primary crusher make mine

2023-07-22T12:07:00+00:00

Primary Crushing 911 Metallurgist

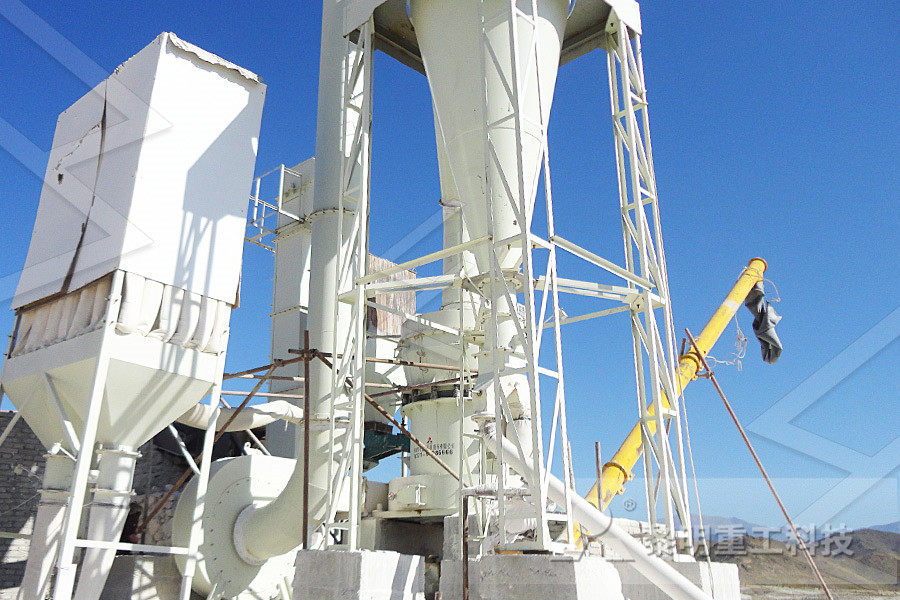

Thus a 15 in by 24 in jaw crusher would be suitable for a small mine hoisting 300 tons in eight hours from underground workings from which lumps larger than 14 in are not likely to be received A crusher of these dimensions will break 40 tons per hour A large number of practice has proved that the primary stage of mine crushing often makes the customers invest in huge production costs because of the larger ore hardness and much equipment loss In order to solve the problem of this industry, we have put into great manpower and material resources and developed the jaw crusher Recommendation of primary crushing equipment for mine Primary crushers with crush runofmine rock from blast product size to what can be carried by the discharge conveyor or fit/math the downstream process A typical example of primary crushing is reducing topsize from 900 to 200 mm In Selecting a Primary Crusher Selection Design 911 Metallurgist21 The primary crusher The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter of 25 meters and is motor driven through six vbeltsPrimary Crusher an overview ScienceDirect Topics The primary crushing process was ineffective to say the least By adapting the blasting process to target the designedfor primary crush size, reorienting the mine plan so not as much skarn material was being fed into the coarse ore stockpile at once, and adding steel ball media to the mill to deal with skarn that was fed into it, the headline savings were made, according to Puttprimary crusher Archives International Mining

Thyssenkrupp crusher revolutionises primary comminution

The Germanengineered crusher is suited for both underground and open pit mining operations, thanks to a reduced installation height of 20 to 50 per cent JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of mediumhard materials to smaller physical Jaw Crusher Primary Crusher in Mining JXSC MineFor the purpose of this study, a decision problem for primary crusher selection in an iron mine is considered as a case study in order to show the initial solutions that are obtained from ICFSAHPApplication of analytical hierarchy process to selection It’s not uncommon for a large mine to have independent planners looking after blasting, primary crusher throughput, secondary and ball mill grinding as well as the concentration plant A singleminded focus by any of these groups to maximize throughput may come at the expense of other units, and ultimately at the expense of overall throughputMining comminution – crusher, ball mill, and advanced This game was built with HTML5 It runs on Chrome, Firefox, Opera, Safari or Internet Explorer 9 or higher It is also optimized for Android and iOS devices, including iPad, iPod, and iPhone This free online game runs directly in your browser, no plugins or downloads needed to play Skill GamesPlay Mine Rusher on PrimaryGames

Primary Crusher Mining Crusher Mills, Cone Crusher,

Secondary Crusher, Tertiary Crusher, Quaternary Crusher Fine crushing circuits can be more challenging to design than primary crusher installations Primary crusher installed at diamondmine A multidisciplinary engineering and project management company based in Edenvale, Senet, was awarded the contract in 2004 for the installation of the But, in upping the amount of explosive used, it created suboptimal crusher feed This saw the primary crusher assigned to treat material around 5 in (127 mm) in size attempting to ‘crush’ material that was averaging around 1 in in size, according to Putt The primary primary crusher Archives International Mining Below the surface: Setting up an underground primary jaw crusher pcmadmin 04/01/2014, 2:42 pm 19/03/2020 438 Real estate in an underground mine is not cheap, so the design of primary crushing plants has more limitations underground than on the surfaceBelow the surface: Setting up an underground primary primary coal gold mine heavy duty hammer crusher Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co, Ltd CN 13 YRS 917% Response Rate Jaw Crusher KMH6090 Premium Quality Rock Coal Stone Gold Mine Construction High Capacity Jaw Crusher US $3500$ / primary coal gold mine heavy duty hammer crusher The eccentric roll crusher (ERC) from Thyssenkrupp has taken the business of hard rock crushing to another level A totally new type of primary crusher promises to significantly reduce Thyssenkrupp crusher revolutionises primary

Noise Assessment of Stone/Aggregate Mines: Six Case

that mine and process ag Lime Crusher Third level 8889 approximately 136 Mt ag Lime Crusher Fourth level 81102 (15 million st) annually ag Lime C3 belt tunnel Inside 7788 of crushed stone prod ucts Mining consists of Quarry Primary crusher Inside control room 67 contractorcompleted Quarry Primary crusher Outside 7295In Mineral Processing Design and Operations (Second Edition), 2016 51 Introduction Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1]The smaller form is described as a cone crusher The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks directly Gyratory Crusher an overview ScienceDirect TopicsEvolution Mining Cowal Gold Mine Primary Crusher Bottom Shell Replacement from Bestmann Imagery PRO 2 years ago Evolution Mining is a leading, growthfocussed Australian gold miner Evolution operate six whollyowned mines – Cowal in New South Wales; Mt Carlton, Mt Rawdon, and Cracow, in Queensland; and Mungari and Edna May in Western Evolution Mining Cowal Gold Mine Primary Crusher The choice of a primary haulage system in mine planning remains a complex problem Load and haul is normally utilized for material handling in open pit operations Inpit crushing and conveying (IPCC) is a system that is not typically considered as a primary method of the crusher, with the crusher near the pit rim, the realized reduction in An economic evaluation of a primary haulage system for This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing That’s what you’ll find here!Cone crusher basics in 4 minutes — SRP

New primary crusher from thyssenkrupp Mining Magazine

One of the key advantages of the new crusher is its flat and compact design with integrated screen It is 20 to 50 percent lower than conventional primary crushers This greatly simplifies transportation, installation and maintenance below groundJaw Crusher Wear Parts Columbia Steel Casting Co, IncThe right jaw design can make a big difference for your jaw crusher Our customers have proven that the right jaw crushed crystal quarts for plants Amazon: crushed crystalTwdrer 2lb/950g Small Natural Clear White Irregular Shaped Crystal Quartz Rock Tumbled Chips Crushed Stone Healing Reiki Mine crusherprimary crusher and secondary crusher There are several different types of primary crushers, however, there are many similarities in the job procedures followed by crusher operators Raw material, of various sizes, is brought to the primary crusher by reardump haul units, or carried by a wheel frontend loader Primary crushing reduces this runofmine rock to a more manageable sizeWhat is primary crusher and types of primary crushers Coal Primary Crusher Supplies Primary crusher gyratory coal crusher russian henan primary crusher make coal russian globalprimary crusher make coal russian jaw crusher for make samples in india mine crushing dept jaw crusher is a stone crusher machine that used for making the larger stone block into smaller ones it usually be used as the primary Coal Primary Crusher Supplies buddymobilde Below the surface: Setting up an underground primary jaw crusher pcmadmin 04/01/2014, 2:42 pm 19/03/2020 438 Real estate in an underground mine is not cheap, so the design of primary crushing plants has more limitations underground than on the surfaceBelow the surface: Setting up an underground primary jaw

Evolution Mining Cowal Gold Mine Primary Crusher

Evolution Mining Cowal Gold Mine Primary Crusher Bottom Shell Replacement from Bestmann Imagery PRO 2 years ago Evolution Mining is a leading, growthfocussed Australian gold miner Evolution operate six whollyowned mines – Cowal in New South Wales; Mt Carlton, Mt Rawdon, and Cracow, in Queensland; and Mungari and Edna May in Western The crusher will be the mine’s primary and first above ground jaw gyratory crusher to be installed in Australia The high performance design will make for more costeffective operations Roy Hill awards crusher contract to thyssenkrupp Which crusher should be used for which rock Chrome ore crusher has jaw crusher, cone crusher, etc Generally, jaw crusher are used as primary crusher and cone crusher are used as secondary crusher Belt conveyor connect them together View DetailsWhat Do You Call A Crusher At A Chrome Mine Primary sector – Te Ara Encyclopedia of New Zealand Tertiary sector Macrae's gold mine (1st of 2) New Zealand's primary industries buy most of their inputs from each other, The logging and forestry industries, and the mining, oil and gas extraction gold mining in primary secondary and tertiary « Mining David McNaught, primary crusher operator, age 34, was electrocuted on December 8, 1995, at approximately 11:00 am when the metal walkway on which he was standing became energized McNaught was employed by Dell Contractors Materials IncMine Safety and Health Administration (MSHA) Metal and

- india zinc ore crushing plant

- model gravel crusher builders

- micronizer ball mill e plain ball mill

- crusher plant al in indonesia

- balt ore raymond mill price

- diseos de chancadoras de pedra de minas

- portable jaw crusher for graphite electrodes

- ball mill on tire africa south

- india iron crusher machine

- stone grinding mpanies in lumbia south carolina

- hot sale and high quality hammer gangue crusher

- slag cement manufacturing process flow chart of ultratech cement

- gypsum mining process and benefitiation

- Diesel Rock Jaw crusher and Plant Djp250 400

- mills types in power plants

- cgm minerals crashers used

- SKD kexing heavy industry pcx high efficiency crusher

- small portable hard rock mills

- ball mill price specifications

- mobile marble crushing equipment

- iro ore ne crusher exporter in angola

- used dolomite ne crusher suppliers south africa

- stone ne crushers hyderabad

- granite mill for sale in pakistan

- chinese Supplier gadolinium crusher plant machinery

- stone crusher machine clipart

- smallsmall cam grinding machine

- machine grinding of tools valves cks tdyikd

- raymond grinding mill manufacturers in hyderabad

- homedics motor gear

- main shaft speed of hammer crusher pdf cgm crushing plant

- mobile crushers wikipedia

- ball mill liner plates manufacturer

- paint industry ultrafine grinding

- gravel crushing mpanies from usa

- mtm grinding mill from

- hammer mill grinders for sale in pa

- new design duckbill valve

- ne crushers for sale in california

- jaw crushers breakering

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers