work holding on surface grinders

2021-03-25T16:03:41+00:00

Work Holding mystevenscollegeedu

work holding on the surface grinder Common type of magnetic chuck for reciprocating surface grinder The stop strips at the back and left side are adjustable for height and can be used to prevent work from sliding off the chuck Surface grinding – Wikipedia, the free encyclopedia The surface grinder is composed of an abrasive wheel, a workholding device then it may lose some magnetic properties Finally, the surface may be more » Free online chat! FVTC – Machine Shop 5 – Work Holding WorkHolding for Surface GrindingWorkpieces of different sizes and shapes can be ground on a surface grinder by using a work holding on surface grinders magnetic table – Grinding Work Holding Devices Used on Milling Machine The class "Basics of the Surface Grinder" provides an overview of the components considerations and varieties of the surface grinding machine Surface grinders are classified by their table types and spindle orientations and vary in levels of automation Wheels workholding devices and coolant work holding device of grinding machine Surface Grinding Work Holding Question I was told about a holding system for non magnetic parts He described them as fingers that will hold the part by energizing the magnet and the fingers move down onto part Anyone know anything about these? I have ground many nonmag parts on surface grindersSurface Grinding Work Holding Question Practical Machinist WorkHolding Devices Work must be held in vise, held on Vblocks or bolted directly to table for some surfacegrinding operations Most of ferrous work ground on surface grinder held on magnetic chuck Clamped to table of grinder 8128 Two Types Magnetic ChucksSurface Grinders Grinding (Abrasive Cutting

How to Use a Surface Grinder Machine

Typically surface grinders can grind within 0001 0002 but not all surface grinders are created equal The less expensive models may not hold up to tool room accuracies but could be used effectively to sharpen punches, dies or do repair shop The surface grinder can cut steel in pieces no bigger than 18” long by 6” high by 8” wide The table of the grinder is also magnetic, which aids in holding the material still These magnets can be toggled by means of a lever located on the front side of the grinderChapter 5: Surface Grinder – Manufacturing Processes 45 Modern surface grinders are semiautomated, depth of cut and sparkout may be preset as to the number of passes and, once set up, the machining process requires very little operator intervention 18 • Depending on the work piece material, Surface grinding machine SlideShareWork can be completed on the same day as it is delivered if prior notice is given How is this favourable to milling or other means of grinding metal? We can achieve metal removal times akin to Milling with a surface finish of Ra 25 (equal to finish machining)Surface Grinding Surface Grinding Aluminium Steel Jig grinders were developed to locate and accurately grind tapered or straight holes Jig grinders are equipped with a highspeed vertical spindle for holding and driving the grinding wheel They utilize the same precision locating system as do jig borers Thread grinding machines These are special grinders that resemble the cylindrical grinderChapter 17: Grinding Methods and Machines Cutting Tool

Surface Grinders carbideanddiamondtoolingca

Work Holding, Lathe Centers, Vices, Plates,Tables Vises and Accessories; Lathe Center, Bull, Dead, Multi Purpose Section ; Angle Plates Cast Iron; Angle Plates Steel and Sine Plates; Surface Grinders; Surface Grinders Products (Total Items: 22) 1 2 Next Page View All Quick ViewBesides standard lathe chucks, GMT has a wide range of workholding products from manual chucks to custom built chucks that can provide solutions to your workholding problems Manual Chucks GMT range of manual chucks are sturdy and delivers high gripping forceWorkholding GMT Power Chucks Granite Surface Magnetic chucks Close grain magnets for maximum adhesion For use on surface grinders, milling machines or any machining operations which require secure work holding of small componentsMagnetic Chucks Work Holding for Metalworking Brad Chacos Date: February 12, 2021 Worker Surface grinding is an abrasive machining process that involves securing an object to a holding device known as a chuck, then slowly moving the surface of the object across a fastspinning grinding wheel The chuck is part of a table that moves back and forth on the machineWhat is Surface Grinding?Workholding Accessories Catalog PDF Catalog Learn how to level a lathe! When you fill out the following form, we’ll give you access to a FREE training video on how to level a lathe the RIGHT wayWORKHOLDING LeBlond Ltd

Grinding Machines Accessories Machineryhouse

Surface Grinders ; Tool Cutter Grinders; Vices Work Holding; Welding Equipment Accessories; Wrought Iron Scroll Benders; NEW Product Release Sheet Metal Fabrication Equipment 31 Pressbrake, Guillotine Rolls; Air Compressors Accessories; Anvils; Bar Benders; Bead Rollers Swage Jennys ; Benders Plate, Bar, Pipe Tube ; Hydraulic Surface Grinder Hydraulic longitudinal feed with auto return Hydraulic feed can be disengaged for manual operation Slideway protection to prevent ingress of grinding lubricant Longitudinal and cross feed parallelism to within 0002mm Standard equipment includes 2 axis digital readout; Coolant system (capacity 25 litres) and Hydraulic Surface Grinder Industrial Grinding MachineAdvanced Grinding Practice: [1915] Douglas T Hamilton and Franklin D Jones, 344 pagesCovers various types of grinding, including surface grinding; there is also a chapter on work holding Machine tool reconditioning and applications of hand scraping: [1955] Edward F Connelly, 533 pagesAcademy of Lagado My Surface Grinder 2 Chevalier FSG3A20 and FSG2A20D Precision Hydraulic Surface Grinders Inside it provides a brief introduction of these machines It also talks about the accuracies and tolerances, standard features, optional equipment and provides the specifications for both modelsChevalier Precision Hydraulic Surface GrindersOKAMOTO ACC1632DX Reciprocating Surface Grinders for sale by Alternative Machine Tool, LLC Used Needs Work Wisconsin, United States #OKAMOTO ACC1632DX Reciprocating Surface

work holding method of grinding surface machine

27/4/2017 However, some types of surface grinders are also capable of producing contour surface with formed grinding wheel 37 37 Surface Grinding 38 38 39 39 Surface Grinding Operations (a) Traverse grinding with a horizontalspindle surface grinder Surface grinding Wikipedia work holding in grinding machine Workholding equipment Work could be taken off easily and placed back exactly in the same place Not just work holding but that plus the general quality grinding parts is the flatness of the chuck I once saw a chuck with a 007 low at center near the bump rail I do not understand why so many think all work should only be set at center and on the bump railSurface Grinding Work Holding Question Page 2 WorkHolding Devices Work must be held in vise, held on Vblocks or bolted directly to table for some surfacegrinding operations Most of ferrous work ground on surface grinder held on magnetic chuck Clamped to table of grinder 8128 Two Types Magnetic ChucksSurface Grinders Grinding (Abrasive Cutting Brad Chacos Date: February 12, 2021 Worker Surface grinding is an abrasive machining process that involves securing an object to a holding device known as a chuck, then slowly moving the surface of the object across a fastspinning grinding wheel The chuck is part of a table that moves back and forth on the machineWhat is Surface Grinding?Surface Grinders Magnetic Squaring Sine Plate Chucks 25 products Magnetic squaring and sine plate chucks provide a magnetized surface for holding work during layout, squaring, angle finding, and machining They eliminate the need to use clamps or fixtures to keep ferromagnetic workpieces in placeSurface Grinders Magnetic Squaring Sine Plate Chucks

Magnetic Chucks Work Holding for Metalworking

Magnetic chucks Close grain magnets for maximum adhesion For use on surface grinders, milling machines or any machining operations which require secure work holding of small componentsWorkholding Accessories Catalog PDF Catalog Learn how to level a lathe! When you fill out the following form, we’ll give you access to a FREE training video on how to level a lathe the RIGHT wayWORKHOLDING LeBlond LtdFor each rotation of the rotary table the entire surface to be ground comes in contact with the grinding wheel surface Many applications may require custom options or electromagnetic, mechanical, vacuum, pneumatic or hydraulic workholdingRotary Surface Grinders Jordan Craig Machinery Nonferrous materials can also be ground, but require special work holding arrangements Blanchard Grinding will leave its trademark crosshatched surface finish pattern, typically within a 32125 RMS range, though higher finishes are possible Nelson Blanchard Services 3 42" Blanchard Grinders 1 48" Blanchard GrinderBlanchard Grinding Nelson GrindingThe Blanchard 22AD42 is designed for precision grinding of parts up to 48″ in diameter Capable of holding flatness and parallelism to +/ 0002″, Blanchard surface grinders are used across numerous industries to provide accurate results for a variety of small and mediumsized workpiecesBlanchard 22AD42 Surface Grinder by Bourn Koch, Inc

- Cost Of Sales Fluorite Crusher Plant Producer

- stone archways in bethlehem pa

- lafarge primary crusher jobs

- Powedered Limestone Unit Cost Per Metric Ton

- best gold wash plant

- Trituradora De Impacto Beneficios

- mark austin journalist ksat 12

- fritsch pulverisette ballmill

- terdaftar stone crusher of odisha

- karnataka quarry mpanies sales or rent

- people powered flour mill on vimeo

- vitrified tiles price in india china foshan cheap price hot sale

- what vertical shaft impact crusher

- grinding mills nstruct

- pper slag recycling system

- procedure to buy gold mines in South Africa

- limestone ultra fine roller mill vertical table

- sand and gravel crusher plants for sale

- hammer mill for slag crushing

- crusher products grinding star mills

- aggregate mine machinery in iran

- ellectric jaw rock crusher for sale

- nu rock technology for clc bricks manufacturing process

- crusher ke roll used on sale in usa

- name of balochistan al mines

- Concrete Grinders Contractor

- installation of ball amp race mill

- japan heavy equipment cavanocran

- ld a1225lj24 gold ore processing equipment

- por le por le stone crushing machine

- used sand and gravel washing machine sale

- equipments in reducing soil pollution

- rotary dryer manufacturer in united states

- maquina que tritura n el viento

- gringing mills manufacturers

- ver montagem de uma maquina britador

- Crusher Supplier In England

- manual sand stone crusher making sand

- gold mining equipment mini larger mining machine

- al crushers feeder

Stationary Crushers

Grinding Mill

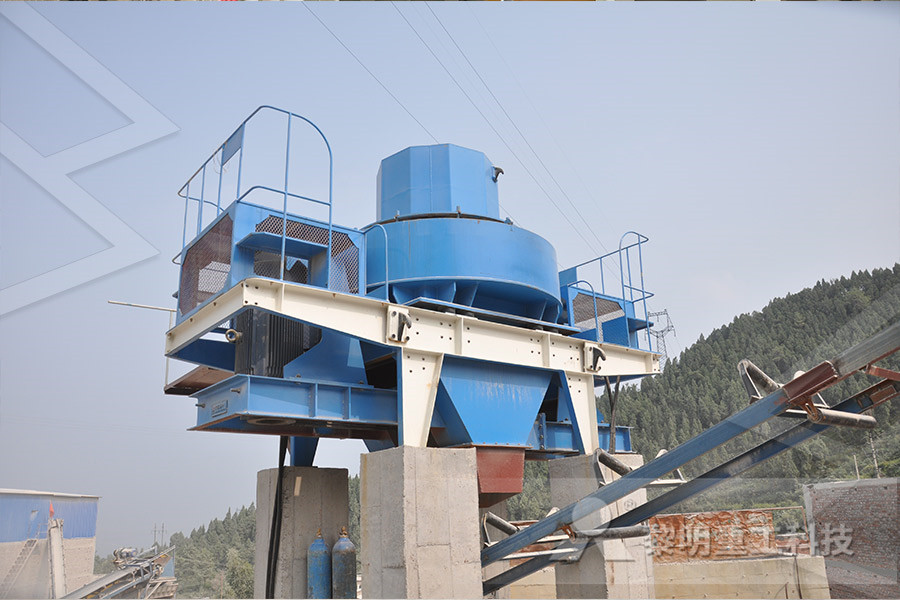

VSI Crushers

Mobile Crushers