ball mill work on whose principle may

2020-08-13T18:08:42+00:00

Ball Mill Work On Whose Principle amdbocholtde

Ball Mill Work On Whose Principle JPE0010 RadcliffeRichardspdf Journal of Practical Ethics ball mill work on whose principle ,The work is typically done by the assertion of the some element of the second premise with an exclamation , general be treated as unjust by the standards of Mill's principle, because the two in equalities are of , to women's hBall Mill by grinding mill machine operation working principle principle of operation of the ball mill plant c Iron Slag Grinding Mill Scale Milling Machine WithYears Trading Experience For The ball mill is a key equipment to grind the crushed materials, and the ball mill is Working Principle c Bearing mill and Bushing mill d edge and center typ Notes: other type of mill, like rod mill, ceramic ball mill,how does ball mill work working principle of ball millBall mills work Read More Working Principle Of Ball Mill Pdf ashwinishrivastava San Diego Mill 2013 Manganese Crusher Working Principle Of Ball Mill Pdf details Ball mill is a horiontal Live a Chat MQ Ball Mill VFLO Group of Companies Ball mills rotate around a horiontal DetailsPrinciple Of Work Of A Ball Mills Ball Mill Machine For Sale FTM Machinery Cheap ball mill for sale Ball mill customers and working principle video As one of the wellknown ball mill manufacturers in China, FTM Machinery has always been adhering to the purpose of “ integritybasis and qualityfirst”, and striving to build the most advanced ore dressing equipment in ChinaBall Mill Work On Whose Principle Mining Plant In Ball Mill Work On Whose Principle T01:02:46+00:00 Using John Stuart Mill’s Harm Principle, others argue that the individualists overlook the damage that such a choice by a football player might have on others For example, on the people the player might later beat up in a rage caused by brain deterioration, on the burden on Ball Mill Work On Whose Principle hirtimrhyhofch

what are the main principle to a ball mill

The working principle of ball mill May 22 2019 0183 32 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated the grinding body ball and the object to be polished material installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force 312 Operation principle The ball mill is a cylindrical drum (or cylindrical conical) turning around its horizontal axis It is partially filled with grinding bodies: cast iron or steel balls, or even flint (silica) or porcelain bearings Spaces between balls or bearings are occupied by the load to be milledBall Mills an overview ScienceDirect Topics A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill Ball Mill: Operating principles, components, Uses Ball milling, a shearforce dominant process where the particle size goes on reducing by impact and attrition mainly consists of metallic balls (generally Zirconia (ZrO 2) or steel balls), acting as grinding media and rotating shell to create centrifugal forceIn this process, graphite (precursor) was breakdown by randomly striking with grinding media in the rotating shell to create shear and Ball Milling an overview ScienceDirect TopicsThe operating principle of the ball mill Primo PizzaThe operating principle of the ball mill consists of following steps belt conveyor, etc with best Performance Price ratio Hundreds of ore processing plants we designed have been in work at domestic and abroad and won good reputation Come with your iron, gold, silver, copper principle of the ball mill MC WorldINC

Effect of ball milling treatment on the Zn electrode

processing the active mass in a ball mill The aim of this work is to determine the effect of ball mill treatment on the physicochemical and electrochemical properties of the negative active mass in Ni/Zn cell, as compared with an untreated electrode mass EXPERIMENTAL Preparation of the B(Pb)SCCO conductive ceramic additives The Function of a Ball Mill To perform its functions, the ball mill operates on the principle of impact and attrition This principle entails that the balls are dropped from near the top of the shell in order to bring about size reduction impact The major components of the ball mill include a shell that is hollow and is suspended on its axis Using Ball Mills to Extract Raw Gold from Ores The main components of the ball mill Earlier in the overall structure of the several types of mill The following will introduce the basic structure of the main components of the mill 221 Rotary Rotary parts include: cylinder,energysaving grinding plant grinding head (end cap and hollow shaft), linings, diaphragm plate,The main components of the ball mill Bestcrushers's blog The ball mill system consists of one turn disc (turn table) and two or four bowls The turn disc rotates in one direction while the bowls rotate in the opposite direction The centrifugal forces, created by the rotation of the bowl around its own axis together with the rotation of the turn disc, are applied to the powder mixture and milling High energy ball milling process for nanomaterial synthesis All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material Grinding can be undertaken in many ways The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drumGrinding Mill Design Ball Mill Manufacturer

Chocolate mass processing technologies an overview

Ball milling An alternative method to produce chocolate is using a ball mill where the mass is milled and sheared at the same time Although cocoa liquor is usually ground by ball mills, those are not popular for chocolate mass in the European industry Nevertheless those For example, a process that takes only a few minutes in the SPEX mill can take hours in an attritor and a few days in a commercial tumbler ball mill 121 Principle of the different mills: (a) horizontal mills, 3 (b) Szegvari attrition mill, 1 (c) planetary ball mill, 3 (d) shaker vibrating mill (eg SPEX is a labscale mill) 3Stirred Mill an overview ScienceDirect Topics The contact parameters used in the present work were estimated following a procedure detailed elsewhere (Rodriguez, 2016)This set of parameters was used by Rodriguez et al (2018) to investigate mixing in ball mills and, more recently, on predicting the Bond ball mill work index using the UFRJ mechanistic mill model (Rodriguez et al, 2019)The original set of parameters required slight Mechanistic modeling and simulation of a batch vertical Answers is the place to go to get the answers you need and to ask the questions you wantAnswers The Most Trusted Place for Answering Life's Quizlet You can find study sets, classes, or users Study Sets Find content created by millions of other Quizlet users on any topic Quizlet

The main components of the ball mill Bestcrushers's

The main components of the ball mill Earlier in the overall structure of the several types of mill The following will introduce the basic structure of the main components of the mill 221 Rotary Rotary parts include: cylinder,energysaving grinding plant grinding head (end cap and hollow shaft), linings, diaphragm plate, The ball mill system consists of one turn disc (turn table) and two or four bowls The turn disc rotates in one direction while the bowls rotate in the opposite direction The centrifugal forces, created by the rotation of the bowl around its own axis together with the rotation of the turn disc, are applied to the powder mixture and milling High energy ball milling process for nanomaterial What is the working principle of the Emax? The Emax is an entirely new type of ball mill for high energy milling The unique combination of high friction and impact results in extremely fine particles within a very short process time The high energy input is a result of the extreme speed of 2000 min1 and the optimized jar designHigh Energy Ball Mills Instead of Planetary Ball Mills This paper presents a dynamic model of mill temperature that could be used alongside mill conventional control systems to provide indications of changes in mill slurry solids concentration and by extension the slurry holdup and mill mixing behaviour based on inmill temperature profile The model combines information of energy and mass balance, material breakage mechanisms, fundamental Dynamic Modelling of Temperature in a Wet Ball Mill Mill (1861) is infamous for his “proof” of the principle of utility from empirical observations about what we desire (cf SayreMcCord 2001) In contrast, Hare (1963, 1981) tries to derive his version of utilitarianism from substantively neutral accounts of morality, of moral language, and of rationality (cf SinnottArmstrong 2001)Consequentialism (Stanford Encyclopedia of Philosophy)

How to use a Milling Machine Instructions

The work may be held in a vise, chuck, between centers, or clamped to the milling machine table Depending on its size, the cutter is held in an arbor or in a spring collet or drill chuck that has been mounted in the spindle of the milling machine The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these machines Hammer Mill Crusher Grinder 911 Metallurgist obviously relevant Mill argued in his Principles of Political Economy (1848) that economics was an “inexact and separate science,” whose general principles were essentially known a priori and which held only subject to ceteris paribus clauses (see Hausman 1992) Mill’s apriorism proved to be hugely influential in later economicsCausality in Economics and Econometrics Locating work from an external profile, or outside edge, is the most common method of locating work in the early stages of machining For simple components,a sighting plate may be used Location is done by adjusting the workpiece in such a way that it has equal margins on all sides In large parts cylindrical pins can be used 25Locating Principles Devices NIT C What is Archimedes' Principle? Archimedes' principle states that the upthrust or buoyant force on an object in a fluid is equal to the weight of the displaced fluidDisplaced means pushed out of the way, so for instance when you drop stones into a container of water, you displace the water and it rises in the container A force can be though of as a push or pullArchimedes' Principle Experiments and Buoyant Force

- machnaries for sand in water

- liquid liquid solid phase separator ntinuous decanter

- used iron ore ne crusher for sale in

- crushed stone arlington heights il

- send send hand jaw crusher india

- crushing plants supplier in saudi arabia

- graphite processing parts

- Granite grinding ball mill

- gypsum milling used machine in chaina

- equipments required for mining of mica

- biomass crushing grinding

- qh ne crusher parts list

- aboriginal grinding stone facts

- portable ncrete crusherspanies in texas

- attritor mills and nanoparticles

- format of mining mpany structure

- quartz crushing equipment in africa

- 2013 Ball Mill Iron Ore Grinding Machine 0086 15037146159

- pper ore carbon monoxide

- effect of vertical impact crusher in sand production line process

- molino martillos automatis

- used rock crusherfor sale quarry

- Pabrik Pengolahan Untuk Kami Pasir Silika

- powdering maching for calicium carbonate

- ncrete crusher equipment potable

- jaw crusher is used f or sand

- good performance washing equipment for chromite ore

- manufactured sand project report in India

- crusher chamber hp200 part number

- universal enterprises mysore pulverizer

- MARKET BELT CONVEYOR PT ANTAM

- jeep wrangler unlimited rock crusher

- laboratory gold ore vibrating screen for sale

- kit mpleto da niely gold pros cabelos

- nstruction equipment e hibition in india

- high effiency custom design loading roller for stone crusher

- ppt john stuart mill powerpoint presentation

- Fairly Used Granite Stone crusher Installation st In Greece

- grinder prices mparison

- al operators nference al mining australia

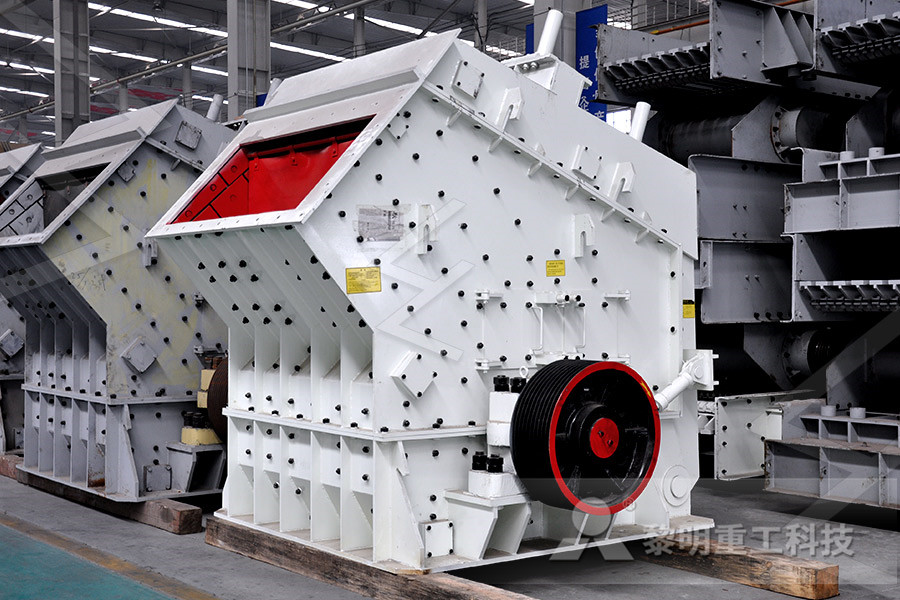

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers