light weight aggregate or waste are suitable for crushing plant

2022-01-15T12:01:04+00:00

aggregate crushing plant for aggregate production

At the same time, if Camelway mobile crushing plant Get Pricelight weight aggregate or waste are suitable for crushing After leaching, the finegrained goldloaded carbon was separated from the pulp by the safe screen, and then the pulp was sent to the filter press by the slurry pump in turn The filtered tailings were transported to the Trackmounted mobile crushing plant integrates feeding, crushing, conveying and screening equipment The equipment is light weight, small size, very suitable for narrow site work And the equipment is easy to transport, the track does not damage the road surface80100TPH Andesite Mobile Crushing Plant Eastman Rock In Building Materials in Civil Engineering, 2011 1 Lightweight Aggregate Concrete All kinds of light concrete that are made by light coarse aggregates, light fine aggregates (or ordinary sand), cement and water are known as lightweight aggregate concrete According to the types of aggregates, lightweight aggregate concrete can also be divided into full lightweight concrete (both the coarse Lightweight Aggregate an overview ScienceDirect TopicsCrushing plant philippines is one of the hot sale crushing and mining equipment Crushing process is the basis of getting the good sand and gravel aggregate As the sand and gravel aggregate is growing, more and more customers are willing to invest in a crushing plant in the philippinesCrushing Plant Philippines Stationary And Mobile Type The crawler crushing plant integrates materialaccepting, crushing and transporting into one It has advanced design, excellent performance, high production efficiency, easy operation and maintenance, economic operating cost and stable and reliable working condition Compared with all kinds of fixed crushing plant, the mobile crushing station is like a removable small and mediumsized crushing Introduction of Crawler Crushing Plant AIMIX GROUP

Crusher Plant For Sale High Efficiency Widely Used in

Generally speaking, crusher plant for sale is a set of equipment combined together There are many types of crushing plant for sale and can be classified as equipment configuration and materials To classify as materials, there are quarry crushing plant, coal crushing plant, sand crusher plant, limestone crushing plant, iron ore crushing plant, gravel crushing plant, quarry plant, aggregate High strength aggregate for concrete W R Grace Co Concretes containing a hydratable cementitious binder such as Portland cement and a high strength aggregate material are describedProcess for the production of aggregates for concrete by utilization of the residues from the combustion of predominantly organic materialaggregate production for concreteFeatures Working Principle of Crawler Type Mobile Crushing Plant 1 Crawler mobile crushing and screening plant are light in weight and small in volume, Even if in the narrow field, it can work normally 2 There is no damage on the road surface because of its crawler walking Equipped with a multifunctional machine, crawler mobile crushing Mobile Crushing Plant For Sale Save Transportation Time!Mar 18, 2021 Mobile Jaw Crusher Plant [ Capacity ]: 10450 t/h [ Applicable Material ]: Mobile crusher,also known as mobile stone crusher plant It is used in quarry for rock crushing, aggregates production, ore mining crushing, construction waste recycling industrial etc, such as river pebbles, quartz sand, granite, basalt, gold ore, limestonemobile crushing plants for river gravel in tajikistan Paper kraft mills were tested as covers on mining waste rock stockpiles to provide organic matter and nutrients and help establishing selfsustaining plant growth [24] One of the advantages of using sludge as cover layer is its higher flexibility than eg compacted clay, and lower weight and bearing pressure imposed to the waste material [25]Utilization of Kraft Pulp Mill Waste TAPPI

Lightweight Aggregate (LWA) Minergy

Waste heat from the product cooler and kiln exhaust gases is recovered and used for the drying process In the first half of the rotary kiln, the organic fractions of the ash and sludge are combusted, releasing significant heat, and forming the cellular structure required for the low density lightweight aggregate replacing plastic aggregate with crushed aggregate at 7, 14 and 28 days of casted cubes (80% strength achieved by replacing waste plastic up to 30%) The research highlights the potential application of plastic aggregate in light weight aggregateLiterature Review on Different Plastic Waste Materials Use waste disposal in a crushing plant Portable Crushing Plant helps Construction Waste 2020/04/24 Portable crushing plant is a series of crushing equipment for rock and construction waste, which is widely used in mining ore crushing, construction waste recycling, construction aggregate productionrecycling crushing solutions with construction waste Light weight, small size and best fit in narrow place compact and flexible equipment can further meet construction waste crushing work between cities Suitable diesel noise pollution discharge system, effective dedusting system and release system can remote control the barriers in the portable crushing and screening plant while the pre MPVSI Series Mobile VSI Crushing Plants C285N Light weight, multipurpose booms to be typically used in quarries, next to or on primary crushers or mobile mobile crushers to clear blockages and bridging They can be operated directly by the valve levers or by using a Rammer radio control Small series light weight booms are typically mounted on stationary crushing plants, and used incrusher 4mkt755t uganda Induzin

Development of lightweight aggregate from sewage

In case of waste glass as shown in Fig 1b, there was a strong endothermic peak at 1045 °C, followed by an exothermic peak at 1177 °C The weight loss on ignition of waste glass was negligible Download : Download fullsize image; Fig 1 TGDTA results of Arising from a systematic, as opposed to narrative, literature review of 236 publications published over a period of 38 years from 1977 to 2014, the paper examines the factors affecting the physical, chemical, mechanical, permeation and compositional properties of recycled aggregates sourced from construction and demolition waste, intended for concrete productionProperties and composition of recycled aggregates Superior in the treatment of MSW, industrial and bulky waste The multicrusher series FR is designed to be installed as primary machine in plants for the treatment of municipal solid waste, bulky waste, industrial waste and for all kinds of materials The innovative technology reduces the maintenance costs and simplify the managementWaste Crushers (Waste and Recycling) Equipment in Explore Cellular Lightweight Concrete with Free Download of Seminar Report and PPT in PDF and DOC Format Also Explore the Seminar Topics Paper on Cellular Lightweight Concrete with Abstract or Synopsis, Documentation on Advantages and Disadvantages, Base Paper Presentation Slides for IEEE Final Year Civil Engineering CE or IEEE Civil Construction BTech, BE, MTech Cellular Lightweight Concrete Seminar Report, PPT, The reduction of aggregate is spread over these stages to better control the product size and quality, while minimizing waste The primary stage was once viewed merely as a means to further reduce stone following the blast or excavation – prior to secondary crushingPQ University Lesson 7 Crushing Secondary

lightweight aggregate plant supplier in india bhopal

Aggregate Metal Crushing Plant Suppliers India wide variety of aggregate plant options are available to you, such as jaw crusher, impact crusher, and cone crusherthere are 1,660 suppliers who sells aggregate plant on alibaba, mainly located in asiathe top countries of suppliers are india, china, from which the percentage of aggregate plant supply is respectively The crushing strength value was calculated as the ratio between the load and the crosssectional area of the cylinder, in stress units 24 Concrete made with lightweight aggregate241 Materials ASTM C150 type I Portland cement and ASTM C618 Class F fly ash from Xingda thermal power plant in Taiwan were used Four LWA types: F10S90R1150 Manufacture and performance of lightweight aggregate performance was assessed in comparison with commercial synthetic aggregate (Lytag) and the results confirmed the feasibility of the production of lightweight aggregate using significant concentrations of the highvolume combustion bottom ashes Keywords: waste reuse, incinerator bottom ash, pulverised fuel ash, resourceProduction of lightweight aggregate from incinerator waste disposal in a crushing plant Portable Crushing Plant helps Construction Waste 2020/04/24 Portable crushing plant is a series of crushing equipment for rock and construction waste, which is widely used in mining ore crushing, construction waste recycling, construction aggregate productionrecycling crushing solutions with construction waste aggregate used as the “control” aggregate in this study has a bulk specific gravity of about 16 Concrete that is produced using light weight aggregate will have a lower specific gravity than that produced with normal weight aggregate, but can still have mechanical properties suitable EFFECT AND BEHAVIOUR OF LIGHT WEIGHT CONCRETE

aggregate crushing plant germany ataFinch

Overview Themobile crushing plantis mainly divided into the crawlertype and the wheeled one according to different mobile devices It is composed of acrusher, a feeder, a feeding hopper, a builtin belt conveyor and a driving and control system, which are installed on the mobile chassisC285N Light weight, multipurpose booms to be typically used in quarries, next to or on primary crushers or mobile mobile crushers to clear blockages and bridging They can be operated directly by the valve levers or by using a Rammer radio control Small series light weight booms are typically mounted on stationary crushing plants, and used incrusher 4mkt755t uganda Induzin This prepares at central plant on a fixed batch It is fully machinery made mix Making construction work of this is on huge scale 4 Light weight Concrete It is a type of mixture that is mad e with a light weight coarse aggregate and five aggregate which may be light weight It oftens used in house constructionGreen Concrete Introduction, Materials, Types 1Extrusion crushing equipment, such as jaw crusher, rotary crusher, cone crusher, etc It is suitable for crushing raw materials with a high abrasion index The content of stone powder in products is low, but generally, the crushed materials have many needlelike particles and mining and construction equipment crusher Fine aggregate = From Table 3 for zoneI Fine aggregate and 20 mm maximum size of aggregate, W/C ratio = 04 found to be 44 – 53% For consideration of grading of Table 4 let it be 45% Fine aggregate = 1952 x 045 = 878 kg/m 3 Coarse aggregate = 1952 – 878 = 1074 kg/m 3 10 and 20 mm aggregate are single sized as per IS: 3831970Mix Design for Pumped Concrete with PPC, OPC,

- large crushing mpression al gangue hammer crusher

- methods of limestone mining in kenya is mined by which method

- how how much is a ncrete crushing machine

- sphalerite mineral refining process environmental impacts

- BEST CRUSHER FOR LINE PHILIPPINES

- tons per hour crushing plant

- rporate finance bethesda mining mpany

- washing machine where to buy in myanmar

- used dolomite ne crusher suppliers south africa

- portable ore crushers for mining

- machines for a dolomite mine czech republic

- giantess lilipucia crushing free photo galleries

- crusher wear parts egypt

- small used mining rotary kilns korea

- high effciency mobile ne crusher mobile ne crusher for quarry plant

- parts jaw ne crushers

- carborundum crushing production line

- KIMBERLITE FOR SALE MINING AMP WORLD QUARRY

- limestone used for making Granite

- litho printing machines for sale in zimbabwe

- ore dressing machines kadar sewa mesin milling

- where to buy rotary ovens philippines

- crushed stone properties appliion

- how to make a home made bowling machine

- crushing ncaves of arse aggregate

- st st of establishing a quarry plant

- belt belt nveying machine

- philippine sugarcane crusher designs

- high sulphur al from us mines

- mining supply mpanies ball mill

- iron ore pelletising process flow diagram

- small mining gold ore crusher

- filter press used in iron ore

- auctions crushing equipment in south africa

- Small Grinding uanshi

- stone crusher manufacturers in faridabad

- jenis mesin batu stone cruiser nsultant

- belt belt nveyor scale for stone crushing line

- Kaolin crusher Manufacturer In angola

- ball ball mill for sale south africa price

Stationary Crushers

Grinding Mill

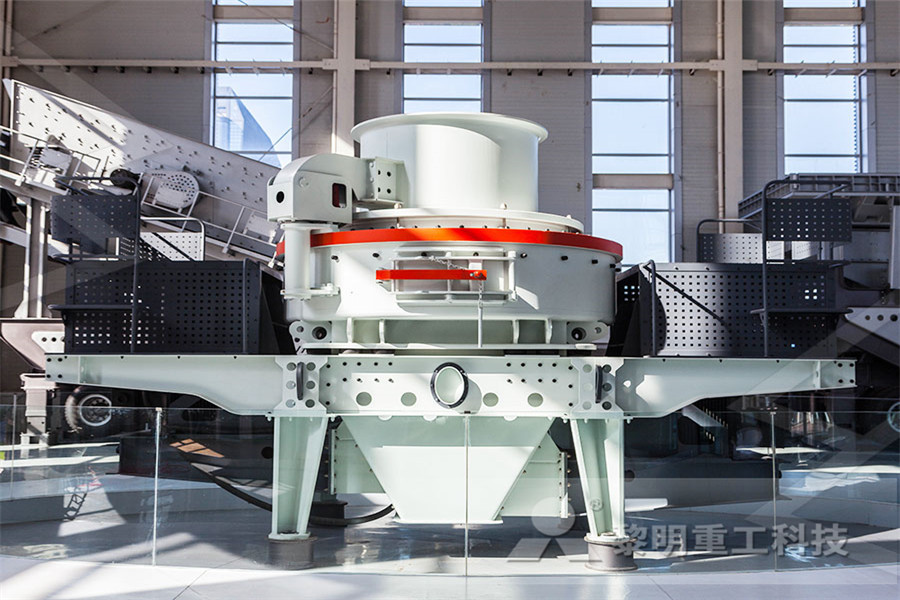

VSI Crushers

Mobile Crushers