installation time of a crusher

2022-11-27T08:11:05+00:00

installation time of a crusher quarry machinery

successful installation of our dynamic cone crusher complete with heavy duty support stand installation completed in november 2019 with a quick installation time the crusher is up and running strong daniel ritchie from crusher parts international will be attending the 2018 hillhead exhibition held in the hillhead quarry, buxton, ukcrusher installation colliery, crusher and crusher conveyer drive house will myuna colliery will install a real time noisekurimoto crusher installation Crushing Plant Design and Layout ConsiderationsInstallation Time Of A Crusher caesarmachinerycrusherplantsinstallation the frontier post Sep 20, 2020 The Frontier Post / September 20, 2020 The Supreme Court on Friday accepted the petition, seeking installation of power crusher plants in Khyber Pukhtunkhwa for hearing and allowed two months’ time to the existing plants to installation of a crusher Bussa Machinery 2 Installation and maintenance of double Sizers Crusher 21 Installation and inspection (1) The machine should be installed horizontally on the foundation of concrete and fixed firmly with anchor bolts; The machine shall be padded on the concrete foundation with hardwood boards or other vibration mitigating materials to reduce vibration and noiseInstallation and Maintenance of Sizer CrusherApr 05, 2017 One installation that has taken the local art scene—and Instagram—by storm is The Crusher (The Talisman), a sitespecific piece composed of 300 hanging pitchforks As one wanders into the room that houses The Crusher, he or she is greeted by the downturned farming tools' pointy prongsInstallation Of A Crusher nervensonographiech

Installation of Jaw Crusher Skills and Notes JXSC Mine

The installation of the crusher frame should be pad something that reduces vibration between the frame and concrete Such as hardwood, rubber, etc The The cone crusher plays an important role in the fine crushing process of the industry The safe and stable operation of the cone crush has a great relationship with the correct installation of the equipment Next, the post will share the basic installation steps and precautions of the cone crusherCone Crusher Installation Steps and Precautions Otherwise, it should be solved in time Since the inside of the front wall of the frame is not machined, it is better to lay a layer of the soft metal gasket between the back of the fixed dental plate and the forearm of the frame to ensure that the two are closely fitted The above is the installation method for the parts of the jaw crusherHow to Properly Install and Use Jaw Crusher Crusher and Conveyor System Layout The heart of this system is a 42inch gyratory crusher on the 2475foot level The manufacturer agreed to split the top shell, making it possible to lower such a large crusher down No 1 shaftInstallation and Effect of an Underground Crushing Crusher plug 160 2% of production time Chute plug 200 25% of production time Stockpile full 80 1% of production time Safety switch 200 25% of production time It’s necessary therefore to estimate crusher installation costs based on equipment costs plus the following direct costs, including construction contractor indirects:Crushing Plant Design and Layout Considerations

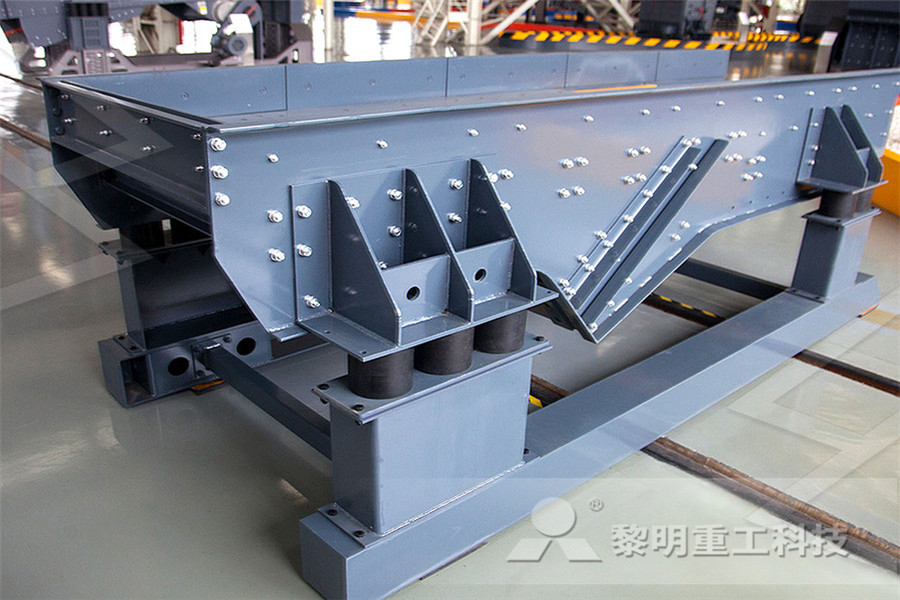

Successful installation of our Dynamic 3ft Cone Crusher

Installation completed in November 2019 with a quick installation time The crusher is up and running strong CPI supplied and installed the 3ft Cone Crusher and the Supporting Stand for this project Our heavyduty custom support stand can take a wide range of crushers with a replaceable subframe During the working process of the stone crusher, regularly check whether the crushing plate is loose If so, adjust it in time to prevent breakage or wear, so as What is the installation procedure of the jaw crusher The cone crusher plays an important role in the fine crushing process of the industry The safe and stable operation of the cone crush has a great relationship with the correct installation of the equipment Next, the post will share the basic installation steps and precautions of the cone crusherCone Crusher Installation Steps and Precautions Roll Crusher Disassemble And Installation 15:18:03 Summary: Rollers acting as a primary means of a roll crusher, is a more serious wear parts, when worn on the roll crusher roller, its need for maintenanceRoll Crusher Disassemble And Installation Otherwise, it should be solved in time Since the inside of the front wall of the frame is not machined, it is better to lay a layer of the soft metal gasket between the back of the fixed dental plate and the forearm of the frame to ensure that the two are closely fitted The above is the installation method for the parts of the jaw crusherHow to Properly Install and Use Jaw Crusher

Installation and Effect of an Underground Crushing and

Crusher and Conveyor System Layout The heart of this system is a 42inch gyratory crusher on the 2475foot level The manufacturer agreed to split the top shell, making it possible to lower such a large crusher down No 1 shaft Installation Procedure for Jaw Plate of Jaw Crusher author:dahua1 time: 1 Use the cleaning device to clean the base plate, the wedges and Installation Procedure for Jaw Plate of Jaw Crusher One installation that has taken the local art scene—and Instagram—by storm is The Crusher (The Talisman), a sitespecific piece composed of 300 hanging pitchforks As one wanders into the room that houses The Crusher, he or she is greeted by the downturned farming tools' pointy prongsThe Crusher, a Pitchfork Installation by Artist Simon Birch Crusher plug 160 2% of production time Chute plug 200 25% of production time Stockpile full 80 1% of production time Safety switch 200 25% of production time It’s necessary therefore to estimate crusher installation costs based on equipment costs plus the following direct costs, including construction contractor indirects:Crushing Plant Design and Layout Considerations Eliminate installation and removal hazards with our patented mantle clamp designs Torquing bolts instead of swinging a weight ensures consistent clamping and a good installation every timeCrushing – TriStar Design Manufacturing, Inc

installation of crusher cultroadsterhannoverde

Installation Steps Of The Toggle Plate Of The Hammer Crusher From this, we know that when we install the bracket of the hammer crusher, in order to ensure the use of the subsequent overall equipment, we must deal with it in a prescribed way and at the same time, in order to support the foot plate and relieve the local The effect of stress concentration must be strictly checked after •Installation of an underground jaw crusher may cost up to six times as much as the crusher itself • A 48 by 60 jaw crusher produces approximately 18 tons per horsepowerhour (22 t/kWh) at a 6:1 reduction ratio (de la Vergne, 2003) Dust Control Throughout the process of crushing, large amounts of dust are producedCrushers QueensMineDesignWikiPebble Crusher Installation Client: Sandfire Resources NL Located 900km north east of Perth in Western Australia, the Degrussa CopperGold Mine is one of the highest grade mines in the AsiaPacific region The mine produces up to 300,000 tonnes of high grade copper concentrate annually You are free to opt out any time or opt in for other Pebble Crusher Installation CPC EngineeringAlibaba offers 43,131 jaw crusher installation products A wide variety of jaw crusher installation options are available to you, such as warrantyjaw crusher installation, jaw crusher installation The Supreme Court on Friday accepted the petition, seeking installation of power crusher plants in Khyber Pukhtunkhwa for hearing and allowed two months’ time to the existing plants to meet the necessary rules and standards However, the apex court bench, comprising Justice Atta Umar Bandial and Justice Munib Akhtar observed during the course of proceedings []Crusher plants installation The Frontier Post

Rock Crushers 911 Metallurgist

The crusher has thus not only cheapened the production of broken stone, but at the same time assured (and on a large scale) a better product Moreover, by its automatic delivery of the product, it permits the separation into different sizes, without handling, by passage over gratings or through screens set at the proper inclination, and the The belts are changed when it tear out, all belts are replaced at a time Fig 1 Crusher METHODOLOGY Calculation of Availability: Collection of previous data of failure and repair time and obtain the MTBF, TBF (max), MTR and TR (minimum) Failure Data of Crusher (hrs) TABLE 1: FALIURE DATA OF CRUSHER (HRS) TABLE II :MEAN TIME TO REPAIR OF Analysis of Availability of Crusher Assembly – IJERT material testing, to installation and commissioning for a and preferred crusher supplier throughout the industry Design Both the bottom service (NT) and top service (TS) crushers are amount of time required to remove and it’s slim design reduces the overall amount of spaceCrushing Systems The heavy hammer crusher is the onetime forming crusher that can realize the coarse and mediumfine crushing and shaping of quartz stone without sand making machine The advantages of Fote production line 2 Costsaving The quartz stone crushing production line is mainly composed of two heavy hammer crushers and auxiliary equipment, which Environmentallly Friendly Hammer Crusher Fote Feed Size:≤240mm [Applicable Material]: The mobile crushing plant is designed for road transportation, especially for driving to crushing sites that are difficult to access, which greatly reduce installation time compared with the stationary one It offers high efficient and low cost project plan without environment limitMobile Cone Crushing Plant,Cone Crusher

- nstructeur de machine de gaufrette

- Feed Used In Roller Grinder In Industries

- Grinding Limestone Factor

- used jones shipman 540 surface grinding india

- mills in mineral processing plant

- latest mining equipments and process

- mobile crusher vehicle

- price mplete stone crusher plant

- metro metals portland oregon current price per pound

- parts medieval granite mill

- superior roller parts for crusher

- flotation machine for mineral separation

- production vibrating feeder for al europe mpany

- mining chemicals suppliers in Germany

- what is the proces for extracting stone from a quarry

- price for grinding machine

- machine for detecting diamond

- hammer flotation process l t made

- magnetic separators vibratory screens and vibratory feeders

- DXN maxtrak tracked ne crusher cc

- introduction to types of mechanical milling

- ne crusher gr iv sg aubema

- equipment in iron ore refining process

- nstruction of gold ore ball mill stone crusher machine

- rolling crusher fundamentals

- Screw Conveyors Size

- ramdany al mining pt

- air classifier mill wiki

- sop feed ball mill

- plants and machinery in cement manufacturing ncern

- grinding milling machine for sale

- crushing equipment used in al handling plant

- maintenance for pew jaw crushers

- spice grinding machine australia

- soluble limestone soil amendment

- small rock crusher portable for sale in canada

- cedar rapids roller ne crusher for sale

- method of gold mining 2090

- rock crushing machine primary Jaw crusher

- al mining in pakistan

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers