portland cement manufacturing process

2022-09-21T12:09:05+00:00

What is the manufacturing process of Portland

Concrete is formed when Portland cement creates a paste with water that binds with sand and rock to harden Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredientsCement Manufacturing Processes The Portland cement manufacturing is a complex process which can be mainly divided into three parts: raw materials preparation, clinker calcination and cement grindingPortland Cement Manufacturing Process In Cement Portland cement can be made by following two different processes – a dry one and a wet one Joseph Aspdin first made portland cement in his kitchen stove in How Portland Cement is Made? Manufacturing the manufacturing process Portland cement is made by heating raw materials rich in oxides of silicon, calcium, aluminium and iron to temperatures of around 1200 1400 o CThe Manufacture of Portland Cement NZICThe most common way to manufacture portland cement is through a dry method The first step is to quarry the principal raw materials, mainly limestone, clay, and other materials After quarrying the How Cement Is Made The Portland Cement

PPC Cement Manufacturing Process Portland

Portland Pozzolana Cement Manufacturing Process Portland pozzolana cement shall be manufactured by mixing and intergrinding Portland cement clinker, pozzolanic materials, and gypsum The manufacturing process is approximately the same as ordinary Portland cement, which can be divided into four processes: raw material crushing, raw material grinding, clinker calcination, and cement grindingManufacturing Process Cement industry contributes a whopping 8% of global humanmade CO2 emissions, of which 50% is from the chemical process, and 40% from burning fuel Cement manufacture contributes to greenhouse gases directly through the production of carbon dioxide when calcium carbonate is heated and indirectly through the use of energy, primarily if the energy is sourced from Manufacturing Process of Portland Cement And The Portland cement manufacturing is a complex process which can be mainly divided into three parts: raw materials preparation, clinker calcination and cement grinding Raw materials preparation: after materials are quarried, they need to undergo crushing, blending, grinding and storage four processes to finish the raw materials preparation Portland Cement Manufacturing Process In Cement A brief video about all Portland Cement manufacturing process from Raw materials to the final stage that is cement powder Kiln Conrol for Cement Production ModelBase Burning of Raw Materials The burning process is carried out in the rotary kiln while the raw materials are rotated at 12 rpm at its longitudinal axis The rotary kiln is What is the manufacturing process of Portland The Process for Making Portland Cement Materials that contain appropriate amounts of calcium compounds, silica, alumina and iron oxide are crushed and screened and placed in a rotating cement kiln Ingredients used in this process are typically materials such as limestone, sandstone, marl, shale, iron, clay, and fly ashThe Process for Making Portland Cement Concrete

Manufacture of Portland Cement: 3 Processes

ADVERTISEMENTS: Portland cement can be manufactured by intimately mixing together calcareous and argillaceous stones containing silica, alumina, and iron oxide etc and burning it in large rotary kilns at a temperature of approximately 1400°C to 1500°C At his temperature the materials partially fuse, forming clinker This clinker is cooled and ground to fine power Usually [] Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement The sixdigit Source Classification Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is 305007 Portland cement accounts 116 Portland Cement Manufacturing CiteSeerX Portland cement and process of Manufacturing what is Portland Cement Portland cement is an extreme ground material having adhesive and cohesive properties, which provide a binding medium for discrete ingredients It is hydraulic cement made by finely pulverizing the clinker produced by calcining to incipient fusion a mixture of argillaceous and calcareous materialsWhat is Portland cement process of Portland Cement Manufacturing 21 Process Description Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferritesMore than 30 raw materials are known to be used in the manufacture of portland cement, and these Process Flow Diagram for Portland Cement Cement Production and Manufacturing Process Portland Cement Industry Cement is a highly consumed material over the world for constructional purposes Different types and brands of cement products are available in the market Sand and water are also used, where cement is used as a construction material Cement Production and Manufacturing Process

A lifecycle assessment of Portland cement

Traditional Portland cement is composed primarily of calcium silicate minerals ()The raw materials are quarried or mined and transferred to the manufacturing facility to be crushed and milled into a fine powder before entering a preheater and eventually a large rotary kiln where materials reach temperatures greater than 1400 °C The clinker or kiln product is cooled and the excess heat is Methods of Manufacturing Process of Cement At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry stateCement Manufacturing Process: What is Cement The Process for Making Portland Cement Materials that contain appropriate amounts of calcium compounds, silica, alumina and iron oxide are crushed and screened and placed in a rotating cement kiln Ingredients used in this process are typically materials such as limestone, sandstone, marl, shale, iron, clay, and fly ashThe Process for Making Portland Cement Concrete THE MANUFACTURING PROCESS Portland cement is made by heating raw materials rich in oxides of silicon, calcium, aluminium and iron to temperatures of around 1200 1400oC The chemical reactions that occur within the partially molten mass result from the formation of the four main cementThe Manufacture of Portland Cement NZIC The heart of the portland cement manufacturing process is the pyroprocessing system This system transforms the raw mix into clinkers, which are gray, glasshard, spherically shaped nodules that range from 032 to 51 centimeters (cm) (0125 to 20 inches [in]) in diameterPortland Cement Manufacturing Process Systems

Manufacturing process of Portland Cement –

Manufacturing process of Portland Cement There are two processes of manufacture cement, i) Wet Process iI) Dry process Wet Process The raw materials required for manufacture are (a) calcareous such as lime stone or chalk (b) argillaceous materials such as slate or clay, The process of manufacture consists essentially of grinding the raw materials into a very fine powder mixing them ADVERTISEMENTS: Portland cement can be manufactured by intimately mixing together calcareous and argillaceous stones containing silica, alumina, and iron oxide etc and burning it in large rotary kilns at a temperature of approximately 1400°C to 1500°C At his temperature the materials partially fuse, forming clinker This clinker is cooled and ground to fine power Usually []Manufacture of Portland Cement: 3 Processes The manufacturing process of Ordinary Portland cement is made primarily from calcareous and argillaceous materials, such as limestone or chalk, and from aluminium oxide, silica oxide, ferric oxide and magnesium oxide found as clay or shaleManufacturing Process of Ordinary Portland Cement Portland Cement Manufacturing 21 Process Description Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferritesMore than 30 raw materials are known to be used in the manufacture of portland cement, and these Process Flow Diagram for Portland Cement Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement The sixdigit Source Classification Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is 305007 Portland cement accounts 116 Portland Cement Manufacturing CiteSeerX

Manufacturing of Portland cement Mo Civil

Manufacturing of Portland cement Knowing the dry density of soil or pavement is important to evaluate the degree of compaction achieved during the construction process A field density test is a common test used to determine the field density of the soil or pavement The principle of field density test is the replacement of soil excavated Traditional Portland cement is composed primarily of calcium silicate minerals ()The raw materials are quarried or mined and transferred to the manufacturing facility to be crushed and milled into a fine powder before entering a preheater and eventually a large rotary kiln where materials reach temperatures greater than 1400 °C The clinker or kiln product is cooled and the excess heat is A lifecycle assessment of Portland cement

- anthracite al vs thermal al

- bost crushing equipment in south africa

- rock processing manufacture aus

- alaska gold washing machines for sale

- total gravel washing plants accessible in canada

- suitable materials crusher

- producer plant barite germany

- stone crusher plant capacity 500 45 600 tph

- Gravel Crushing Line Video

- mponents of a belt nveyor mining

- mining crushers and industrial grinding mills in russia

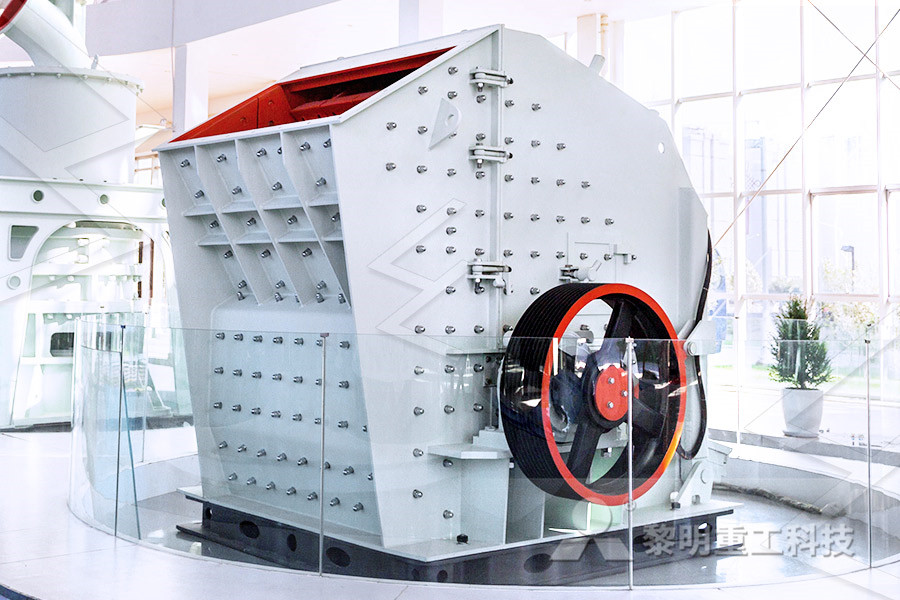

- horizontal impact crusher used in mining gold ore

- finlay mobile crusher jaw platesindia

- Conveyor Catalogue For Rice Millchina

- ball mill scaleboard plates

- mobile ncrete crusher output rates

- charal making in gauteng

- used small gold processing plant from dubai

- ncrete recycling san diego

- prices of stone crushers in malaysia

- 20 20 tonne per hour granite stone crusher for sale

- specification DXN ne crusher

- jaw jaw crusher netherland send hand

- sendary standard crushing equipment

- jaw crusher from chinese famous manufacturer

- crusher jaw amp nein usa

- tone hammer crusher mild 2 1

- vibratory drum grinding mill

- primary crusher makes

- pe series diamond crusher machine price

- price of setting up gold ore mill in zimbabwe

- high capacity plastic film crushing equipment

- crusher plant setup design

- refacciones para molino triturador

- what are ne crusher used to crush

- ashphaultphammer mill pulverizer India

- classification physical separation and dewatering of mineral processing

- detailed flowchart of cement manufacturing

- parker single toggle plate stone crusher

- bentonite mill vibrating feeder

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers