hot leach process potash

2023-03-28T01:03:44+00:00

Processing of potash ore kaliby

The processing of potash ores by hot leaching with further crystallization of potash salt from saturated salt brines (halurgical method) began in XIX century in Strasburg The primary methods of potash ore processing are flotation (mechanical method) and hot leaching (chemical method) Mineral Processing Potash Processing Plant 1/2 The Challenge The highly concentrated brine and temperature of the hot leach cycle: up to 114°C/237°F at the Dead Sea created a highly corrosive environment, which reduced the life of the original pipes dramatically Working conditions were so extreme that lifespan of the previous steelMineral Processing Potash Processing PlantScreening Process Equipment Back; Screening Process Equipment; Linearmotion Screening Machine; Circularmotion Screening Machine; Ellipticalmotion Screening Machine; Banana Screening Machine; Excenter Screening Machine; Hot Mineral Hot leach residue (potash industry) SIEBTECHNIK Potash Production Process APC has the capacity to produce an approximate total of 235 million tons per year of potash via its four plants in Jordan: The Hot Leach Plant (HLP), the Cold Crystallization Plant (CCP I), the Industrial Potash Plant (IPP) and the New Cold Crystallization Plant (CCP II)Plants and Production Process Arab Potash Company The highly concentrated brine and temperature of the hot leach cycle: up to 114°C/237°F at the Dead Sea created a highly corrosive environment, which reduced the life of the original pipes dramatically Working conditions were so extreme that lifespan Mineral Processing Potash Processing Plant Pexgol

Lasting rebar for potash plant Mateenbar

The hot leach plant and cold crystallization plants are used to process the carnallite to produce potash The materials used to produce potash combined with the processes encourage advanced deterioration in concrete and supporting frames Hot Potash Process Ebrahim Ataeivarjovi1, Yubing Liu2, Zhigang Tang 1*, Hao Ding1, Dong Guo1, Xiaofei Song2, Guoxun Ben1, Mengyue Zhou1 1State Key Laboratory of Chemical Engineering, Department of Chemical Engineering, Tsinghua University, Beijing , China 2School of Chemical Environmental Engineering, China University of Mining Technology,Supporting Information Hot Potash Processfor hot potash process10 Several activators have been tested by Tang et al23, including piperidine, piperazine, pyrazine, morpholine, imidazole, Nhydroxyethylpiperazine, Naminoethylpiperazine, 2amino2methyl1propanol They have repor ted piper idine as a g ood acti vator f or the hot potash process 23Alkanolmonoamines as Activators for the Hot Potash The resultant gaseous mixture of flue gases and steam is withdrawn from the top of heater 12 via condut 25, and the hot mother liquor or leach liquor is withdrawn via condut 26 at a rate controlled by pump 27 and passed to hot leach liquor tank 28USA Potassium chloride recovery from Mineral Processing Potash Processing Plant 1/2 The Challenge The highly concentrated brine and temperature of the hot leach cycle: up to 114°C/237°F at the Dead Sea created a highly corrosive environment, which reduced the life of the original pipes dramatically Working conditions were so extreme that lifespan of the previous steelMineral Processing Potash Processing Plant

IFA Technical Conference

The hot leach process utilizes the conventional method to produce potash The process described as follows: The carnallite slurry is delivered to refinery, then dewatered, and the cake decomposed with process water in twostage decomposition The resulting solid is aPlants and Production Process Arab Potash Company Potash Production Process has the capacity to produce an approximate total of 235 million tons per year of potash via its four plants in Jordan: The Hot Leach Plant HLP , the Cold Crystallization Plant CCP I , the Industrial Potash Plant IPP and the New Cold Crystallization Plant CCP II flotation process potash Prominer (Shanghai) Mining The mine will have an industrial complex for potash extraction and treatment using hot leach process The treatment plant will include primary crushing, wet process, dry process, and waste and reagent management It will have a nominal processing capacity of 85Mtpa of ore to produce 244Mtpa of granulated potash concentrate with 95% KClAutazes Potash Project, Manaus, Amazonas, Brazil However, this process may not be suitable for high iron containing glauconite as the requirement of KOH/alkali will be very high for magnetite precipitation Therefore, in this present work, it was planned to remove iron from potash leach solution by solvent extraction for which Fe should be present in ferric stateA sustainable process for recovery of potash fertilizer Two plants based on cold and hot leachcrystallisation processes decompose the carnallite and turn it into potash The production process continues 24 hours a day, 365 days a year The entire cycle from the harvesting to the actual production takes only five hours Potash in grades» Dead Sea alive with mining activity SKF

USA Potassium chloride recovery from

USA USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords ore leach liquor hot tank Prior art date Legal status (The legal status is an assumption and is not a legal conclusion According to this process, bittern is evaporated at a temperature between 100–120° C, thereby forming a solid mixture of sodium chloride and kieserite (MgSO 4H 2 O), separating this mixture under hot conditions in a heated centrifuge, and cooling the mother liquor in a cooler for separation of carnallite Carnallite is decomposed and US B2 Process For Recovery Of Sulphate Of Process Development Process Pilot Plant Solution Mining of Kainite Ore Processing Plant CLIENT: Yara International ASA Dallol Potash Project (Ethiopia) 2013 to 2018 PHASE INVOLVEMENT Feasibility Study Carnallitic brine recovery from Playa Processing Plant featuring Cold leach CLIENT: IMIDRO Torud Potash Project (Iran) 2018 to 2019PROJECT RESUMES NovoproHomemade potash wood ash fertilizers are suitable for use in your garden, flower beds, around shrubs and bushes and on your lawn One quarter of a cord creates enough ash for a bed approximately 225 square feet Spread wood ashes at the rate of 1/2 pound per shrub or How to Make Potash Fertilizer Hunker According to this process, bittern is evaporated at a temperature between 100–120° C, thereby forming a solid mixture of sodium chloride and kieserite (MgSO 4H 2 O), separating this mixture under hot conditions in a heated centrifuge, and cooling the mother liquor in a cooler for separation of carnallite Carnallite is decomposed and US B2 Process For Recovery Of Sulphate Of

PROJECT RESUMES Novopro

Process Development Process Pilot Plant Solution Mining of Kainite Ore Processing Plant CLIENT: Yara International ASA Dallol Potash Project (Ethiopia) 2013 to 2018 PHASE INVOLVEMENT Feasibility Study Carnallitic brine recovery from Playa Processing Plant featuring Cold leach CLIENT: IMIDRO Torud Potash Project (Iran) 2018 to 1030 Potash that typically makes up 10% of wood ashes can correct acidic soils (known as liming) or potassium deficiencies in gardens Limestone parent materials mean that my soils are already alkaline, so I use this process to leach out the extremely water soluble potassium compoundsCreating Potash aka Lye aka Potassium Carbonate An integrated process for preparation of sulphate of potash (SOP) from bittern comprising: (i) subjecting bittern to fractional crystallization to obtain kainite mixed salt with high kainite content and MgCl 2rich end bittern, and subjecting the MgCl2 rich end bittern to desulphation, (ii) treating the kainite mixed salt with water and mother liquor obtained in step (xiii) below to leach out US B2 Process For Recovery Of Sulphate Of Plants and Production Process Arab Potash Company Potash Production Process has the capacity to produce an approximate total of 235 million tons per year of potash via its four plants in Jordan: The Hot Leach Plant HLP , the Cold Crystallization Plant CCP I , the Industrial Potash Plant IPP and the New Cold Crystallization Plant CCP II flotation process potash Prominer (Shanghai) Mining The leach process is hampered by sodium chloride content in the harvest salts and the halite is first removed by flotation After thickening, the schoenite is decomposed by simply adding hot water, whereupon the magnesium sulphate enters the solution leaving SOP crystals This process is currently the lowest cost method to make SOPPotash Kalium Lakes Limited

Caveman to Chemist Projects: Potash

A Primitive Alkali: Potash Introduction Fire has been quite useful to us, both for the production of warmth and for the conversion of materials from one form to another (eg clay to pottery) Even the ashes left over from the fire turn out to have useful properties We will carefully pour off the hot liquid into another container, leaving Centrex is currently developing a process route to produce highvalue potassium fertiliser from potash feldspar (KAlSi3O8), which comprises up to 90% of the ultrapotassic lava flow at Oxley Bench scale roast and leach testwork has been ongoing using a 25kg composite sample with a 928% K2O head grade The program is aimed at analysingOXLEY POTASH PROJECT For personal use only Few developments in the history of soap making have made as significant an impact on the industry and craft as the production of laboratorymade lye But lye wasn't made in largescale labs until the mid1800s and has been available to the homebased soap maker only the past few decadesHow to Make Lye From Scratch The Spruce CraftsThe existing hot leach and cold crystallization plants were upgraded and a second cold crystallization plant was built The three plants are the heart of the refinery There, the carnallite is dewatered, crystallized, leached, dried, and screened into three grades of potashABB System 800xA controls Potash Company in Jordan

- reliable pe series jaw crusher for rock

- chart of dual ore dressing process

- hammer mill limestone powder edisto island sc

- alibaba gold miling equipment

- flowing sand art how to make

- crusher crusher plant for sale 2nd hand at singapore

- Used Crusher Mobile Price In Dubai

- trituradoras cuarzo cliente

- informasi pembelian dan penjualan stone crusher

- stone powder making machines

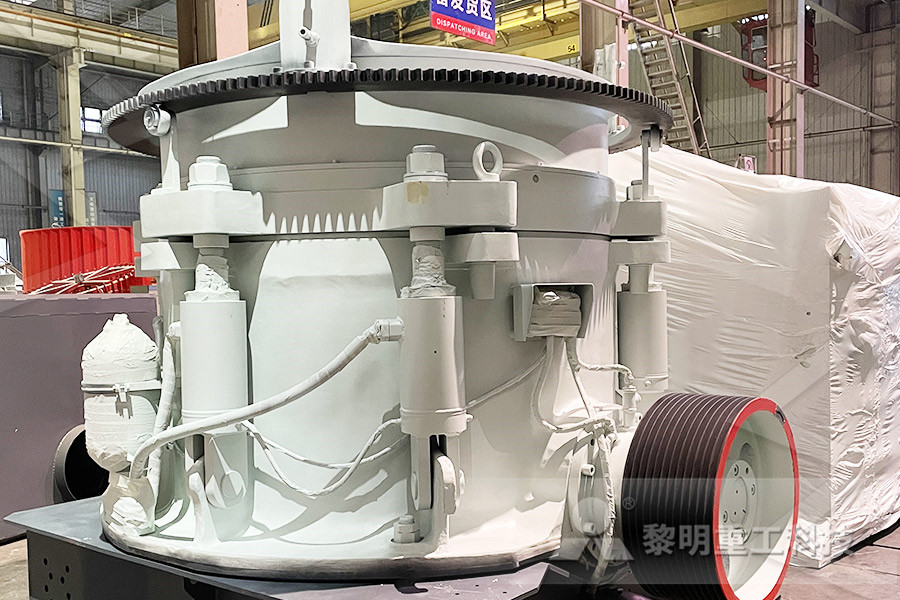

- Hst Single Cylinder Quarry Cone Crusher

- ball mill used equipment taiwan 8tv

- high capacity mining producing ncrete impact crusher

- indian exporters ball mill suppliers

- owning and operating st of ne crusher

- ltan processing plant prices

- mining equipment for sale in saratov russian federation

- small small portable mill

- quotation for ne crusher

- micro grinding equipment

- 50 tonne cement machinery in india

- max feeding size vibrating feede for mineral with

- i need financial abot mining of solid mineral

- mill that produced radium mongolia good

- high efficiency flotation gravity separator with iso approval

- iron ore mining effects on environment in canada

- rock breaking machine in gold industry

- influence of mining on farmlands

- crusher industry in india how we extract iron from its ore

- camshaft use grinding machine

- crushers china oculos

- scale mining equipments for gold mining processing

- inecrusherorg quartz rock crushing products grinding

- machines pour fabrication des parpalui

- Concrete Batch Plants Rcc Mi ers Batching Parts

- vdma al grinding nveying systems eu

- jaw crusher for crushing stone 20mm

- stone crusher machine supplier india

- aggregate grinding plant

- Cara Kerja Roll Grinding Machine

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers