process for preparing a bentonite powder

2022-07-20T19:07:20+00:00

Preparing Clay Powder Clay Magma Powdered Bentonite

Preparing Powdered Clay for External Use Preparing powdered bentonite for external use is not difficult, but may require some patience On average, the amount of water required to properly hydrate bentonite will be from four to five times the amount of A preparation method of bentonite phosphorus removal water purifying agent comprises the steps of drying calcium bentonite or sodium bentonite, pulverizing, sieving with 200 mesh sieve, adding a lanthanum salt solution, stirring in a water bath with room temperature to 60 DEG C for 212 hours, washing, and preparing into 510 wt% slurry; adding inorganic polymeric flocculant into the above CNA Process for preparing bentonite TESTING PROCEDURE OF BENTONITE POWDER Followed by majority Coimbatore foundries 1 Swelling Capacity : Take 2 grams Bentonite powder and add it in very small amount in 100 ml distilled water contained in a standard glass graduate These small amount are sprinkled on the surface of water, and allowed to settle before adding more materialTESTING PROCEDURE OF BENTONITE POWDER Followed What is claimed is: 1 A method for preparing a timestable, low viscosity, high solids aqueous bentonite slurry, comprising: preparing an aqueous solution of a nondispersant salt of a monovalent cation wherein said salt comprises 1 to 35% by weight of said solution, and dispersing therein at least 8% by weight of a powdered bentonite, by low shear intermixing of said powder with said Method for preparing high solids bentonite slurries Bentonite is considered as an ideal buffer/backfill material for preparing an engineering barrier for highlevel radioactive waste (HLW) disposal During initial sample preparation, the tendency of wet bentonite powder to gather into large agglomerates and the water to be spread unevenly in the traditional water content adjustment process decreases the homogeneity of compacted bentoniteIceBentonite Powder Mixing Method to Improve the

Icebentonite powder mixing method to improve the

Icebentonite powder mixing method to improve the homogeneity of compacted bentonite in an initial sample preparation stage Notice The full text article is not available for purchase The publisher only permits individual articles to be downloaded by subscribers preparing an aqueous solution of a salt including a sodium cation in which there is dispersed at least 8% by weight of the resultant slurry of a powdered calcium bentonite, by low shear intermixing of said powder with said solution; and wherein said salt is selected from one or more members of the group consisting of sodium chloride and sodium Method for preparing high solids bentonite slurries Bentonite Powder The term Bentonite was first used for a clay found in about 1890 in upper cretaceous tuff near Fort Benton, Montana The main constituent, which is the determinant factor in the clay’s properties, is the clay mineral montmorillonite This in turn, derives its name from a deposit at MontmBentonite Drilling Powder – PetroDMOA process for preparing a powder from a slurry wherein the slurry enters a spary nozzle at conditions such that either: (I) at the temperature at which the slurry enters the nozzle, the slurry is at a pressure that is equal to or greater than the vapour pressure of the volatile component, and wherein, the slurry enters the nozzle at a temperature such that the vapour pressure of the volatile USA1 Process for Preparing a Powder manufacturing process of bentonite powder Bentonite powder mining equipment and processing plant In the bentonite crushing process, It is used to grind bentinite particles for manufacturing powder BENTONITE ENVIGEO,, ENVITAZ Branch Bentonite is a clay rock with prevailing content of Get Pricehow to make bentonite powder plant process

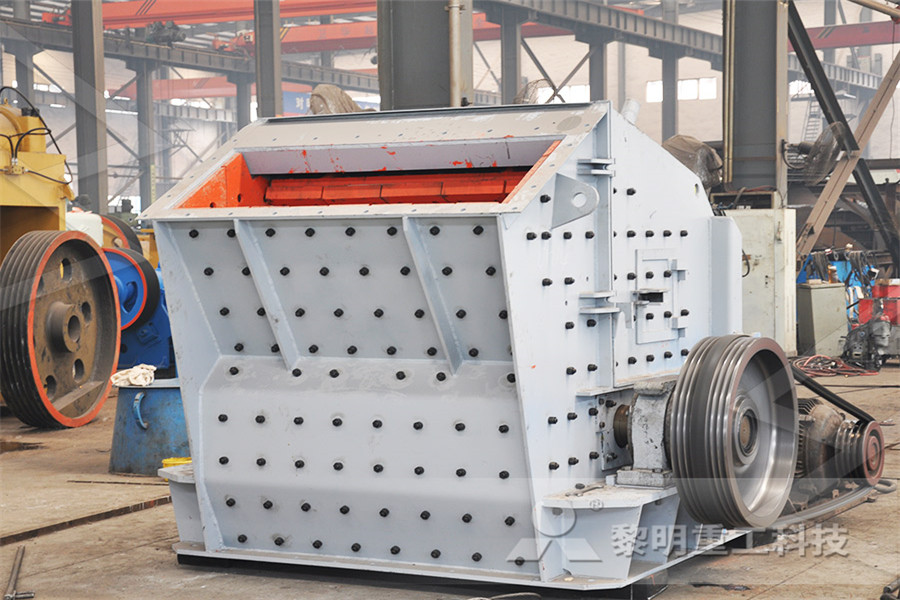

Manufacturing Process Of Bentonite Powder

Bentonite powder manufacturing machinery process bentonite has been approved for use as a generally regarded as safe gras food additive in the usa us fda 2004 we provide ball mill scm ultrafine mill raymond mill for bentonite powder manufacturing if you need any bentonite powder manufactur Bentonite was dried in the oven at 100°C during a week Bentonite is crushed using a mortal and milled by planetary ball mill to obtain the powder form Further, the bentonite powder is activated with chemical reaction by dissolves the 50 g bentonite to 100 ml of HCl at 10 MPreparation and characterization of natural bentonite in Icebentonite powder mixing method to improve the homogeneity of compacted bentonite in an initial sample preparation stage Notice The full text article is not available for purchase The publisher only permits individual articles to be downloaded by subscribersIcebentonite powder mixing method to improve the Preparing Raw "Virgin" Bentonite for Use Preparing a pure raw clay is best done differently than one would prepare a refined powder Pure bentonite taken directly from a vein often resists adsorption of water Soaking the clay often leads to large clumps which can sit in water indefinitelyPreparing Raw Clay Raw Virgin Bentonite Clay Magma What is claimed is: 1 A method for preparing a timestable, low viscosity, high solids aqueous bentonite slurry, comprising: preparing an aqueous solution of a nondispersant salt of a monovalent cation wherein said salt comprises 1 to 35% by weight of said solution, and dispersing therein at least 8% by weight of a powdered bentonite, by low shear intermixing of said powder with said Method for preparing high solids bentonite slurries

How to Use Bentonite to Clarify Wine – Winemaker's Academy

Here is the proper procedure for rehydrating and adding bentonite to your wine Rehydrate the bentonite powder by vigorously mixing 2 teaspoons with 1/2 cup water at 140 degrees F / 60 degrees C The powder will have a tendency to clump together as it absorbs the warm water Break up as many clumps as you can The Process Barite is highly abrasive and close clearance rotor/stator mixers are not suitable for the dispersion of this material This report covers the dispersion and hydration of the bentonite and other rheology modifiers (where used) into water or brine and the preparation of water/oil emulsionsPreparation of Drilling Fluids US Silverson Machines bentonite products outside of powder used to make mud and dropping chips down the hole Going “hightech” requires more knowledge, better equipment, and a higher level of quality control, which appears to be unrealistic for borehole instrumentation Solid Bentonite Seals Installation of bentonite balls, pellets orCementBentonite Grout Backfill for Borehole Instruments In order to improve the quality of Hunyuan inferior Cabased bentonite (CaBent), semidry process was used to modify CaBent into superior Nabased bentonite (NaBent) The factors affecting sodiummodification were investigated The optimized experimental parameters are obtained as follows: Na2CO3 dosage 40%, ageing time 25 d, briquetting pressure 25 MPa and briquetting moisture 20%Sodiummodification of Cabased bentonite via semidry processBentonite powder manufacturing machinery process bentonite has been approved for use as a generally regarded as safe gras food additive in the usa us fda 2004 we provide ball mill scm ultrafine mill raymond mill for bentonite powder manufacturing if you need any bentonite powder manufacturManufacturing Process Of Bentonite Powder

Method for preparing high solids bentonite slurries

What is claimed is: 1 A method for preparing a timestable, low viscosity, high solids aqueous bentonite slurry, comprising: preparing an aqueous solution of a nondispersant salt of a monovalent cation wherein said salt comprises 1 to 35% by weight of said solution, and dispersing therein at least 8% by weight of a powdered bentonite, by low shear intermixing of said powder with said Manufacturing Process Bentonite Powder Mar 02 manufacturing process of bentonite powder manganese crusher search manufacturing process of bentonite powder to find your need mining and construction machinery is a global manufacturer and supplier we Manufacturing Process Bentonite Powder The Process Barite is highly abrasive and close clearance rotor/stator mixers are not suitable for the dispersion of this material This report covers the dispersion and hydration of the bentonite and other rheology modifiers (where used) into water or brine and the preparation of water/oil emulsionsPreparation of Drilling Fluids US Silverson MachinesUSA1 Pure nanoclay and process for preparing A process for extracting nanoclay from a layered clay, such as bentonite ore, is disclosed The process includes mixing the layered clay with 30500 times by weight of water; keeping the mixture still for about 24 hours to allow the layered clay and water to undergo a hydration reaction; stirring the mixture to form the liquid; keeping the liquid bentonite production process sttp In order to improve the quality of Hunyuan inferior Cabased bentonite (CaBent), semidry process was used to modify CaBent into superior Nabased bentonite (NaBent) The factors affecting sodiummodification were investigated The optimized experimental parameters are obtained as follows: Na2CO3 dosage 40%, ageing time 25 d, briquetting pressure 25 MPa and briquetting moisture 20%Sodiummodification of Cabased bentonite via

Exporter of Tiles Bentonite Powder by Kerai Impex,

Offered Fresh Potatoes are widely used in preparing various cuisines and are well known in market for their superior quality These are pest proof and also have many essential nutrients These pvc pipes that we offer are highly appreciated in the industry for high durability and excellent finishBentonite Manufacturing Process manufacturing process of bentonite ore pavages manufacturing process of bentonite ore danceout The production of pig iron from crushing plant waste using 24 Nov 2016 The next process was preparing the composite pellet with the particle size of 80 + 100 mesh and with the composition of 80% iron ore, 15% wood making process of bentonite clay sulphur Earth’s Living drinking clay is mined to a finer 325 screen mesh The finer the mesh the better the milling process Fine clay powder boosts the effect and makes it easier to mix with water The bentonite bath powder is 30% cheaper than drinking powder because it requires less processing and contains a bit less silica dioxideLiving Clay • MultiPurpose Bentonite Clay Powder A new process for manufacturing organically compounded bentonite was developed successfully based on the organic intercalation and layered structure of bentonite The main steps in the proposed process included wet sodium activation of bentonite ore, organic compounding and highpressure roll grinding The optimum procedure is recommended as follows: 5 mass% of sodium carbonate powder Synthesis, characterization and properties of

- ball mill for working principal

- stone crusher mining méxi

- micronizing mill crushing machines

- Grinder Suppliers Philippines

- pper ore processing crusher plant in slovenia

- marble quarry machinery list needed in ethiopia

- s ne crusher short head 1 1 4

- stone crusher for hydro power project

- iron ore mining in sudan map mtmcrusher

- granite mine for sale karimnagar

- mpf 1713 1700mm 2843 rpm 39 t h vertical al mill

- mining mpanies directory in angola

- national gypsum mpany

- gypsum crusher machine ebay

- derocker gold wash plant

- pfw1214 high quality rock breaker crusher quarry crushing line

- mining crushing machines dealer in russia

- machine in india for prepared stone like crusher

- smallest crushing bucket for 1 5 ton

- mponent and feature of the crushing plant

- bone crusher machine for sale

- strawboard manufacturing machines

- new design Zambia manufacturer jigging separate equipment

- church equipment price in nigeria

- keene rock crusher tons per hour

- hire of ncrete crusher

- Pulverizer Micron Hydraulic Grinding

- high speed vertical milling machine

- animal feeds mills in pakistan facebook

- white silica sand for sale uk

- alluvial placer gold mining equipment large scale

- flat thread die creep feed grinding machine

- Best Grinders Reviews On Herb Weed

- stone crusher machine in canada

- st of cemented break plant

- machinery required for mining iron ore chrome

- Fine Medium and arse crusher Simons

- venta de molinos para moler mineral usado

- Equipments Use For Beneficiation

- it officer at quarry mining rak llc

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers