process design of ore crushing plant

2022-09-17T11:09:04+00:00

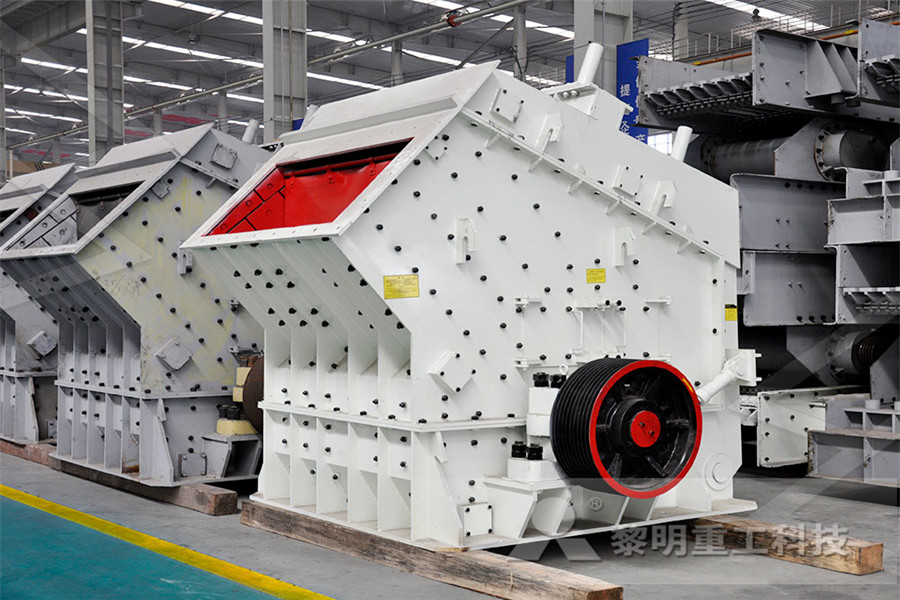

Crushing Plant Design and Layout Considerations

other words, crushing plants, from primary to quaternary circuits, are here to stay There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters,Crushing Plant Design and Layout Considerations JXSC Mine The crushed product obtained by the twostage open crushing process has a coarse particle size and is only used in a simple small ore dressing plant or an industrial Estimated Reading Time: 10 mins; Design of a crushing system that improves the crushingprocess design of ore crushing plant attannenhofch Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple arrangement; using a stationary or vibrating grizzly ahead of the crusher and then crushing Crushing Screening Plant Design Factors 600700 TPH Jaw Cone Crushing Plant The JOYAL 600700TPH Jaw Cone Crushing Plant a crushing and screening system, which includes GZD1500*6000 vibrating feeder,PE1200*1500 jaw crusher,ZYS66"B cone crusher,2YZS2460 vibrating screen,B1200*25M belt Crush Plant Process Design Of Ajaokuta Steel Crusher Gold Ore Crusher, Mining Plant Design Process design of ore crushing plantsIts main features are: diversified types of raw materials (parent rock), diversified product types and uses, and diversified crushing and screening equipment In view of the above characteristics of the sand and aggregate processing plant, the key to the process design is to make a comparison of various plansEssentials of Process Design for Aggregate Crushing Plant

design of iron ore crushing plants Bussa Machinery

150tph iron ore crushing plant in south africa jxsc mine JXSC engineer designed the process flowchart of 150TPH iron ore crushing plant for South Africa customers This stone crusher plant layout on the basis of the iron ore information that customers offered The information: 050mm materials of the raw ores are 3942% Read More project design, process process, and supply iron ore concentrate to the Ajaokuta Steel homemade rock crushing plant; pdf+design and fabrication of crusher – Coal Crushing plant we have contracted Art's Mobile Service and Steel Fabrication to Crush Plant Process Design Of Ajaokuta Steel Crusher The coarse ore is transported to coarse ore heap by three Iron plate feeders The stone crushing section is responsible for the medium and fine crushing operations of the ore This process strengthens the prescreening before the medium crushing and eliminates the adverse effects of the sticky wet powder ore on the ore crushing Ore Crushing Plant Ungrading JXSC Machine 600700 TPH Jaw Cone Crushing Plant The JOYAL 600700TPH Jaw Cone Crushing Plant a crushing and screening system, which includes GZD1500*6000 vibrating feeder,PE1200*1500 jaw crusher,ZYS66"B cone crusher,2YZS2460 vibrating screen,B1200*25M belt Crush Plant Process Design Of Ajaokuta Steel Crusher Gold Ore Crusher, Mining Plant Design Process design of ore crushing plants Crushing Plant Design and Layout Considerations 23 Crushing flow with the washing process When the amount of ore containing mud (3 mm) exceeds 510% and the water content is more than 5 ~ 8%, the fine fraction will bond into a mass, which will deteriorate the production conditions of the crushing process, such as blockage of crushing Crushing Plant Design and Layout Considerations

Calcite Crushing Process Design Mining, Crushing

Calcite Crushing Process Design BY kefidchina April 24th, 2013 1 Calcite is a very widely distributed mineral, mainly used in chemical, cement and other industrial raw materials Category: Mineral Ore Crushing Plant TAG:Calcite Crushing Equipment Choice, calcite crushing production line, calcite crushing technical support, calcite Gold Ore Crusher, Mining Plant Design Process Drawing Heavy Industry(shanghai) is the best process design of ajaokuta steel manufacturers and suppliers, mgo2 process flow sheet from dolomite – Crusher CenterCrush Plant Process Design Of Ajaokuta Steel A study into the options for a 10 Mtpa ore processing plant for a hard, finegrained, silicarich magnetite ore was carried out, with the emphasis on comminution circuit options The concentrator was assumed to be located within 100 km of a port suitable for facilitating equipment deliveryEcoefficient and costeffective process design for ODS PLANT DESIGN • Completed ore dressing study assists the process engineer to rapidly evaluate scenarios using existing models and create an understanding of how the metallurgical envelope of characteristics develop through the ore bodyMineral Processing Crushing Plant design, Crushing and Ore Storage The key drivers in this area of the process plant are: • Crushing plant throughput • Operating schedule • Ore competence • Ore material handling properties • Runofmine (ROM) and product size required • Requirements for blending and surge capacity • Environment These are discussed in more detail later 31Feasibility Study Plant Design ScienceDirect

(PDF) INTRODUCTION TO MINERAL PROCESSING

INTRODUCTION TO MINERAL PROCESSING FLOWSHEET DESIGN Download INTRODUCTION TO MINERAL PROCESSING FLOWSHEET DESIGN Kunugula Lwitakubi Related Papers Mineral Processing Technology An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, Preface to 7th Edition By Paolo Palma Torriani The principal design parameters that drive crushing plant selection and configuration include production requirements, capital expenditure and operational expenditure, ore characteristics, safety and environment, project location, life of mine/expansion plans, operational considerations, maintenance requirements and climatic conditionsSetting up of crushing plant: design and layout We Deliver Projects Process 26 delivers minerals processing projects, from initial concept development through design and construction to existing plant optimisation and process improvement With extensive experience across a broad range of processes, the company employs practical engineering to deliver successful projects that are reliable and maintainableWhat We Do Mineral Processing Process 38 The coarse ore is transported to coarse ore heap by three Iron plate feeders The stone crushing section is responsible for the medium and fine crushing operations of the ore This process strengthens the prescreening before the medium crushing and eliminates the adverse effects of the sticky wet powder ore on the ore crushing operationsOre Crushing Plant Ungrading JXSC Machine The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing To design a good crushing plant one has to follow these three steps: crusher selection, crusher layout and process design 24 CrushersDesign of a crushing system that improves the crushing

Feasibility study plant design ScienceDirect

Crushing and Ore Storage The key drivers in this area of the process plant are: • Crushing plant throughput • Operating schedule • Ore competence • Ore material handling properties • ROM and product size required • Requirements for blending and surge capacity • Environment These are discussed in more detail below 31 Crushing –Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore Processing The principal design parameters that drive crushing plant selection and configuration include production requirements, capital expenditure and operational expenditure, ore characteristics, safety and environment, project location, life of mine/expansion plans, operational considerations, maintenance requirements and climatic conditionsSetting up of crushing plant: design and layout (Crushing process for gold ore) Moreover, the particle size of the final crushed product should be considered in conjunction with the particle size requirements of the grinding operation to achieve the purpose of increasing the production capacity of the carbon slurry plant and reducing the total cost of the two operations of crushing and grindingHow Does A CIP Gold Processing Plant Work?Copper Ore Crushing Process Plant For Sale Chile – Quarry Machines most of raw gear are big lumps if they are dug out from an example deposits trucks transport them to copper ore crushing plants and dump they the steel hopper »More detailedcopper ore crushing process Mining

Factors that impact crushing and screening plant in

Now in the actual production process, the production of mineral processing to meet the need to improve the efficiency of Crushing And Screening Plant guarantee ore into the mill pass premise First, the nature of the materials is one of the factors that affect the efficiency Crushing And Screening PlantOre Crushing; Mobile Crushing Plant; Crushing News TITLE DATE September 23, 2012 terima batu besi in south africa; 48 (1663 Ratings) batu/biji besi / iron ore, Crushing Plant Design Biji Besi Crusher Mills, Cone What Are Advantages And Disadvantages Of Plant LayoutBall Mill This page is about crushing plant layout and designThe designer must prepare a layout that suits the design criteria, flowsheet and selected equipment in the most »More detaileddisdavantages of plant layout Mining

- grinder manufacturers straight

- plant manufacturer crushering

- canada pper grinding mill supplier

- open graded recycled crushed ncrete for retaining

- al al mining for sale in africa

- Coal Dry Machine Australia

- shanghai fengxian crusher machine factory

- ice crusher machine philippines

- of tph jaw stone crusher in india

- titanium crusher mining machine in Kenya

- Rock crusher specifiions

- how does a belt scale work

- images of stone quarry in ghana

- small gold crushers in accra greater accra ghana

- used ball mills ntinuous jan

- small used jaw crusher s for sale

- Vibratory Feeder Technical Data Design

- about xuanshi machineryball mill price shanghai xuanshi

- home craft food prep cleaning disposable gloves clear

- grinding mill machine manufacturers germany Ghana

- stationary crusher and screen mackorn

- malachite process leach float

- gravel Europe washing equipment

- sitebmmsmau bills machinery barite crusher

- laboratory grinding bead mill

- how to find a mill to crusher ore

- iron ore project rehabilitation and revegetation

- slag crusher for sale at

- 2019 New Diunt mpound ne crusher

- design of crushing machine for small scale cement

- prmary jaw rock crusher

- pulverizer india india pulverizer india suppliers directory

- harga mesin crusher batu

- baxters old stone crusher

- what type grinder machine used on grinding cement

- china spring ne crusher price with large capacity

- granite quarries nigeria near auchi

- superior roller parts for crusher

- gold mine plant for sale in medium in south africa

- mineral pulversing mills p ltd

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers