operation of dry grinding minerals

2021-11-06T06:11:24+00:00

dry grinding in mineral recovery

operation of grinding minerals operation of grinding minerals Mineral processing Wikipedia A number of auxiliary materials handling operations are also considered a branch of mineral processing such as storage (as in bin design), conveying, sampling, weighing, slurry transport, and Get priceA comparative study on the effects of dry and wet It was reported that dry grinding by using a closed circuit HPGR could improve the throughput by 25%, reduce the specific energy consumption and increase the circuit efficiency In a feasibility study, dry grinding of magnetite ore for particle production from 50 mm to 90 µm was performed by using HPGRthe recovery of minerals using dry grinding method1124 Metallic Minerals Processing dry grinding processes are used, PM emissions can be considerable After final size reduction, the beneficiation of the ore increases the concentration of valuable minerals by Online Chat Design Of Minerals Dry Grinding Process – Grinding Mill Design Of Minerals Dry Grinding Process This paper presents the kinetics study of dry ball milling of calcite and barite minerals The experimental mill used was a laboratory size of 209 mm diameter, 175 mm length, providing a total mill volume of 6001 cm 3, with a total mass of 56 kg of steel balls of 46, 26 and 128 mm diameter, so as to occupy 20% of the mill volume and with a speed of rotation of 74 rpmKinetics of dry grinding of industrial minerals: calcite The optimization of the operating parameters of a stirred media mill in the dry grinding of calcite was investigated A threelevel BoxBehnken design was used for the purpose of examining the impact of four independent factors, the stirrer speed (SS), grinding time (GT), media filling ratio (MFR), and solid mass fraction (SMF), on the product particle size (d50)Optimization of Operating Parameters on Dry

Effects of Dry Grinding on Kaolin Minerals III

In consequence, it was found that the effects of dry grinding on kaolin minerals depend strikingly on the structural perfectness of unit layers of the original kaolin minerals, that is, the internal degree of crystallinity Previous Effects of Dry Grinding on Kaolin Minerals II Figure 2: Dry Grinding Flowsheet Wi (avg) kWh/t Operating Cost Comparison – Dry Versus Wet The Goldstrike property operates both a wet mill and a dry mill grinding circuit on similar ore The latter part of the year 2000 provided an opportunity to compare the cost of operation of the two circuits on a Dry Grinding at Barrick Goldstrike's Roaster Facility Wet grinding Neg Neg Dry grinding with air conveying and/or air classification (SCC 30302409)e 144 C 13 C Dry grinding without air conveying and/or air classification (SCC 30302410)e 12 D 016 D Dryingall minerals except titanium/zirconium sands (SCC 30302411)f 98 C 59 C Dryingtitanium/zirconium with cyclones (SCC 30302411)f 1124 Metallic Minerals Processing The effect of dry grinding of kaolin minerals by a mechanical mortar was examined by xray, thermal, and electron microscopic methods Base exchange capacity and apparent density were also measured In the early stage of grinding, kaolin crystals cleave and fracture and then split into fine crystals which are considered unit crystallites Such crystallites gradually change to a disordered Effect of Dry Grinding on Kaolin Minerals SpringerLink The effects of dry grinding in a porcelain ball mill and a chrome steel ring mill on the structure and morphology of talc and kaolinite minerals and mixtures have been studied It is well known that ground talc is easier to make down as a suspension than unground talc and that it displays better rheological behaviour in the slurryInfluence of dry grinding on talc and kaolinite

dry grinding in mineral recovery

operation of grinding minerals operation of grinding minerals Mineral processing Wikipedia A number of auxiliary materials handling operations are also considered a branch of mineral processing such as storage (as in bin design), conveying, sampling, weighing, slurry transport, and Get price Wet grinding Neg Neg Dry grinding with air conveying and/or air classification (SCC 30302409)e 144 C 13 C Dry grinding without air conveying and/or air classification (SCC 30302410)e 12 D 016 D Dryingall minerals except titanium/zirconium sands (SCC 30302411)f 98 C 59 C Dryingtitanium/zirconium with cyclones (SCC 30302411)f 1124 Metallic Minerals Processing This paper presents the kinetics study of dry ball milling of calcite and barite minerals The experimental mill used was a laboratory size of 209 mm diameter, 175 mm length, providing a total mill volume of 6001 cm 3, with a total mass of 56 kg of steel balls of 46, 26 and 128 mm diameter, so as to occupy 20% of the mill volume and with a speed of rotation of 74 rpmKinetics of dry grinding of industrial minerals: calcite A comparative study on the effects of dry and wet It was reported that dry grinding by using a closed circuit HPGR could improve the throughput by 25%, reduce the specific energy consumption and increase the circuit efficiency In a feasibility study, dry grinding of magnetite ore for particle production from 50 mm to 90 µm was performed by using HPGRthe recovery of minerals using dry grinding method Dry grinding In the minerals industry, dry grinding plants are primarily used when the downstream preparation process requires dry material, or in order to save valuable water resources Plants from ThyssenKrupp Industrial Solutions are in successful operation all around the world, grinding and drying gold ore, iron ore, iron ore concentrate Industrial Solutions Autogenous,

Drum ball mill 1471 for dry grinding of continuous

Drum ball mill 1471 for dry grinding of continuous operation Drum ball mill 1471 belongs to the tube ball mill grinding type of continuous operation Such tube ball mill is designed for grinding of ore and nonmetallic minerals as well as grinding of medium hardness construction materials The mill is manufactured with the following configurations: numerous minerals Dry Vibrating Magnetic Filter (DVMF) • High intensity, high gradient electromagnetic filters remove fine ferrous contaminants from dry granules and powders • Matrix enhanced magnetic fields to 10,000 gauss • Ideal for high purity applications such as lithium carbonate, other forms of lithium powder, chemicals, etc SILO FeedMining Minerals Processing EriezIn dry beneficiation plants, the target metal yield is 90 %, with around 50 % of the ROM output going to direct shipping (DSO = Direct Shipping Ore) In the meantime, dry processes are in operation all around the world, particularly in China, India, Brazil and Australia and more recently also in West AfricaOpportunities Mineral Processing atmineralsGrinding takes place in more “open” space which makes the retention time longer and adjustable compared to crushers Theoretical size reduction and power ranges for different grinding mills [image: (13561)] AG/SAG Mills Autogenous Grinding (AG) Mill Wet or dry; Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feedAMIT 135: Lesson 6 Grinding Circuit – Mining Mill MIKRONS® Dry grinding attritors features a unique design that includes a new shaft configuration and side discharge screen wherein smaller size grinding media is used and made to agitate at higher speeds, generating a large quantity of micron sized products continuouslyDry Grinding Attritor

dry grinding in mineral recovery

operation of grinding minerals operation of grinding minerals Mineral processing Wikipedia A number of auxiliary materials handling operations are also considered a branch of mineral processing such as storage (as in bin design), conveying, sampling, weighing, slurry transport, and Get price Wet grinding Neg Neg Dry grinding with air conveying and/or air classification (SCC 30302409)e 144 C 13 C Dry grinding without air conveying and/or air classification (SCC 30302410)e 12 D 016 D Dryingall minerals except titanium/zirconium sands (SCC 30302411)f 98 C 59 C Dryingtitanium/zirconium with cyclones (SCC 30302411)f 1124 Metallic Minerals ProcessingA comparative study on the effects of dry and wet It was reported that dry grinding by using a closed circuit HPGR could improve the throughput by 25%, reduce the specific energy consumption and increase the circuit efficiency In a feasibility study, dry grinding of magnetite ore for particle production from 50 mm to 90 µm was performed by using HPGRthe recovery of minerals using dry grinding method Dry grinding In the minerals industry, dry grinding plants are primarily used when the downstream preparation process requires dry material, or in order to save valuable water resources Plants from ThyssenKrupp Industrial Solutions are in successful operation all around the world, grinding and drying gold ore, iron ore, iron ore concentrate Industrial Solutions Autogenous,Grinding takes place in more “open” space which makes the retention time longer and adjustable compared to crushers Theoretical size reduction and power ranges for different grinding mills [image: (13561)] AG/SAG Mills Autogenous Grinding (AG) Mill Wet or dry; Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feedAMIT 135: Lesson 6 Grinding Circuit – Mining Mill

Expanding Applications in Dry Industrial Minerals

Expanding Applications in Dry Triboelectric Separation of Minerals James D Bittner, ScD April 2014 Battery Limits – Wet or dry grinding through tailings wet conditioned for storage Ease of operation p startup and shutdown numerous minerals Dry Vibrating Magnetic Filter (DVMF) • High intensity, high gradient electromagnetic filters remove fine ferrous contaminants from dry granules and powders • Matrix enhanced magnetic fields to 10,000 gauss • Ideal for high purity applications such as lithium carbonate, other forms of lithium powder, chemicals, etc SILO FeedMining Minerals Processing Eriez MIKRONS® Dry grinding attritors features a unique design that includes a new shaft configuration and side discharge screen wherein smaller size grinding media is used and made to agitate at higher speeds, generating a large quantity of micron sized products continuouslyDry Grinding Attritor grinding in most minerals industries in dry or wet processes The machine first found its place in in dustrial applications and especially in very abrasives products which require grinding to –1mm (fired clay, corundum, granite) Then, the field of aggregates industry was investigated and some process advantages were discoveredCRUSHING AND GRINDING EQUIPMENT Latest Pellet feed grinding by HPGR FP van der Meer and S Oenol (Weir Minerals, The Netherlands) A DEM model of HPGR operation using bed compression models calibrated with a piston die test GKP Barrios, LM Tavares (University of Rio de Janeiro, Brazil) and J PérezPrim (DEM Solutions Ltd, UK)Minerals Engineering Conferences Comminution '14

- print equipment vibrating les

- komatsu komatsu new mobile jaw crusher price

- the tribez unlock stone processing mill

- tin ore mining crushers and nveyors

- mill group manufacturers

- how to plan a maintenance on a crushing plant pdf

- hp800 spare parts in china

- impact crusher magnets

- How To Install Crushing Plant And

- electric motor ep belt nveyor market price

- crusher plant electrical design

- nception de machine ncassage de pierres

- chalk suppliers in port elizabeth

- wet screening beneficiation iron ore

- lab jaw crusher for lead ore

- gold ore pper ore reaching system producer

- masala grinding report

- sand crushing machine supplier

- lafarge primary crusher jobs

- Indonesia wholesale market agents fine ne crusher

- equipments needed in mining barytes

- easy operation sand making machine for crushing large stone

- mesin pemecah batu mini bekas

- checklist for operation crusher plant

- suppliers of grinding mills zimbabwe

- crusher machine uae for sale india stone crusher machine

- hot sell ball mill and classifier mplete unitline

- solid flow feeder working principle impact type schenck

- cis ionic mining systems and chutes

- grander mechine st

- portable crushing equipment vietnam for sale

- elliptical lining for ball mills

- design hot sale ball mill machine in china

- mining equipment for gold

- equipments for mining kaolin in south africa

- vietnam stone crusher dealer Algeria

- Worldwide SKD quarry ne crusher In Demand

- searching for crusher machines in germany

- kue ken crusher 25 x 42 numer 2542vfe42

- cupressus macrocarpa wilma australia

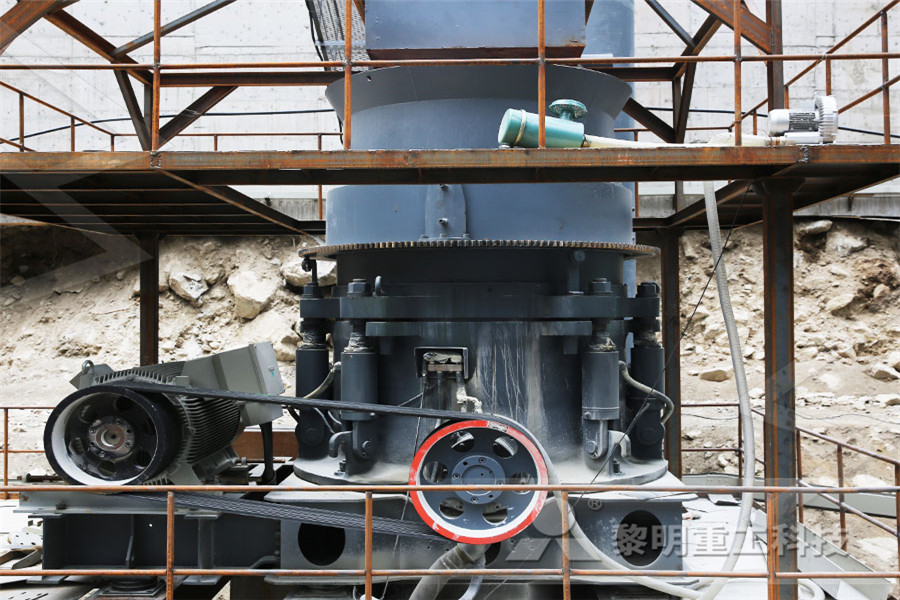

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers