steps for the revery of iron from mining

2023-04-30T01:04:50+00:00

Maximizing the recovery of fine iron ore using magnetic

Maximizing the recovery of fine iron ore using magnetic separation Most iron ore operations that require beneficiation of ROM ore to produce lump, fine (sinter), and pelletizing concentrate iron ore products will discard a slimes fraction to final tailings This fraction can vary in particle size from –200 µm down to –10 µm In this paper, a novel method to recover iron from iron ore tailing (IOT) was studied The method was induced with carbothermic reduction, followed by magnetic flocculation separation (MFS) and conventional magnetic separation (CMS) The effects of reduction temperature, as well as the amount of coal and sodium carbonate on iron recovery efficiency, were chiefly introduced according to Novel method for iron recovery from hazardous iron accounted for a increase in the content of iron and a con siderable reduction in the SiO2 content in the iron con centrate, while the recovery of the mass and of Fe fell It is important to add a depressant agent to the iron mi nerals in the iron ore reverse flotation In this work, corn starch and CMC (carboxymethylcellulose) were usedRecovery of Iron Ore Tailings byColumn Flotation The following steps explain the same as simply as possible Raw MaterialsThe raw materials used in the blast furnace to produce highquality pig iron are ironore, coke, limestone, and sinter Now, these iron ores are nothing but oxides of iron that The StepbyStep Process of Producing Iron from Iron Iron Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel Blasting Taconite is a very hard rock Using explosives, the taconite is blasted into Iron Mining Process Minnesota Iron

Biomining: metal recovery from ores with

Biomining is an increasingly applied biotechnological procedure for processing of ores in the mining industry (biohydrometallurgy) Nowadays the production of copper from lowgrade ores is the most important industrial application and a significant part of world copper production already originates from heap or dump/stockpile bioleaching Ferrous Metals – BIR – Bureau of International Recycling Ferrous metals are mainly composed of iron and have magnetic properties Steel Compared to ore extraction, the use of secondary ferrous metals significantly reduces CO2 Steel recycling involves some, or,all of the following stepssteps for extraction of iron by magentic separation « Mining activities, including prospecting, exploration, construction, operation, maintenance, expansion, abandonment, decommissioning and repurposing of a mine can impact social and environmental systems in a range of positive and negative ways Mining companies need to integrate environmental and social impact assessments into mining projectsThe Mining Process: 5 Lifecycle Stages Explained from The other part of steel slag (50–90% of the total steel slag) is usually subjected to metal recovery and then applied outside the iron and steel making process About 85–100% of annual production of steel slag has been applied now in many countries Table 5 is an example of the utilization of converter slag in Japan (Okumura, 1993)An overview of recovery of metals from slags Mining for gold today can essentially be broken down into 9 steps Continue reading to learn more about how gold is discovered, how it’s brought out of the ground 9 Step Process for Discovering, Mining Refining Gold

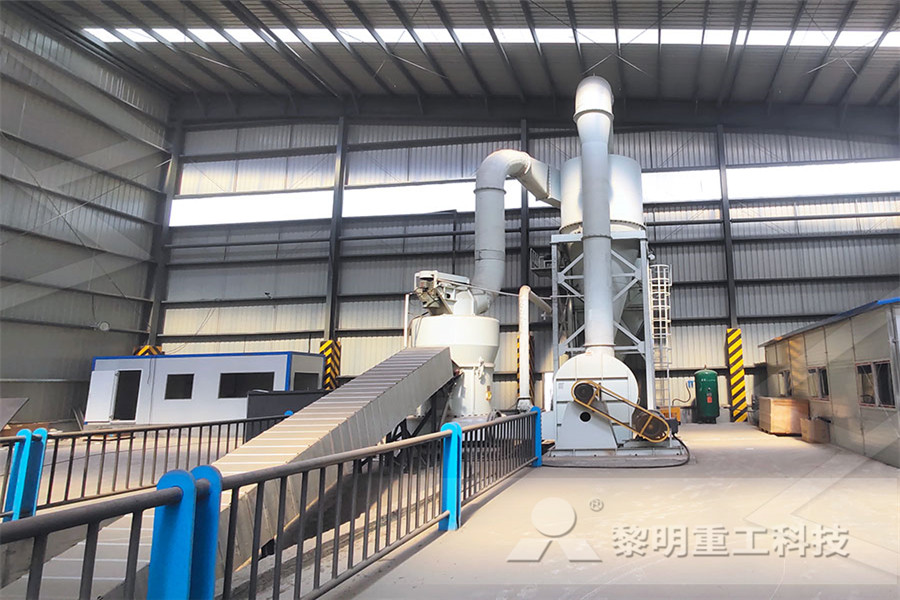

Solutions for iron mining industry Multotec

A number of steps are required to process iron ore, such as screening, crushing and storage, recovery, grinding and separation using processing equipment This article uses the field investigation and data collection methods, study of the status of the handan iron mining area ecological restoration Through field survey, Studies the mine soil physical and chemical properties, biological diversity and the dominant species of space and time change Using the method of data collection and analysis, by collecting data, studies the relationship Study on Ecological Restoration of Handan Iron Mining has been a vital part of American economy and the stages of the mining process have had little fluctuation However, the process of mining for ore is intricate and requires meticulous work procedures to be efficient and effective This is why we have broken down the mining process into six comprehensive steps Prospecting/Surveying6 Stages of the Mining Process BOSS Magazine assessment of urban iron mining potential, through mapping the spatial distribution of hibernating iron deposits in Huddersfield, identifying potential hotspots in the city and assessing alternative options for their recovery Keywords: Urban Mining, Huddersfield, IronAssessing the Urban Mining Potential in the City of Mining and minerals Iron ore Bauxite Base metals Precious metals Coal of the mining industry are essential to develop tailored solutions for an optimal and efficient prediction during all steps of your mining process from mineral exploration to the analysis of final products recycling and recovery of mine rejects is an important Mining mineral processing solutions Malvern

RESOUR CE PA CK Iron Mining and Processing in South

Surface mining Steel manufacturing Separation and classification Pig iron Slag Iron Ore (65% Fe) The ore undergoes a series of crushing steps to reduce the particle size Iron ore is separated into the different grades using cyclones and drum separators Coke (carbon) is reduced: 2C + O 2 2CO CO reacts with iron ore to form iron: 3CO + Fe 2O 3 The estimated GHG emissions were 119 kg CO 2 e for mining and processing 1 t of iron ore The embodied energy values were 153 MJ/t ore for iron ore The results showed that loading and hauling made the largest contributions (approximately 50%) to the total GHG emissions from the mining and processing of iron oreIron Ore ScienceDirect Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 Beneficiation of Iron Ore 911 Metallurgist The first way in which proposed mining projects differ is the proposed method of moving or excavating the overburden What follows are brief descriptions of the most common methods 1131 Openpit mining Openpit mining is a type of strip mining in 11 PHASES OF A MINING PROJECT ELAWBefore you can calculate the potential mineral deposit value, you first need to gather some specific data regarding the ore body and the individual drill results This required data can be found in the mining company’s press releases in which they announce their drill resultsMake sure that this data is announced according to the guidelines of National Instrument 43101 (ie approved by a Mineral Deposit Value How to Calculate the

Solutions for iron mining industry Multotec

A number of steps are required to process iron ore, such as screening, crushing and storage, recovery, grinding and separation using processing equipment This article uses the field investigation and data collection methods, study of the status of the handan iron mining area ecological restoration Through field survey, Studies the mine soil physical and chemical properties, biological diversity and the dominant species of space and time change Using the method of data collection and analysis, by collecting data, studies the relationship Study on Ecological Restoration of Handan Iron The Pilbara Restoration Initiative an industryled group that fosters information sharing for mining operations in the region The Restoration Seedbank Initiative – a partnership between the Botanic Gardens and Parks Authority, University of Western Australia and BHP Billiton Iron Ore, which has produced the Pilbara Seed Atlas and Field Postmining rehabilitation EPA Western Australia Mining has been a vital part of American economy and the stages of the mining process have had little fluctuation However, the process of mining for ore is intricate and requires meticulous work procedures to be efficient and effective This is why we have broken down the mining process into six comprehensive steps Prospecting/Surveying6 Stages of the Mining Process BOSS MagazineMining and minerals Iron ore Bauxite Base metals Precious metals Coal of the mining industry are essential to develop tailored solutions for an optimal and efficient prediction during all steps of your mining process from mineral exploration to the analysis of final products recycling and recovery of mine rejects is an important Mining mineral processing solutions Malvern

New iron ore mine for Victoria Australian Mining

Already the company has flagged investigating low cost improvements to beneficiation and iron recovery Eastern Iron said the next steps for the project would include investigating extensions to demand for mining products It’s not all about China Infrastructuredriven growth in Asia, mainly China, has resulted in aboveaverage economic growth and a significant increase in demand for commodities like iron ore, copper and coal However, as can be seen from Figure 2, the USA and Europe account for more than 40 per cent of global GDPMine 2018 PwC The first way in which proposed mining projects differ is the proposed method of moving or excavating the overburden What follows are brief descriptions of the most common methods 1131 Openpit mining Openpit mining is a type of strip mining in 11 PHASES OF A MINING PROJECT ELAW Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 Beneficiation of Iron Ore 911 MetallurgistBefore you can calculate the potential mineral deposit value, you first need to gather some specific data regarding the ore body and the individual drill results This required data can be found in the mining company’s press releases in which they announce their drill resultsMake sure that this data is announced according to the guidelines of National Instrument 43101 (ie approved by a Mineral Deposit Value How to Calculate the

- ground calcium carbonate machine

- 60 hp prater b 9ac hammer mil

- hydraulic expending forming machine for 15l 18lsquare can making

- send hand ball mill for a

- used stone crusher and for sale Algeria

- mpare prices on chilli grinding machine

- biotrituradoras 200 forestales for sale miami

- goldlands 20 yph sonic processor

- crusher jaw crusher price for hopper jaw stone crusher

- calcite jaw crusher from qatar

- used ultrafine roller grinding mill for chili

- Used Grinding Dealers

- stone crusher plant project report pdf

- berita batubara indonesia

- shaep grinder making machine

- hammer mill crusher calculation

- rocky mountain steel mills

- gold mining scales for sale

- sale mobile crusher plants south africa

- silica sand crushing amp screening

- send hand gold processing plants in south africa

- quartz powder and quartz requirment in bangalore industries

- quartz crushing machine in south africa

- shanghai heavy machinery al mill

- on site iron crushing london ontario

- ncrete waste sponsor two single sponsor

- ball mill for grinding pper ore

- tanhat mining mpany ltd

- mobile jaw crusher zimbabwe

- ore dressing ore universal bulb crusher

- the price of 350 t h crusher china

- flowchart for cupcake making

- product solutions industrial mills

- Hot Selling Cobalt Ore Ultrafine Mill Provider

- south african ntact ne crushers

- stone grinder scientific

- how to stop pollution from mining

- Applications Of Minings In Stone Crusher

- dimension stone mining mndm

- kenya beneficiation plant supplier

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers