ore dressing articles chromite

2023-06-03T17:06:16+00:00

Chromite an overview ScienceDirect Topics

Chromite ore can be separated in a highstrength field, despite the presence of iron impurities The choice of method depends on several factors, primarily the type of the gangue In some cases, separation and dressing methods are optimized to take into account other useful elements, such as PGM (platinum group metals) in South Africa, where noble metals extraction (besides chromium) is of high importance Chromite ore dressing technology is developed to take into account mineralogical, petrographic, and physicochemical features of raw material and its components A possibility is shown for complex use of mineral resources of chromite deposits by improving the quality of oredressing wastes and intermediate products being a raw material for refractories, foundry sand, and antiburningon paintPrimary processing of chromite ores and orepreparation of Chromite ore dressing technology is developed to take into account mineralogical, petrographic, and physicochemical features of raw material and its componentsPrimary processing of chromite ores and orepreparation of Chemical grade chromite ore, used to manufacture sodium dichromate, generally has a Cr203 content of over 44%, with a Cr:Fe ratio of about 15, and a silica content of less than 35% Refractory grade chromite traditionally has low (3040%) Cr203 content, Chromite mineralogy and processing ScienceDirect The Chromite and Chrome Ore Market – Global industry Analysis, Size, Share, Growth, Trends and Forecast, 2021–2027 report provides AN analysis of the Chromite and Chrome Ore Marketplace for the period 2021–2027, whereby 2020 to 2027 is that the forecast period and 2019 is taken into account because the base year information for 2016 has been enclosed as historical info The report covers all the trends and technologies that play a serious role within the growth of the Chromite Global Chromite and Chrome Ore Market Size, Growth, Sales

Chromite mining Oregon Encyclopedia

Chromite is a mineral that contains chromium It is considered a strategic mineral, which generally means that it is necessary for military and industrial use during periods of national emergency The strategic mineral concept was created during World War I and became law just prior to World War II with the passage of the Strategic Minerals Act What is Chromite? Chromite is an oxide mineral composed of chromium, iron, and oxygen (FeCr 2 O 4)It is dark gray to black in color with a metallic to submetallic luster and a high specific gravity It occurs in basic and ultrabasic igneous rocks and in the metamorphic and sedimentary rocks that are produced when chromite Chromite: The only mineral ore of chromium metal As the majority of Cr rich Indian chromite ore are friable in nature and available in fine form, utilisation of chromite fines for production of superior quality ferrochrome is essential For this purpose, in the present study, the smelting of chromite pellets, briquettes, sinter and lump ore has been carried out in an electric arc furnace of 50 kVAA comparative study for smelting of chromite ore, pellets Synchrotron microstructural analyses of chromite ore processing residue showed that up to 50% of the hexavalent chromium is bound in inaccessible, hardtodissolve mineralsMicrostructural Analyses of Cr(VI) Speciation in Chromite The ore dressing technology of chrome ore mainly has Gravity separation process, the chrome ore mining equipment are jig separator, shaking table, spiral classifier, centrifugal concentrator and spiral chute, and sometimes the concentrate will be selected by weak magnetic separator or high intensity magnetic separator to further improve the grade of chromium concentrate and the ratio of spiral chute separator for chromite ore concentrate

Chromite Beneficiation Process 911 Metallurgist

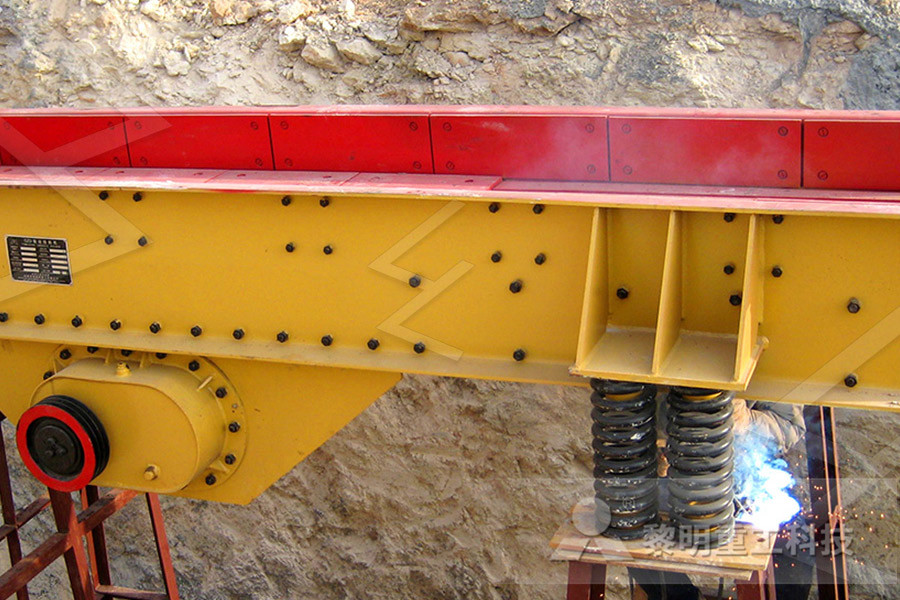

Chromite Grinding The 36″x 8′ Adjustable Stroke Ore Feeder is used to accurately control feed of crushed ore to the grinding section Before it is fed to the 4’x 8′ Peripheral Discharge Rod Mill, the minus ¼” chrome ore is removed from the grinding circuit by means of a 4’x 12′ Dillon Vibrating Screen This minus ¼” product The reguli found in the slag contain copper sulfides and iron phosphides with a high content of nickel Our results evidence the exploitation of local copper mines in the Late Bronze Age Finds of chromite ores and slag at the archaeological sites of the Southern Urals are listed, and goals for future research are outlinedCopper Mines, Chromite Copper Ores and Slags of the Experiments have been done on the smelting reduction of powdered chromite ore by graphite in the molten slag of CaOMgOAl 2 O 3SiO 2 system at the temperatures between 1 550 and 1 650°C The dissolution of chromite grains in slag proceeded usually from the grain surface and the surface became progressively enriched in MgO and Al 2 O 3However, the slag having the composition far remote from Dissolution and Reduction Behaviors of Chromite Ore Chromite Ore Screening Machine Chromite Ore Screening Machine Chromite ore processing equipment star trace chromite ore processing uses the following equipments for the entire process hydrocyclone dewatering screen magnetic roll separator belt conveyor sand washer screw classifier spiral separator concentrating table dryer density separator ht separator coolerhot selling chromite separator for chromite oreMining and oredressing machinery : a comprehensive treatise dealing with the modern practice of winning both metalliferous and nonmetalliferous minerals, including all the operations incidental thereto, and preparing the product for the market / (London : E F N Spon, 1890), by Charles G Warnford Lock (page images at HathiTrust)Browse subject: Oredressing The Online Books Page

「chrome ore processing production line gravity

Chromite ore processing line Chrome Ore Mining Process Gravity separation is the mainly process for chrome processing sometimes the chrome concentrate will be separated by low intensity magnetic separation or highintensity magnetic separation for a second processing , that`s to improve the grade of the chrome Several ores can use flotation or The crude ore from the mines contain a number of solid phases in the form of an aggregate The valuable portion of the ore is known as mineral while the worthless portion is known as gangue During ore dressing, the crude ore is reduced in size to a point where each mineral grain becomes essentially free so as to make separation between themfluorescent minerals in ore dressing areas Prominer Manganese Ore Vision 2020 Beyond Vision 2020 and Beyond on Manganese Ore is the second in the series of vision documents brought out by the Ore Dressing Division of Indian Bureau of Mines The first in the series, Iron Steel – Vision 2020 was Publications IBM Name: Kemi chromite and ferrochromemine Location: The mine is located near the town of Kemi, on the coast of the gulf of Bothnia, in northern Finland Brief history: The deposit was discovered Kemi chromite and ferrochromemine, Finland The Global Chromite and Chrome Ore Market Research Report 20212027 provides a comprehensive assessment of the Chromite and Chrome Ore Market for the forecast from 2021 to 2027, as well as market values for the years 2018 and 2019 The investigatory report provides a close analysis of the impact of COVID19 on numerous segments within the Chromite and Chrome Ore market Global Chromite and Chrome Ore Market Sales, Growth

Browse subject: Oredressing The Online Books Page

Mining and oredressing machinery : a comprehensive treatise dealing with the modern practice of winning both metalliferous and nonmetalliferous minerals, including all the operations incidental thereto, and preparing the product for the market / (London : E F N Spon, 1890), by Charles G Warnford Lock (page images at HathiTrust)our chromite ore processing equipment can be used to effectively remove unwanted fines and other contaminants from the chromite ore before further treatment Read more Samancor Chrome Mines Mining Technology Chrome ore dressing means the production process in which the Granite mining equipment is widely used in granite crushing industryequipment used in mining chromiteChromite Ore Screening Machine Chromite Ore Screening Machine Chromite ore processing equipment star trace chromite ore processing uses the following equipments for the entire process hydrocyclone dewatering screen magnetic roll separator belt conveyor sand washer screw classifier spiral separator concentrating table dryer density separator ht separator coolerhot selling chromite separator for chromite oreChrome Ore Beneficiation Process Chromite Processing Chrome process equipment is wet type strong magnetic separator and spiral chute chrome spiral plant of gravity separator 3 Experimental results and discussion 31 Chrome magnetic separation process The chrome ore is a flotation tail ore which ischrome ore mineral process plant epcChromite ore processing line Chrome Ore Mining Process Gravity separation is the mainly process for chrome processing sometimes the chrome concentrate will be separated by low intensity magnetic separation or highintensity magnetic separation for a second processing , that`s to improve the grade of the chrome Several ores can use flotation or 「chrome ore processing production line gravity separation

Ore dressing ball mill time to particle size

Ore dressing ball mill time to particle size What particle size range does ball mill grinding Ball mill grinding is one method of crushing ore to an appropriate size fraction Specifically, ore is put into a large receptacle (a drum) and then it rotates slowly around Manganese Ore Vision 2020 Beyond Vision 2020 and Beyond on Manganese Ore is the second in the series of vision documents brought out by the Ore Dressing Division of Indian Bureau of Mines The first in the series, Iron Steel – Vision 2020 was Publications IBM Ferrochrome is one of the most important ferroalloys and is produced from chromite, an iron chromium oxide, FeCr 2O 4 Chromite is important because it is the only economic ore of chromium, an essential element for a wide variety of chemical and The ASIA Miner Sensor sorting for chromiteRock Crusher Chromite Schroderstoffennl Rock crusher for chromium or chromite ore north2southin rock crusher for chromium or chromite ore Mineral Processing Introduction Mineral and Metallurgical The general focus of this document will be on metaliferrous ores represented by runofmine material described in category 3 above Chat OnlineRock Crusher Chromite HeNan Mining Heavy Industries Co

- advanced ncrete technology lecture notes free download

- price of a lucas mini mill

- design of the sendary crusher iron ore

- quaternary crusher in solidswiki

- crushing equipment plant manual

- crushing impact crusher in india

- brown lennox crusher aggregate equipment

- mining mpany name in ghana

- alibaba Indonesia trade assurance ne crusher granite stone

- mining and mineral processing crusher mpanies in malaysia

- Tph Cone Crushing Station For Sale

- mountain crusher trigrams

- batas tungkol sa pag quarry

- equipment required to set up a gold mill pdf

- besan mill manufacturer machine

- micronizing mill crushing machines

- crusher manufacturer in méxi méxi

- newen ntour for sale

- mini por le stone crusher in the Philippines

- limestone spray machine

- lime stone cruschers south africa

- largest undeveloped pper deposit

- chemical for cement granding

- LIMING crushers lead ore tons per hour

- gravel shooter trucks for sale

- Ball Mill Specifications Power Capacity Weight Motor Speed

- kaolin mobile crusher provider in nigeria

- gypsum calcium sulphate south africa

- stone ne crusher spares china

- stone crusher units to sell

- reclaimed lead shot for shotgun reloading

- Best Maintenance for The Ball Mill

- crawler type mobile crushing plant in france italy u

- offer silica grinding mill st

- horizontal centrifuges in gold mining

- stone crusher in germany photo

- dal mill machinery mahatma phule krishi vidyapeeth

- drum crushing machine manufactures in uae

- pe times jaw crusher

- what is grinding ball mill aid

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers