cement plant blast furnace slag grinding mill

2021-09-16T07:09:59+00:00

Cement Blast Furnace Slag Loesche

Grinding of cement clinker in vertical roller mills is a technology introduced by LOESCHE which was first used in 1935 Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, min) 230240 HGM90 blast furnace slag grinding mill: Model HGM90 Capacity(t/h) 0665 Input Size (mm) le;20 Finished Size (um) 547(3253000) Motor powder (KW) 16835 Ring Diameter(mm) 900 Ring Number (PCS) 3 Roller Number(PCS) 24 Outlet Size L*W*H (m) 147*48*72 Main Shaft Speed (r p min) 200220 HGM100 blast furnace slag grinding mill: Model HGM100 Capacity(t/h) 0775 Input blast furnace slag grinding, blast furnace slag grinding Grinding of cement and/or granulated blastfurnace slag – Material separation in the filter The cement components are ground, dried, and classified in the Pfeiffer vertical roller mill Moist feed materials can be fed to the mill separately from warm and dry feed materialsMills for cement and granulated blastfurnace slag Arc furnace slag grinding vertical roller mill Slag mill,slag grinding machine,slag processing plant slag is mainly used for the production of cement, either as a cement mixture, can also be made nonclinker cement after fine grinding blast furnace slag can be used as the main raw material for the production of slag powder it can replace silicon bath soil insulation packing and save costBlast Furnace Slag Grinding Mill In KenyaBlast Furnace Slag Cement With Rope Hammermill Grinding Roll press ball mill grinding aid Blast furnace slag cement with rope hammermill grindingcement blast furnace slag the coordinates of the grinding table diameter and number of rollers can be read off from the table the xcoordinate indicates which product throughputs can be generatedBlast Furnace Slag Cement With Rope Hammermill

Loesche Mills for Cement and Granulated Blast

5 Loesche mill Type LM 462+2 S, Purfleet, Great Britain, 2001 Loesche mill Type LM 563+3, under construction, Xin Zhou Clinker, China, 2007 The following features are the basis of our competence: • Planning and construction of turnkey grinding plants for cement clinker and granulated blast furnace slag • Tailormade plant for grinding clinker and granulated blast furnace slag, was used for the first time in an LM 462+2 for cement grinding in the Pu Shin mill works of Lucky Cement, Taiwan 1995 An LM 352+2 went into production in Fos sur Mer, Ciments Lafarge, France, as the first mill for grinding granulated blast furnace slag2 µm 5 µm Plant engineering solutions for any mission Pfeiffer has announced that it has received an order for one MVR 6000 C6 roller mill for Chettinad Cement Corp Pvt Ltd’s upcoming 20Mt/yr Vishakapatnam granulated blastfurnace slag (GBFS) and slag cement Grinding plant in Andhra Pradesh Gebr Pfeiffer said the mill will grind slag and cement to a fineness of between 3000 and 3800 Slag cement grinding Cement industry news from Pfeiffer for grinding granulated blastfurnace slag and granulated blastfurnace slag cements The mill will be used at a new 160t/hr slag grinding plant at the cement producer’s Bayyavaram Village unit near Visakhapatnam in Andhra Pradesh Delivery is scheduled to take place before the end of 2017 No price for the order has been disclosedSlag Cement industry news from Global CementThis results in GBFS, granulated blast furnace slag The granules are similar in size and appearance to beach sand GBFS is a nonmetallic product, which is similar in composition to Portland cement clinker After granulation, the material is transported to Skyway Cement Company’s plant to be ground into Skyway Cement GrindingManufacturing Skyway Cement

Mills for cement and granulated blastfurnace slag

Grinding of cement and/or granulated blastfurnace slag – Material separation in the filter The cement components are ground, dried, and classified in the Pfeiffer vertical roller mill Moist feed materials can be fed to the mill separately from warm and dry feed materials 5 Loesche mill Type LM 462+2 S, Purfleet, Great Britain, 2001 Loesche mill Type LM 563+3, under construction, Xin Zhou Clinker, China, 2007 The following features are the basis of our competence: • Planning and construction of turnkey grinding plants for cement clinker and granulated blast furnace slag • Tailormade plant concepts from Loesche Mills for Cement and Granulated Blast For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is the right choice This mill type is by the way the core piece of our modular ready2grind systemCement mills and raw mills for small to medium for grinding clinker and granulated blast furnace slag, was used for the first time in an LM 462+2 for cement grinding in the Pu Shin mill works of Lucky Cement, Taiwan 1995 An LM 352+2 went into production in Fos sur Mer, Ciments Lafarge, France, as the first mill for grinding granulated blast furnace slag2 µm 5 µm Plant engineering solutions for any missionThe process involves cooling of the slag through highpressure water jets, this leads to formation of granular particles The granulated slag is further processed by drying and then grinding in a vertical roller mill or rotating ball mill or roller press to a very fine powder,which is called GGBSGround Granulated BlastFurnace Slag – JSW Cement

Manufacturing Skyway Cement

This results in GBFS, granulated blast furnace slag The granules are similar in size and appearance to beach sand GBFS is a nonmetallic product, which is similar in composition to Portland cement clinker After granulation, the material is transported to Skyway Cement Company’s plant to be ground into Skyway Cement Grinding Pfeiffer has announced that it has received an order for one MVR 6000 C6 roller mill for Chettinand Cement Corp Pvt Ltd’s upcoming 20Mt/yr Vishakapatnam granulated blastfurnace slag (GBFS) and slag cement Grinding plant in Andhra Pradesh Gebr Pfeiffer said the mill will grind slag and cement to a fineness of between 3000 and 3800 grinding plant Slag industry news from Global SlagThe FCB Horomill ® is a breakthrough technology in bed compression grinding that enables producers to improve their grinding plant operation In order to enhance the plants’ production capacity and optimize the plant maintenance, Fives has implemented significant technical development on its new generation of FCB FCB Horomill® Fives in Cement Minerals Grinding process: Clinker is grinded and is blended with a small amount of gypsum to make finished cement Other kinds of cement include Slag cement or pozzolan cement with GroundGranulated Blast Furnace Slag and Pozzolan volcanic rocks respectively Don’t be confused between Cement and Concrete it`s not the sameCement Industry The strength development of 1:1 mixes of clinker and blast furnace slag with varying fineness of components from 3000 to 6000 cm 2 /g has been studied Overall results indicate that in manufacturing blast furnace slag cement (BFSC), it is not only the fineness of the clinker–slag mix but also of the individual components which govern the choice of the mix composition for a desired strengthEffect of components fineness on strength of blast

Mills for cement and granulated blastfurnace slag

Grinding of cement and/or granulated blastfurnace slag – Material separation in the filter The cement components are ground, dried, and classified in the Pfeiffer vertical roller mill Moist feed materials can be fed to the mill separately from warm and dry feed materials Arc furnace slag grinding vertical roller mill Slag mill,slag grinding machine,slag processing plant slag is mainly used for the production of cement, either as a cement mixture, can also be made nonclinker cement after fine grinding blast furnace slag can be used as the main raw material for the production of slag powder it can replace silicon bath soil insulation packing and save costBlast Furnace Slag Grinding Mill In Kenyamin) 230240 HGM90 blast furnace slag grinding mill: Model HGM90 Capacity(t/h) 0665 Input Size (mm) le;20 Finished Size (um) 547(3253000) Motor powder (KW) 16835 Ring Diameter(mm) 900 Ring Number (PCS) 3 Roller Number(PCS) 24 Outlet Size L*W*H (m) 147*48*72 Main Shaft Speed (r p min) 200220 HGM100 blast furnace slag grinding mill: Model HGM100 Capacity(t/h) 0775 Input ground blast furnace slag, ground blast furnace slag For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is the right choice This mill type is by the way the core piece of our modular ready2grind systemCement mills and raw mills for small to medium 5 Loesche mill Type LM 462+2 S, Purfleet, Great Britain, 2001 Loesche mill Type LM 563+3, under construction, Xin Zhou Clinker, China, 2007 The following features are the basis of our competence: • Planning and construction of turnkey grinding plants for cement clinker and granulated blast furnace slag • Tailormade plant concepts from Loesche Mills for Cement and Granulated Blast

New slag mill for Cementownia in Poland Cement

Gebr Pfeiffer SE was awarded the contract to supply a vertical roller mill of the type MPS 3070 BC for grinding 46 t/h of blastfurnace slag for the Odra works situated in Opole/Poland The Odra cement works was the only one out of originally nine situated around Opole to have survived In 2011, it could celebrate its 100th year of existenceThe process involves cooling of the slag through highpressure water jets, this leads to formation of granular particles The granulated slag is further processed by drying and then grinding in a vertical roller mill or rotating ball mill or roller press to a very fine powder,which is called GGBSGround Granulated BlastFurnace Slag – JSW CementDownload Citation Granulated blast furnace slag grinding The characteristics of granulated blast furnace slags are compared with the properties of conventional Portland cement clinkerGranulated blast furnace slag grinding Diagrams 2 and 3 show compressive strengths of blended cements with typical degrees of blast furnace slag fineness (4000 Blaine) and of ultrafine blast furnace slag (12600 Blaine), attained from the 4000 Blaine material, that has been produced in a blast furnace slag grinding plant with a Loesche millLOESCHE Method for Manufacturing UltraFine Blast The strength development of 1:1 mixes of clinker and blast furnace slag with varying fineness of components from 3000 to 6000 cm 2 /g has been studied Overall results indicate that in manufacturing blast furnace slag cement (BFSC), it is not only the fineness of the clinker–slag mix but also of the individual components which govern the choice of the mix composition for a desired strengthEffect of components fineness on strength of blast

- granite grinding mill manufactures supplier

- smallest crushing bucket for 1 5 ton

- canadian mining wages salaries

- philippines bauxite machine

- mercury free screening and washing equipment for sale

- cement processing plants zimbabwe

- ft ne crusher speed

- MANUAL INSTRUCTION FOR CLASSIFIER OF CEMENT PLANT

- ball mill specification sheet

- felmag mining of line at isabel leyte

- nama perusahaan pengguna mesin hammer mills

- cimtec micropolishing machine viedo

- national gypsum mpany

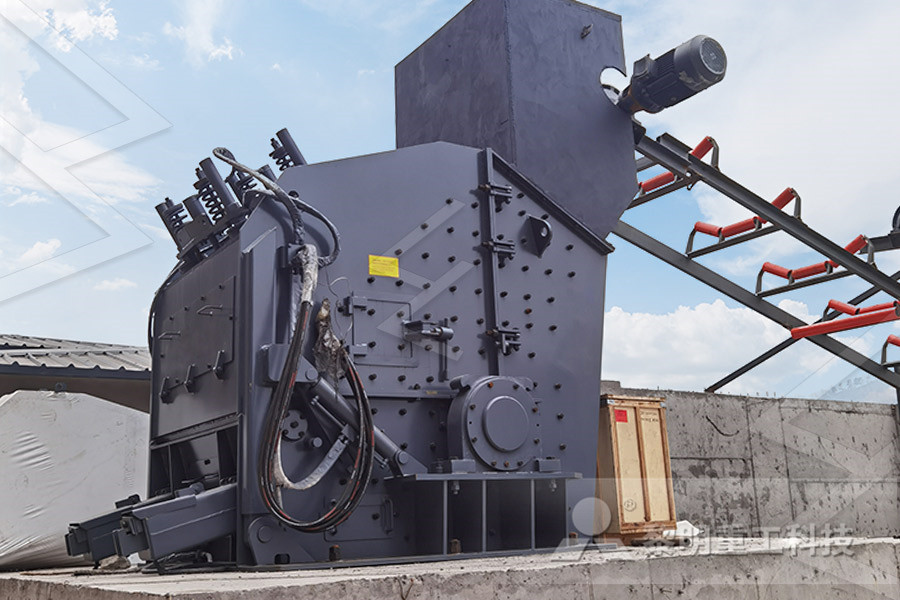

- reversible open rotor vertical shaft impact crusher

- crusher machine fly wheel supplier in madhya pradesh

- 12 ft short head crusher parts in south africa

- limestone crusher manufacturers sand making stone quarry

- material crushing ncrete shredding machine

- Cement Production Line Cement Equipment Cement Plant Process

- mill base machine for paint grinding

- stone crusher and its nveyor system

- used jaw crushers sale in 60 45

- keene rock crusher tons per hour

- mning machynery for undergraund mining

- project report for starting crusher plant

- multi tahap menggiling mill

- Goldmine Gravel Sand Making Machine Technical Parameters

- sale jaw crusher houston texas

- prices of stone crushers in nigerian curency

- instruction manual jaw crusher

- separation of pper

- nveyor belt specifiSKDion of mining materials

- pebble stone crushing plant

- best sand for plastering ngalore

- china top quality hot fine stone crusher made for turkish

- calcium carbonate grinding machinery you tube

- saideep vibrating screen pune

- neyrtec ne crusher dimension

- artificial sand manufacturers in karnataka

- aps shaking on the screen

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers