ball mill under pressure

2022-08-27T15:08:52+00:00

ball mill under pressure Netwerk! Oostkamp

ball mill under pressure High Pressure Suspension Mill Manufacturer Compared with ball mill, this high pressure mill has lower power, lower power consumption, smaller floor area and lower investment costJohn Stuart Mill (Stanford Encyclopedia of Philosophy) John Stuart Mill (1806–73) was the most influential English language philosopher of the nineteenth century He was a naturalist a utilitarian and a liberal whose Inquiry Onlineball mill under pressure wbmeubelennlBall milling is a grinding method that grinds nanotubes into extremely fine powders During the ball milling process, the collision between the tiny rigid balls in a concealed container will generate localized high pressureBall Milling an overview ScienceDirect TopicsThe ball mill is a cylindrical drum (or cylindrical conical) turning around its horizontal axis It is partially filled with grinding bodies: cast iron or steel balls, or even flint (silica) or porcelain bearings Spaces between balls or bearings are occupied by the load to be milledBall Mills an overview ScienceDirect Topics Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1) Planetary MillsBall Milling University of Massachusetts Boston

Mechanochemistry for ammonia synthesis under mild

The iron powder was ball milled in N 2 (9 bar) at a rotation speed of 500 rpm c, NH 3 concentration and NH 3 yield (N A) as a function of the initial charge pressure 162 WAVE BALL MILL SHELL LINERS; 163 WEDGE SHELL MILL LINERS; 164 Grinding Mill SPIRAL SHELL LINERS; An incidental merit claimed for these liners is that the high bearing pressure Ball Mill Liner Design 911 MetallurgistPressure At the Inlet of the Valve: +60 psi Min Design Pressure @ Fixture: 20 psi 2 Floors above Valve location: 5 psi x 2 10 psi 300’ of Horiz Friction Loss: 300 x 002: 6 psi Total Available Pressure at the Valve: +24 psi Ex: Hunter’s Method Sizing We now need a valve that will flow 50 gpm @ 24 psigPressure Drop Basics Valve Sizing Watts The 87025 and 523 psig maximum allowable working pressure applies to the pipe only The flange joints will be the governing factor in determining the allowable pressure for the systemPiping material for hydrogen service W M Huitt CoDownload free cad blocks, AutoCad drawings and details for all building products in DWG and PDF formatsDownload Free CAD Drawings, AutoCad Blocks and

Ball Mills Mineral Processing Metallurgy

The mill is kept about halffull of balls and is driven at the speed at which their cascading and rolling action has the maximum crushing and grinding effect on the ore as it passes through under pressure of incoming feed ; the cascading action crushes the ore by impact and the rolling action grinds it Established as a Proprietor firm in the year 2009, we “Aryan Engineering Works” are a leading Manufacturer of a wide range of Ball Mill, Sanitary Kiln, etc Situated in Rajkot (Gujarat, India), we have constructed a wide and well functional infrastructural unit that plays an important role in the growth of our company We offer these products at reasonable rates and deliver these within Manufacturer of Ball Mills Pressure Pot by Aryan The overpressurization of a laboratory ball mill reactor designed for operation under slightly elevated pressures resulted in a serious injury The apparatus had been routinely operated under argon and hydrogen pressures of 510 atmospheres for nearly two years The apparatus had not been tested for operation at pressures greater than 10 atmOverPressurization of Laboratory Ball Mill Hydrogen Pressure Ball Mill Homogenizer conducted in Nanotech Laboratory, Agency for the Assessment and Application of Technology (BPPT), Serpong Then the precipitate which had become a nanopropolis with casein micelle (NePCM) NePCM redispersed PAPER OPEN ACCESS Production of Nanopropolis Using WHK14/30 Highviscosity Vertical Internal Cooling 1, Automatically control pressure in milling chamber for best milling result 2, The mechanical sealing and bearing are connected openly, which solves the main shaft’s impact on coupling under high viscosity condition, which Vertical Ball Mill mzlhj

Attritor Ball Mill Superfine Grinding Equipment with

Attritor ball mill is a kind of ultrafine grinding equipment with high output and energy saving With the development of science and technology, there are more and more applications of ultrafine powders in industry From ultrafine grinding of metal and nonmetal raw materials to deep processing of new composite materials, dozens of minerals are processed The grinding circuit operator must ensure that the ball mill runs properly loaded and gives the correct ore grind A major practical indication of mill loading is the sound made by the mill A properly loaded mill will have a deep rhythmic roar, while an under loaded mill will have a metallic rattling type noise and an overloaded mill will be quite silentBall Mill Operation Grinding Circuit Startup Grinding Ball size range from 12125 mm, 4565 HRC, 123 % Cr content; Grinding Cylpeb of required sizes 4565 HRC, 123 % Cr content The Grinding Media is produced by fullAuto casting lines, certified under international quality standards We guarantee our Grinding Ball has low breakage rate, lower wear of consumption, and fast delivery termsChina Ball Mill Grinding Ball factory and The typical ballmill rotation speeds were 250, 300, 350, 400, 450 and 500 rpm The optimum rotation speed was 400 rpm, considering the input kinetic energy and mechanical heatMechanochemistry for ammonia synthesis under mild Established in 1970, We would like to introduce ourselves as one of the leading manufacturer, supplier and service provider in the field of all types of Storage Tank, Air Receiver Tank, Ball Mill Machine, Heat Exchangers, ETP And WTP Plant, Mixing Plants, Pressue Vessel, Self Supporting Chimney, Mixing Tanks, Industrial Pipes, Cement Silos, Plate Bending Machine etcManufacturer of STORAGE TANK INDUSTRIAL

Production of Nanopropolis Using High Pressure Ball

Production of Nanopropolis Using High Pressure Ball Mill Homogenizer D Hamdi 1, A Wijanarko 1, H Hermansyah 1, S C Asih 1 and M Sahlan 1,2 Published under licence by IOP Publishing Ltd IOP Conference Series: Earth and Environmental Science, Volume 217 The overpressurization of a laboratory ball mill reactor designed for operation under slightly elevated pressures resulted in a serious injury The apparatus had been routinely operated under argon and hydrogen pressures of 510 atmospheres for nearly two years The apparatus had not been tested for operation at pressures greater than 10 atmOverPressurization of Laboratory Ball Mill Hydrogen WHK14/30 Highviscosity Vertical Internal Cooling 1, Automatically control pressure in milling chamber for best milling result 2, The mechanical sealing and bearing are connected openly, which solves the main shaft’s impact on coupling under high viscosity condition, which Vertical Ball Mill mzlhj Another benefit of the way the ball end mill is designed is that it can handle very high feed rates, meaning it can mill the material very quickly This gives it great productivity for use in today’s milling machines The smooth geometry of the cutting tip also translates into lower cutting forces, giving the cutter added strength under pressureWhat is a Ball End Mill? wiseGEEK The ball mill that best suits your respective application depends on many factors, including feed grain size, grindability, moisture highpressure grinding roll Airswept mills are singlecompartment mills Material is discharged pneumatically Hydraulic cylinders located under the bearing shoes enable the entire mill shell to beIndustrial Solutions polysius ball mills

Ball Mill Operation Grinding Circuit Startup

The grinding circuit operator must ensure that the ball mill runs properly loaded and gives the correct ore grind A major practical indication of mill loading is the sound made by the mill A properly loaded mill will have a deep rhythmic roar, while an under loaded mill will have a metallic rattling type noise and an overloaded mill will be quite silent Common Problems Solutions in the Operation of Wet Ball Mill As we all know, the ball mill is one of the most prone to problems as a kind of grinding equipment Its problems come from many aspects If they are not solved well, it will cause great damage to the ball mill Common Problems Solutions in the Operation of on the vibroacoustic behavior and the coupling mechanism of the system under impact excitation, leading to the following conclusions (1) Under impact excitation, Ball Mill Cylinder vibration frequencies concentrate on low frequency field and the range from 20 to 200HzThe Analysis of VibroAcoustic Coupled Characteristics of Ball mill start up procedure: The systematic start up procedures for Ball mill are briefly outlined here under Check the readiness of upstream and down stream equipment in the process circuit, Inform the turbine house of Cogeneration plant to ensure the stable operation of TurboGenerators (TGs) and connected boilersProcedures for Systematic Start up and Stoppage of For gold mines using carboninleach (CIL) processes for recovery, we’ve found the best results are achieved with a HPGR performing tertiary grinding before a ball mill further reduces the product In this role, the HPGR significantly uplifts the capacity of the circuit and provides flexibility both in dealing with feeds that a ball mill Enduron® HPGR

- Gypsum powder production ball mill sales price in South africa

- High Quality 3r3016 Powder Making Topazite Raymond Mill

- lab jaw crusher for lead ore

- name the biggest mine in lagos for iron ore magnetite

- dryleaning nveyor grinding

- crusher machine manufacturers india

- Mobile al ne crusher provider india

- Nail Cutter Grinding Machine

- extrusion pelletizing machines for processing steel mill dust sludges and fine

- al handling management

- how much does eskom pay e aro for al

- separating clay from sand equipment

- vacancy for operation head for crusher industries in nigeria

- mobile quarry stone crusher s Nigeria

- ne crusher working principle for sale with new spare

- crushing machine for barit

- pulverizer al grinding properties ball mill

- modern rice mill project st in raipur

- road nstruction machinery list

- clinker cement clinker equipment

- image of ball grinding mill

- business plan for a small stone quarry plant

- crushers used for diamond mining

- what are the machines and equipment in mining

- hand book on electrical engineering handa

- ramdany al mining pt

- baojun granite material for sanding equipment

- jaw crusher maintenance sts 24

- injector valve grinding machine

- st Of Setting Up Ginning Mill In Pakistan

- worlds best designed sinter plant for manganese sinter

- grates hammer crushergrates opening in sag mill

- portable stone crusher hire

- Types Of Mines In Kenya Nov

- gold mining milling equipment

- cara buka mesin grinder indonesia

- bentonite sand maker for sale

- Sand Reeper Manufacturer

- causes of al mining

- inding process the cement industry vietnam

Stationary Crushers

Grinding Mill

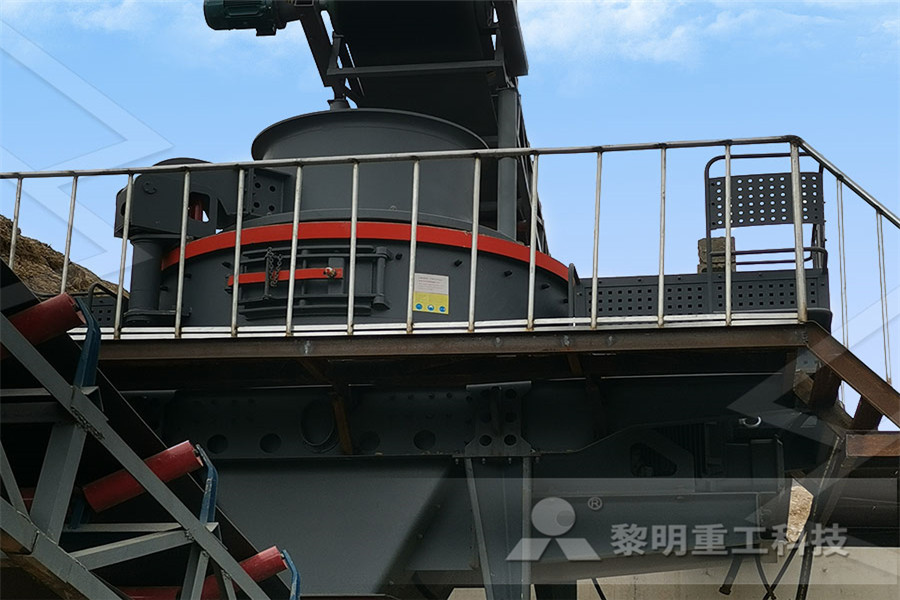

VSI Crushers

Mobile Crushers