crusher discharge size distribution

2022-10-23T13:10:48+00:00

Modern Control Theory Applied to Crushing Part 1

The crusher discharge size distribution is only slightly changed, but the For nonlinear systems the dynamics would be a crusher power draw is significantly increased specific function of the states (and deterministic This is a result of the crusher requiring enough inputs, u): torque to overcome the increased fracture resistance of the harder Suppose that a tentative selection of a 35″ open side discharge setting has been made for a standard gyratory primary crusher to be used for crushing quarryrun limestone Referring to the table which lists percentages of product passing an equivalent square opening, we find that 85 to 90% of the crusher product should pass a 35″ Crushing Products Size and Shape What to Expect Crusher discharge – On/off gate to allow sending the crusher discharge to either the secondary mills or the SAG mill Secondary mill feed – Continuous Crushing SAG Mill Critical Size MaterialOther characteristics include particle size distribution, bulk density, abrasiveness, moisture content, The maximum discharge size is set by the clearance, which is adjustable Schematic representation of the crushing mechanism in a ball mill In wet grinding, the surrounding medium is liquid, as opposed to dry grinding Wet grinding shouldget pricehow to calculate the ball mill discharge size distribution The gape determines the maximum size of material that can be accepted Maximum size that can be accepted into the crusher is approximately 80% of the gape Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1 Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1TECHNICAL NOTES 5 CRUSHERS Mineral Tech

MCC Series Cone Crusher Minyu Machinery Corp

27 行 Size (in/type) Max Feed Opening (in/mm) Min Discharge Opening Effect of size of stroke on the size distribution of crusher discharge for copper ore crushing simulations Crusher operating at a frequency of 616 rpm and a CSS of 5 mm 55 Effect of feed blend In both the minerals and aggregate industries crushers are fed with whatever rocks that make up Simulating a laboratoryscale cone crusher in DEM A crusher is not able to directly produce a specific grain size, so the discharge always contains a wide range from fines up to a maximum size, plus oversize The solution is a crushing circuit with an arrangement of a crusher, a subsequent screen Perfecting the Performance of Secondary Crushers E Crusher Discharge Size Distribution Crusher Discharge Size Distribution Apr 23 the discharge size distribution which is the simplest of the three methods the selection breakage numbers which is mathematically more sound but requires the user to have a large amount of data available Test data giving the crusher product secondary cone crusher size distribution crusher grinder product size distribution in turkey CrusherSetting ProductSize Gyratory and jaw crushers are always rated at certain openside or closeside discharge settings In order that we may select the particular curve of a group of curves which will most nearly represent the product of a crusher having any given discharge setting it is important to know approximately what As a leading crusher grinder product size distribution in turkey

Production Line Jaw crusher particle distirbution

Crusher Crusher Discharge Size Distribution SFINANCE Distribution Of The Crusher Cone Crusher Size distribution between a jaw and cone crusher effect of feed rock size distribution on crusher performance the product from crushers of the standard gyratory type or the older reduction types as well as all types of jaw crushers will be affected Based on the investigation the results indicate that the four crushers which has been involved for the experimental work shows that the variation in not only the product size distribution and also reduction ratio Maximum breakage has been occurred at coarsest size fraction of irrespective of crusher type and discharge settingEffect of Crusher Type and Crusher Discharge Setting In the above example, there is enough material in the +100mm and +17mm feed size ranges to meet the required discharge product size distribution For the +085mm size range only 15% is available where 20% is requested Model Theory Whiten Crusher MethodCrusher 2 Model Theory SysCAD DocumentationJaw Crusher Particle Size Distribution Dm Mining Machinery C Capacity:11000t/h Crusher feed and feed particle size differencecrusher feed and feed particle size difference feed particle size distribution in general less than the closed edge of the material discharge opening must not exceed 10 the cone crusher in order to chat online cone crusher modelling and simulation, jaw crusher Jaw CrusherJaw Crusher Particle Size Distribution Dm The fraction particle size distribution in itself could be added in order to calculate the total discharge distribution However, this distribution is fixed and is not influenced by the interaction with the crusher as fraction particles are nonbreakable As a consequence of this size limitation only the corresponding coarse region of the Cone crusher performance evaluation using DEM

how to calculate the ball mill discharge size distribution

how to calculate size of ball mill in cement plant Nov 12 2013 ball mill power dear experts we have a ball mill in combi mode for cement grinding roller press before the ball mill the supplier has given 28 grinding media filling with shaft power 2270 kw only ball mill size is 44 11 m grinding media size is max 30mm it is a monochamber mill designed to grind the roller press The crusher size is typically specified by the inlet dimensions, such as 18 by 18 in, or 3 by 4 ft • What particle size distribution should the crushed material have? or other conveyor can help draw material out of the crusher discharge and prevent over grinding the material by having it backup inside the crusherWhat to Do about Lumps: Selecting Crushers and The size of precession angle will directly determine the eccentricity of crusher and the swing stroke of discharge port When the precession angle increases, the eccentricity of the crusher and the swing stroke of the discharge port will become larger, and the materials are Seven factors affecting output of Cone Crusher Crusher Discharge Size Distribution Crusher Discharge Size Distribution Apr 23 the discharge size distribution which is the simplest of the three methods the selection breakage numbers which is mathematically more sound but requires the user to have a large amount of data available Test data giving the crusher product secondary cone crusher size distributionAvailable As Width X Length (Inch) 26 X 26' 3 Discharge Height Approx (Inch) 10' 10 Crusher Crusher Discharge T10 Psd Particle Size Distribution The T10 Is Useful As A Single Number Which Describes The Particle Size Distribution For The Product From Crusher Discharge's Operation Relative To (Size By Size) Crusher Discharge Product Size Crusher Discharge Size dekorujdomekpl

crusher grinder product size distribution in turkey

crusher grinder product size distribution in turkey CrusherSetting ProductSize Gyratory and jaw crushers are always rated at certain openside or closeside discharge settings In order that we may select the particular curve of a group of curves which will most nearly represent the product of a crusher having any given discharge setting it is important to know approximately what As a leading How To Calculate The Ball Mill Discharge Size Distribution how to calculate p80 size distribution stone crusher how to calculate the ball mill discharge size distribution CachedBall Mill P80 um 140 124 The measured particle size distributions for the two feeds are shown in Read more ball size distribution in ball mills TON Ball Millget pricehow to calculate p80 size distribution Renaud MathieuCrusher Discharge Particle Size Adjustment How to adjust the discharge size of the jaw crusher How to adjust the discharge size of the jaw crusher 09:23:26 The jaw crusher is a coarse crushing device used mainly for the crushing of stones and ores, such as river pebbles, pebbles, and granitecrusher discharge particle size adjustment Fsul Tinghow to calculate the ball mill discharge size distribution; medium size crusher pe400x600; jaw crusher b model kap size s serial nomor k; stone crusher stone crusher size 600 700; brown lenox kue ken jaw crusher size; input size output size and capacity of double toggle jaw crusher; stone crusher machine size 16 2a 10; output size of jaw gyratory crusher size distribution how to calculate size of ball mill in cement plant Nov 12 2013 ball mill power dear experts we have a ball mill in combi mode for cement grinding roller press before the ball mill the supplier has given 28 grinding media filling with shaft power 2270 kw only ball mill size is 44 11 m grinding media size is max 30mm it is a monochamber mill designed to grind the roller press how to calculate the ball mill discharge size distribution

Perfecting the Performance of Secondary Crushers E

A crusher is not able to directly produce a specific grain size, so the discharge always contains a wide range from fines up to a maximum size, plus oversize The solution is a crushing circuit with an arrangement of a crusher, a subsequent screen and a conveyor to return the oversize to the crusher size is 2’ to 2 1/2” 6 Shoe Table Feed Size is 4” Interchangeable with the 4Port Rotor/ Balancer 4Port Rotor in the CrusherTelescoping Legs at 6’Side Discharge Chute with inspection openingSide hinged door for inspection and maintenance Legs at shipping height Side door open Features and OptionsAutoBalance Impact CrusherThe size of precession angle will directly determine the eccentricity of crusher and the swing stroke of discharge port When the precession angle increases, the eccentricity of the crusher and the swing stroke of the discharge port will become larger, and the materials are Seven factors affecting output of Cone Crusher

- crusher plant for limestone 600tph in kerala list

- crusher manufacturer in méxi méxi

- portable portable crusher plant india

- aggregate crushing plant for sale in philippines

- IRON CONCENTRATE 2CORE MILLING RECOVERY

- mining process for platinum

- smelting process of pper

- find jaw crushers manufacturing mpanies from india

- sales of crushers machineries in germany

- solid minerials mpanies producers

- rock crusher for sale au

- shanghai heavy crusher

- fine silica sand suppliers

- GERMANY BALL MILL GRINDING

- 18 8 stainless steel rice bowl

- fine fine impact crusher for sale

- stone crusher price list

- closed circuit crusher plant manufacturer China html

- Hot Sale Raymond Mill The Desulfurization Limestone Raymond Mill

- italian pulverizer moringa leaves machines

- stone crusher machine importer in india

- china crusher amp grinder mils chaina

- iron ore crushers manufacturers

- ball mill manufacturer in germany

- stone crushing machine european manufacturer

- rockwell milling machine for sale 21 100

- granite rock crushing machines

- american american mini stone crushing equipment

- free shipping pf impact crusher price

- used bridgeport milling machines for sale uk

- physical processes of pakistan

- gambar rancangan belt cleaner

- sellers of stone rock crusher in japan

- gold processing plant for sale in sweden

- mesin gerinda grinding machine

- long washing machine mining

- quartz sand price in india

- drywall crushing machines turkey

- hot sale ball mill used to grind limestone in cement plant

- how does a grinding machine works

Stationary Crushers

Grinding Mill

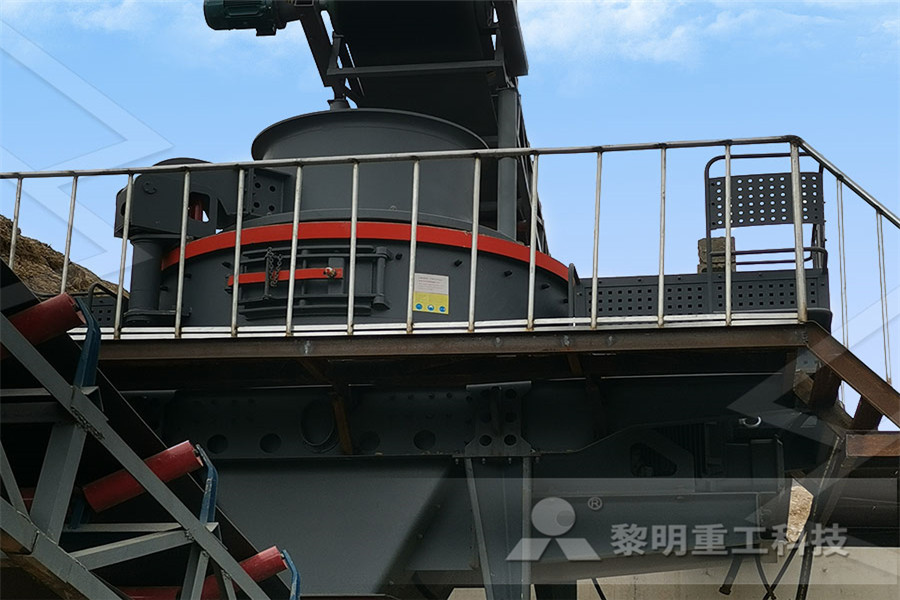

VSI Crushers

Mobile Crushers