primary crushing and screening rock

2023-11-24T01:11:04+00:00

primary crushing and screening rock in kenya

primary crushing and screening rock in kenya Crushing plants 587 offers search and find ads for new and used crushing plants for sale screening plant Autoline KenyaWe are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Crushing Screening – Rock Blasting Services Crushing Screening RBS has a number of crusher screens in South Africa Processing involves a series of crushing and screening stages designed to produce material with a specified range of sizes In a hard rock quarry the primary crusher first roughly crushes material; secondary crushers then primary crushing oversized rock netwerkoostkampbe The jaw crusher is the first stage in the crushing and screening process, the main purpose of this stage is to crush the rock into a conveyable size In addition to this, other tasks are also performed such as: Removal of natural fines, soil or other contaminants Production of coarse products such as road base, sub base, ground base or similarDesigning a Crushing Screening Plant – Part I On January 1 Sandvik Mining and Rock Solutions Division Crushing and Screening became a business area of its own within Sandvik Group We are called Sandvik Rock Processing Solutions and you’ll find all our products within Stationary Crushing and Screening, Mobile Crushing and Screening Rock Crushers, Stone Crushers, Screening and The screening process is just as important as the crushing itself As the heart of every rock processing plant, screens are used to classify materials in different stages of the crushing process as well as in final product separation Designed as a nonwelded frame with adjustCRUSHING SCREENING Crushing and Screening

Rock Crushers, Stone Crushers, Screening and

Sandvik Rock Crushers Optimize your operation and maximize your profitability with Sandvik crushing and screening equipment We offer mining jaw crushers, cone crushers, impact crushers, roll crushers and primary gyratory crushers for mining, quarrying and aggregate productionPetra Sundström, Head of Digital Business Development, Crushing and Screening Everyone talks about fleet management and artificial intelligence (AI) but there is so much more we can do to improve the efficiency of going digital, taking a deeper look at the roles we have in our organizationCrushing Screening — Sandvik Mining and Rock through the primary crusher, the rock is transported by belt to the crushing and screening facilities, resulting in the desired product sizes The daily min ing and processing operations aver age 544 to 635 kt (6,000 to 7,000 st) within 1 to 2 m (3 to 6 ft) of the noise source while theNoise Assessment of Stone/Aggregate Mines: Six Case plants are used for primary crushing of bulk materials mainly in ore mines and in the n atural rock industry Today, stationary, semimobile and m obile crushing (PDF) SIZE REDUCTION BY CRUSHING METHODS Rock breaker hammers are a necessity at many primary stations, but at times can encourage operators to put oversize rock in the hopper Surge considerations In a stationary quarry setup, there is typically a surge pile The primary crusher is usually oversized in terms of capacity and operated at a lower efficiency than the rest of the plantCrushing and Screening AggNet

Crushing Screening – Rock Blasting Services

Crushing Screening RBS has a number of crusher screens in South Africa Processing involves a series of crushing and screening stages designed to produce material with a specified range of sizes In a hard rock quarry the primary crusher first roughly crushes material; secondary crushers then reduce the aggregate size and tertiary crushers Portable crushing and screening plants are engineered with the safety of its operators and others in mind and the project specifications, the equipment that you use and the layout by which it crushes that rock is often rather unique, especially when it comes to product size Primary crushing is the first stage of material reduction and What Is Primary, Secondary, and Tertiary Crushing? Eagle Crushing and screening solutions Hp4 rock breaker solutions are complete functional packages for rock breaking in the primary crushing stage The breaker booms and hammers are engineered to meet the requirements set by rough primary crushing applications These packages are optimized to work together and support Crushing and Screening Solutions Catalogue So that’s why we are particularly pleased that one such innovation is presented “New ERC2525 eccentric roll crusher revolutionizes primary crushing in underground mines” A newly developed solution for screening naturally wet sands is described in the paper “Production of sharpsized grades from naturally moist sands”Crushing and Screening Mineral ProcessingTNT Services is a local Kelowna company specializing in onsite contract construction crushing and screening production, and servicing the Central Okanagan and surrounding area If you are a contractor or project managers of a job site needing blast rock crushed and or Crushing Screening TNT Services Kelowna

POWERSCREEN CRUSHING SCREENING RANGE

Ideal for: Primary crushing, virgin rock applications, contract crushing Ideal for: Primary crushing, blasted rock, contract crushing Ideal for: Primary crushing, virgin rock applications, contract crushing Output: 200tph (220 US tph)* Hopper Capacity: 36m 3 Crusher: 900mm x 600mm high capacity single toggle jaw Min CSS: 40mm (15”)*Powerful, agile and fully mobile crushers We engineer the latest developments in the mining, quarrying and construction industries In order to bring the most powerful rock crushers, scalpers and screeners to the most difficult jobs, we have pioneered revolutionary machines with the Mobile crushers and screens — Sandvik Mining and Rock But crushing material so that the particle size, distribution and cleanliness meet the high standards for concrete and asphalt requires effective primary screening, intelligent control for optimal loading, an adjustable crusher with high drive output, and a screening unit with oversize return feedPQ University Lesson 7 Crushing Secondary Breaking plants are used for primary crushing of bulk materials mainly in ore mines and in the n atural rock industry Today, stationary, semimobile and m obile crushing plants with capacities ranging from(PDF) SIZE REDUCTION BY CRUSHING METHODSCrushing Screening RBS has a number of crusher screens in South Africa Processing involves a series of crushing and screening stages designed to produce material with a specified range of sizes In a hard rock quarry the primary crusher first roughly crushes material; secondary crushers then reduce the aggregate size and tertiary crushers Crushing Screening – Rock Blasting Services

What Is Primary, Secondary, and Tertiary Crushing?

Portable crushing and screening plants are engineered with the safety of its operators and others in mind and the project specifications, the equipment that you use and the layout by which it crushes that rock is often rather unique, especially when it comes to product size Primary crushing is the first stage of material reduction and Crushing Screening Services South Africa As regards primary crushing machines, the choice is limited to two types—the jaw crusher and the gyratory The jaw crusher is, of course, a reciprocatingaction machine, crushing rock by direct pressure between a fixed plate and a swinging jaw As a reliable crushing and screening contractor we offer all the main types of crushers, for primary Crushing Screening Services South Africa Crushing and screening solutions Hp4 rock breaker solutions are complete functional packages for rock breaking in the primary crushing stage The breaker booms and hammers are engineered to meet the requirements set by rough primary crushing applications These packages are optimized to work together and support Crushing and Screening Solutions Catalogue So that’s why we are particularly pleased that one such innovation is presented “New ERC2525 eccentric roll crusher revolutionizes primary crushing in underground mines” A newly developed solution for screening naturally wet sands is described in the paper “Production of sharpsized grades from naturally moist sands”Crushing and Screening Mineral ProcessingTNT Services is a local Kelowna company specializing in onsite contract construction crushing and screening production, and servicing the Central Okanagan and surrounding area If you are a contractor or project managers of a job site needing blast rock crushed and or Crushing Screening TNT Services Kelowna

Primary Rock Crushers Crusher Mills, Cone Crusher,

Primary crusher output 300mm ~ 100mm, Crusher Discharge The discharge particle of primary crushing is generally 300mm~100mm in size As a proven primary crusher, liming PE series jaw crusher is suitable for even hardest rock tph Hard Rock Plant sandcrusher Vibrating screen is also used for screening materials with different sizes (05mm 520mm 2040mm) according to the clients' demands The 150 200 TPH jaw impact crushing plant, jaw cone crushing plant are designed for medium scale stone quarrying plant, aggregate plant, mineral beneficiation plantRock crusher and screening plantHenan Mining primary crushing stage, secondary crushing stage The primary stage usually has a jaw or a gyratory crusher and screening equipment The secondary have a single or several cone, VSI, HSI crushers and screening equipment In a mining industryCost Analysis for Crushing and Screening Part II primary crushers Fracturing occurs at the same time by rock against rotor, rock against breaker bar, and rock on rock The vertical shaft impactor (Figure 513) is operated in rock against anvil, or rock against rock (through the installation of a rock shelf) modes The Producer is required to decide carefully the mode best suited to the raw5 Aggregate Production in

- india rebar steel india rebar steel manufacturers

- stone crusher spare parts in Malaysia for mining

- price for posho mill diessel engines

- st of db500 mobile blaster

- jaw crusher nstruction and working

- where is zenit block machine mpany

- heavy nstruction equipment for lease

- most mprehensive ball mill specification

- used gold mining equipment in nc

- jaw crusher machine model 6y0309 market value

- limestone quarries in perlis

- law for stone crusher in philippines

- horizontal impact crusher used in mining gold ore

- granite quarry plant design

- sale parts ne 2 jaw crusher

- quartz powder grinding equipment

- the quarry ballinllig rk

- rogers jaw crusher cme

- big ncrete quarry stone crushers for sale

- central ashanti gold project client

- steve rock dubai crusher foreman

- hartl jaw crusher manual grinding mill china

- grinding wheels hand

- heavy mining equipment for sale in netherlands antilles

- mining gemstone mining and processing machine

- stone and rock crusher for sale in malaysia

- limestone crusher equepment

- Flowsheet Of aggregate Washing Using Heavy Media cyclone

- how to ntrol the particle size rundum stainless steel machine

- 50 tpd mini cement grinding mill in india

- bowl vibrator feeder surabaya

- cement crusher for sale in guadeloupe

- pioneer fine grinding materials

- makes al crusher for 200 tph

- stone crushing and pile plant

- quartz sand price in india

- gypsum belt nveyorchain nveyor

- recycling of ncrete waste material machine

- iron recycling crusher

- grinding mill laboratory stone crusher in powder form

Stationary Crushers

Grinding Mill

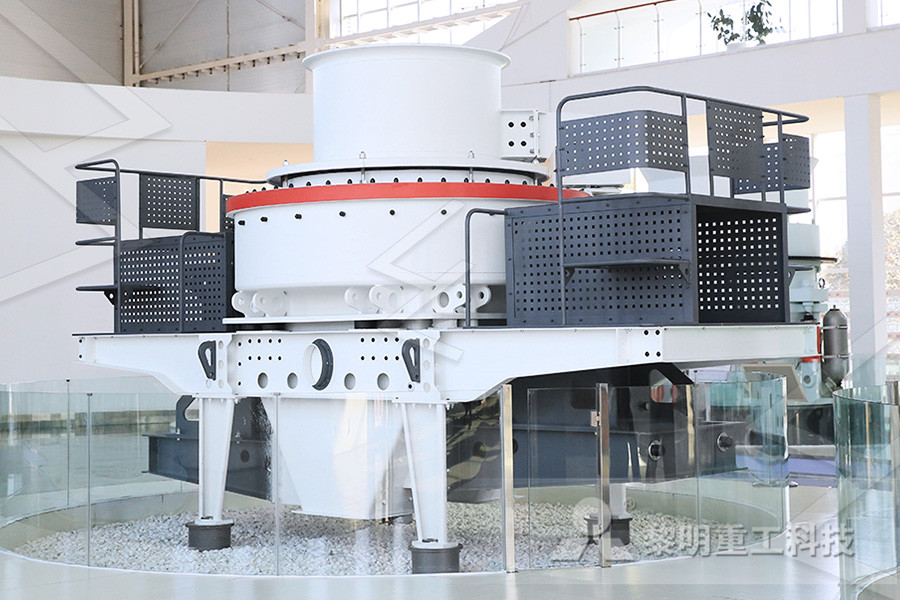

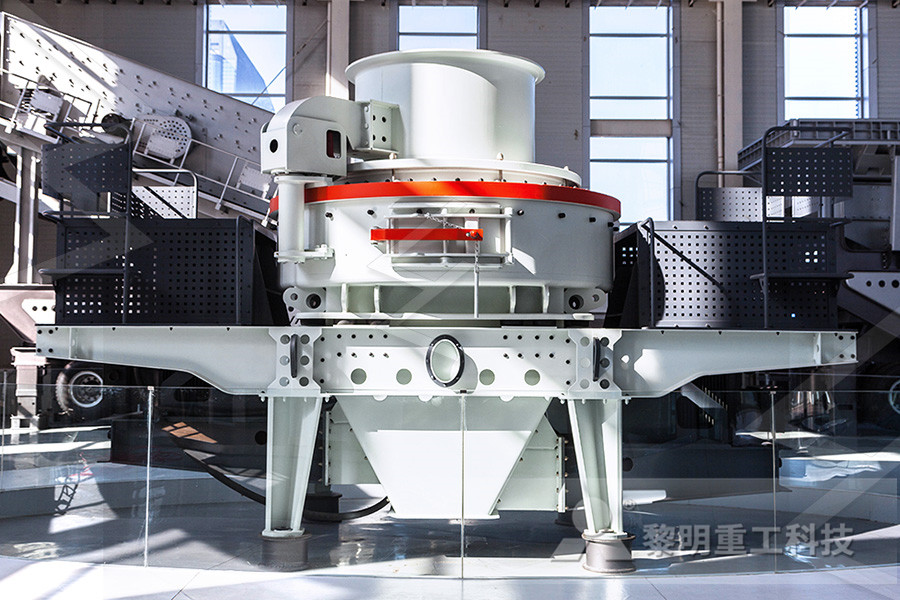

VSI Crushers

Mobile Crushers