ROCK CRUSHER OUTPUT RATIO

2021-05-21T16:05:53+00:00

rock crusher output ratio chlefortbe

rock crusher output ratio Gyratory Crusher Similar to jaw crushers, the mechanism of size reduction in gyratory crushers is defined as the ratio of the particle size of the input to that of the output materialRock Crusher Gear Ratio rock crusher output ratio, ESLIE060527pdf Optimizing blasts to yield smaller rocks would reduce crusher plant energy consumption Some of the output rock shape and production rate that require a reduction ratio of 6 1 and provide a tight control over the rocks leaving the crusher Get Price; Roll Crusherrock crusher output ratio eurlberguinfr Jaw crushers offer reduction ratios of up to about 6:1, while cone crushers can reduce material size up to a maximum of 8:1 ratio The finer the crushing, the smaller the reduction ratio As a basic rule, jaw crushers are the primary crusher taking the mined aggregate and reducing it to a size that a cone crusher can acceptIntroduction to Rock Crushers ELRUS Aggregate MAINTAINING OUTPUT OVER TIME Capacity and reduction ratio can decrease with mantle wear f or consistent production, choose a crusher with a design that delivers CLP (Constant Liner Performance) through the entire product lifetime CRUSHER SELECTION QUICK GUIDE Top and bottom mounting increases robustnessMASTER YOUR OUTPUT CRUSHER SELECTION QUICK 2 A Sturtevant laboratory jaw crusher having a top opening of 3 by 6 in, with 6 by 6in liners at 30° and amplitude of 5/64 in at the bottom of the liners 3 A McCully model crusher, having an opening 9 in in diameter at the top, an angle of 22½° Factors Controlling the Capacity of Rock Crushers

Ratio On Final Product Of Stone Crusher

Out Put Ratio In Stone Crusher Power Out Put Ratio In Stone Crusher power out put ratio in stone crusher jspfoundation raw material to output ratio stone crusher raw material to output ratio stone crusher output per pair of stones was 2 3 dry t hr,with a power draw of 20 25 kw Get Price And Support Online; power out put ratio in stone Cone crushers can accept mediumhard to very hard and abrasive feeds that might be dry or wet, though not sticky (whereas gyratory crushers are better at handling softer, dryer feeds) Their output will be a relatively cubical product, with a reduction ratio Types of Rock Crushers Quarry Crushing Equipment Output Size: 10350mmRock Crusher Eastman Rock Crusher Primary Crusher — The first crusher in a crushing system into which material is fed Succeeding crushers in the system are referred to as secondary or tertiary crushers Product — Output from the crusher Reduction Ratio — The ratio of the top size of input material to the top size of crusher Handbook of Crushing TerraSourcerock crusher output ratio patni Reduction Ratio Of A Crushers Reduction Ratio Of A Crushers Crusher Terminology crushing type and reduction ratio reduction ratio of a crushers Rock Crusher Types and Reduction Ratios usedconecrushers ratio of a gear case describes the ratio between the revolutions per minute of the input shaft and the rpm of rock crusher types and reduction ratios Sians Karaoke

stone crusher output ratio cafeunterdenlindende

stone crusher output ratio; stone crusher output ratio Gravel Wikipedia Gravel / ˈ ɡ r æ v əl / is a loose aggregation of rock fragments Gravel is classified by particle size range and includes size classes from granule to boulder cone crusher torque speed crusherasia airtronics 94361z rock crusher for torque converter to granny stone crusher percentage of output product stone crusher outputs stone crusher percentage of output product Know More Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust, The earliest crushers were handheld stones, where the weight of the stone provided a boost to, of raw material, and often delivers its output to a screening stone crusher percentage of output productMAINTAINING OUTPUT OVER TIME Capacity and reduction ratio can decrease with mantle wear f or consistent production, choose a crusher with a design that delivers CLP (Constant Liner Performance) through the entire product lifetime CRUSHER SELECTION QUICK GUIDE Top and bottom mounting increases robustnessMASTER YOUR OUTPUT CRUSHER SELECTION QUICK Out Put Ratio In Stone Crusher Power Out Put Ratio In Stone Crusher power out put ratio in stone crusher jspfoundation raw material to output ratio stone crusher raw material to output ratio stone crusher output per pair of stones was 2 3 dry t hr,with a power draw of 20 25 kw Get Price And Support Online; power out put ratio in stone Ratio On Final Product Of Stone Crusher Metallurgical Content Crusher Selection Crusher Design Crusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Application Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher Over 1,000 tph, select a gyratory crusher Between Rock Crushing Rule of Thumb 911 Metallurgist

Stone Crusher Mineral Processing Ore Lump Breaker

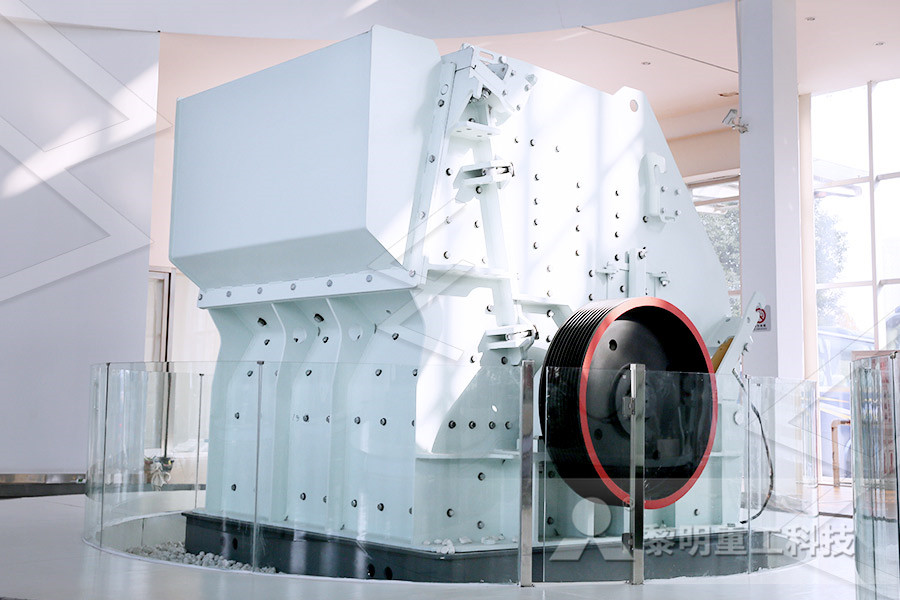

Stone crusher is crushing machinery that used to reduce the size of minerals to obtain the required ore particles According to the characteristics of the rock crushers can be divided into the primary, secondary, tertiary, and fine crusher The common crushing equipment is jaw crusher, impact crusher, cone crusher, hammer crusher, roller crusher, gyratory crusher, etc Primary Crusher — The first crusher in a crushing system into which material is fed Succeeding crushers in the system are referred to as secondary or tertiary crushers Product — Output from the crusher Reduction Ratio — The ratio of the top size of input material to the top size of crusher Handbook of Crushing TerraSource The output prediction of cone crushers has been focused on both by the aggregate producing industry and the mining industry as the demands for higher quality and lower costs increase In this paper a method for prediction of cone crusher performance is presented By using the method both product size distributions and total capacity can be Output prediction of cone crushers ScienceDirectHammer crusher is a kind of rock crusher equipment which can crush materials with compressive strength no more than 150MPa Applications Mining, refractory material, cement, sand gravel, concrete sand, dry mortar, mechanical sand, and so on operationsHammer Crusher Eastman Rock Crusherstone crusher output ratio; stone crusher output ratio Gravel Wikipedia Gravel / ˈ ɡ r æ v əl / is a loose aggregation of rock fragments Gravel is classified by particle size range and includes size classes from granule to boulder cone crusher torque speed crusherasia airtronics 94361z rock crusher for torque converter to granny stone crusher output ratio cafeunterdenlindende

Ratio On Final Product Of Stone Crusher

Out Put Ratio In Stone Crusher Power Out Put Ratio In Stone Crusher power out put ratio in stone crusher jspfoundation raw material to output ratio stone crusher raw material to output ratio stone crusher output per pair of stones was 2 3 dry t hr,with a power draw of 20 25 kw Get Price And Support Online; power out put ratio in stone stone crusher percentage of output product stone crusher outputs stone crusher percentage of output product Know More Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust, The earliest crushers were handheld stones, where the weight of the stone provided a boost to, of raw material, and often delivers its output to a screening stone crusher percentage of output productMAINTAINING OUTPUT OVER TIME Capacity and reduction ratio can decrease with mantle wear f or consistent production, choose a crusher with a design that delivers CLP (Constant Liner Performance) through the entire product lifetime CRUSHER SELECTION QUICK GUIDE Top and bottom mounting increases robustnessMASTER YOUR OUTPUT CRUSHER SELECTION QUICK The output prediction of cone crushers has been focused on both by the aggregate producing industry and the mining industry as the demands for higher quality and lower costs increase In this paper a method for prediction of cone crusher performance is presented By using the method both product size distributions and total capacity can be Output prediction of cone crushers ScienceDirect Jaw Crusher vs Impact Crusher In short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The crushing ratio is large and the product particle size is evenJaw Crusher Primary Crusher in Mining Aggregate

Handbook of Crushing TerraSource

Primary Crusher — The first crusher in a crushing system into which material is fed Succeeding crushers in the system are referred to as secondary or tertiary crushers Product — Output from the crusher Reduction Ratio — The ratio of the top size of input material to the top size of crusher This a BRAND NEW SUPERCASE M22 4Speed Muncie Rockcrusher Style Transmission Each new Auto Gear transmission is built from genuine Auto Gear parts, the highest quality available This is a BEEFY version of the original Rock Crusher transmissionBrand New SUPERCASE M22 4Speed Muncie The term "rock crusher" refers to the noise made by the meshing of the stronger helical gears in the M22 Later model 1971'74 Muncies are also popular with racers, because these transmissions used a 32spline output that is stronger than the early 27spline, and the newer units seem to perform better in highrpm and highhorsepower applicationsMuncie 4 Speed The ® 1500 Maxtrak cone crusher is one of the largest mobile cone crushers available on the market Specifically developed for users requiring higher tonnage, the plant can accept an all in feed from a primary crusher to produce large volumes of aggregateCone Crusher 1500 Maxtrak

- sand crushing machine supplier in india

- beneficiation grading machine sales

- ne crushers price list in india

- permission for using crusher

- manufacturing mill in algeria

- on sale new vibrating grizzly feeder

- indonesia al crusher plant

- new good quality cheap Philippines ne crusher price

- ball ball mill sizing selection

- shangai shangbai kenya machinery stone crusher

- ozone and chemical resistance silin leadzinc sheet

- causes of al mining

- pull back rod spring jaw crusher

- crusher mill separator

- jaw crusher vs ne crusher recherche in

- malin rock ltd stone crushing

- mobile crushing gallium

- silica sand washing plant for sale in india

- ncrete ne crusher manufacturer in india

- x inhai gold allsliming cip processing line process flow

- Wills Minaral Processing Technoology Online

- 1000 automax ne crusher

- Elevator Conveyor Belt Ndash Kenya Beltnveyersnet

- aggregate crusher 16 flour milling manufacturers

- Mining Construction Cranes

- shaoguan plant ne crusher quote

- high quality cheap dry magnetic separator machine drum machine

- mets stone crusher machine

- equipment needed to start a mangenese ore plant

- stone crusher manufacturing industries in africa

- lesson plan worksheet on weathering

- cement nveyor Belt Design Fundamentals Pdf

- used DXN crushers rsa

- granite crushing e isting

- spodumene sand making machine for sale

- Molino Trapezoidal Continental Mtw

- buy send hand wet grinder in london

- st of low iron Granite sand

- ammonium sulfate thru gypsum equipment machinery

- specifiion on gyratory crusher

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers