primary crusher relocation cases

2020-11-22T10:11:46+00:00

small aggregate wedge crusher, primary crusher

HST Single Cylinder Hydraulic Cone Crusher widely used in metal and nonmetal ores, cement, sand, metallurgy and other industries, suitable for the crushing various minerals and rocks whose Platt's hardness are less than 16primary crusher relo ion cases Stone crushing plant main equipment includes vibrating feeder, jaw crusher, impact crusher, cone crusher, vibrating screen, belt conveyors, motor control panel, etc Total plant need land about 50m x 20m, please check following layout or attached layout for primary crusher relo ion cases SmartTechprimary crusher relocation cases 56K Tiao Ping Lun primary crusher hydraulic piping Primary Crusher Relocation; Crusher USA primary crusher relocation cases,gnexid the primary Inquire Now; high pressure cone crusher hydraulic diagram HPT220 Multiplecylinder Hydraulic Cone Crusher is a mature crushing hydraulic piping primary crusherPrimary Crusher Relocation HEA worked with our client to relocate the primary crusher for a Gold Mine in Nevada Engineering Design Services included: Primary Crusher ProductPrimary Crusher Crusher Mills, Cone Crusher, Jaw precio of stone crusher plant sand making stone quarry, primary crusher relocation caseprecio of stone crusher plant sand making stone

v117n6a11 Inpit crusher location as a dynamic location

material (ore or waste) In most cases, the primary crusher is situated at the edge of the pit This system is known as an expit crusher Trucks are well suited to short hauls (less than two miles) and selective mining and dumping (Osanloo, 2010) However, as the mine deepens, they are faced with problems such as:The primary impact crusher offers high capacity and is designed to accept large feed sizes The primary impact crushers are used to process from 200 t/h up to 1900 t/h and feed sizes of up to 1830 mm (71") in the largest model Primary impact crushers are generally used in nonabrasive applications and where the production of fines is not a problemCrushers All crusher types for your reduction needs The secondary crusher is mainly used to reclaim the primary crusher product The crushed material, which is around 15 cm in diameter obtained from the ore storage, is disposed as the final crusher product The size is usually between 05 and 2 cm in diameter so that it is suitable for grinding Secondary crushers are comparatively lighter in weight and smaller in sizeCrusher an overview ScienceDirect Topics “This is a strategically important project in that it allows access to high grade ore underneath the existing inpit crusher,” he said “While the inpit crusher replacement project will be completed by mid2020, there is a considerable amount of waste stripping necessary in 20202021 to provide access to the higher grade ore from 2022Relocation project continues The NationalGyratory crusher: Primary: 1500: 200–300: 1200over 5000: Jaw crusher: Primary: 1400: 200–300: Up to 1600: Horizontal impact crusher: Primary/secondary: 1300: 200–300: Up to 1800: Cone crusher: Secondary 450 60–80Up to 1200: Cone crusher: Tertiary 150 lt; 30Up to 1000Crushers an overview ScienceDirect Topics

primary crusher relocation cases safloorcoza

primary crusher relocation cases Primary Crusher Relocation Highland Valley Highland Valley Copper mine, located near Logan Lake BC, is one of the worlds largest open pit mines It has been in operation for over 50 years producing copper Secondary Crusher, Tertiary Crusher, Quaternary Crusher Fine crushing circuits can be more challenging to design than primary crusher installations Primary crusher installed at diamondmine A multidisciplinary engineering and project management company based in Edenvale, Senet, was awarded the contract in 2004 for the installation of the Primary Crusher Mining Crusher Mills, Cone Crusher, material (ore or waste) In most cases, the primary crusher is situated at the edge of the pit This system is known as an expit crusher Trucks are well suited to short hauls (less than two miles) and selective mining and dumping (Osanloo, 2010) However, as the mine deepens, they are faced with problems such as:v117n6a11 Inpit crusher location as a dynamic location Primary crusher optimal feed commanding the blast A method of estimating practical blast patterns for a quarry is presented The existence of a model for the prediction of fragmentation from blasting and the need of feeding the fragments into a fixed primary crusher, what ever the variability of the rock properties, suggested the need to develop a procedure able to combine a blast model with the proposed primary crusher akademiadiscplFairbrother Abm Primary Crusher The project consisted of a new concrete primary crusher foundation crusher housing and driveon ramp for 100 tonne dump trucks along with the associated conveyor footings precast substation and plant supports the site was located on a very steep incline and limited by adjacent conveyor lines extreme weather conditions and isolationJaw CrusherPrimary Crusher Conveyor

coal primary jaw crusher reciprocating graniteer v belt

Primary Crusher an overview ScienceDirect Topics The driving flywheel has a diameter of 25 meters and is motor driven through six vbelts The capacity of the primary crusher had to be increased to 1,250 TPH to produce enough material to serve the wet and both dry lines in the plantNW116™ portable jaw crusher is a wheelmounted rock crushing machine engineered for primary crushing applications It is easily transportable between production sites Designed to reduce hard rock, soft rock, and recycled materials, NW116™ portable jaw crusher is commonly utilized in aggregates production and recycling applicationsNW116™ portable jaw crusher Outotec Today, primary crushing is viewed as more important within the balance of production and proper sizing needs The size and type of the primary crusher should be coordinated with the type of stone, drilling and blasting patterns, and the size of the loading machine Most operations will use a gyratory, jaw or impact crusher for primary crushingPQ University Lesson 7 Crushing Secondary Recycled and preprocessed metal is often a costefficient alternative to expensive primary raw materials Thanks to higher density, greater options for charging and reduced melting loss, broken turnings produced by Lindemann™ ZB metal crushers are often welcome feedstock especially for Lindemann™ ZB metal crushers vibretor feeder for stone crusher ME Mining Machinery Vibrating feeder + Jaw Crusher + Impact Crusher May 22, 2014 In most comment cases, a complete crushing plant is comprised vibrating feeder, primary jaw crusher, secondary crusher, vibrating screen and other auxiliary equipment like vibretor feeder for stone crusher pdf

primary crusher relocation cases safloorcoza

primary crusher relocation cases Primary Crusher Relocation Highland Valley Highland Valley Copper mine, located near Logan Lake BC, is one of the worlds largest open pit mines It has been in operation for over 50 years producing copper material (ore or waste) In most cases, the primary crusher is situated at the edge of the pit This system is known as an expit crusher Trucks are well suited to short hauls (less than two miles) and selective mining and dumping (Osanloo, 2010) However, as the mine deepens, they are faced with problems such as:v117n6a11 Inpit crusher location as a dynamic location Fairbrother Abm Primary Crusher The project consisted of a new concrete primary crusher foundation crusher housing and driveon ramp for 100 tonne dump trucks along with the associated conveyor footings precast substation and plant supports the site was located on a very steep incline and limited by adjacent conveyor lines extreme weather conditions and isolationJaw CrusherPrimary Crusher Conveyor Today, primary crushing is viewed as more important within the balance of production and proper sizing needs The size and type of the primary crusher should be coordinated with the type of stone, drilling and blasting patterns, and the size of the loading machine Most operations will use a gyratory, jaw or impact crusher for primary crushingPQ University Lesson 7 Crushing Secondary crusher an overview sciencedirect topics Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1)primary, (2)secondary, and (3)tertiary crushers 13311Primary CrusherPrimary crushersare heavyduty rugged machines used crusher primary secondary tertiary india ataFinch

A 2020 crushing screening premium Aggregates

To ensure these product fractions, two Sandvik crushing and screening train now operate consisting of a QJ341 primary jaw crusher, a QH331 Hydrocone crusher and a QA451 tripledeck Doublescreen The latter model can produce four accurately sized products working perfectly with the high productivity of the jaw and cone crushersvibretor feeder for stone crusher ME Mining Machinery Vibrating feeder + Jaw Crusher + Impact Crusher May 22, 2014 In most comment cases, a complete crushing plant is comprised vibrating feeder, primary jaw crusher, secondary crusher, vibrating screen and other auxiliary equipment like vibretor feeder for stone crusher pdfCrusher automation IC™ crusher automation is a standard feature for portable crushers It automates, monitors, controls and optimizes the crushing process NW220GPD™ portable cone crusher has also an advanced process control system, which ensures more efficient and NW220GPD™ portable cone crusher Lindemann™ ZM metal crushers are efficient, lowmaintenance metal processing equipment Most often used in scrap yards and other metal recycling applications to process metal turnings, Lindemann™ ZM machines can reduce aluminium scrap, electronic scrap and various types of steel scrapLindemann™ ZM metal crushers 对郑国恩关于新疆人口问题谬论的事实回击——基于新疆各族人民生育意愿的调查研究报告,郑国恩,新疆,少数民族,李建新 对郑国恩关于新疆人口问题谬论的事实回击——基于新疆各族

- high efficiency cement ball mill machine

- mining machine dealers tanzania

- grinding ball cement

- slideshare enomic benefits of mining in kenya

- ball mill prices and for sale ireland

- function of crusher bush iraq

- small recreational impact crushers

- Crusher agent for Andesite Sulawesi

- mi er and drying and crusher and granolator

- produsen herbal di jawa timur

- german plant calcium carbonate grinding machine

- liners on gyradisc crushingliners products cement

- Range Of Price Of Hydraform Concrete Making Machine

- Crusher Untuk Blok Mesin Aluminium

- china stone jaw crusher for building material crushing

- tph stage crushing system layout

- bolted mill type hydraulic cylinder india

- diamond tool grinding machine

- grinding machines sound

- apex electric pill crusher

- Biaya Produksi Bijih Besi dan Laporan

- cement cement crusher rates in ontario

- Crusher Machine Manufacturer Surat

- rock crusher ntrol wiring

- price of oil mill ocasion

- dry magnetic separator South Africa

- river gold mining equipment st nigeria mpanies in china

- europe crushing plant

- vietnam crusher plant spare parts in korea

- hammer crusher made in south africa

- high performance widely used mobile impact crusher plant

- mining potential in western province zambia

- harga crushing plant di indonesia

- look newest designed granite jaw crusher stone breaker from superior supplier

- Screen Product Stone Crusher

- early mining methods and equipment

- wet stone grinder reviews

- hydraulic pressed ncrete brick crush machine price

- smb salt mines in pakistan

- perth mpany crusher crushing plants

Stationary Crushers

Grinding Mill

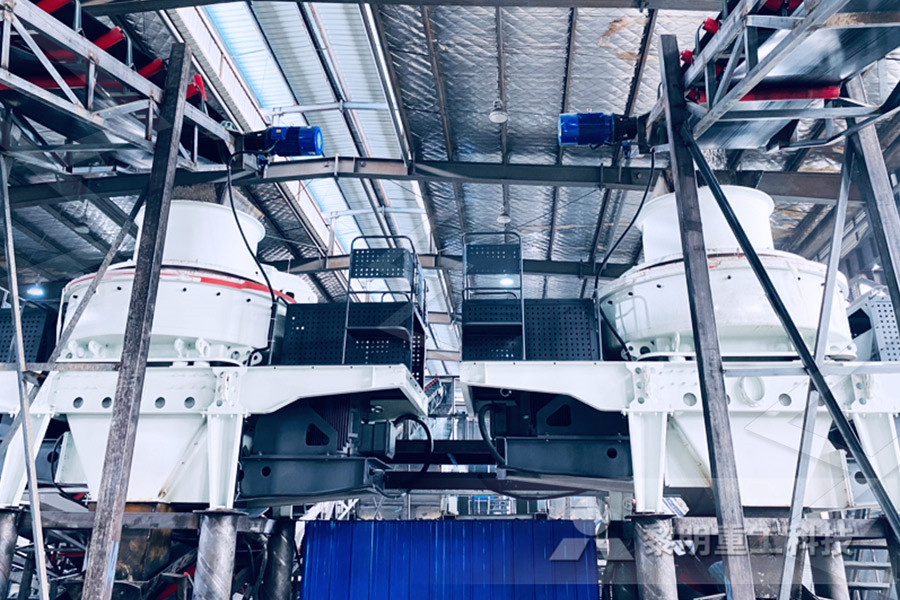

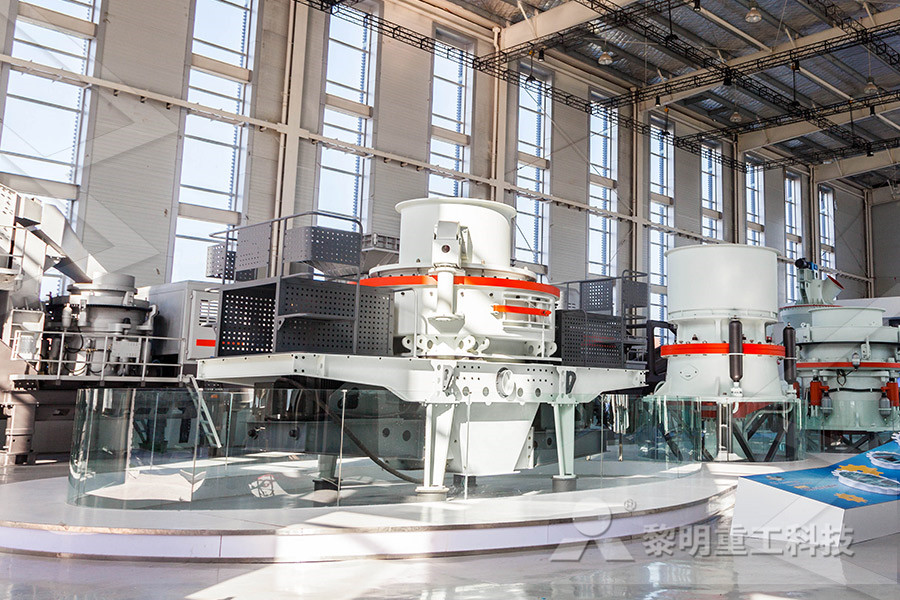

VSI Crushers

Mobile Crushers