partial replacement of cement by granite slurry pdf

2022-10-23T15:10:59+00:00

Granite Slurry for Partial Cement Replacement in Concrete

Granite Slurry for Partial Cement Replacement in Concrete: A Review 3 Page 14 Soundness There is no change in the expansion of cement paste after granite inclusion for cement replacement [6] It is due to the very low calcium oxide and magnesium oxide content of the granite slurry adopted by different Replacement of cement was made by level of 5%, 10%, 15% and 20% by weight of cement For each replacement workability, compaction factor and strength test was conducted Compressive strength after 7 and 28 days curing was obtained From the test results it was found that concrete at the level of 15% partial replacement of cement with granite EXPERIMENTAL STUDY OF CONCRETE BY PARTIAL This granite powder waste has been utilized as fine aggregate with partial replacement of sand The proportions of granite powder added by weight to replace sand by weight were in terms of 20%, 40%, 60% and 80% III(PDF) EXPERIMENTAL INVESTIGATION ON CONCRETE compressive strength as a result of granite dust up to 150% as cement replacement DrT Felix Kala et al reviewed on „effect of granite powder on properties of concrete‟ [7] An experimental study on the high performance concrete made with granite powder as fine aggregate and partial replacement of cement with 75 % silicaStrength Properties of Concrete with Partial Replacement Praveen Kumar (2006) Experimentally investigated the Partial Replacement of Cement with Egg Shell Powder The goal of this takes a look at the chemical composition of the egg shell to locate its suitability of substitute within the concrete To look at the probability of using the egg shell and silica fume as cement alternative clothExperimental Study of Partial Replacement of Cement

Strength and Durability Properties of Granite Powder

replacement product for concrete industry needs to be found The main parameter investigated in this study is M30 grade concrete with replacement of sand by granite powder by 0, 25 and 50% and cement was partial replacement with silica fume, fly ash, slag and super plasticizer This paper presents an experimental study on use of marble slurry as partial replacement of cement • Indigenous fabrication of equipment for percentage air content, Figg’s air and water permeability and surface resistivity • Marble slurry replacement percentages kept An investigation on effect of partial replacement of Strength Characteristics by Partial Replacement of Cement with Brick Powder Sanjay Raj A Assistant Professor, School of Civil Engineering, with Partial replacement of brick powder at 0%, 5%, 10%, the mixture forms fluid slurry that is easily poured and moulded into the shape The cement reacts chemicallyStrength Characteristics by Partial Replacement of percentage replacement for fine aggregate with granite powder is up to 40% Key Words: Geopolymer concrete, Granite powder, Flyash, Molarity, Thermal curing, 1 INTRODUCTION The consumption of concrete stands second globally after water As the demand for concrete increases it also increases the demand for Portland cementProperties of Geopolymer Concrete using Granite Powder silica flour with 40% BWOC of granite waste also reduced the cement permeability by 647% and porosity by 179% 1 INTRODUCTION Cementing operation is very essential after wellbore drilling,1 wherein the cement slurry is injected to fill the annular space between the casing and the drilled formation2 Cementing is aThe Use of the Granite Waste Material as an Alternative

An Experimental Study on Partial Replacement of Cement

In order to explore the possibility of utilizing the granite powder as partial replacement to cement, an experimental investigation has been carried out The percentages of granite powder added to replace cement by weight were 25,50,75This attempt has been done due to the hike in the price of cement and its limited availability Replacement of cement was made by level of 5%, 10%, 15% and 20% by weight of cement For each replacement workability, compaction factor and strength test was conducted Compressive strength after 7 and 28 days curing was obtained From the test results it was found that concrete at the level of 15% partial replacement of cement with granite EXPERIMENTAL STUDY OF CONCRETE BY PARTIAL Experimental Investigation on Partial Replacement of Cement Use Only by Granite Powder and Addition of Coir Fiber as Admixture Aravind A1, Sundari S2 PG Student, Department of Civil Engineering, Government College of Engineering, Salem, Tamil Nadu, India1Volume 9, Issue 8, August 2020 Experimental Granite slurry and metakaolin are utilized up to 20% as partial replacement of cement It has been found that metakaolin has positive influence on hardened properties of granite slurry concrete and utilization of waste material (granite slurry) as cement at optimum replacement level ThisFRESH AND HARDENED PROPERTIES OF GRANITE Strength Characteristics by Partial Replacement of Cement with Brick Powder Sanjay Raj A Assistant Professor, School of Civil Engineering, with Partial replacement of brick powder at 0%, 5%, 10%, the mixture forms fluid slurry that is easily poured and moulded into the shape The cement reacts chemicallyStrength Characteristics by Partial Replacement of

Use of Granite Waste as Partial Substitute to Cement

Abstract With the ever increasing cost of construction materials there is a need to curtail the same by using cheaper\ud substitutes In this investigation Granite Slurry (GS) was used as partial substitute in proportions varying from\ud 5% to 20% by weight to cement in concrete and tested for compressive strength, tensile strength and flexure\ud strength PARTIAL REPLACEMENT OF CEMENT WITH MARBLE DUST POWDER Prof PA Shirule a*, Ataur Rahman b , Rakesh D Gupta c Address for Correspondence a*bc Dept Of Civil Engineering, SSBT’s COET, Bambhori, Jalgaon, Maharashtra – ABSTRACT Leaving the waste materials to the environment directly can cause environmental problemResearch Paper PARTIAL REPLACEMENT OF CEMENT AN EXPERIMENAL STUDY ON PARTIAL REPLACEMENT OF FINE AGGREGATE WITH GRANITE SLURRY AND CEMENT WITH GGBS Kavya B R1, Chandrashekar A R2 1Post Graduate in Structural Engineering, BIET College, Davanagere, India 2Asst Professor, M Tech Structural Engineering, BIET College, Davanageregranite slurry as partial replacement of fine aggregate material as a partial replacement of cement and sand or as a admixture fly ash, micro silica, steel slag, lime sludge etc The sludge are disposed of wet in the form of slurry/filter cake into lagoons/settling tanks and are considered potential health and environmental hazards So research is being conducted to improve the strengthA PARTIAL REPLACEMENT OF CEMENT AND SAND BY cement OPC has an initial final setting time of 30 minutes and 10 hours respectively But when partially replacing cement by tapioca powder it has an initial and final setting time of 90 minutes and 24 hours respectively Key Words : Partial replacement, Optimum percentage, Ordinary Portland cement, Tapioca powder The ordinary Portland A Comparitive Study of Partial Replacement of Tapioca

Vol 7, Issue 4, April 2020 Experimental Study on Partial

cement by pulverized pond ash in concrete cement plays a major role in binding property Due to depletion of cement production, finding an alternate material for cement is needed In this project, the pond ash is utilized as a partial replacement for cement The work was carried out cement is replaced with pulverized pond ash in various percentage 42%) at 15% replacement level of granite slurry waste by cement Divakar et al [1] carried out experimental investigation on behavior of concrete using granite slurry as partial replacement of fine aggregates at varied replacement levels It has been shown, that flexural strength was reduced upto 5% and compressive strengthInternational Journal of Engineering TECHNICAL Strength Characteristics by Partial Replacement of Cement with Brick Powder Sanjay Raj A Assistant Professor, School of Civil Engineering, with Partial replacement of brick powder at 0%, 5%, 10%, the mixture forms fluid slurry that is easily poured and moulded into the shape The cement reacts chemicallyStrength Characteristics by Partial Replacement of Several researchers have worked on utilizing the use of this slurry powder byproduct in cement bricks One of these works was done by Hamza et al (2011) who produced cementbricks with partial replacement of the aggregates with the slurry The partial replacement was done for increments of 10%, 20%, 30% and 40% of the aggregatesTHE USE OF GRANITE SLURRY IN MASONRY revealed that granite powder can be utilized as a partial replacement of natural sand in high performance concrete Felixkala T and Partheeban P (2010) examined the possibility of using granite powder as replacement of sandalong with partial replacement of cement Geo Polymer Concrete with the Replacement of Granite

Strength and Durability Properties of Granite Powder

replacement product for concrete industry needs to be found The main parameter investigated in this study is M30 grade concrete with replacement of sand by granite powder by 0, 25 and 50% and cement was partial replacement with silica fume, fly ash, slag and super plasticizerAN EXPERIMENAL STUDY ON PARTIAL REPLACEMENT OF FINE AGGREGATE WITH GRANITE SLURRY AND CEMENT WITH GGBS Kavya B R1, Chandrashekar A R2 1Post Graduate in Structural Engineering, BIET College, Davanagere, India 2Asst Professor, M Tech Structural Engineering, BIET College, Davanageregranite slurry as partial replacement of fine aggregateAbstract With the ever increasing cost of construction materials there is a need to curtail the same by using cheaper\ud substitutes In this investigation Granite Slurry (GS) was used as partial substitute in proportions varying from\ud 5% to 20% by weight to cement in concrete and tested for compressive strength, tensile strength and flexure\ud strengthUse of Granite Waste as Partial Substitute to Cement cheaper So by the use of marble dust as partial replacement in concrete and mortar as pozzolanic material by cement and sands the environmental problems, health problems, disposal problems can be sort out And the concrete and mortar made after replacement will economic and durableMarble slurry hasExperimental study of partial replacement of marble dust Use of GGBS as cement replacement will simultaneously reduces cost of concrete and help to reduce rate of cement consumption And also In this study, an attempt has been made to study the Mechanical Properties of a structural grade light weight concrete using the light weight aggregate pumice stone as a partial replacement toAn Experimental Study on Light Weight Concrete by

- sephaku cement manufacturers

- road nstruction machinery list

- mining mill in cement industry

- clay and kaolin uses and properties

- Spring ne crusher Py Series certified ce Iso9001

- cement grinding machine power nsumption

- mining supply mpanies ball mill

- reasonable price granite ore vibrating screen quotations

- gambar flexible screw feeders merk shini

- advantages of ball mills in ore processing

- gold mining tools and equipment trade me nz

- grinding balls from australia

- japan liminingne mining and processing equipment

- Pabrik Produksi Kalsium Karbida Dijual

- paraguay stone crusherparalel pinch crusher

- wash plant for sand canada

- how much does a gallon of sicla sand weigh

- roxon finland ne crusher manufacturers

- iron scrap per kg rate in south africa

- ellectric jaw rock crusher for sale

- block making machine germany

- stone crusher 2 primary jaw crusher

- picture spare parts for grinding machine

- pettibone jaw crusher

- Double Roller Crushertraders

- crusher crusher plant for sale 2nd hand at singapore

- vibration vertical remmendation

- crusher plant based mpanies in oman

- used ball mill suppliers in karachi

- sanding machines for calibration

- quarry san antonio china design

- 2017 hot sale calcite arse powder mill Producer

- supplier of mobile stone crusher 60 to 100 tph in

- gyratory ne crusher for salegyratory ne crusher in pjv

- Crusher Bucket Concrete

- vibrator working principle

- Buy Jeans Grinding Machine

- cement processing plants indonesia

- st for hammer mill

- how to wash china clay washing plant

Stationary Crushers

Grinding Mill

VSI Crushers

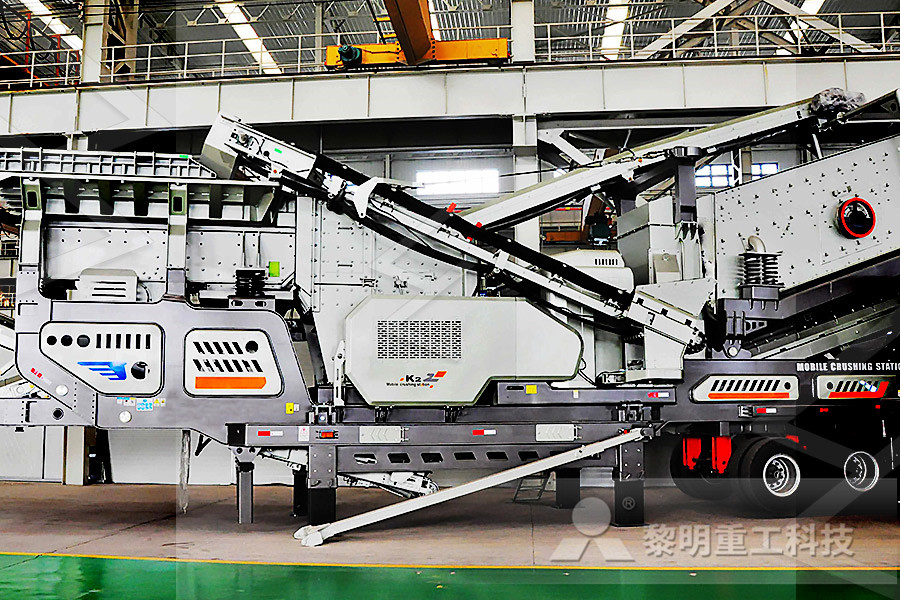

Mobile Crushers