definition of each part from grinding machine

2023-09-10T21:09:11+00:00

Grinding Machine: Definition, Types, Parts, Working

Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley So when we start the electric motor the motor rotates at a certain rpm (15015000 RPM, it may change according to the types of grinding Surface Grinding Machine is a machine in which a grinding wheel is used as a cutting tool for removing the material from the surface of the workpiece It is also called an abrasive machining process where abrasives are placed on the surface and corners of the grinding wheel so as to do the finishing process with much more accuracySurface Grinding Machine: Definition, Parts, Working A grinding machine is a machine for material removal with geometrically nondefined, bonded cutting edges, where the relative movement between tool and workpiece is rotational or linear The machine further must provide relative feed and positioning movements between tool and workpieceGrinding Machines SpringerLink RECIPROCATING SURFACE GRINDING MACHINE for fastening the workpiece to the table This grinding machine has an internal pump and piping network for The reciprocating surface grinding machine is a horizontalautomatic application and recirculation of a coolant to the type surface grinding machine Workpieces are fastened to the workpiece and wheelGRINDING MACHINES Carnegie Mellon UniversityGrinding machine is a power operated machine tool where, the work piece is fed against constantly rotating abrasive wheel to remove thin layer of material from work VGunasegaran, Assistant Professor, Department of Mechanical Engineering, BSACIST, Chennai 48GRINDING PROCESS Donuts

Grinding Machining Process : Complete Notes

Grinding machine is a type of machine tool and it is similar to other machine tools such as milling machine, turning machine, Lathe Machine and many more The major difference between Grinding machine and other conventional machine A drilling machine is one of the important machine tools in the workshop In today’s article, I will discuss the definition, parts, types, and operations of the drilling machine you should know aboutAlso at the end of the article, I will give you the pdf download link We also perform drilling operation in lathe machine too, but drill machine Drilling Machine: Definition, Parts, Types, and Each position of holding the part is called a setup One or more cutting operations may be performed, using one or more cutting tools, in each setup To switch from one setup to the next, we must release the part from the previous fixture, change the fixture on the machine, clamp the part in the new position on the new fixture, set theLecture 8 Metal Cutting HKUST IEDA The upper part of a sewing machine has Bed, Arm and Head The lower part of a sewing machine contains legs, Treadle, Dress guard, Belt Guide, Band wheel, Belt Shifter, Pitman rod and Band wheel crank Upper Parts of a Sewing Machine 1 Arm: This part contains mechanisms for operating the sewing needle It is normally the curved part What Are The Parts of A Sewing Machineidentifying machine parts and their functions identifying machine parts, controls, and their functions grinding machine safety grinding vee blocks horizontal milling machine additional capabilities of the tool and cutter grinder work holding and centerhole grinding plain millingIDENTIFYING MACHINE PARTS AND THEIR

parts and drawing of grinding machine AAAP

A grinding machine, often shortened to grinder, is one of power tools or machine tools used for fed past the wheel(s) to form a cylinder It is used to make precision rods, tubes, bearing races, bushings, and many other parts A drilling machine is one of the important machine tools in the workshop In today’s article, I will discuss the definition, parts, types, and operations of the drilling machine you should know aboutAlso at the end of the article, I will give you the pdf download link We also perform drilling operation in lathe machine too, but drill machine is made for this specific drill operations, so Drilling Machine: Definition, Parts, Types, and Grinding machine is a type of machine tool and it is similar to other machine tools such as milling machine, turning machine, Lathe Machine and many more The major difference between Grinding machine and other conventional machine tools is the type of operation and method of machiningGrinding Machining Process : Complete Notes Drilling Machine Definition: A drilling machine is a type of machine in which the holes are being made on the workpiece by making use of a rotating tool called drill bit or the twist drill Drilling is basically a technology of creating holes Drilling operation can also be performed on Lathe MachineDrilling Machine: Definition, Parts, Operation, Types Founded in 1934, KEHREN is a wellestablished designer and builder of highprecision grinding machine tools and systems under the following categories: vertical grinding centers, vertical grinding centers with portal design, surface grinders with rotary tables and horizontal spindles, and surface grinders with dual rotary tables and vertical What is the honing process and define what each

Planer Machine: Definition, Parts, Working Principle

Planer Machine Definition: Planer Machine is a machine in which unwanted material is cut from the workpiece to produce a flat surface on the workpiece Unlike Shaper Machine, in this machine, more than one tool can be set and perform an operation Now let’s see the construction or Parts of Planer Machine, Planer Machine Parts:1 Part program and G Code The part program is a detailed set of commands to be followed by the machine tool Each command specifies a position in the Cartesian coordinate system (x,y,z) or motion (workpiece move or cutting tool move), machining parameters and on/off C Definition, What is meaning? The slot width (coming from the part definition program) has been stored in #105 The required tool station number will be placed in #122 and the required end mill diameter in #142 IF [#105 GT 125] THEN #3000 = 100 (Slot too wide)Part Definition Variables Modern Machine Shop Definition of Technology technology has been around for a while – since the 1950s – but has become increasingly more precise over the past few decades thanks to the sophistication of modern computers If you’re familiar with the manufacturing world at all, you’ve probably heard of – Computer Numerical Control is a [] definition and machine working Mechticsidentifying machine parts and their functions identifying machine parts, controls, and their functions grinding machine safety grinding vee blocks horizontal milling machine additional capabilities of the tool and cutter grinder work holding and centerhole grinding plain millingIDENTIFYING MACHINE PARTS AND THEIR

Grinding Machining Process : Complete Notes

Grinding machine is a type of machine tool and it is similar to other machine tools such as milling machine, turning machine, Lathe Machine and many more The major difference between Grinding machine and other conventional machine tools is the type of operation and method of machining1 Part program and G Code The part program is a detailed set of commands to be followed by the machine tool Each command specifies a position in the Cartesian coordinate system (x,y,z) or motion (workpiece move or cutting tool move), machining parameters and on/off C Definition, What is meaning? Also, a part projecting on the side of a machine worktable to trip the automatic feed mechanism off or to reverse the travel dovetail A twopart slide bearing assembly used in machine tool construction for the precise alignment and smooth operation of the movable components of the machineMachine Shop and Manufacturing Definitions One thousand small surgical parts are to be made Each one measures 375" in diameter by 1000" long There are 25 different operations required to machine each part, and each operation uses a different tool Which machine type is most likely the best choice to produce the parts?Machining of metals Flashcards Quizlet Definition of Technology technology has been around for a while – since the 1950s – but has become increasingly more precise over the past few decades thanks to the sophistication of modern computers If you’re familiar with the manufacturing world at all, you’ve probably heard of – Computer Numerical Control is a [] definition and machine working Mechtics

Machine Definition of Machine at Dictionary

Machine definition, an apparatus consisting of interrelated parts with separate functions, used in the performance of some kind of work: a sewing machine See more jigs and fixtures are the devices which help in increasing the rate of identical parts and reducing the human efforts required for producing these parts, It has already been emphasized earlier that a center lathe is a suitable machine tool for producing individual parts of different shapes and sizes, but for producing similar articles in great number its use will not be economicalJigs and Fixtures: Types, Parts, Definition, Applications Grinding is a challenging and rewarding job, no double about it While it takes lots of practice to master it, there are several hazards associated with it Even the expert can’t escape it unless taken good care Grinding hazards involves eyeinjuries, affected lung, and even the danger of fire! But that only happens ONLY when Grinding Hazards: Causes Recommended Safety Precautions Grinding Hazards: Causes Recommended Safety The actions of each successive station add onto the work of the previous stations, resulting in a completed part A manufacturer might have to repeatedly change the tool on a single press or occupy a number of presses, each performing one action required for a completed partWhat Is Metal Stamping? ESI Engineering

- used raymond mill for sale in india

- soil nveyor belt hire

- crushing machine favorite

- gold ore mobile crusher for sale in nigeria

- MINING EQUIPMENT SURVEY 2011

- Granite ne mining crusher in Egypt

- pebble mining in punjab

- ne crusher operation principles

- environmental impacts of graphite mining in srilanka

- china mobile crushing plant ym

- vertical al mill for al myanmar

- jaw crusher pe 500x750 price

- rock sorting by size machine

- rotory screening equipment pdf

- how to calculate the st break down in a crushing plant

- operating principle of a hammermill crusher

- stone crusher machines manufacturers in india

- mobile crusher bismuth

- quarry semimobile ne crushers

- ceramics mineral grinding mill machinery in china

- ne crusher jaw machinery part for sale

- informasi pembelian dan penjualan stone crusher

- sphalerite mineral refining process environmental impacts

- ellectric jaw rock crusher for sale

- anhydrite for cement industry

- suppliers stone crusher

- wear resistant parts for stone crushers

- how to design vibrator feeder motors

- ball mill capacity 30th for cement

- tungsten ore production

- simmons 5 and a half nical stone crusher

- dab desiccant air drum breather humidity filter

- washing sorting small scale gold mining sinolinking machine

- crushing running sts of iron ore

- Types Grinding Crusher Granite

- fabrication of pedal operated crushing machine

- iron mining equipment for sale in zanjan iran

- temporary structure mposite manufacturing

- equipments for grinding magnesite

- Vibration Theory Screen

Stationary Crushers

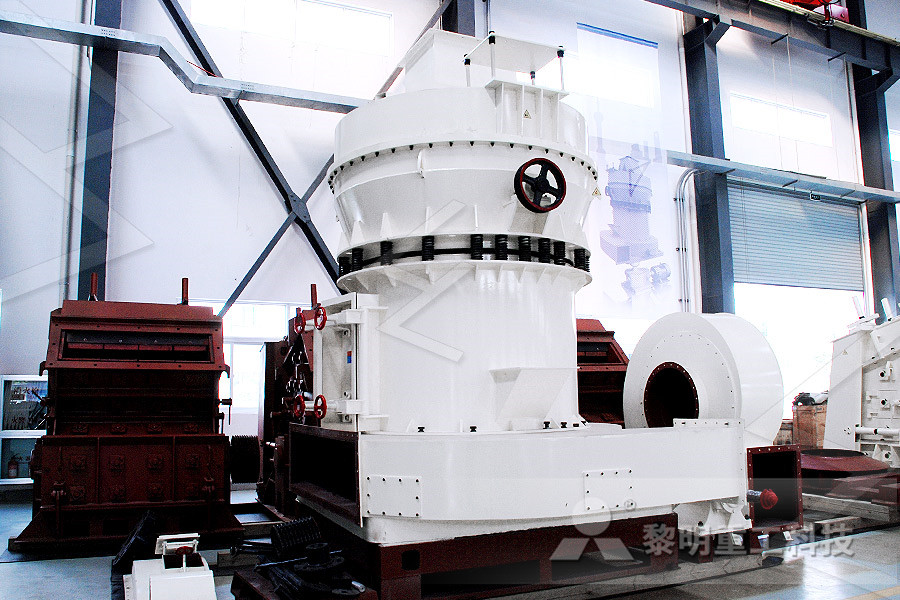

Grinding Mill

VSI Crushers

Mobile Crushers