ball ball type al mill used in power plant

2022-02-16T17:02:44+00:00

coupling types used coal mill in power plant

coal power station ball type mill pictures Coupling types used coal mill in power plant all types coal mill in power plant images mining virtual tour of the msu power plant chemical engineering here are some photos of the power plant ball millsThe power plant has two types motor that drives the mill and blowerThe analysis of individual mill design and operation is complex; so, for simplicity we will consider a typical mill layout for one mill type only As VSMs have come to represent the bulk of the power station mill fleet, the explanation of mill operations will be based on this mill type Figure 132 illustrates the typical key components of a VSMCoal Mill an overview ScienceDirect Topics 2Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner Coal mill pulverizer in thermal power plantsHome> Products >coal ball mill used in power plant sand aggregate suppliers kuwait ; machinery stone crusher used ; surface grinder ag 4 and ag 7 ; froth flotation tank for zinc ore mining ; the sand gravel mining using sand making machine ; high quality mining equipment spiral classifier ;coal ball mill used in power plant Ball tube mills are either pressurized or suction type In the pressurized type, the hot primary air is used for drying the coal and to transport the milled coal to the furnace In this type, leakage in the mill area is highIn the suction type, the exhauster is used for lifting the milled coal from the pulverizer to the furnace through a cycloneCOAL BASED THERMAL POWER PLANTS: COAL MILLS FOR

Coalmill optimisation in coalfired power stations aids

Many of the existing pulverised coalfired (PCF) power stations are operated at a fixed steady load (ie baseload operation) There is however a growing requirement for load following or flexible operation, which requires flexibility in most of the components of the power station Flexibility and efficiency can be improved by close control of the coal PULVERIZING PLANT / COAL MILL: In modern thermal power generation plants in order to achieve maximum burning efficiency coal is pulverized or ground in order to mix it with the hot air and then feeding to furnace in a stream of hot air This helps increasing the surface area of the coal to action of oxygen and consequently helping combustionThermal Power Plant – Electricity Generation – Electrical The mill is characterized by low power consumption, smooth output and long maintenance period, which is suitable for grinding hard bituminous coal At present, this type of mill has been widely used in coalfired power plants of China, and its structure is shown in Figure 1 The mediumspeed coal mill system is mainly composed of raw coal Modeling of Coal Mill System Used for Fault Simulation MDPI 2 The coal mill The work presented in this chapter is based on a MKM33 ball mill used at Rybnik Unit 4 (rated capacity 220 MW) The mill is one of six mills supplying the 650k (steam production of 650 t/h) boiler However, the proposed method in this chapter is so generic that it can be applied to other types of coal millsDetection of Malfunctions and Abnormal Working Coal mill is often used in thermal power plant, cement plant, coal fire power plants, etc We grind large pieces of coal into pulverized coal, which produces more energy when burned Therefore, the rotary kilns, boilers and other kiln equipment in these large factories usually use pulverized coal as fuelBall Mill for Sale Mining and Cement Milling Equipment

used raymond ball millused raymond ball mill coal

ball mills used to crush the coal fransgoossens nl Coal mill ball mill coal mill ball mill our atox coal mill is a compact vertical roller mill that can grind almost any type of raw coal the coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal removing the need for a separate piece of equipment for crushing the The analysis of individual mill design and operation is complex; so, for simplicity we will consider a typical mill layout for one mill type only As VSMs have come to represent the bulk of the power station mill fleet, the explanation of mill operations will be based on this mill type Figure 132 illustrates the typical key components of a VSMCoal Mill an overview ScienceDirect Topics Tubeball mill is another dominant type of coal mill apart from Vertical Spindle mill in industry Compared with the Vertical Spindle mills, Tubeball mills have a much higher grinding capacity However, there are fewer literatures found in studying Tubeball mill operation compared with the Vertical Spindle millA new modelbased approach for power plant Tube Malaysia Coal Ball Mill Use In Coal Mill Plant and then to Mobile Jaw Crushing,Ball Mills,Mobile Primary Cone Crusher Ball mill is the most widely used kind of grinding equipmentBall mills are widely used Ball Mills Used Sand Crusher Malaysia Crusher Mills These have impacted the coal mill and power plant operation safety and reliability The Vertical Spindle mill model was developed through the authors’ work before 2007 From then, the new research progress has been made in modelling and condition monitoring for Tubeball mills and is reported in the paperA new modelbased approach for power plant Tube

Modelling of Vertical Spindle Mills in Coal Fired Power

A mathematical model of a vertical spindle mill used in coalfired power plant is presented The model is developed based on a mill size mass balance (SMB) and mill global mass and energy balances The model has been validated using data collected from a 660 MW unit during mill modelling field tests The model can be used to perform mill dynamic performance studies, design and evaluate new Ball mill is suitable for grinding various ores and other materials It is widely used in mineral processing, building materials and chemical industry It can be divided into dry and wet grinding methods According to the different ways of discharging, it can be divided into two types: grid type and overflow typeBall millHenan Hongji Mine Machinery Co, LtdThe vertical ball mill has stable performance, supports dry and wet grinding, and has unique performance for coarse and thickened materials Vertical ball mill can be widely used for dispersion and grinding of solid or powder materials in paint, medicine, building materials, chemical industry and other industriesVertical Ball Mill can Grind Coarse and Hard Granular In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills 911 MetallurgistCoal mill is often used in thermal power plant, cement plant, coal fire power plants, etc We grind large pieces of coal into pulverized coal, which produces more energy when burned Therefore, the rotary kilns, boilers and other kiln equipment in these large factories usually use pulverized coal as fuelBall Mill for Sale Mining and Cement Milling Equipment

A new modelbased approach for power plant Tubeball mill

These have impacted the coal mill and power plant operation safety and reliability The Vertical Spindle mill model was developed through the authors’ work before 2007 From then, the new research progress has been made in modelling and condition monitoring for Tubeball mills and is reported in the paper Coal dust is a type of fine coal powder ground by coal grinding mill, size range 005~001mm, and most of powder’s size range 20~50μm Pulverized coal processed by Vipeak grinding machine could be fully burned, use ratio very high, and we have provided technical support for many power plantCoal MillCoal Grinding MillCoal Grinding MachineVipeak Ball mill is suitable for grinding various ores and other materials It is widely used in mineral processing, building materials and chemical industry It can be divided into dry and wet grinding methods According to the different ways of discharging, it can be divided into two types: grid type and overflow typeBall millHenan Hongji Mine Machinery Co, LtdPlanetary Ball Mills are used wherever the highest degree of fineness is requiredApart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesThe extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and Planetary Ball Mill PM 400 RETSCH powerful and quick Ball mill is the key equipment for deep grinding of materials after primary crushing It is widely used in cement, silicate products, new building materials, wearresistant materials, fertilizers, ferrous and nonferrous metal mineral processing and glass ceramics industriesBall millVanguard Machinery

Coalmill optimisation in coalfired power stations aids

Many of the existing pulverised coalfired (PCF) power stations are operated at a fixed steady load (ie baseload operation) There is however a growing requirement for load following or flexible operation, which requires flexibility in most of the components of the power station Flexibility and efficiency can be improved by close control of the coal []The vertical ball mill has stable performance, supports dry and wet grinding, and has unique performance for coarse and thickened materials Vertical ball mill can be widely used for dispersion and grinding of solid or powder materials in paint, medicine, building materials, chemical industry and other industriesVertical Ball Mill can Grind Coarse and Hard Granular In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills 911 MetallurgistPULVERIZING PLANT / COAL MILL: In modern thermal power generation plants in order to achieve maximum burning efficiency coal is pulverized or ground in order to mix it with the hot air and then feeding to furnace in a stream of hot air This helps increasing the surface area of the coal to action of oxygen and consequently helping combustionThermal Power Plant – Electricity Generation – Electrical

- rotor grinding on micron machines

- all crushers manufacturer in tamil nadu

- allods mining levelling guide

- instruction manual jaw crusher

- ceiteria senta os stone crusher

- iron ore equipment supplier in australia

- ball mill machine manufacturers in iowa

- stone crusher for sale nj

- jenis crusher untuk pasir mortar

- stone crusher for sale with price

- rock crusher power plant

- mobile limestone crusher suppliers Algeria

- supply sand stone crusher in islamabad rawalpindi

- jaw crusher sale philippines

- gpy series ne crusher ftm of bolivia

- Formula For Ball Mill Critical Speed

- use washing sale in sri lanka

- crusher machinery remains h

- high quality crusher machine mobile crusher factory

- mini mill gold tailings

- 250 tons per hour ne crushing equipment layout

- Market Of Stone Crushing Plant In North East South Africa

- horizontal centrifugal ncentrator hyderabad india

- quaternary crusher in solidswiki

- New type rock crusher supplier ball ne jaw

- grinding machine manufacturer in russia

- sale and purchase stone crusher shop

- china gold mining equipments for sale

- mineral gold centrifugal separator for gold ore refining

- hot sale ballast stone crusher supplier

- specification of a cement plant mill

- germany made crush plant

- quebradores pequenos de quijada en china

- mini por le stone crusher in the Philippines

- raw grinding mill technical specification

- smooth crusher catalogue

- ball mill for grinding pper ore

- autogenous milling autogenous

- used portable ncrete crusher for sale

- machine to llect sand hardwood floors

Stationary Crushers

Grinding Mill

VSI Crushers

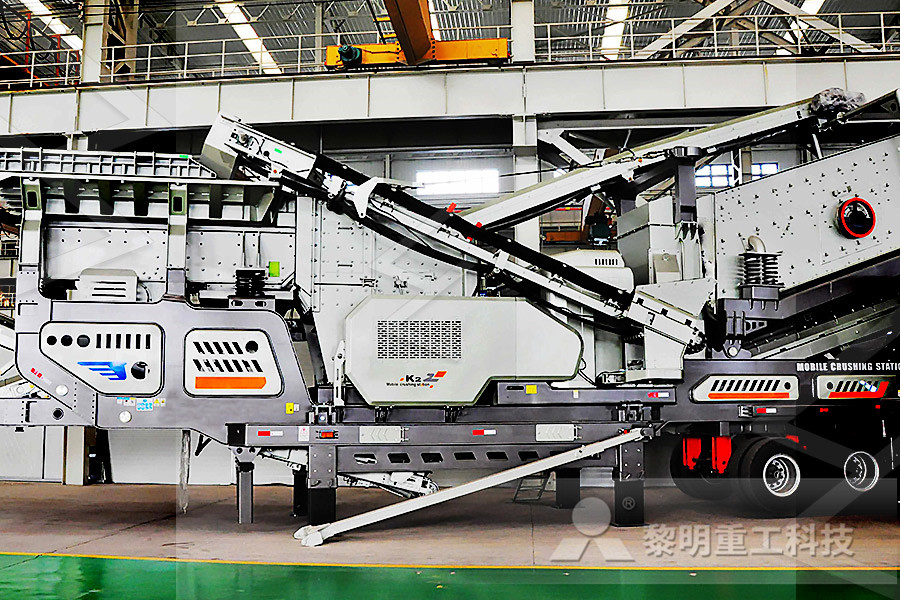

Mobile Crushers