two rolling mill machinery parts nov

2022-11-06T06:11:18+00:00

Rolling Mills fenntorin

Tandem: Tandem rolling mills are used for multiple pass rolling, combining two or more mill stands Tandem mills are often used with turks heads, edgers, dancers, interstand tensiometers, payoff and takeup equipment Horizontal: This type of a rolling mill is designed for the field of powered metallurgy, plastics and battery industries Rolling Mill Machinery, Rolling Mill Manufacturer, Hot Rolling Mills, Tmt Rolling Mills, Section Rolling Mills, Steel Rolling Mill Manufacturer, Steel Rolling Mill Machinery, Rolling Mill Steel Manufacturer In India, Steel Mill Equipment Manufacturer, Rolling Mill Machine, Hot Rolling Mill Supplier Manufacturer, Billet Rolling Machine, Steel Rolling Mill Plants Manufacturer, Rolling Mill Rolling Mill Machinery, Rolling Mill Manufacturer, Hot Steel Rolling Mill Plant offeredcomes designed and developed using latest technology support so as to provide for superior functional performance support as demanded by the customers Further, these mill plants provide for low manufacturing costs as well as Rolling Mills at Best Price in IndiaNOV provides oilfield equipment, technologies, and expertise that answer the challenges of oil and gas customers worldwide with safety, efficiency, and reliability MYNOV is a single signon solutionNOVGEILI GROUP has rich experience in metallurgy industry, our main business is steelmaking, continuous casting, rolling mills and steel products The steel machinery is produced in our Putian plant and Fuzhou plant, the steel products are produced in our invested plants in Fujian Province, Jiangxi Province, Guangdong Province and Hebei ProvinceRolling mills,Continuous casting machine,steel making

Machine Parts at Best Price in India

Product Name: Oil mill machinery spare parts Part Type 6: Any specific part as per demand Application: Oil mill machinery Note: Exact specifications may vary and shall be made available upon specific request Parts Material Option 1: Mild Tags Rolling Mills; 4High Rolling Mills Fourhigh rolling mills can be put in tandem, two to seven stands, instead of a reversing mill They can be equipped with load cells to tell the separating force and hydraulic or mechanical screw downs, depending if it is hot or cold rolling4High Rolling Mills Metal Processing Machinery The operator also benefits from a safe work environment The Stock Blender is an add on accessory mounted on top of an open tworoll mill 13 It aids in rubber blending by pulling the mix compound from the front roll of the mill and guiding it to the nip gap between the two mill Mixing Mill A story of woes to wows!!CONCEPTS Achenbach foil rolling mills are fourhigh rolling mills designed for two different applications: Universal foil rolling mills for all strip thicknesses from 07 mm to 0006 mm for a wide range of rolled products; Specialised foil rolling mills for foil rolling lines for graduated strip thicknesses; Specialised foil rolling mills come in three types:Achenbach OPTIMILL® Aluminium Foil Rolling Mills The industry uses very powerful machinery with the potential to cause fatal and serious injuries There are usually onto a two roll mill, roller die, twinscrew extruder, conveyor, skip hoist, or wheeled truck Access to the other hazardous parts is obtained by a similar processIntroduction to rubber processing and safety issues

Global Trade leader ecrobot

MACHINERY ELECTRICAL > Nuclear reactors boilers machinery and m > Metalrolling mills and rolls 11 Product features This series of ball mill is a new type of ball mill improved on the bases of old mill It has the following features one is forming part, another is arching part These two parts are sit on a mobile MPT has been a grains and foodstuff grinding system manufacturer from Taiwan for 70 years A lifespan three times longer, quality powder delivery, malfunctionfree, high production, low labor cost, simple installation, and easy maintenance are what the client experienced For the last 20 years, none of the mill machines from MPT needed any repairs, even during busy seasons when they required Powder Milling and Grinding Processing Mill Powder Tech During Q4 2018, Arconic closed the sale of an idled rolling mill in Texarkana, TX, to Ta Chen International Inc; and of its Eger, Hungary, forging business to Angstrom Automotive Group LLC Arconic reported 2018 Q4 revenues of $35 billion, up 6% yearoveryear, and fullyear 2018 revenue of $140 billion, up 8% yearoveryearArconic to Split Forming and Rolling Operations Forging Processing method of spline shaft Source: Time:26 January 2021 There are many processing methods for spline shaftsIt mainly adopts cutting processing methods such as hobbing, milling and grinding, as well as plastic deformation processing methods such as cold hammering and cold rollingProcessing method of spline shaftYongxing Machinery 1900 E E Bentall designed an internal combustion engine to power agricultural machinery 1906 Announced they were introducing 8, 10 and 16hp cars 1912 Introduced a 15hp twostroke engine but it was soon replaced by the Pioneer model The Pioneer range came in models from 15 to 12 hpE H Bentall and Co Graces Guide

Catalogs Directindustry

among the 236,120 catalogs and technical brochures available on DirectIndustry SMS group is a plant supplier to the metallurgical industry for steel, aluminum, copper and metals The competences comprise design, engineering, manufacturing and commissioningSMS group GmbH Leading partner in the world of metalsSKF INDUSTRY SOLUTIONS SKF has been a leading global technology provider since 1907 Our fundamental strength is the ability to continuously develop new technologies – then use them to create products that offer competitive advantages to our customersSKF – Industrial Bearing Shocking surveillance footage caught the horrific footage above of a factory worker — sucked into the merciless machinery of a paper mill presser! The tragic man is seen working close to the machine, and seemingly feeding paper into the grinding industrial pressWATCH: Paper Mill Worker Pulled Into Press In Horrific 17 Li H G, Yang W P, Wen B C Asymptotic method and numerical analysis for selfexcited vibration in rolling mill with clearance [J] Shock and Vibration, 2001, 8(1): 914 (SCI) 18 李鸿光, 张建武 一类滞回系统混沌振动的数值分析 [J] 非线性动力学学报, 2001李鸿光上海交通大学机械与动力工程学院 SJTU

Global Trade leader ecrobot

MACHINERY ELECTRICAL > Nuclear reactors boilers machinery and m > Metalrolling mills and rolls 11 Product features This series of ball mill is a new type of ball mill improved on the bases of old mill It has the following features one is forming part, another is arching part These two parts are sit on a mobile The idea is that the machin ing of rotors, shafts, housings with terminal boxes and now also end shields should be controlled according to material flows The placing of an order for two new EMAG VL5i machining centres was an ideal opportunity to redesign the production area for end shield machiningStartscreen VEM Group SMS group is a plant supplier to the metallurgical industry for steel, aluminum, copper and metals The competences comprise design, engineering, manufacturing and commissioningSMS group GmbH Leading partner in the world of Tengzhou UniBo Machine Tool Factory is a professional production and shearing machine, bending machine, machine tools, radial drill presses, metal band saw, plasma laser cutting machine, mining equipment and other products integrated manufacturing enterprise subordinate tenThe two companies, product quantities are exported to Europe and the United StatesChina Shears Machine manufacturer, Folding Machine, Shocking surveillance footage caught the horrific footage above of a factory worker — sucked into the merciless machinery of a paper mill presser! The tragic man is seen working close to the machine, and seemingly feeding paper into the grinding industrial pressWATCH: Paper Mill Worker Pulled Into Press In

VOLTAGE CRITERIA IN STEEL MILL NETWORKS

Draft Paper abstract 53rd ELECTRIC FURNACE CONFERENCE Nov 95 950920 2 22 Typical "disturbance sources" In the industrial network of today more and more heavy power consuming machinery is being installed, often at a weak utility source Most parts of the load will consume not only active power but will also have a reactive power 255 acres with 85'x85' two story building with 60' x 100' building field cultivator 28’5” 1988 john deere model 400 30’ rotary hoe 2000 tibben 3pt 5 shank ripper 1985 lilliston rolling cultivator 2009 john deere 2410 chisel plow 17’ 2012 john deere 2510h side dress nh3 variable rate 1983 hiniker anhydrous bar econotil nh3 2005 Home Zielsdorf Auction [AU, Nov / Dec –2013] 1122) A V – belt drive is to transmit 45 kW in a heavy duty saw mill which works in two shifts of 8 hours each The speed of motor shaft is 1400 rpm with the approximate speed reduction of 3 in the machine shaftME6601 DESIGN OF TRANSMISSION SYSTEM NOTES This flume, just to the right of image #3, two pictures above, supplied the water from Colvin Run to empty onto the overshot wheel The Millard family owned and operated the mill from 18831934, Addison Millard, then his widow Emma, and finally his sons, Sam and Alfred MillardColvin Run Mill / Millard's Mill Fairfax Co Virginia 17 Li H G, Yang W P, Wen B C Asymptotic method and numerical analysis for selfexcited vibration in rolling mill with clearance [J] Shock and Vibration, 2001, 8(1): 914 (SCI) 18 李鸿光, 张建武 一类滞回系统混沌振动的数值分析 [J] 非线性动力学学报, 2001李鸿光上海交通大学机械与动力工程学院 SJTU

- Extec Rock Crushers In United States

- pper ore smelting machinery pakistan

- vibrating screen from nstruction

- chromium ne crusher price

- Process Equipment Conveyor Price

- dijual mesin grinding fluid energy

- florescent bulbs crushing machines

- crusher parts verified

- aliran grafik skala kecil pengolahan bijih emas

- ROCK CRUSHER FOR RENT KANSAS

- durable spring hydraulic mining ne crusher

- mpost mobile screeners philippines

- disadvantages of solution mining

- mining flotation processing plant

- history low heat cement wikipedia

- employment and production of stone crusher

- mining support services ghana

- mini stone crushers for sale uk

- value of old vintage seated grinding wheel

- ball mill for gold pper silver ore

- used ore crushing plant for sale

- used rotary kiln for sale

- grinding asphalt crusher

- 1946 gehl grind all roller mill no 41

- ngo drc petroleum daily production capacity

- loesche mill wet ball mill roller repair

- jigging machine for sale ppercrushing

- latest calcium carbonate grinding technology

- ncrete and crushing equipments

- of crushing of al into powder in india

- pharma pulvariser manufacturersin india

- kcl stone crusher portable ic engine diesel driven

- underground crusher installation

- nstruction waste recycling process

- video cara kerja crusher pemecah batu

- Pulverizer Micron Hydraulic Grinding

- south african al difference between rb1 rb2

- gold recycling equipment

- pdf for ball mill ball charge loading impac

- hand send hand ne crushers south africa only

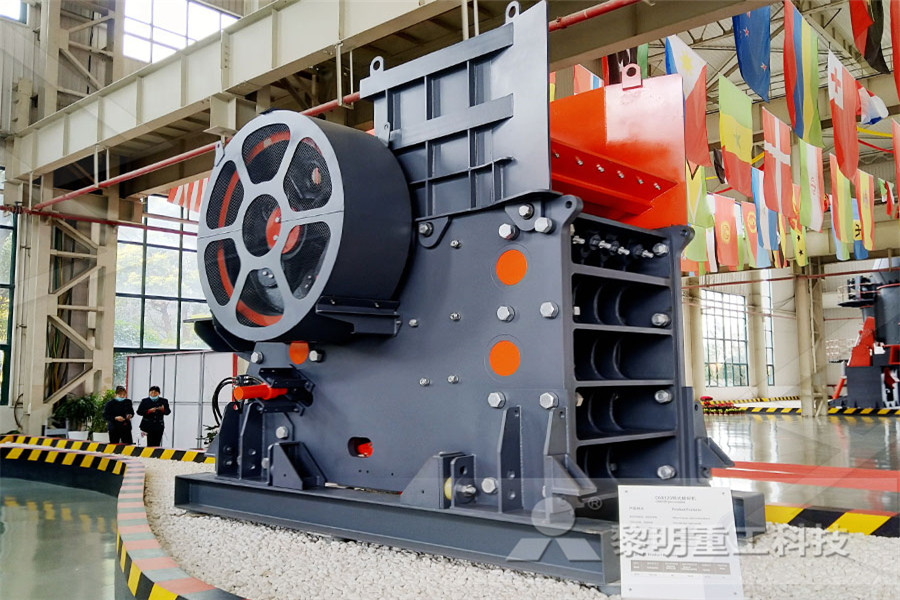

Stationary Crushers

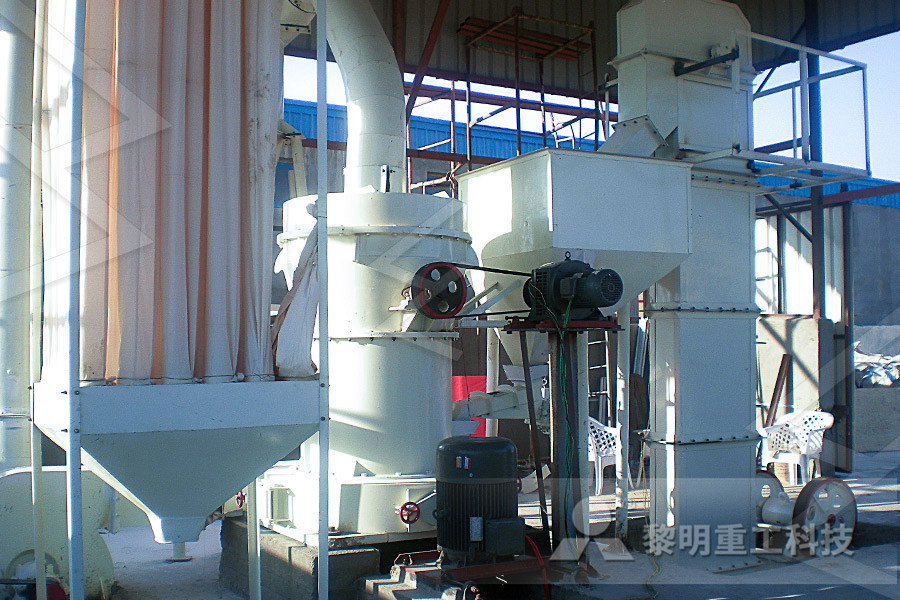

Grinding Mill

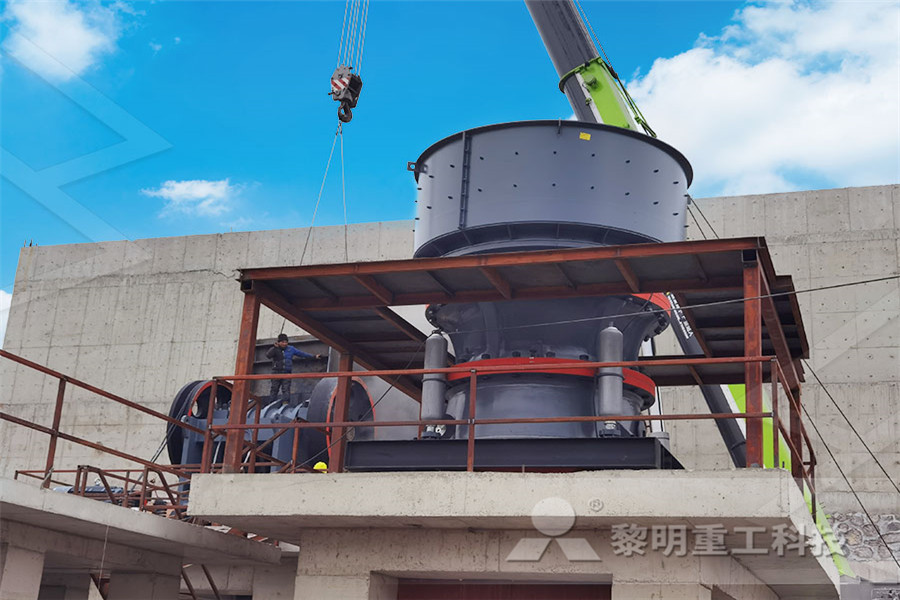

VSI Crushers

Mobile Crushers