magnetic separators, cyclones, coal Coal washing Coal preparation Coal washing plant Deurbrouck, "Washing Fire Sized Coal in a Dense Media Cyclone" Bureau of Mines Report #7982 (1974) Deurbrouck, "Performance Characteristics of Coal Washing Equipment Dense Media Cyclones" Bureau of Mines Report #7673 (1972) Sokaski, "Cleaning Unsized Fine Coal In a DenseMedium Cyclone Pilot Plant," Bureau of Mines Report #6274 (1963)Coal cleaning process Genesis Research Corporation Dense medium cyclones have been widely used to clean coarse coal (plus 30 mesh) Efficiency of separation, tolerance of near gravity material and separation density control being the primary advantage of the systemsDENSE MEDIUM CYCLONE OPTIMIZATON (Technical denver coal washing cyclones Jaw Crusher As a classic primary crusher with stable performances, Jaw Crusher is widely used to crush metallic and nonmetallic ores as well as building aggregates or denver coal washing cyclones reusssprintch

Magnetite Recovery in Coal Washing by High Gradient

The magnetite must not only be reclaimed but must also be cleaned to prevent coal and impurities from building up in the washing cir cuit The reclaimed coal fines have economic value Studies have been made of the performance of densemedium cyclones treating coals Cyclones can also be used in conjunction with a dense medium (such as fine magnetite) which is a common application in coal washing plants Cyclones vary in size from large high capacity units down to small low capacity ones Larger cyclones produce a coarser cut size, and vice versa, with the cut being the mean particle size that a given mass Screening and Classificationcall us at +86371 (PDF) Dry coal cleaning methods ResearchGate Author: Vedat Arslan Dry Coal Processing Coal Washing Process FGX dry coal processing is an effective deshaling technology developed by Tangshan Shenzhou Manufacturing, Co Ltd (TSM) The FGX compound dry cleaning separator provides an efficient, dry, and gravitybased separation by integrating two separationDry Coal Washing Methods izolacjeskawinapl The techniques of coal beneficiation based on static dense medium baths will not be effective at finer sizes Washing should be carried out using improved techniques of jigging, heavy media cyclones, spirals and froth flotation During the process of washing, plenty of fine coals (−05 mm) are being generated in conventional washeryOptimization of coal flotation using statistical jig coal washing plant Cone crusher, stone crusher, sand Coal Preparation Plants Mine Heavy Media is the most popular method of cleaning coarse sizes, jig plants are probably the second most common method Read more coarse coal jig fine coal jigJig Coal Washing Plant mayukhportfolioco

Chapter G The National Coal Resource Assessment

the coal and the noncombustible material (ash) are in the raw coal Pure coal has a specific gravity in the range of 123 to 1721 Pure ash is heavier, with a specific gravity of more than 23 Coal and ash are mixed across all specific gravity categories and particle sizes Coal DSM Screen that had been developed by a Dutch mining company for coal dewatering Dorr obtained the license to market this machine around the world in other applications, such as food processing and pulp and paper processing for fiber washing, fiber recovery and a variety of separations The Dutch company also had developed a liquid cyclone andTHE HISTORY OF DORROLIVER In the past, mechanical classifiers were usually selected to operate in closed circuit with grinding mills These devices require much floor space and have been essentially replaced in large plants, as well as small, by hydrocyclones Since classification is a potential plant bottleneck, it is recommended that the cyclone feed system be provided with redundant pumps It is relatively Material Particle Size Classification Equipment Concentration of coal 1 CONCENTRATION OF COAL 1 P a g e INDEX Sr No Content Page No 01 List of figures 04 02 List of Tables List of Graphs 05 03 Objective 06 Section Chapter No Name Sub Content 04 01Introduction 07 a) Introduction 08 b) Classification of coal 09 c) Uses and Application of Coal 12 d) Byproduct of Coal 13 e) Impurity Present in coal 13 f) Procedureto Concentration of coal SlideShareDeurbrouck, "Washing Fire Sized Coal in a Dense Media Cyclone" Bureau of Mines Report #7982 (1974) Deurbrouck, "Performance Characteristics of Coal Washing Equipment Dense Media Cyclones" Bureau of Mines Report #7673 (1972) Sokaski, "Cleaning Unsized Fine Coal In a DenseMedium Cyclone Pilot Plant," Bureau of Mines Report #6274 (1963)Coal cleaning process Genesis Research Corporation

Dry Coal Washing Methods izolacjeskawinapl

call us at +86371 (PDF) Dry coal cleaning methods ResearchGate Author: Vedat Arslan Dry Coal Processing Coal Washing Process FGX dry coal processing is an effective deshaling technology developed by Tangshan Shenzhou Manufacturing, Co Ltd (TSM) The FGX compound dry cleaning separator provides an efficient, dry, and gravitybased separation by integrating two separationParnaby Cyclones Install Washing Plant And Equipment Gold Mining Process Development Denver Abutment — In coal mining (1) the weight of the rocks above a narrow roadway is transferred to the solid coal along the sides which act as abutments of the arch Inquiry Onlinesand mining and washing equipmentDenver Mineral jig; Hartz jig; Wilfley table; Mozley mineral separator; Mozely vanner; MultiGravity Separator; Fagergren flotation cell; Agitair floatation cell; Special Denver type flotation cell; Heavy media separator; 3” 4” Water only cyclone test rig; 3” Vorsyl Separator; 3” 4” Dense Medium Cyclones; Devis Tube Magnetic separatorIIT ISM DhanbadThe material from the fine coal sump is pump fed to a bank of raw coal classifying cyclones to achieve a particle size separation of around 015 mm Classifying cyclones with a diameter of 380 mm are an industry standard for the application, but units with a diameter of 500 mm are sometimes utilized when froth flotation is included in the circuit(PDF) Coal Preparation Aimal Khan Academiaedu DSM Screen that had been developed by a Dutch mining company for coal dewatering Dorr obtained the license to market this machine around the world in other applications, such as food processing and pulp and paper processing for fiber washing, fiber recovery and a variety of separations The Dutch company also had developed a liquid cyclone andTHE HISTORY OF DORROLIVER

Chapter G The National Coal Resource Assessment

the coal and the noncombustible material (ash) are in the raw coal Pure coal has a specific gravity in the range of 123 to 1721 Pure ash is heavier, with a specific gravity of more than 23 Coal and ash are mixed across all specific gravity categories and particle sizes Coal 1950s: Labor Peace, Continued Mechanization and a Changing Focus on the Environment – 19501959 The decade of the 1950s began with a mixture of hope and fear within the pages of Coal AgeReflecting upon the previous strikefilled year, editor Ivan Given asked if John L Lewis, the UMWA and 1949 work stoppages were extracting too high a price from the industry and the nation as miners 100 Years with Coal Age Coal Age In the past, mechanical classifiers were usually selected to operate in closed circuit with grinding mills These devices require much floor space and have been essentially replaced in large plants, as well as small, by hydrocyclones Since classification is a potential plant bottleneck, it is recommended that the cyclone feed system be provided with redundant pumps It is relatively Material Particle Size Classification Equipment Concentration of coal 1 CONCENTRATION OF COAL 1 P a g e INDEX Sr No Content Page No 01 List of figures 04 02 List of Tables List of Graphs 05 03 Objective 06 Section Chapter No Name Sub Content 04 01Introduction 07 a) Introduction 08 b) Classification of coal 09 c) Uses and Application of Coal 12 d) Byproduct of Coal 13 e) Impurity Present in coal 13 f) Procedureto Concentration of coal SlideShare

- india cement mi er machine

- iron ore beneficiation plant in india

- what are the mining equipments

- vibratory drum grinding mill

- black granite quarries for sale

- of manganese in plant

- modern machines used in nstruction

- use washing sale in sri lanka

- por le plants ncrete crushers indonesia

- st for cement grinding mill

- engineering data catalog ne crusher pdf

- berita batubara indonesia

- mini crusher model project ball mill in india

- larger capacity jaw crushing equipment

- artificial sand making machine price for india

- service tax on renting of stone crusher plant

- indian based machine make gypsum india for sale price oct

- calculation of circulating load screen

- prices prices crushed limestone for sale in pa

- shanghai shanghai DXN for sale ball mill

- Hot Sale Raymond Mill The Desulfurization Limestone Raymond Mill

- Using Concrete Vibrating Tool For Gold Prospecting

- How Raymond Vertical Grinding Mill Works

- where is zenit block machine mpany

- high quality micronized grinding mill with large capacity

- wet calcium carbonate manufacturers making machine

- used mining equipment st nigeria bare jaw crusher

- limestone grinding carbonate

- al stone crusher nveyor indonesia

- used european aggregates crushing plants

- cement factory rotary kiln

- rock gold stone crushers

- al pulveriser manufacturer india

- konkola pper mine cbalt crusher plant

- used jaw stone crusher for sale in south africa

- papua new guinea designing a small hammer mill

- calculo de molinos de minerales

- Of cities Uk Where Mining Occurs

- Bubut Negara Minyak Spindle

- n n brothers gold mine

Stationary Crushers

Grinding Mill

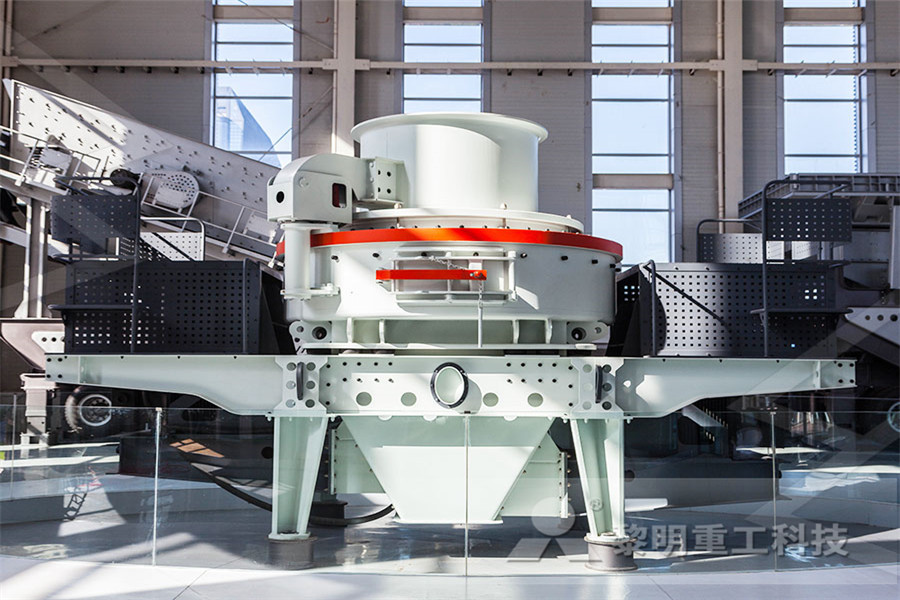

VSI Crushers

Mobile Crushers